Patents

Literature

68results about How to "Inhibit direct contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

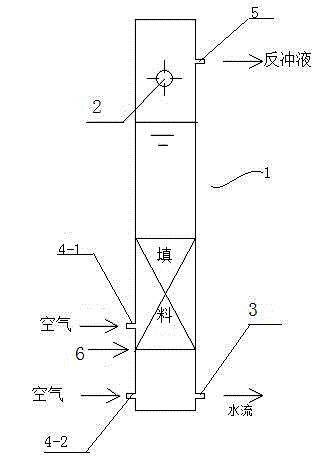

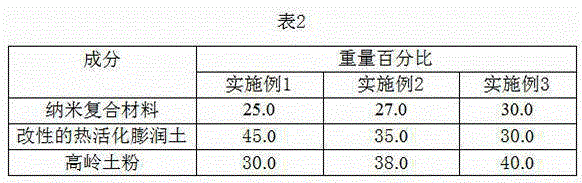

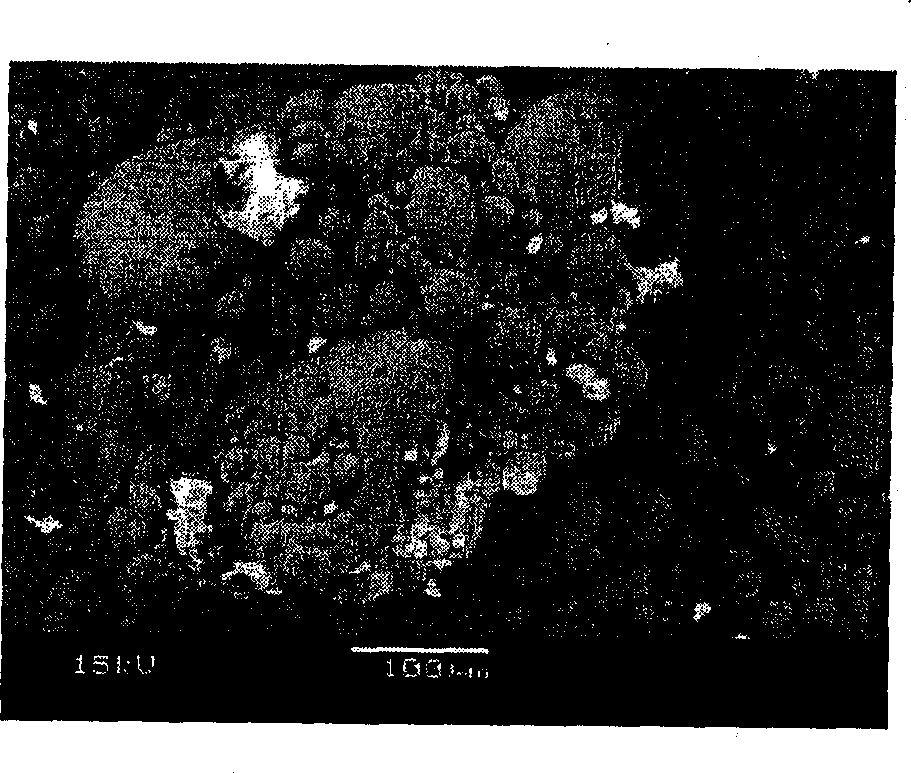

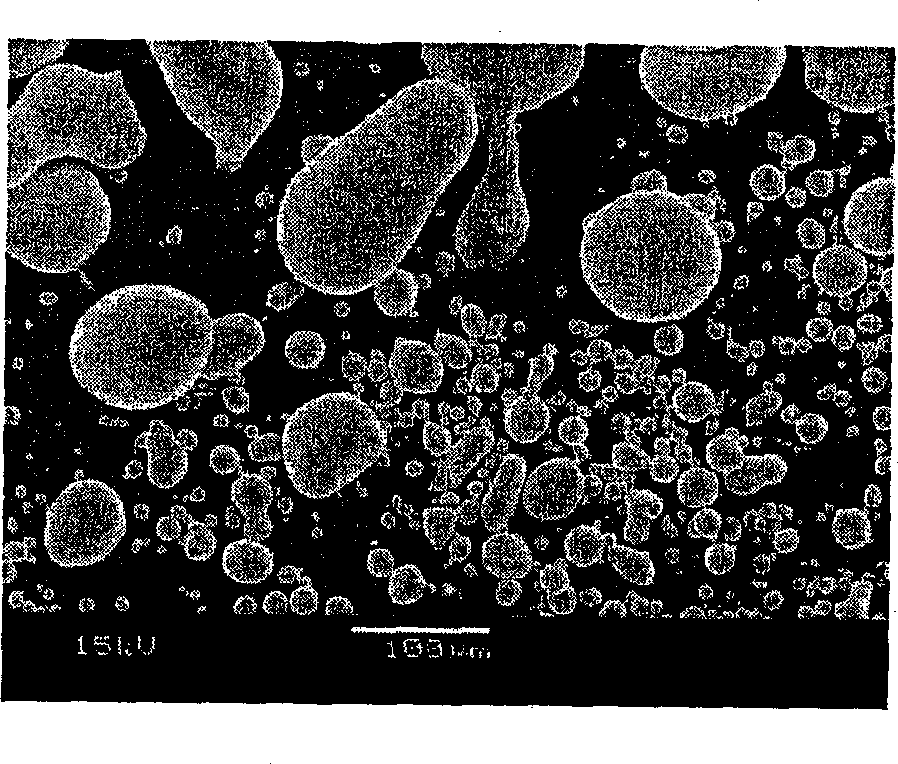

Nano biological filler for purifying aquaculture wastewater in biological filter tank and preparation method of nano biological filler

InactiveCN104085979AGood biocompatibilityLarge specific surface areaSustainable biological treatmentOn/in inorganic carrierBiological filterKaolin clay

The invention discloses nano biological filler for purifying aquaculture wastewater in a biological filter tank and a preparation method of the nano biological filler. The biological filler comprises an EM rejuvenation solution and an adsorption carrier of the EM rejuvenation solution, wherein the EM rejuvenation solution is a product obtained by performing mixed fermentation on an EM stock solution, molasses and deionized water; the adsorption carrier is obtained by performing mixed pressing on composite nano powder, kaolin powder and modified bentonite; the composite nano powder is a product obtained by performing mixing and high-temperature sintering on nano-level aluminum oxide, titanium dioxide and silicon dioxide; modified bentonite is prepared from sodium diethyldithiocarbamate modified original soil. The preparation method comprises the following steps: pressing adsorption carrier particles; fermenting to obtain the EM rejuvenation solution; dipping the EM rejuvenation solution by using the adsorption carrier to obtain the nano biological filler. The obtained nano biological filler is high in pore volume, high in cell adsorption capacity, large in specific surface area and strong in stability, has a good treatment effect on aquaculture sewage, and can be used for rapidly removing ammonia nitrogen, phosphorus and heavy metal ions in an aquaculture water body.

Owner:江苏三新山水生物科技有限公司

Soft magnetic composite powder and production method of the same, and production method of soft magnetic compact

ActiveCN1830043AAvoid direct contactReduce frictionInorganic material magnetismInductances/transformers/magnets manufactureMetallurgyMagnetic characteristic

A soft magnetic compact which is produced by using soft magnetic composite powder in which the surface of magnetic powder is covered with an electrical insulating material containing at least an inorganic insulating material, and a resin material is fusion-bonded to the surface of the inorganic insulating material so as to partially cover the surface of the soft magnetic powder. Accordingly, it is possible to ensure an electrical insulating property between pieces of soft magnetic material powder to secure a good magnetic characteristics and to easily mold a compact.

