Production method of thin prepreg with high-content filler adhesive system

A prepreg, production method technology, applied in chemical instruments and methods, layered products, circuit substrate materials, etc., can solve problems such as increasing product manufacturing costs, increasing the risk of product quality problems, and affecting the electrical insulation performance of PCB boards. Ensure electrical performance and reliability, solve apparent pinhole defects, and ensure the effect of electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

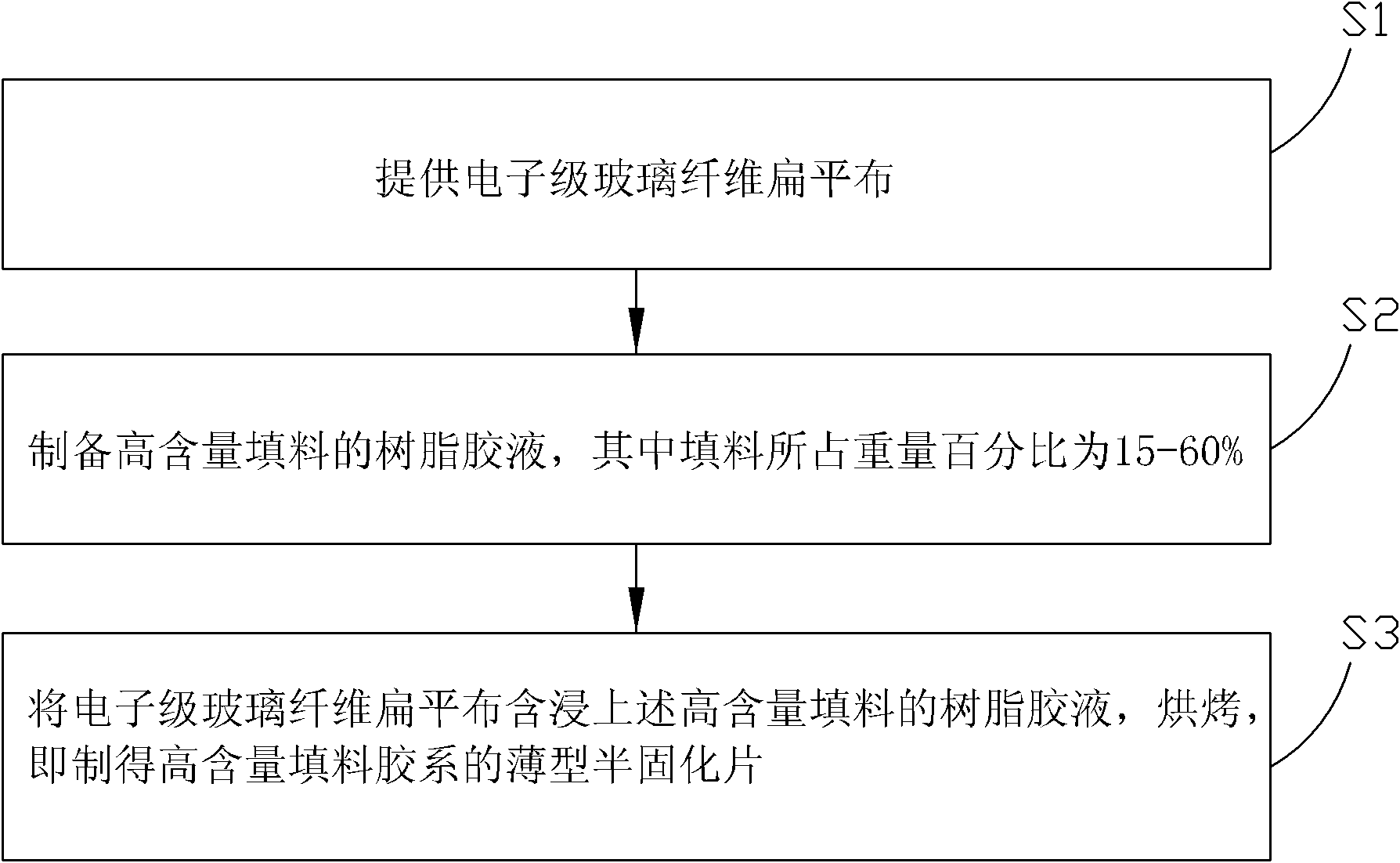

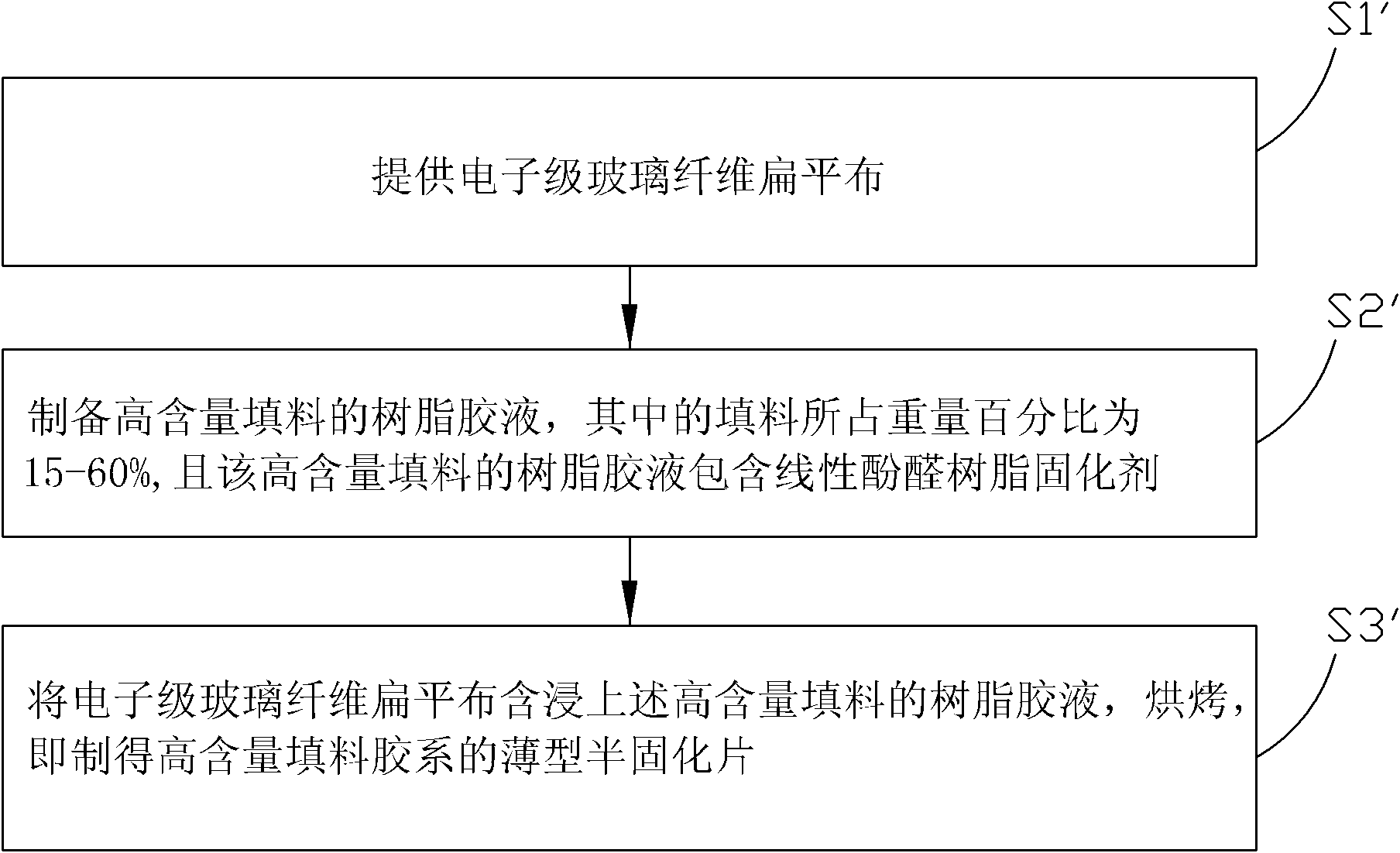

Method used

Image

Examples

Embodiment 1

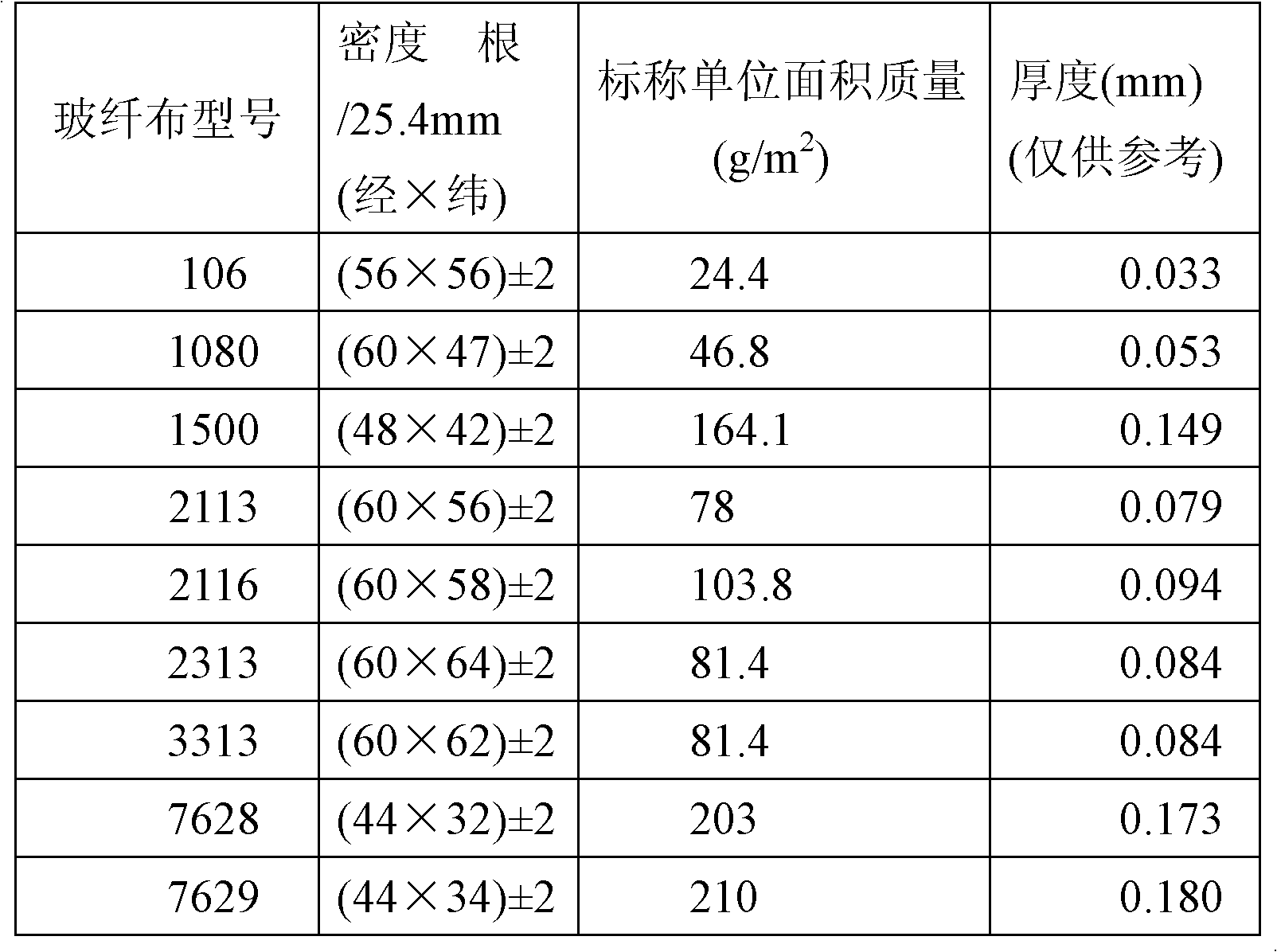

