Inner electrode of glass-ceramic stacked capacitor and preparation method of the inner electrode

A technology of laminated capacitors and glass ceramics, applied in the direction of laminated capacitors, fixed capacitor electrodes, fixed capacitor dielectrics, etc., can solve the problems of reduced effective area of internal electrodes, expensive preparation costs, and restrictions on the application environment of capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Prepare a square glass-ceramic dielectric thin monolithic sample with a size of about 20mm×20mm×0.3mm by traditional cutting, thinning and polishing methods;

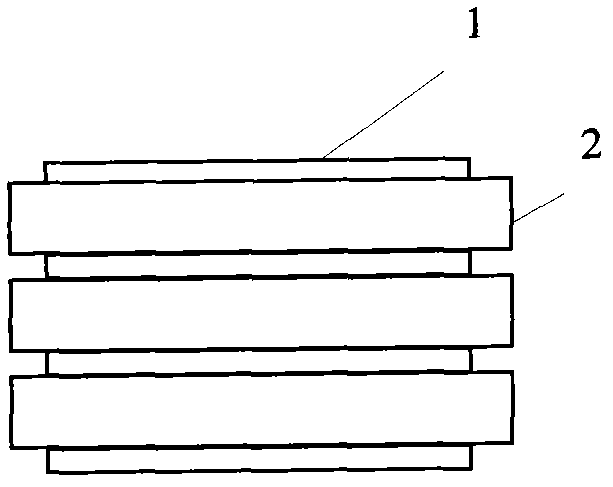

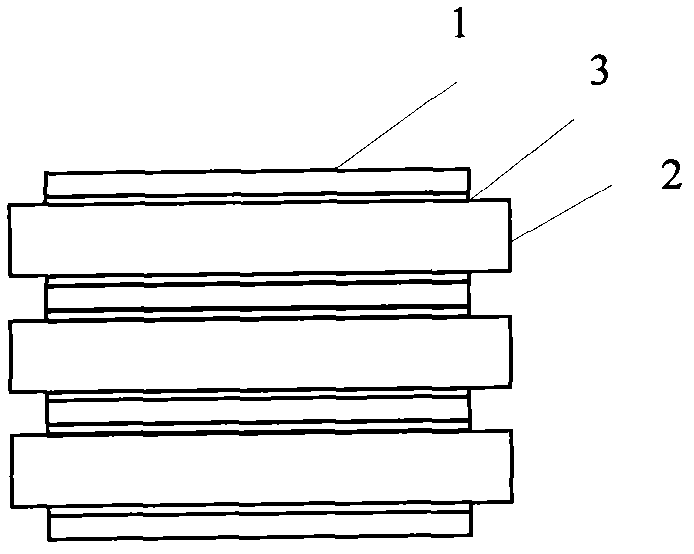

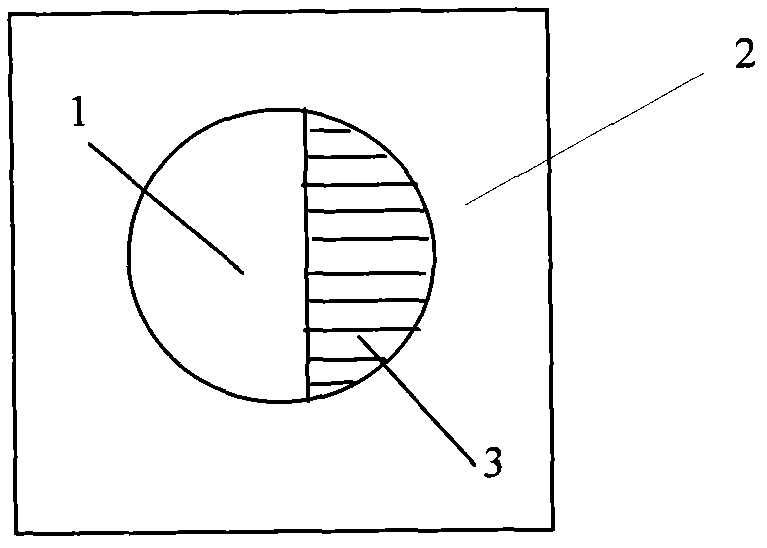

[0041] (2) Use DC magnetron sputtering coating technology to coat the two surfaces of the thin monolithic sheet obtained in step (1) into a dense nickel layer with a diameter of φ10mm as the interface transition layer electrode in the internal electrode, and then use screen printing technology on Ni The same area of low-temperature silver paste electrode is coated on the surface of the film layer. According to the capacitance requirements, the glass-ceramic sheet printed with silver paste electrodes is subjected to multi-layer lamination treatment with micro-pressure, and sintered at 240°C to obtain a three-layer series internal electrode structure between multi-layer glass ceramic dielectric materials (schematic diagram as shown in Fig. Figure 4 shown).

[0042] (3) test leakage current, breakdown field ...

Embodiment 2

[0044] Glass-ceramic dielectric thin monolithic sample The thin monolithic acquisition method is the same as the step (1) of embodiment 1, adopting DC magnetron sputtering coating technology to be plated on the two surfaces of the thin monolithic obtained with a diameter of φ 10mm dense silver layer as the internal electrode The interfacial transition layer electrode, and then use screen printing technology to coat the same area of low-temperature silver paste electrode on the surface of the Ag film layer. According to the capacitance requirements, the glass-ceramic sheet printed with silver paste electrodes is subjected to a multi-layer lamination process with micro-pressure, and sintered at 300 ° C to obtain a three-layer series internal electrode structure between multi-layer glass ceramic dielectric materials. And test the leakage current, the breakdown field strength, the dielectric constant of the capacitor of the gained glass-ceramic lamination (see respectively Figu...

Embodiment 3

[0047] Glass-ceramic dielectric thin monolithic sample The thin monolithic acquisition method is the same as the step (1) of embodiment 1, adopting DC magnetron sputtering coating technology to be plated on the two surfaces of the thin monolithic obtained with a diameter of φ10mm dense copper layer as the internal electrode The interfacial transition layer electrode, and then use screen printing technology to coat the same area of low-temperature silver paste electrode on the surface of the Cu film layer. According to the capacitance requirements, the glass-ceramic sheet printed with silver paste electrodes is subjected to a multi-layer lamination process with micro-pressure, and sintered at 150 ° C to obtain a three-layer series internal electrode structure between multi-layer glass ceramic dielectric materials. And test the leakage current, the breakdown field strength, the dielectric constant of the capacitor of the gained glass-ceramic lamination (see respectively Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com