Owner:NTN CORP

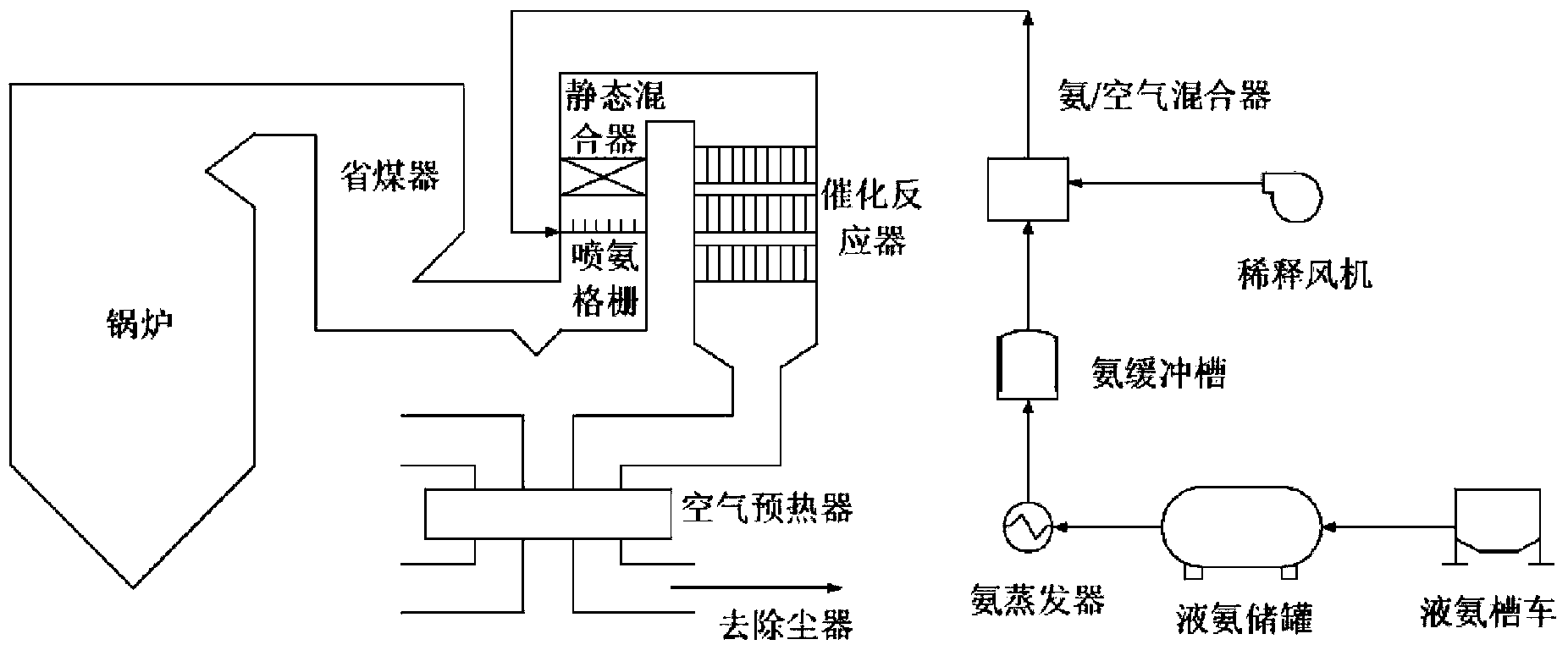

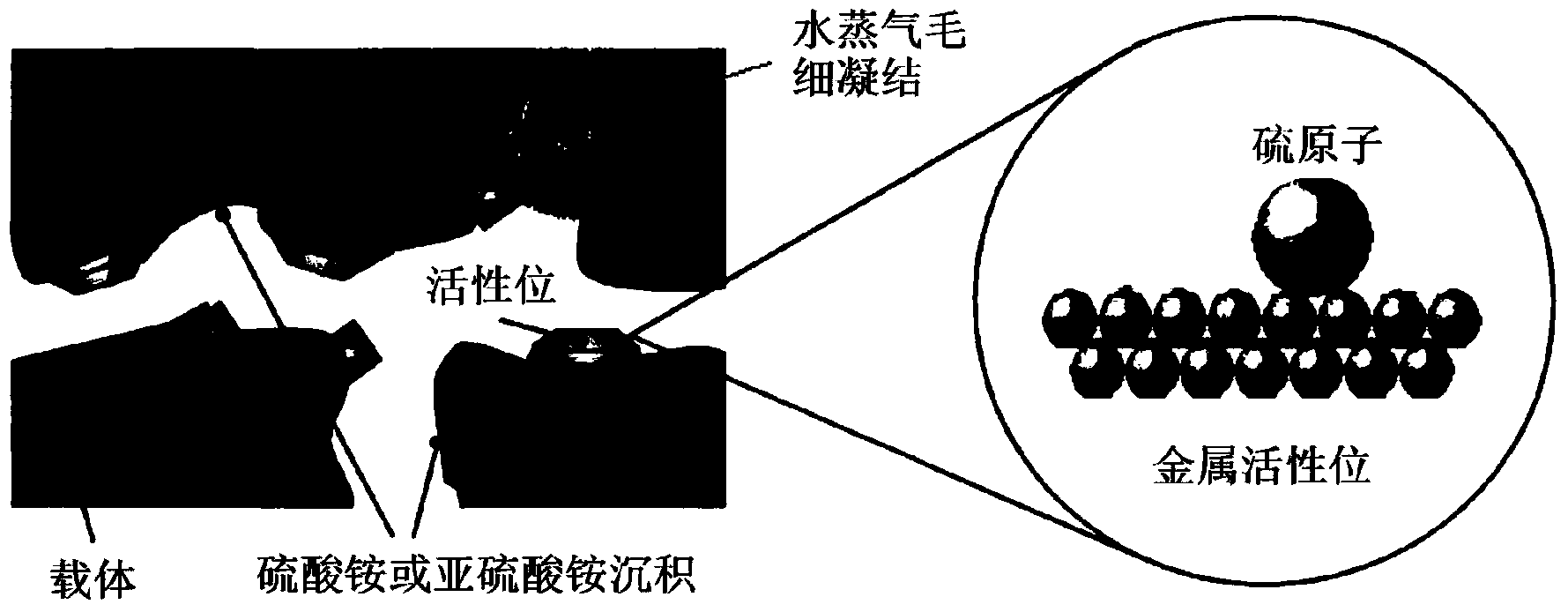

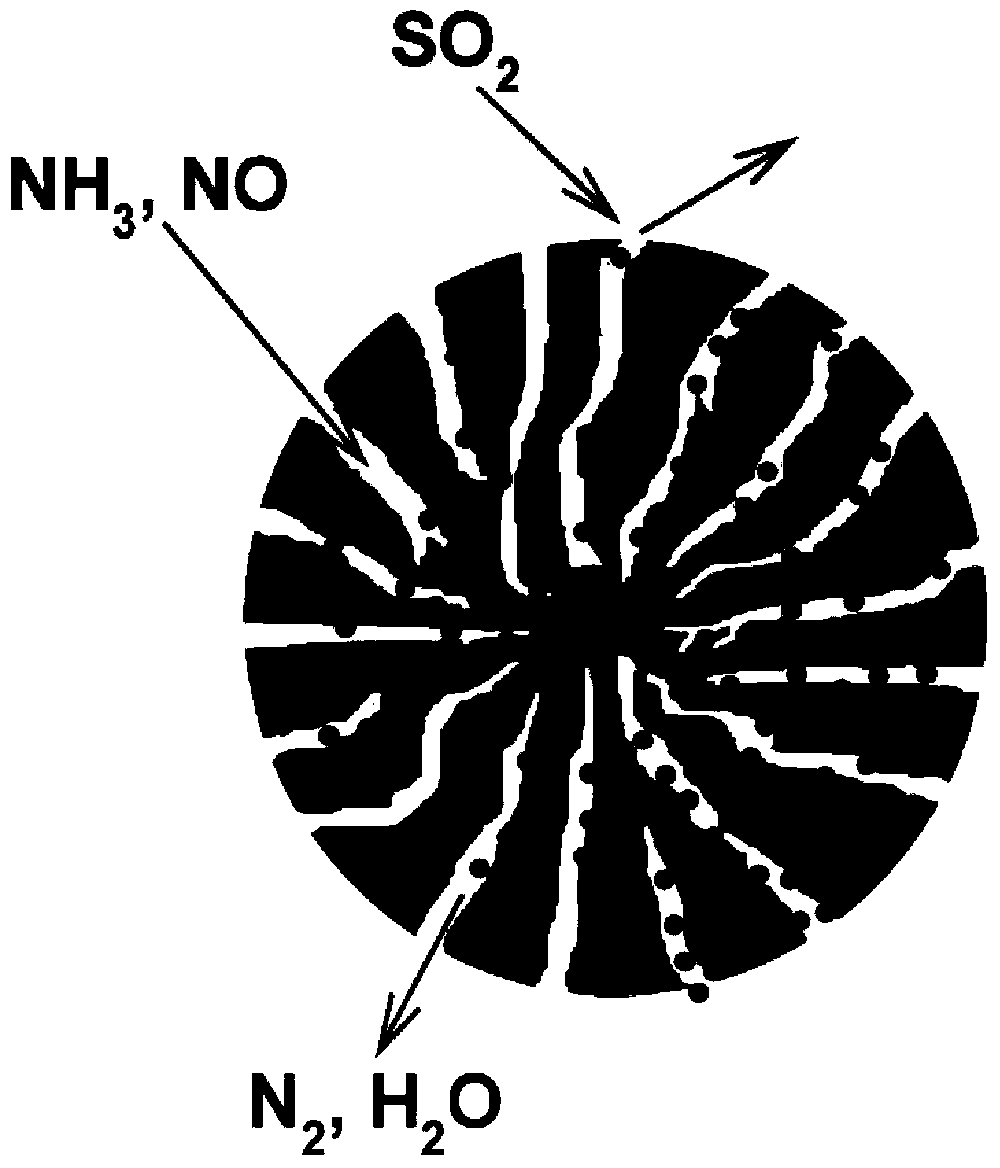

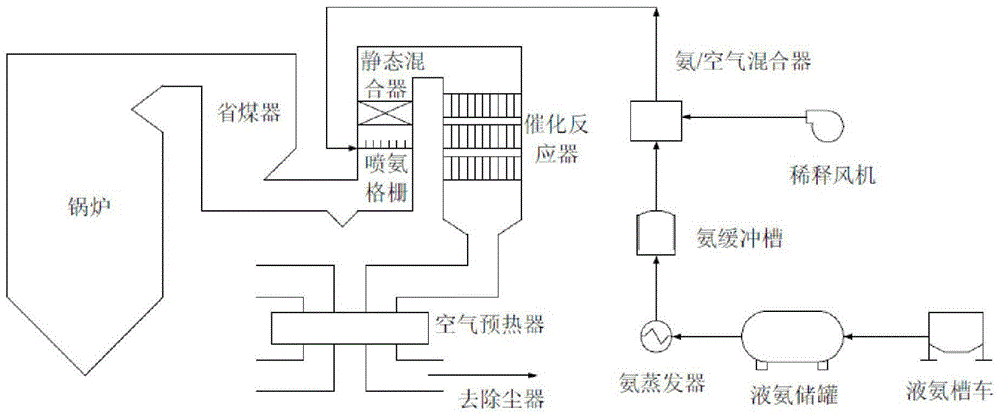

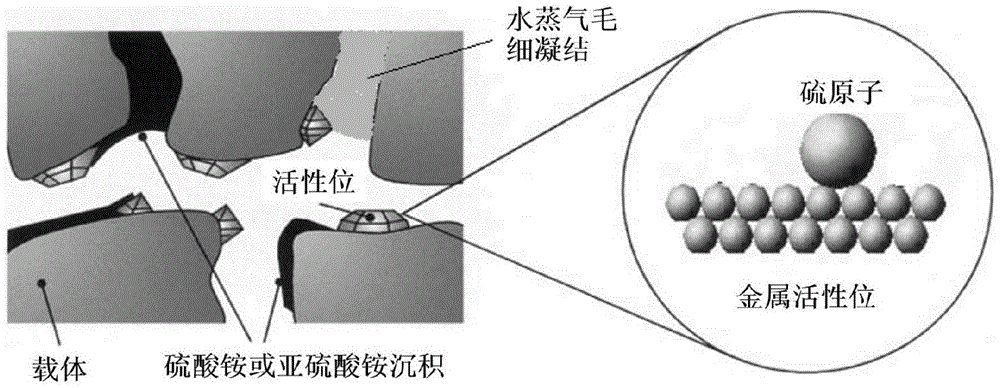

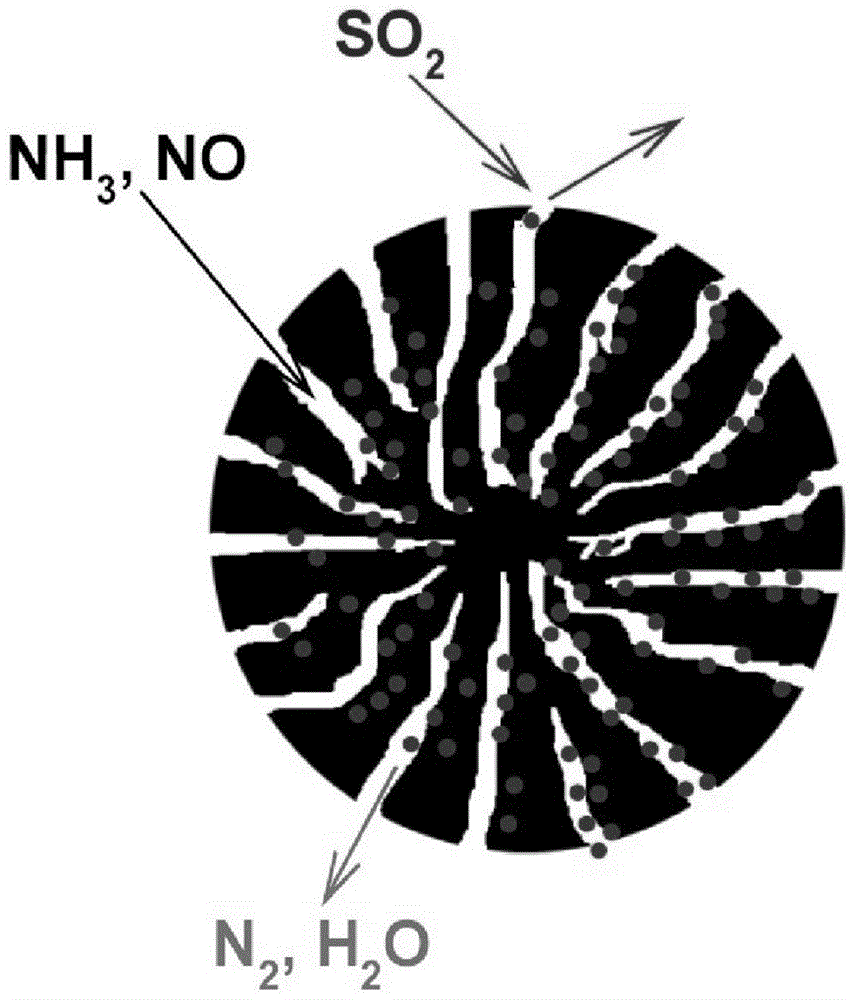

Low-temperature sulfur-resistant denitration catalyst and preparing method thereof

ActiveCN104056658AStrong water resistanceImprove low temperature denitrification performanceMolecular sieve catalystsDispersed particle separationCapillary condensationMolecular sieve

The invention discloses a low-temperature sulfur-resistant denitration catalyst and a preparing method of the low-temperature sulfur-resistant denitration catalyst. The low-temperature sulfur-resistant denitration catalyst is formed by mixing, by weight, 15%-100% of active sites and 0-85% of carbon-based carriers; the active sites are formed by mixing one or two of the first active sites and the second active sites; the first active sites are composed of Mn(0.1-0.8)Ce(0.2-0.9)Ox or Mn(0.1-0.8)Mg(0.2-0.9)Ox dispersed into a 3A molecular sieve, and the value of the x is determined according to the content and the oxidation valence state of metallic elements in the chemical formula; the second active sites are composed of Mn (0.1-0.8)Mg(0.2-0.9) or Mn (0.1-0.8)Ce (0.2-0.9)Ox with the surface coated with a TiO2 or SiO2 protecting layer. According to the method, one or more of the first active sites and the second active site are mixed with carbon-based carriers to obtain the low-temperature sulfur-resistant denitration catalyst. As surface dewatering is performed on the catalyst, water molecules contained in flue gas are attached in an open-framework structure of the catalyst to form capillary condensation very difficultly or form vitriol or sulphurous acid ammonium salt with NH3 and SO2 or SO3 to cause deactivation of the catalyst.