[0047] Preparation of resin glue with high content of fillers, wherein the weight percentage of fillers in the total components is 20%, and the void area of warp and weft yarns is 0.005-0.008mm 2 The 106 thin electronic-grade glass fiber flat cloth (flat and thin 106) is soaked in the resin glue solution with high filler content, and baked to obtain a thin prepreg with a resin content of 71% and a 106 high filler glue system. The prepared prepreg Compared with the prepreg using ordinary thin 106 glass fiber cloth, there is no pinhole problem in its appearance, which improves the qualified rate of the product. The comparison is shown in Table 4 below:

[0048] Table 4, the appearance contrast of prepreg of the present invention and existing prepreg

[0049]

Embodiment 2

[0051] On the basis of Example 1, a novolac resin curing agent with a number average molecular weight ranging from 1200 to 2000 is used in the resin glue with a high content of filler, and 106 thin electronic grade glass fiber flat cloth (flat and thin 106) is used to infiltrate In the resin glue solution with high filler content, a thin prepreg with a resin content of 71% and a 106 high filler glue system is baked. Compared with a prepreg made of ordinary thin 106 glass fiber cloth, the prepreg has The appearance can completely avoid pinhole defects, greatly improving the pass rate of products. The comparison is shown in Table 5 below:

[0052] Table 5, the appearance contrast of prepreg of the present invention and existing prepreg

[0053]

[0054] To sum up, the production method of the thin prepreg with high content of filler adhesive system of the present invention effectively solves the apparent pinhole defects of the thin prepreg, improves its qualification rate, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com