Photoluminescent transparent epoxy nanometer composite material, preparation method and application thereof

A nanocomposite material and photoluminescence technology are applied in the field of photoluminescence transparent epoxy nanocomposite materials and their preparation, which can solve the problems of easy agglomeration, growth, change in the fluorescence properties of ZnO quantum dots, and decrease in fluorescence efficiency, etc. Long service life, avoid light scattering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

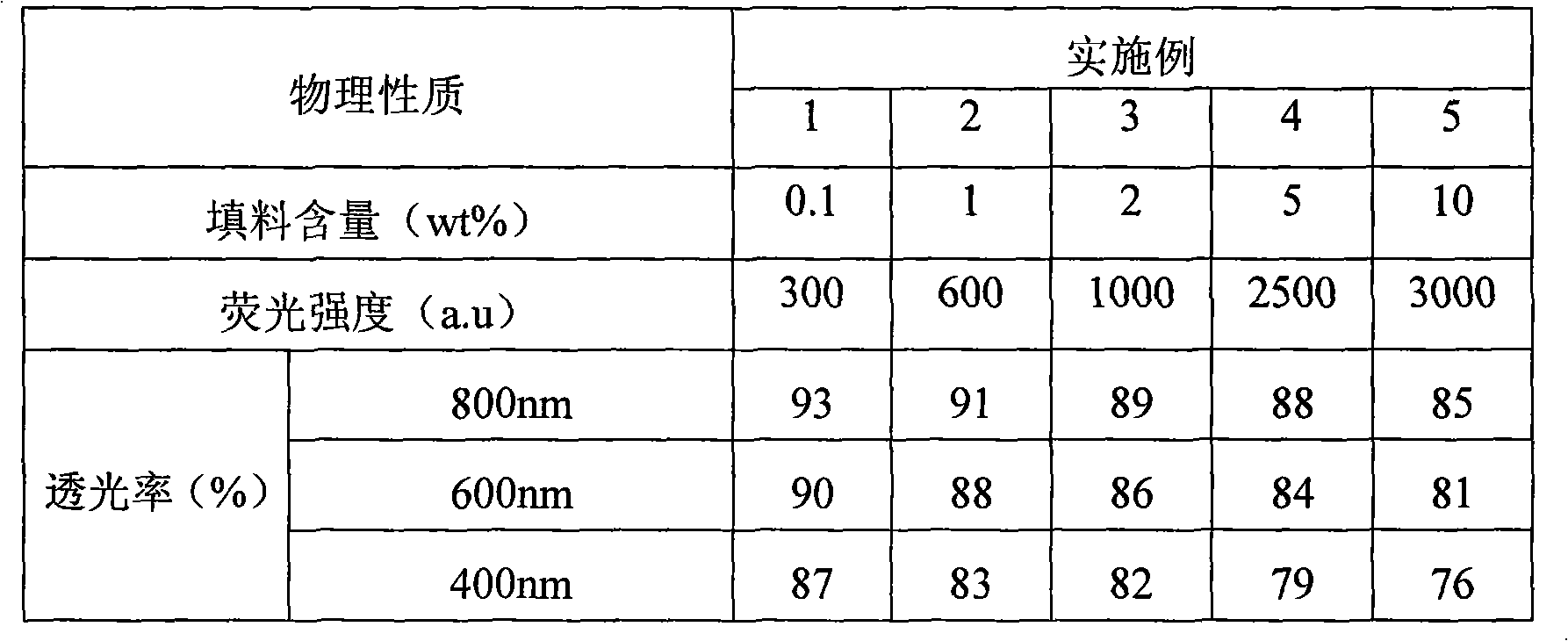

Examples

Embodiment 1

[0039] Add 0.439g of zinc acetate to 50ml of ethanol solution to obtain a 0.04mol / L ethanol solution of zinc acetate, reflux distillation for 3 hours, during which about 30ml of distilled fractions are added; 0.173g of lithium hydroxide is added to 30ml of ethanol solution, and ultrasonically dissolved After 1 h, a 0.25 mol / L lithium hydroxide solution in ethanol was obtained. About 20ml of the remaining fraction was uniformly mixed with 30ml of lithium hydroxide solution under an ice-water bath, and magnetically stirred for 5min. The prepared colorless transparent solution is the ethanol solution of the ZnO quantum dots (the obtained ZnO quantum dots have a particle diameter of 1-5 nm).

[0040] Add 0.3 ml of oleic acid dropwise to the ethanol solution of ZnO quantum dots prepared in the above steps, stir with magnetic force for 5 min and then centrifuge the fraction. Pour off the upper layer solution, immediately add acetone to the resultant, and ultrasonically disperse for...

Embodiment 2

[0042] Add 2.195g of zinc acetate to 100ml of ethanol solution to obtain a 0.10mol / L ethanol solution of zinc acetate, reflux distillation for 3 hours, during which about 60ml of the distilled fraction was added; 0.587g of lithium hydroxide was added to 60ml of ethanol solution, and ultrasonically dissolved After 1 h, a 0.42 mol / L lithium hydroxide solution in ethanol was obtained. About 40ml of the remaining fraction and 60ml of lithium hydroxide solution were uniformly mixed under an ice-water bath, and magnetically stirred for 10min. The prepared colorless transparent solution is the ethanol solution of ZnO quantum dots (the obtained ZnO quantum dots have a particle diameter of 2-10 nm).

[0043] Add 0.6 ml of oleic acid dropwise to the ethanol solution of ZnO quantum dots prepared in the above steps, and centrifuge the fraction after magnetic stirring for 5 min. Pour off the upper layer solution, immediately add acetone to the resultant, and ultrasonically disperse for 30...

Embodiment 3

[0045]Add 3.285g of zinc acetate to 100ml of ethanol solution to obtain a 0.15mol / L ethanol solution of zinc acetate, reflux distillation for 2h, during which about 40ml of the distilled fraction is added; 0.46g of lithium hydroxide is added to 40ml of ethanol solution, and ultrasonically dissolved After 1.0 h, a 0.50 mol / L lithium hydroxide solution in ethanol was obtained. The remaining fraction of about 60ml was uniformly mixed with 40ml of lithium hydroxide solution under an ice-water bath, and magnetically stirred for 20min. The prepared colorless transparent solution is the ethanol solution of the ZnO quantum dots (the obtained ZnO quantum dots have a particle diameter of 5-15 nm).

[0046] Add 0.8 ml of oleic acid dropwise to the ethanol solution of ZnO quantum dots prepared in the above steps, stir with magnetic force for 2 min and then centrifuge the fraction. Pour off the upper layer solution, immediately add acetone to the resultant, and ultrasonically disperse for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com