Owner:XIAN SINO GREEN HI TECH CO LTD

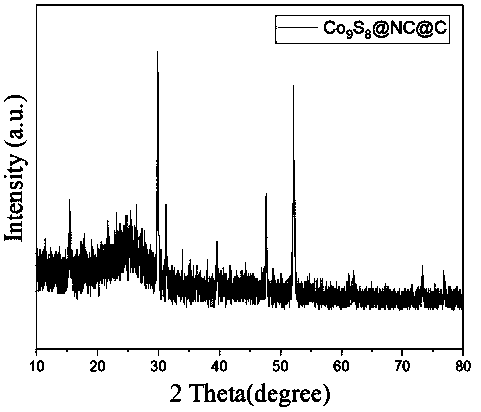

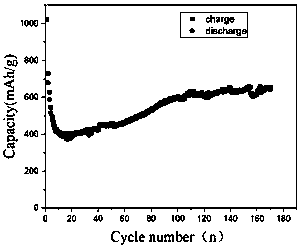

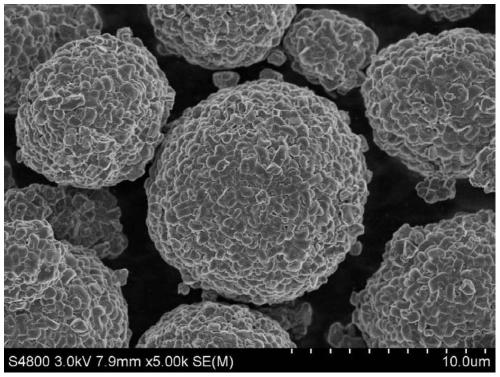

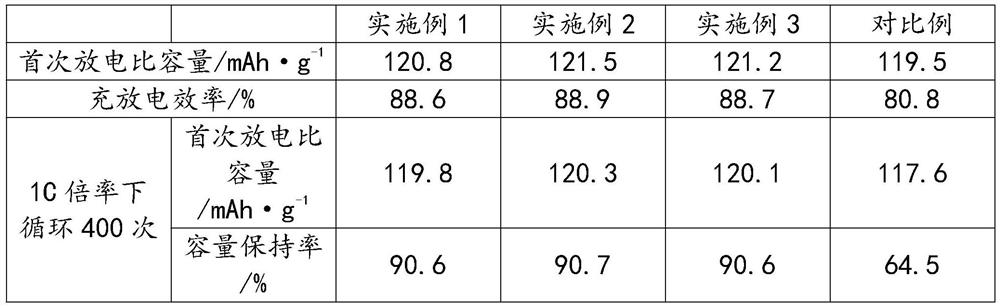

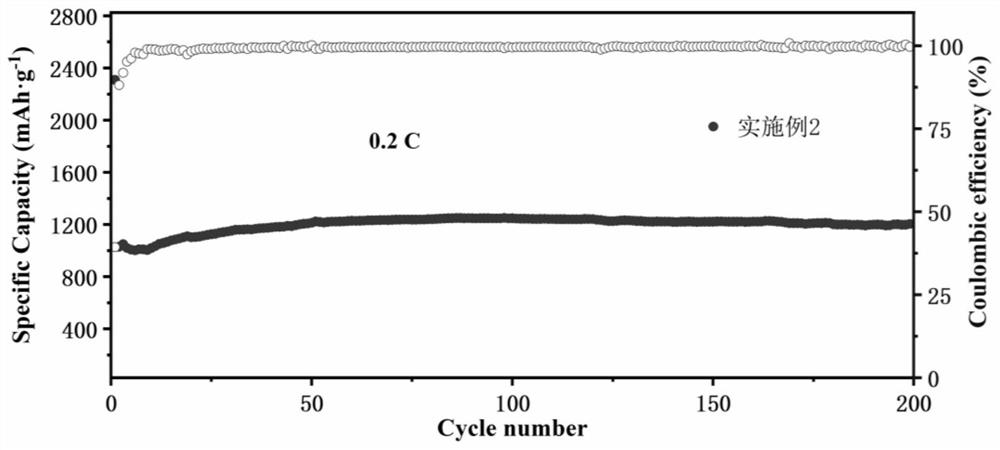

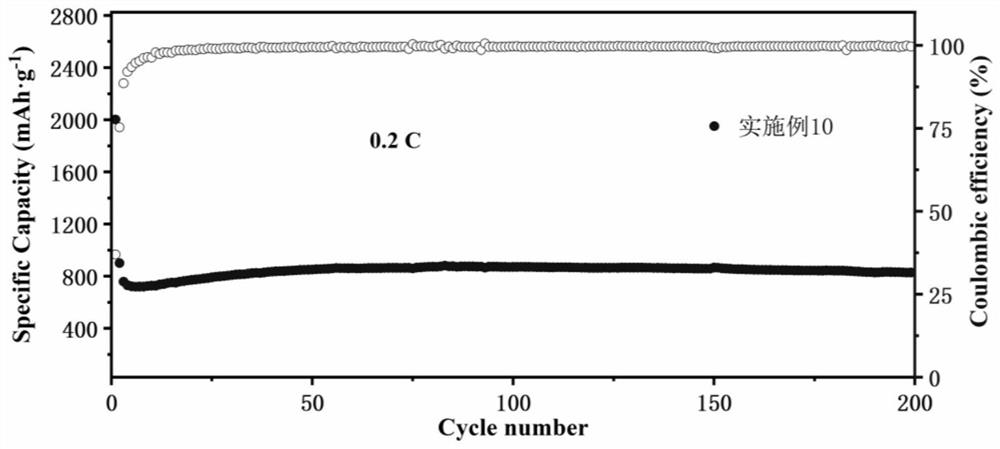

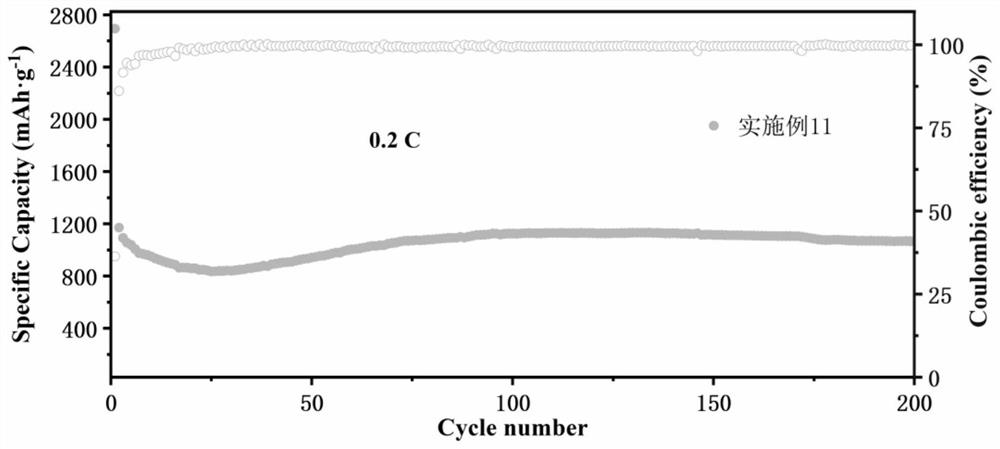

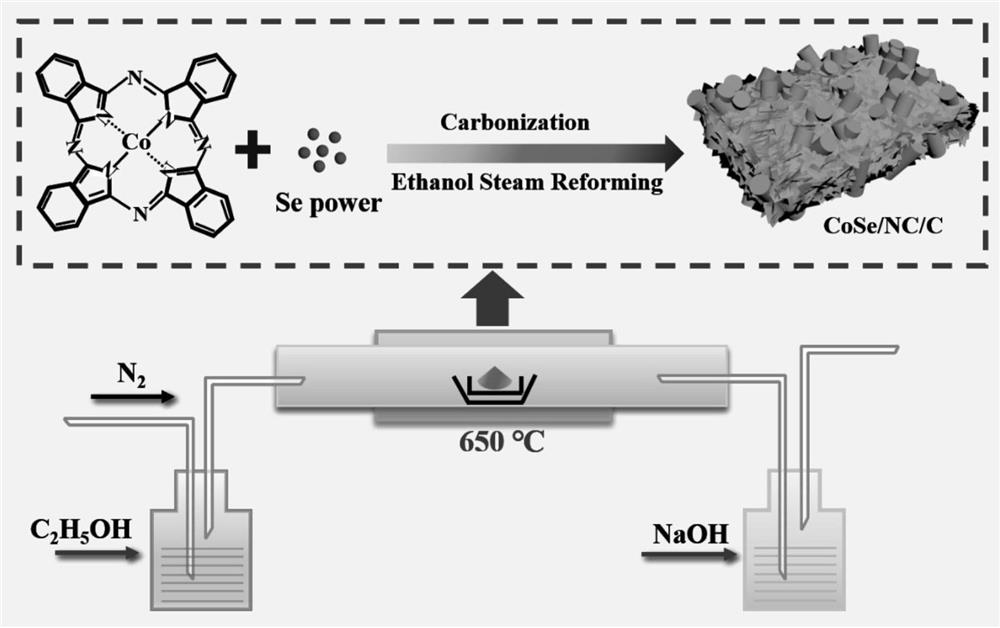

Preparation method for double-layer carbon coated metal sulfide composite electrode material with core-shell structure

The invention discloses a preparation method for a double-layer carbon coated metal sulfide composite electrode material with a core-shell structure. An amorphous carbon material is arranged on an outer layer of the composite electrode material and a nitrogen-doped carbon coated metal sulfide is arranged on an inner layer. The preparation method disclosed by the invention is simple and feasible. The double-layer carbon coated metal sulfide composite electrode material with the core-shell structure is acquired according to the following steps: adopting a room temperature aggregation method foracquiring a polypyrrole coated Co9S8 precursor, and then taking a shielding gas as a carrier gas for uniformly filling ethyl alcohol into a tube furnace, and performing thermal treatment. When the composite material prepared according to the method is used as a cathode material of a lithium ion secondary battery, the outer layer carbon is capable of effectively inhibiting the direct contact between active material metal sulfide and electrolyte, so that the initial coulombic efficiency and cycle performance of the composite material are promoted. Meanwhile, the nitrogen-doped carbon material isintroduced, so that the conductivity of the material is further promoted, the huge volume expansion of the metal sulfide in charging and discharging processes is relieved and the structural stabilityand rate capability of the composite material are greatly improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Non-aqueous electrolyte and lithium secondary battery of using same

ActiveCN106532120ARich variety and range of choicesInhibit direct contactSecondary cellsOrganic electrolytesLithium electrodePhenylboronic acid

