High-thermal-conductivity ceramic crucible and preparation method thereof

A ceramic pot and high thermal conductivity technology, which is applied in the field of ceramic products, can solve the problems of heat resistance (thermal shock resistance, poor thermal expansion coefficient, poor appearance, strength and other comprehensive properties, poor thermal conductivity, etc., to improve quality stability , Optimize raw material cost, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

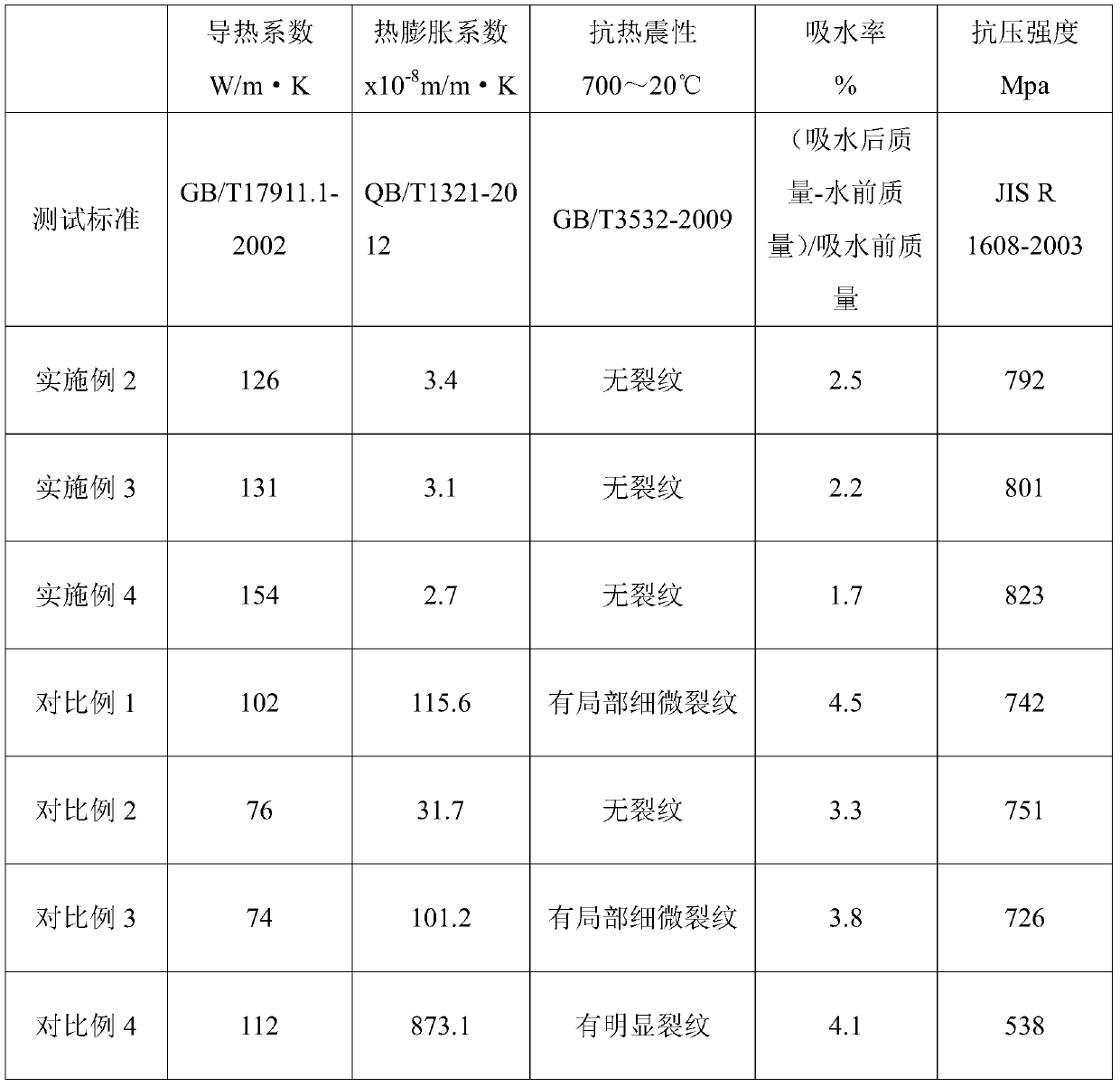

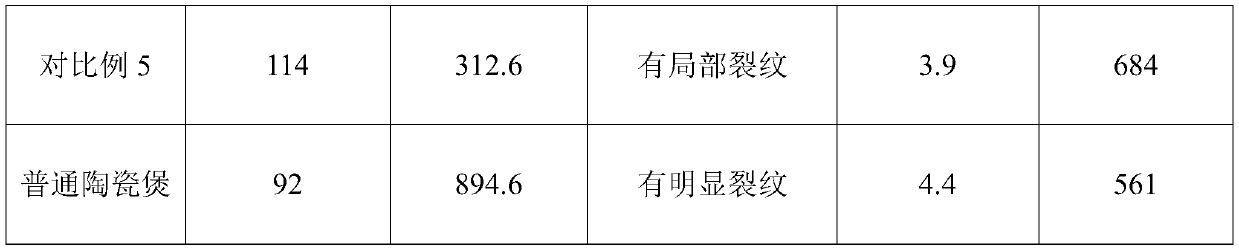

Examples

Embodiment 1

[0036] A ceramic pot with high thermal conductivity, comprising the following raw materials in parts by weight: 60-75 parts of a mixture of calcined spodumene powder and petalite powder, 15-25 parts of quartz, 25-35 parts of bauxite, 12 parts of a mixture of copper silicide and copper powder ~17 parts, 5~7.5 parts of silicon carbide fiber, 9~15 parts of calcined kaolin; the mass ratio of calcined spodumene powder and petalite powder in the mixture of calcined spodumene powder and petalite powder is 1:( 0.2-0.4); the mass ratio of copper silicide and copper powder in the mixture of copper silicide and copper powder is 1:(0.8-1.1).

[0037] In this embodiment, the preparation method of the high thermal conductivity ceramic pot includes the following steps:

[0038] A, take calcined spodumene powder and petalite powder respectively, and mix uniformly, obtain calcined spodumene powder and petale feldspar powder mixture;

[0039] B, take copper silicide and copper powder respectiv...

Embodiment 2

[0043] A high thermal conductivity ceramic pot, comprising the following raw materials in parts by weight: 67 parts of a mixture of calcined spodumene powder and petalite powder, 18 parts of quartz, 28 parts of bauxite, 13 parts of a mixture of copper silicide and copper powder, and 5.5 parts of silicon carbide fiber parts, 10 parts of calcined kaolin.

