Heat conduction nylon composite material and preparation method thereof

A technology of nylon composite material and thermally conductive insulating material, which is applied in the field of nylon composite materials, can solve the problems of difficulty in meeting the performance of use, restricting the wide application of thermally conductive plastics, difficult thermal conductivity of thermally conductive plastics, etc., and achieves improved fusion effect, excellent mechanical properties, The effect of excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

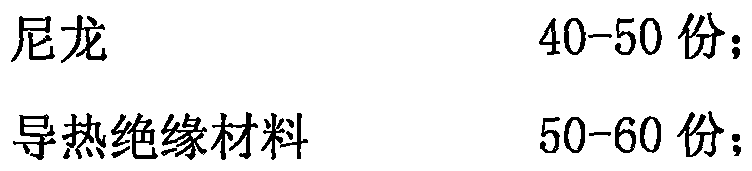

Method used

Image

Examples

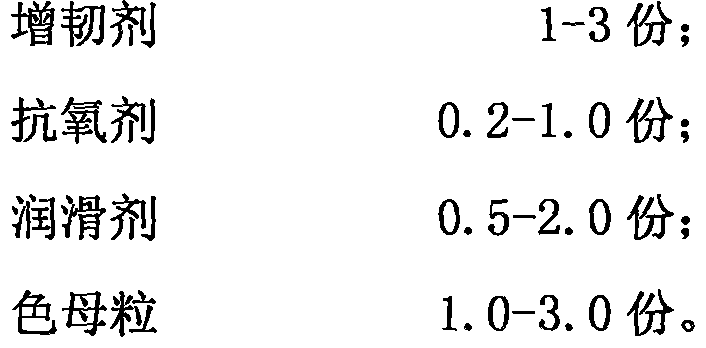

Embodiment 1

[0030] Step 1. First place the nylon 6 resin in an oven at 100°C to dry for 3-4 hours, so that the moisture content is less than 5‰; then weigh 50kg of the dried nylon 6 resin and 3kg of polyethylene octene copolymerized elastomer in proportion -Maleic anhydride copolymerization (toughening agent), 0.25kg N, N'-1,6-hexylene-bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionamide] (anti Oxygen agent), 0.25kg tris(2,4-di-tert-butylphenyl) phosphite (antioxidant), 1kg silicone powder (lubricant) and 2kg black masterbatch, and add them together in the high-speed mixer , stir and mix until uniform to obtain a mixture;

[0031] Step 2, then weigh 50 kg of aluminum nitride powder (thermally conductive insulating material) with a diameter of 40 μm, and add the mixture obtained in step 1 and the thermally conductive insulating material to the double-layer aluminum alloy with a length-to-diameter ratio of 40:1 through the main feed and side feed respectively. In the screw extruder, the ...

Embodiment 2

[0033] Step 1. First place the nylon 6 resin in an oven at 100°C to dry for 3-4 hours, so that the moisture content is less than 5‰; then weigh 50kg of the dried nylon 6 resin and 3kg of polyethylene octene copolymerized elastomer in proportion -Maleic anhydride copolymerization (toughening agent), 0.25kg N, N'-1,6-hexylidene-bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionamide]( Antioxidant), 0.25kg tris(2,4-di-tert-butylphenyl) phosphite (antioxidant), 1kg silicone powder (lubricant) and 2kg black masterbatch, and add them together to the high-speed mixer , stir and mix until uniform to obtain a mixture;

[0034] Step 2, then weigh 50kg of barium sulfate powder (thermally conductive insulating material), and add the mixture and thermally conductive insulating material obtained in step 1 into the twin-screw extruder with a length-to-diameter ratio of 40:1 through the main feed and side feed respectively , the frequency of the main engine is 25HZ, the processing temperature ...

Embodiment 3

[0036] Step 1. First place the nylon 6 resin in an oven at 100°C to dry for 3-4 hours, so that the moisture content is less than 5‰; then weigh 50kg of the dried nylon 6 resin and 3kg of polyethylene octene copolymerized elastomer in proportion -Maleic anhydride copolymerization (toughening agent), 0.25kg N, N'-1,6-hexylidene-bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionamide]( Antioxidant), 0.25kg tris(2,4-di-tert-butylphenyl) phosphite (antioxidant), 1kg silicone powder (lubricant) and 2kg black masterbatch, and add them together to the high-speed mixer , stir and mix until uniform to obtain a mixture;

[0037] Step 2, then weigh 30kg of aluminum nitride powder (thermally conductive insulating material) and 20kg of barium sulfate powder (thermally conductive insulating material) with a diameter of 40 μm, mix uniformly, and pass the mixture obtained in step 1 and the uniformly mixed thermally conductive insulating material through the main feeder respectively. The raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com