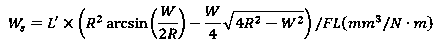

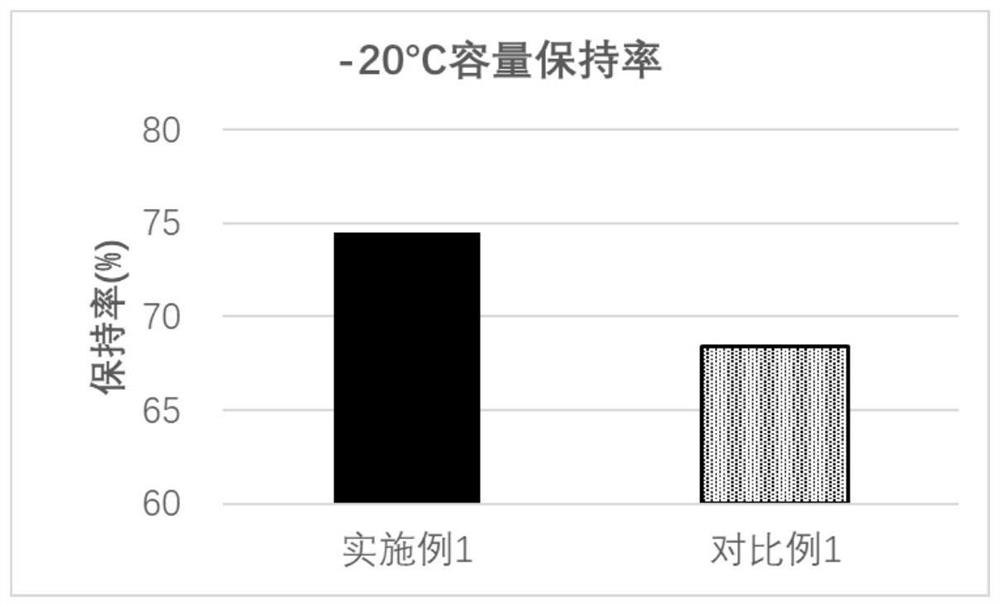

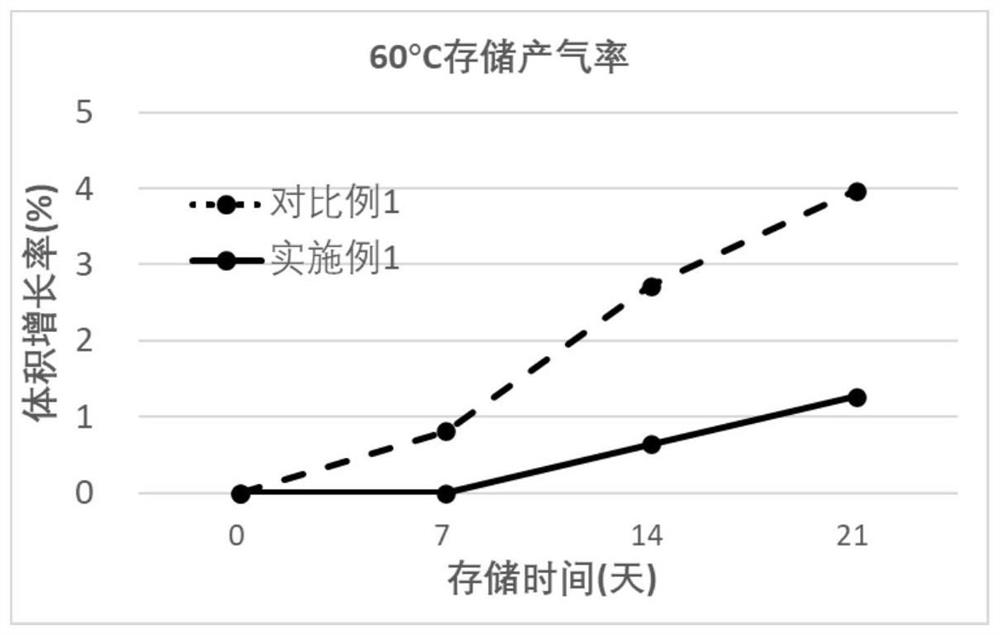

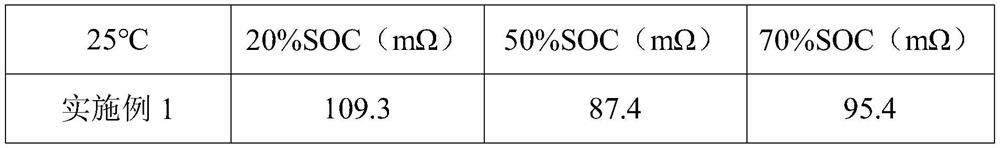

The invention belongs to the field of lithium-ion battery materials, and discloses a non-aqueous electrolyte and a lithium secondary battery of using the same. The non-aqueous electrolyte comprises a non-aqueous organic solvent, a lithium salt and an additive, wherein the additive comprises at least one of a pyridineboronic acid pinacol ester compound and a phenylboronic acid pinacol ester compound. The pyridineboronic acid pinacol ester compound and the phenylboronic acid pinacol ester compound are used for the electrolyte for the lithium secondary battery for the first time, the variety and the selection range of the additive of the electrolyte are enriched, and the cycle performance, the rate capability and the high-and-low temperature performance of the lithium secondary battery can be obviously improved by the obtained electrolyte.

Owner:GUANGZHOU TINCI MATERIALS TECH

Microalloying synergistically strengthened graphene titanium-based composite material and preparation method thereof

ActiveCN111270101AAvoid contactImprove distribution uniformityTransportation and packagingMetal-working apparatusMetal coatingNanoparticle

The invention discloses a microalloying synergistically strengthened graphene titanium-based composite material. The microalloying synergistically strengthened graphene titanium-based composite material takes titanium or titanium alloy as a matrix, metal for microalloying is uniformly coated on the surface of the titanium or titanium alloy matrix in a quasi-continuous manner through a physical bonding manner, graphene is dispersed on the outer surface of the metal-coated titanium or titanium alloy matrix for microalloying, the graphene is dispersed on the outer surface of the metal-coated titanium or titanium alloy matrix, the graphene, in-situ synthesized TiC nanoparticles and intermetallic compound particles jointly form a quasi-continuous net structure; and the invention further discloses a preparation method of the microalloying synergistically reinforced graphene titanium-based composite material, and the preparation method comprises the following steps of ball milling the raw material powder, uniformly stirring with the graphene nanosheet suspension solution, drying, and carrying out hot pressed sintering. According to the microalloying synergistically strengthened graphene titanium-based composite material and the preparation method thereof, microalloying metal coating is adopted, so that direct contact between graphene and the matrix is avoided, the distribution uniformity and structural integrity of the graphene are improved, the graphene, TiC nanoparticles and intermetallic compound particles have a synergistic reinforcing effect; and the method is high in operability, and the microalloying synergistically strengthened graphene titanium-based composite material is suitable for industrial production.

Owner:西安稀有金属材料研究院有限公司

Low-temperature anti-sulfur denitration catalyst by taking organic porous material as carrier and preparation method thereof

InactiveCN107029800AGood activity at low temperatureSolve easy poisoningGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsFlue gasReactive site

The invention provides a low-temperature anti-sulfur SCR denitration catalyst by taking an organic porous material as a carrier and a preparation method thereof. The method is characterized in that an immersion method is employed, one or more than two of metal element oxides of Mn, Fe, Cu, Co, Ce, and Zr can be loaded on the organic porous material, the material is subjected to silicatization, and the operating temperature of the catalyst is 120-250 DEG C. The catalyst takes the organic porous material with large specific surface area as the carrier, disperse optimization of the active components and catalysis cooperation among the components are realized, so that good low temperature denitration activity can be obtained, after silicatization, active site contact of SO2 and the catalyst can be effectively isolated, problem of easy SO2 poisoning of the low temperature denitration catalyst can be effectively solved, and the method has good prospect in denitration industrialization application of low temperature sulfur-containing flue gas.

