Copper terminal and aluminum wire joint and magnetic induction welding method thereof

A welding method and technology of copper terminals, which are applied in the field of wire harnesses, can solve the problems of inability to meet the industrial-grade preparation requirements of copper terminals and aluminum wire joints, the inability to directly apply copper terminals and aluminum wire joints, and the inability to solve copper and aluminum welding, etc. Achieve ideal welding effect, save material and time costs, and save manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

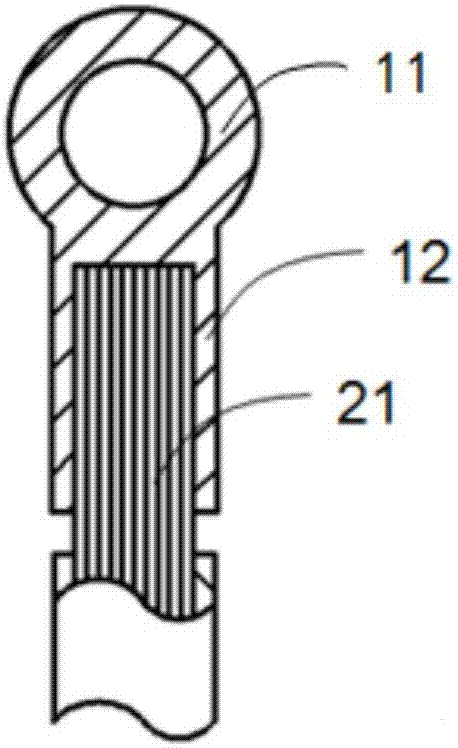

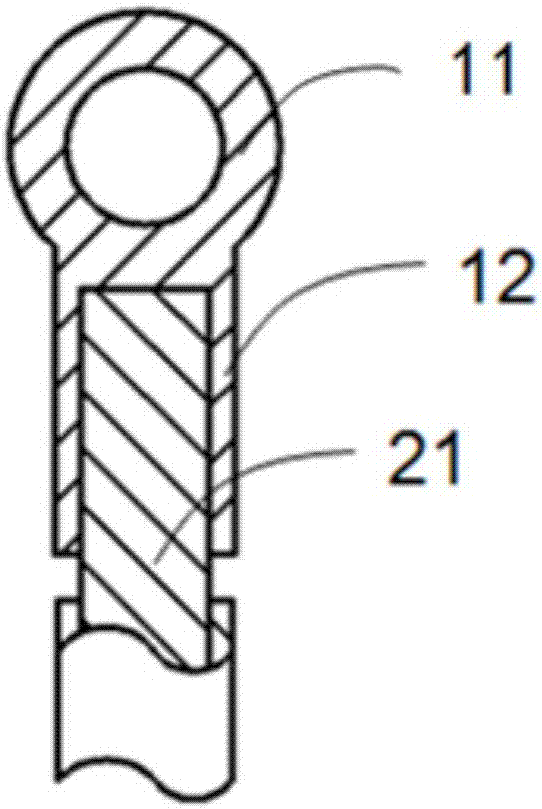

[0058] This embodiment is one of the preferred implementations of the joint between the copper terminal and the aluminum wire of the present invention. Such as figure 1 As shown, the copper terminal is divided into a connecting piece 12, and a functional piece 11 connected to the connecting piece, and the aluminum core of the aluminum wire 21 is connected to the connecting piece of the copper terminal; preferably, the aluminum guiding core Extend or not extend to the feature.

[0059] Preferably, the material of the copper terminal is copper or copper alloy; preferably, the material of the aluminum core of the aluminum wire is aluminum or aluminum alloy.

[0060] In this embodiment, the aluminum wire is a multi-core aluminum wire. In other implementations, the aluminum wire can also be a solid aluminum wire, such as figure 2 shown.

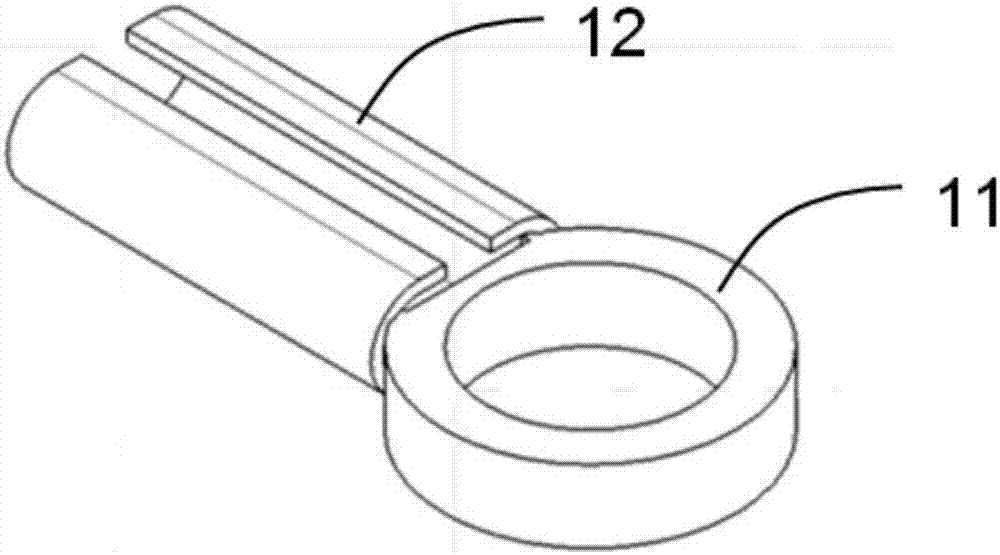

[0061] In one of the preferred implementations, the shape of the connector is flat or arc-shaped or wing-shaped open or circular closed or po...

Embodiment approach

[0077] This embodiment is a more preferred implementation of the magnetic induction welding method between copper terminals and aluminum wires of the present invention, which includes the following steps:

[0078] S1: Assemble the aluminum guide core and the copper terminal connector, the distance between the aluminum guide core and the copper terminal connector is 0-10mm; preferably, the distance between the aluminum guide core and the copper terminal connector is 0 -3mm;

[0079] S2: Welding the aluminum guide core and the copper terminal connector together by using a magnetic induction welding method, so that the outer surface of the aluminum guide core is connected to the surface of the copper terminal connector.

[0080] Before S1, remove the insulation layer of the aluminum wire according to the size of the terminal connector; then assemble the connecting part of the aluminum wire with the insulation layer removed and the copper terminal. Such as image 3 Shown is a sc...

Embodiment 3

[0095] This embodiment is another preferred embodiment of the magnetic induction welding method between copper terminals and aluminum wires and the joint structure formed by the present invention. The difference between this embodiment and the above-mentioned embodiments lies in:

[0096] The S1 further includes the following step: adding a spacer metal layer between the welding end of the aluminum wire and the copper terminal connector. Since copper and aluminum belong to different elements, the metal inertness of copper is greater than that of aluminum, and the electrode potential difference between copper and aluminum is relatively large (+0.337 for copper and -1.662 for aluminum). When the two metals are in direct contact, in the air and water Under the action, aluminum will gradually lose electrons and form an electrochemical reaction, causing corrosion of aluminum wires and reducing the service life of the wiring harness. In severe cases, accidents (such as burning cars) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com