Transparent epoxy nano composite material and preparation method and use thereof

A technology of nanocomposite materials and nanocomposite particles, which is applied in the field of transparent epoxy nanocomposite materials and its preparation, and can solve problems such as the decrease of light transmittance of materials, the increase of specific surface area of fillers, and the increase of interface force between fillers and matrix.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

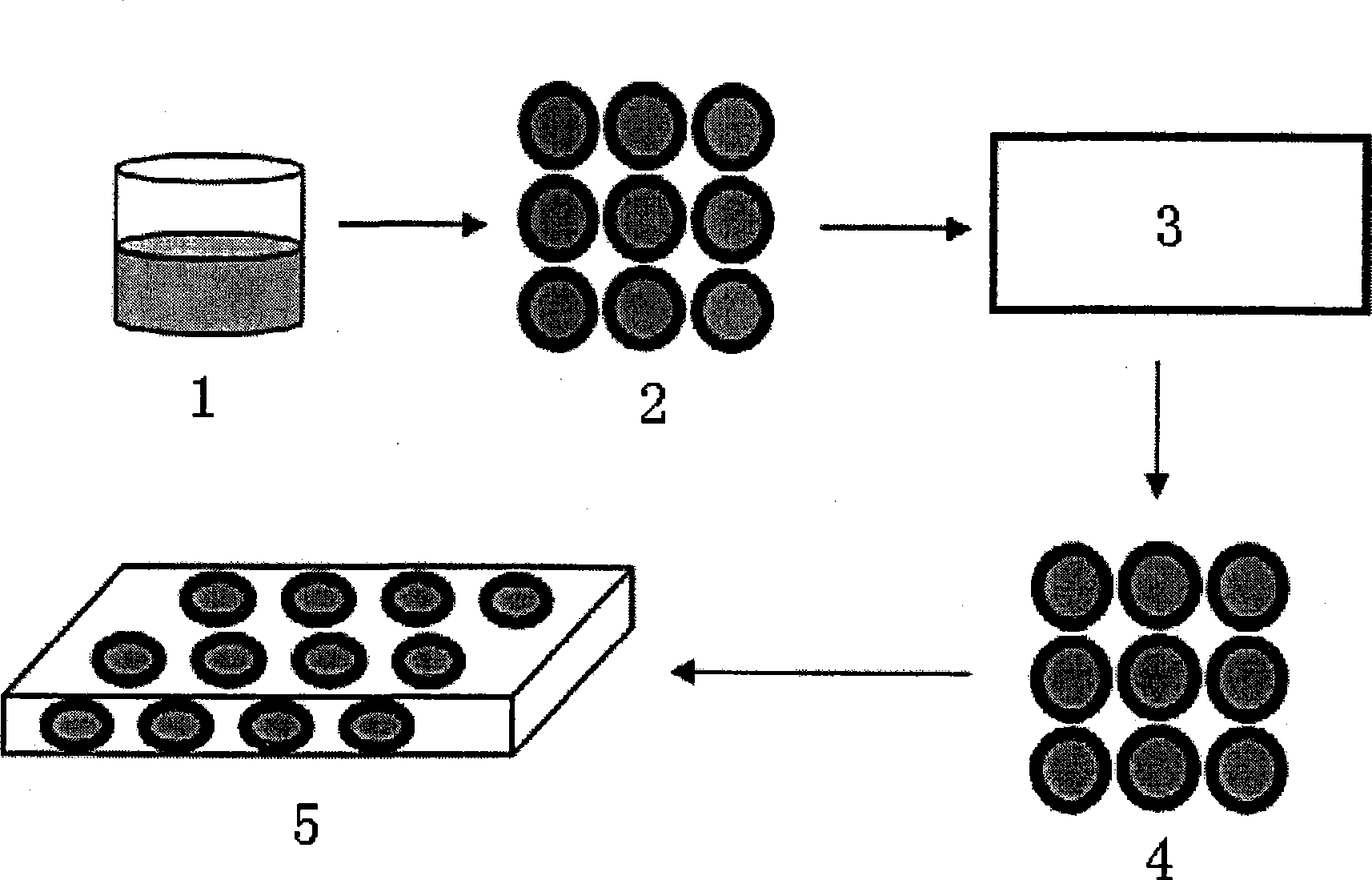

Method used

Image

Examples

Embodiment 1

[0049] Ultrasonic disperse 5 g of spherical silica particles with a particle size of 10 nm in 1 L of methanol solution, and then add 3.6 g (0.2 mol) of H 2 O makes the concentration of water in the solution 0.2mol / L. While stirring, add 6.43g (0.0189mol) butyl titanate (TBOT) to the above solution within 1h, and add 1.36g (0.0756mol) H at the same time 2 O, keep the concentration of water in the solution at 0.2 mol / L, continue to stir the solution for 2 hours to complete the hydrolysis reaction of butyl titanate, and form composite nanoparticles (S-T) coated with titanium dioxide and silicon dioxide.

[0050] Add water and ammonia water to the above solution, so that the concentration of water and ammonia water in the solution reaches 2mol / L and 0.05mol / L respectively. After stirring evenly, add 0.23g (0.0011mol) tetraethyl orthosilicate (TEOS) within 1h to coat the surface of the S-T composite nanoparticles with silicon dioxide. After continuing to stir for 2 hours, centrif...

Embodiment 2

[0053] Ultrasonic disperse 10 g of spherical silica particles with a particle size of 100 nm in 1 L of ethanol solution, and then add 5.4 g (0.3 mol) of H 2 O makes the concentration of water in the solution 0.3mol / L. Under the condition of stirring, 16.16g (0.0475mol) butyl titanate (TBOT) was added to the above solution within 5h, and 3.42g (0.19mol) H 2 O, keep the concentration of water in the solution at 0.3 mol / L, continue to stir the solution for 5 hours to complete the hydrolysis reaction of butyl titanate, and form composite nanoparticles (S-T) coated with titanium dioxide and silicon dioxide.

[0054] Add water and ammonia water to the above solution, so that the concentration of water and ammonia water in the solution reaches 5mol / L and 0.1mol / L respectively. After stirring evenly, 0.98g (0.0047mol) TEOS was added within 2h to coat the surface of the S-T composite nanoparticles with silica. After continuing to stir for 5 hours, centrifuge to obtain a white precipi...

Embodiment 3

[0057] Ultrasonically disperse 20 g of spherical silica particles with a particle size of 1000 nm in 1 L of ethylene glycol solution, and then add 7.2 g (0.4 mol) of H 2 O makes the concentration of water in the solution 0.4mol / L. While stirring, add 41.17g (0.121mol) butyl titanate (TBOT) to the above solution within 10h, and add 8.71g (0.484mol) H at the same time 2 O, keep the concentration of water in the solution at 0.4 mol / L, continue to stir the solution for 10 h to complete the hydrolysis reaction of butyl titanate, and form composite nanoparticles (S-T) coated with titanium dioxide and silicon dioxide.

[0058] Add water and ammoniacal liquor to above-mentioned solution, make the concentration of water and ammoniacal liquor in the solution reach 10mol / L and 0.2mol / L respectively. After stirring evenly, 5.43g (0.026mol) TEOS was added within 5h to coat the surface of the S-T composite nanoparticles with silica. After continuing to stir for 10 h, centrifuge to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com