Owner:江苏万德环保科技有限公司 +1

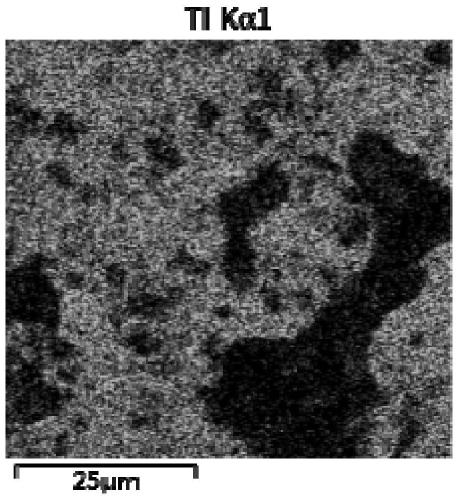

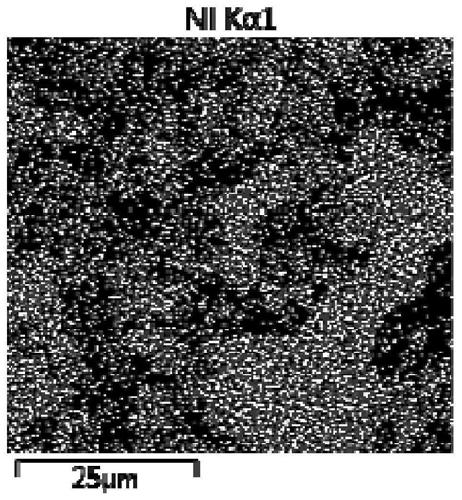

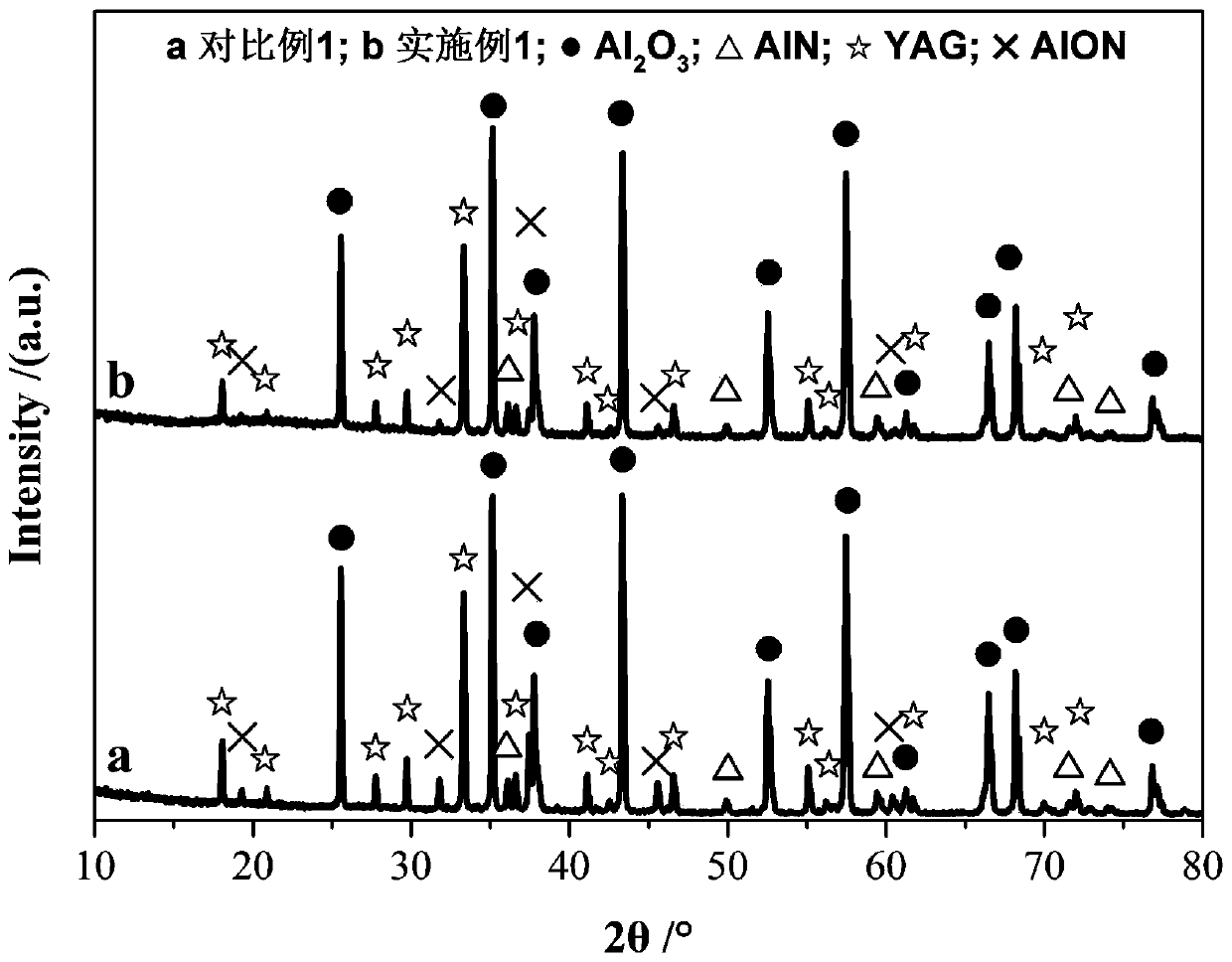

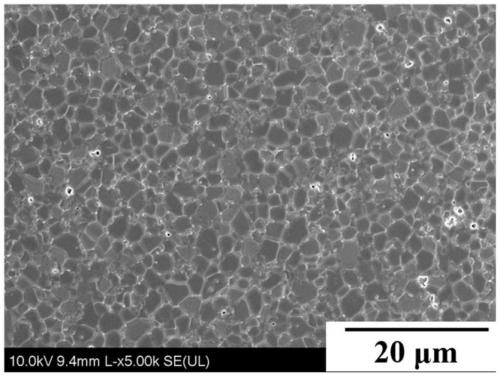

Composite ceramic and preparation method and application thereof

ActiveCN110451936AInhibit direct contactReduce generationModifications by conduction heat transferChemical reactionComposite ceramic

The invention belongs to the technical field of ceramic materials and particularly relates to a composite ceramic and a preparation method and application thereof. The preparation method of the composite ceramic comprises the steps: coating the surface of first-phase ceramic powder and the surface of second-phase ceramic powder with a rare-earth metal oxide and / or an alkaline-earth metal oxide, then obtaining composite ceramic powder through mixing and granulation, conducting forming and sintering treatment on the composite ceramic powder to obtain the composite ceramic, wherein the rare-earthmetal oxide and / or the alkaline-earth metal oxide can inhibit direct contact and a high-temperature chemical reaction of the first-phase ceramic powder and the second-phase ceramic powder in the preparation process, the rare-earth metal oxide and / or the alkaline-earth metal oxide can be uniformly distributed in a composite ceramic matrix as a sintering aid, the microstructure uniformity of the composite ceramic can also be improved, and the mechanical strength of the composite ceramic can be effectively improved on the premise that the thermal conductivity of the composite ceramic is not reduced.

