Wear-resistant electric insulating rubber material and preparation method thereof

A technology for insulating rubber and electricity, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of high cost, poor viscosity, difficult and cumbersome preparation process, etc., to improve plasticity, improve wear resistance, and a wide range of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

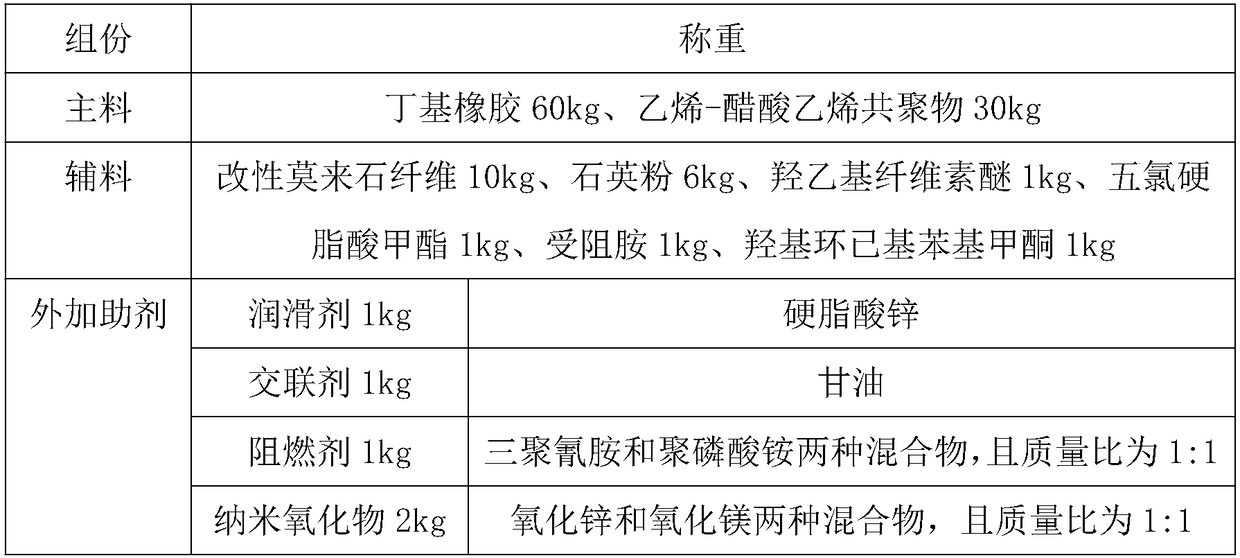

[0020] A wear-resistant electrical insulating rubber material, which is prepared by weighing the raw materials in the following table 1:

[0021] Table 1

[0022]

[0023] Preparation of modified mullite fiber: get 10 kg of raw material mullite fiber and place it in a grinder for grinding, so that the length of the mullite fiber is less than or equal to 100 μm, and the aspect ratio is less than 10 to obtain mullite fiber fines; Laishi fiber fines were added to dimethylformamide solution with a mass concentration of 8%, soaked for 6h at a temperature of 44°C, ultrasonically treated for 25min after soaking, filtered and washed, and then added to a dimethylformamide solution with a mass concentration of 4%. Ultrasonic treatment in sulfuric acid solution for 60min, filtering and washing, and drying; then use acrylic acid copolymer to infiltrate the treated mullite fiber fines, and the infiltration temperature is 42°C; then use low-carbon polyhydric alcohol to infiltrate the inf...