[0044] In this embodiment, the mass ratio of the calcined spodumene powder and the petalite powder in the mixture of the calcined spodumene powder and the petalite powder is 1:0.2.

[0045] In this embodiment, the mass ratio of copper silicide and copper powder in the mixture of copper silicide and copper powder is 1:0.95.

[0046] In this embodiment, the particle sizes of the calcined spodumene powder, petalite powder, quartz, bauxite, copper silicide and copper powder are all 1000-5000 mesh.

[0047] In this embodiment, the particle size of the calcined kaolin is 3000 mesh.

[0048] In this embodiment, the preparation meth...

Embodiment 3

[0054] A high thermal conductivity ceramic pot, comprising the following raw materials in parts by weight: 72 parts of a mixture of calcined spodumene powder and petalite powder, 23 parts of quartz, 34 parts of bauxite, 16 parts of a mixture of copper silicide and copper powder, and 6.5 parts of silicon carbide fiber parts, 14 parts of calcined kaolin.

[0055] In this embodiment, the mass ratio of the calcined spodumene powder and the petalite powder in the mixture of the calcined spodumene powder and the petalite powder is 1:0.35.

[0056] In this embodiment, the mass ratio of copper silicide and copper powder in the mixture of copper silicide and copper powder is 1:1.05.

[0057] In this embodiment, the particle sizes of the calcined spodumene powder, petalite powder, quartz, bauxite, copper silicide and copper powder are all 1000-5000 mesh.

[0058] In this embodiment, the particle size of the calcined kaolin is 4000 mesh.

[0059] In this embodiment, the preparation met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com