Dry-method winding formation method for carbon fiber composite transmission axle tube

A transmission shaft tube and composite material technology, applied to tubular objects, other household appliances, household appliances, etc., can solve problems such as poor working environment, fiber wear, resin waste, etc., and achieve excellent mechanical properties, high specific strength, and satisfy torsion The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

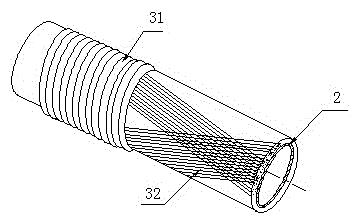

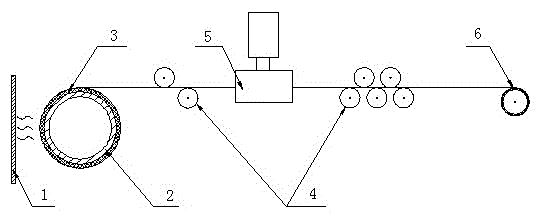

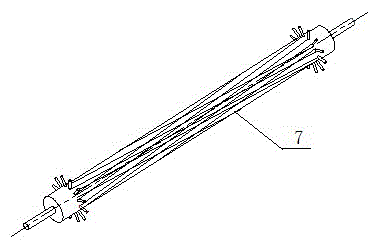

[0038] use as image 3 The shown pin mold 7 realizes winding at a small angle through the hooking of the pins on the prepreg yarn 6 . After the winding is completed, the carbon fiber composite transmission shaft tube is surface treated with a silicone film or a PET film. After the curing is completed, cut a length near the inner side of the pin, such as 100mm-200mm, to obtain the carbon fiber / epoxy prepreg yarn 6 transmission shaft tube.

Embodiment 2

[0040] use as Figure 4 The shown head mold 8 achieves small-angle winding through the head. After the winding is completed, the carbon fiber composite transmission shaft tube is surface treated with a silicone film or a PET film. After the curing is completed, the head part is cut, and then demolded to obtain the carbon fiber / epoxy prepreg yarn 6 transmission shaft tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com