High temperature self-restoring fibre enhancement epoxy composite material and preparation method thereof

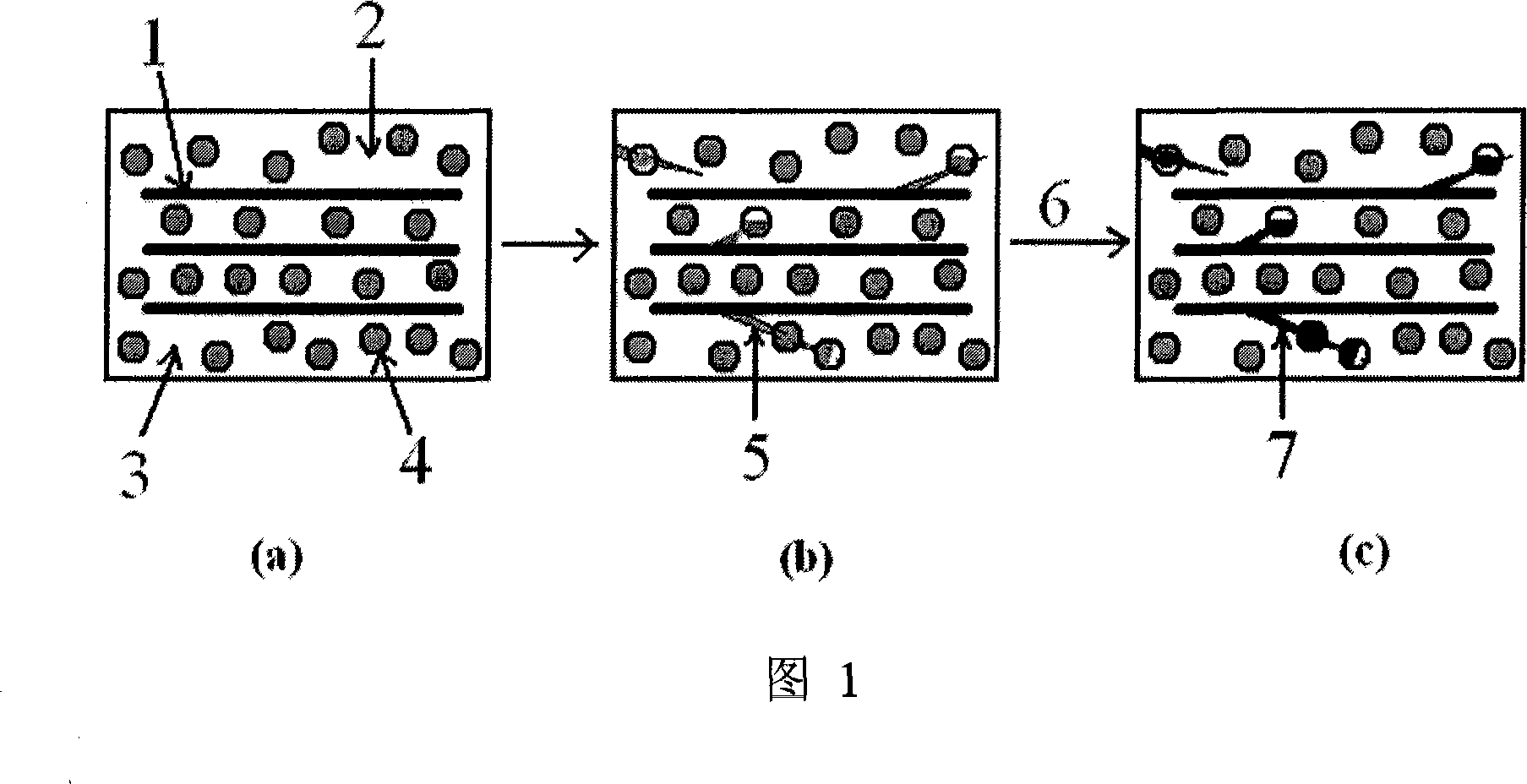

A fiber-reinforced material and fiber-reinforced technology are applied in the field of high-temperature self-healing fiber-reinforced epoxy composite materials and their preparation, which can solve the problems of self-healing research lag, inability to repair micro-cracks, and poor repair effect, and achieve good self-healing. Repair performance, improved repair effect, high durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A high-temperature self-healing fiber-reinforced epoxy composite material is prepared by the following preparation method:

[0028] (1) 5g microcapsules (the core is bisphenol A diglycidyl ether epoxy resin, the wall is polyurea aldehyde, the content of the core epoxy resin is 64% of the total weight of the microcapsules, the average particle size of the microcapsules Is 37μm) and 1g catalyst (complex of copper bromide and 2-methylimidazole) are added to 100g epoxy resin matrix (bisphenol A diglycidyl ether epoxy resin), mix well and add 19g epoxy resin The curing agent for the matrix (the adduct of tetraethylenepentamine and acrylonitrile), and then mix it evenly;

[0029] (2) Infiltrate 42.5g of fiber reinforced material (C-glass fiber checkered cloth) with the above mixture, layer, cure and post-curing to form. The curing and post-curing process are: 60℃ 2h, 80℃ 2h, 120 ℃ 2h.

[0030] For the high-temperature self-healing fiber-reinforced epoxy composite material of this...

Embodiment 4

[0032]The high-temperature self-healing fiber-reinforced epoxy composite material of Example 4 has the composition and dosage ratio shown in Table 1, and the preparation method thereof except that the microcapsule in step (1) is changed to the core of bisphenol A diglycidyl ether ring Oxygen resin, the capsule wall is a copolymer of epoxy acrylate and sodium hydroxypropane methacrylate, the epoxy resin content of the capsule core is 72% of the total weight of the microcapsules, and the average particle size of the microcapsules is 10μm; The resin matrix was changed to triglycidyl trimeric isocyanate, and the rest was the same as in Example 1.

[0033] The high-temperature self-healing fiber-reinforced epoxy composite material of Example 5 to Example 7 has the dosage ratio of each component as shown in Table 1, and the preparation method of each example is except for the curing agent for epoxy resin matrix in step (1) Change to 2-ethyl-4-methylimidazole, the curing and post-curing ...

Embodiment 8

[0034] The high-temperature self-healing fiber-reinforced epoxy composite material of Example 8, its component dosage ratio is shown in Table 1, and its preparation method except that the curing agent for epoxy resin matrix in step (1) is changed to 2-ethyl-4 -Methylimidazole, the fiber reinforced material in step (2) is changed to E-glass fiber and replaced with (45 / 0 / -45 / 90) 2s Laying method, curing and post-curing process are 80°C for 2h, 120°C for 2h, and 140°C for 2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com