Embodiment 2

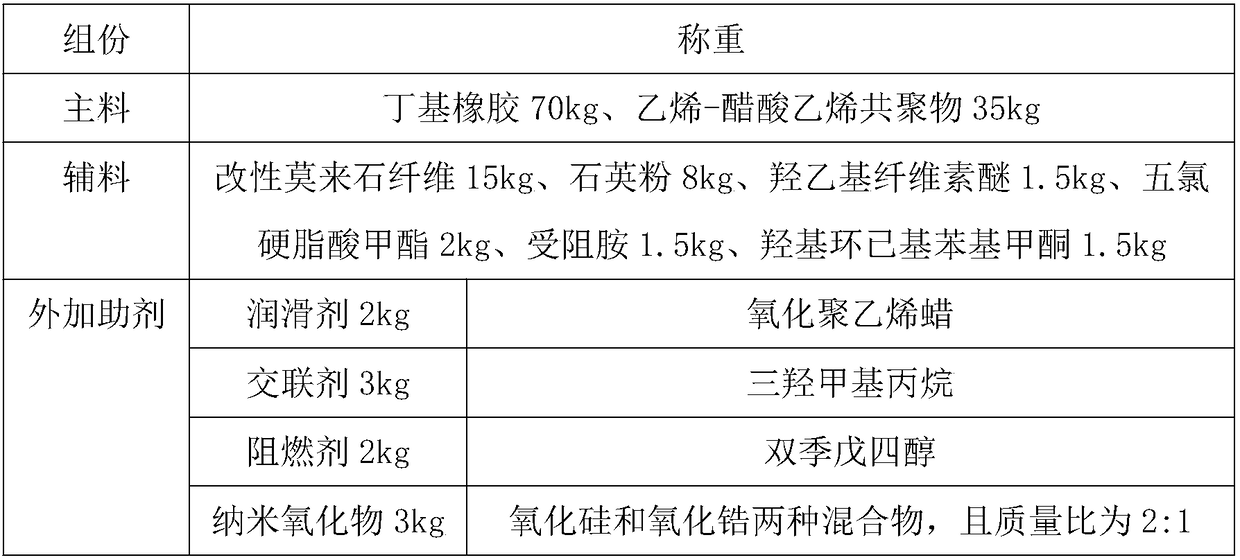

[0028] A wear-resistant electrical insulating rubber material, which is prepared by weighing the raw materials in the following table 2:

[0029] Table 2

[0030]

[0031] Preparation of modified mullite fiber: get 15 kg of raw material mullite fiber and place it in a grinder for grinding, so that the length of the mullite fiber is less than or equal to 80 μm, and the aspect ratio is less than 11 to obtain mullite fiber fines; Laishi fiber fines were added to a dimethylformamide solution with a mass concentration of 10%, soaked at a temperature of 46°C for 7 hours, ultrasonically treated for 30 minutes after soaking, filtered and washed, and then added to a dimethylformamide solution with a mass concentration of 6%. Ultrasonic treatment in sulfuric acid solution for 70 minutes, filtered and washed, and then dried; then the treated mullite fiber fines were infiltrated with acrylic acid copolymer, and the infiltration temperature was 43°C; Coating with stone fiber fines, the...

Embodiment 3

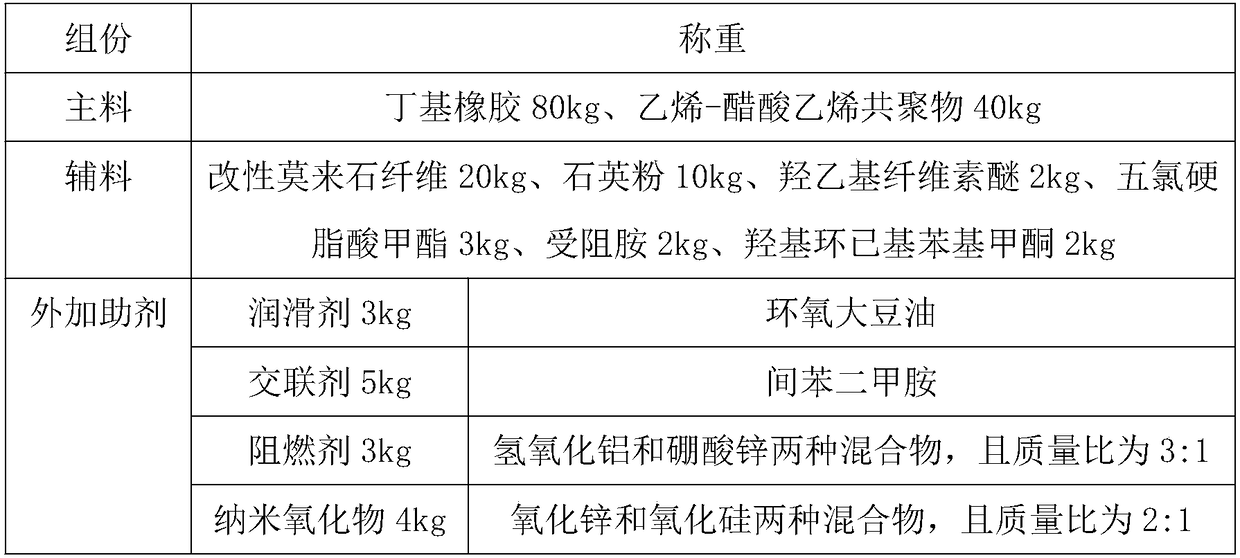

[0036] A wear-resistant electrical insulating rubber material, which is prepared by weighing the raw materials in the following table 3:

[0037] table 3

[0038]

[0039] Preparation of modified mullite fiber: get 20 kg of raw material mullite fiber and place it in a grinder for grinding, so that the length of the mullite fiber is less than or equal to 90 μm, and the aspect ratio is less than 10 to obtain mullite fiber fines; Laishi fiber fines were added to a dimethylformamide solution with a mass concentration of 12%, soaked at a temperature of 48°C for 8 hours, ultrasonically treated for 35 minutes after soaking, filtered and washed, and then added to a dimethylformamide solution with a mass concentration of 8%. Ultrasonic treatment in sulfuric acid solution for 80min, filtering and washing, and drying; then use acrylic acid copolymer to infiltrate the treated mullite fiber fines, and the infiltration temperature is 44°C; then use low-carbon polyhydric alcohol to infiltra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com