Owner:GUANGDONG UNIV OF TECH

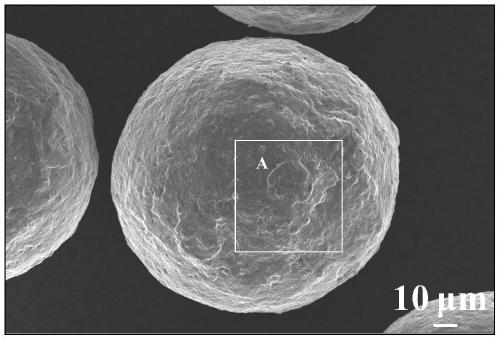

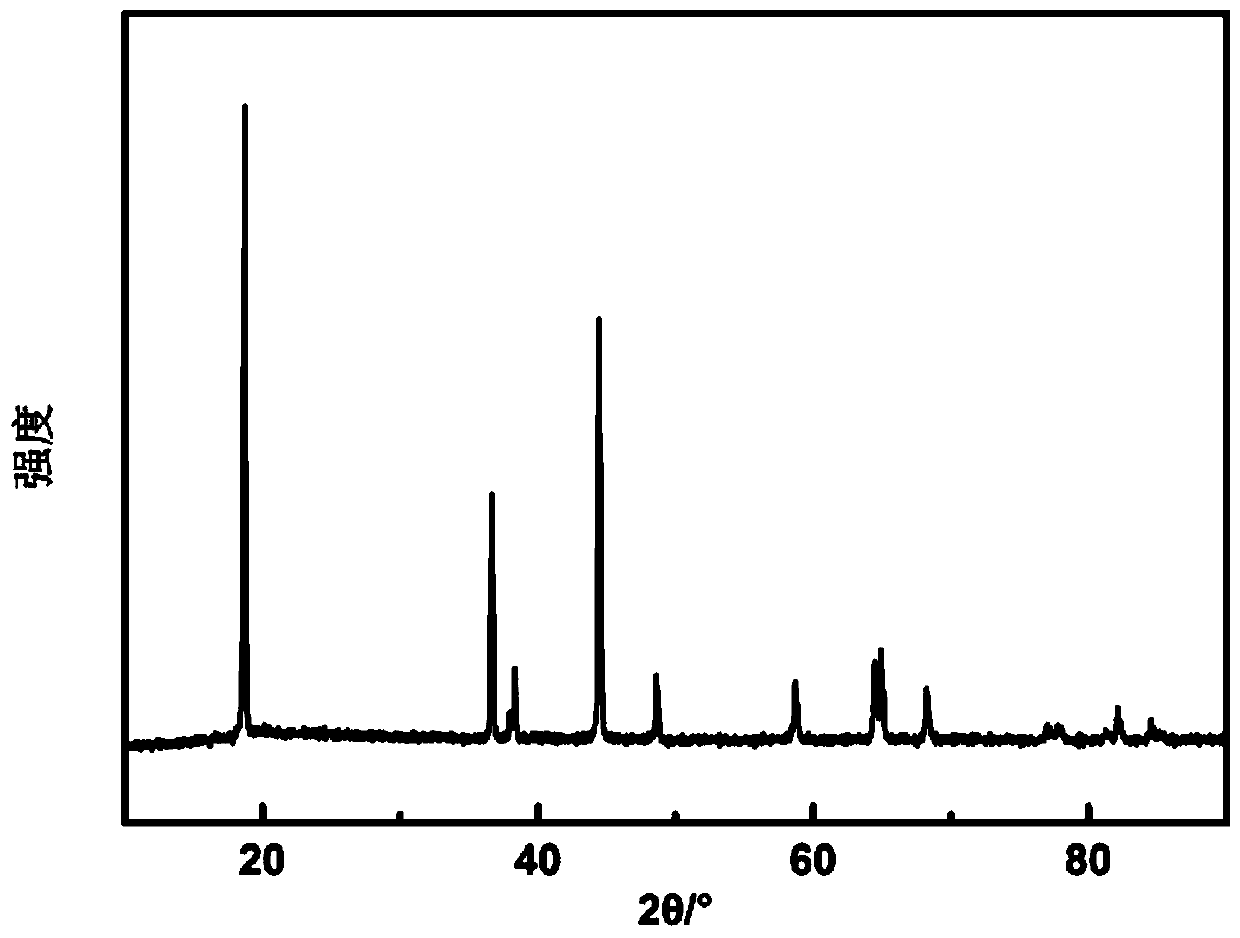

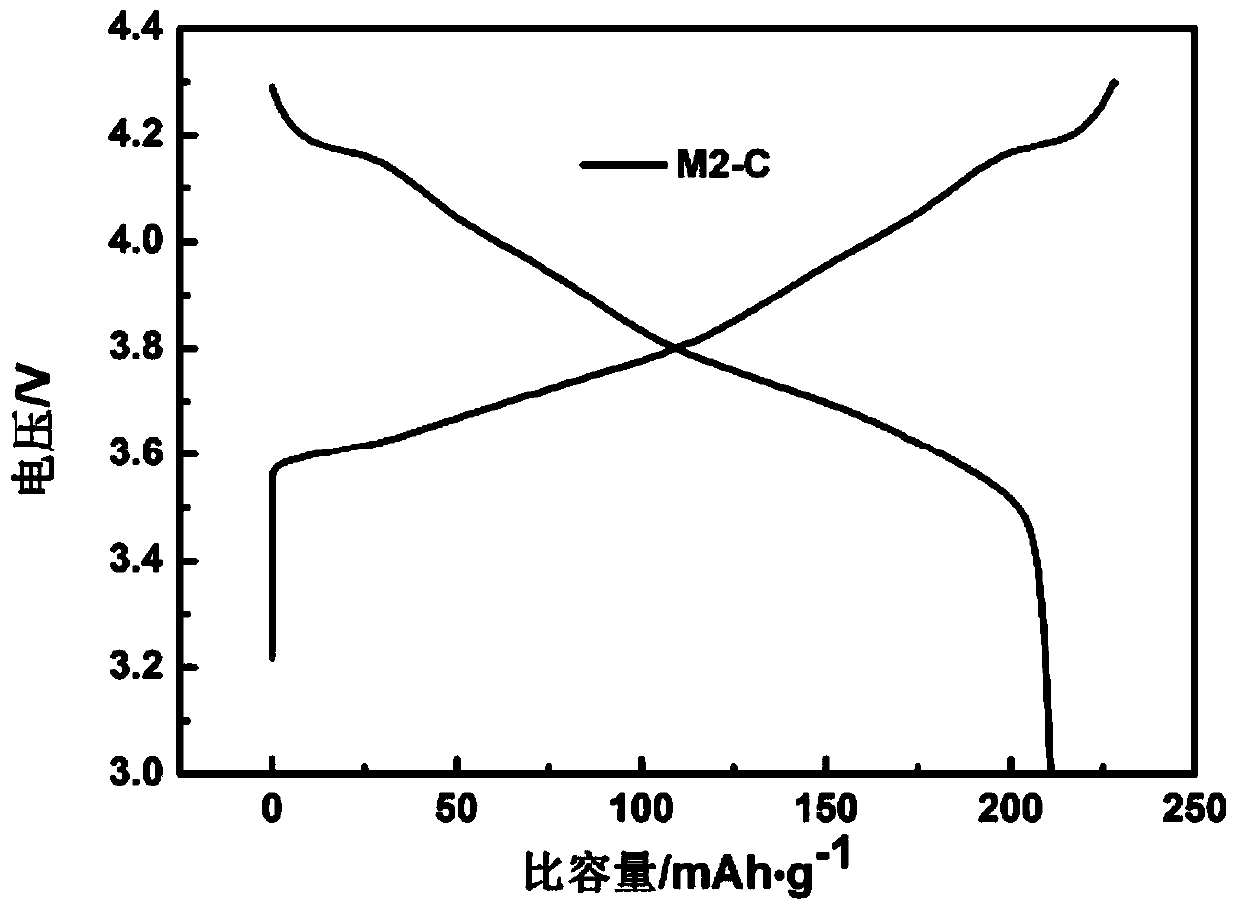

Ternary positive electrode material and preparation method thereof, lithium ion battery and electric equipment

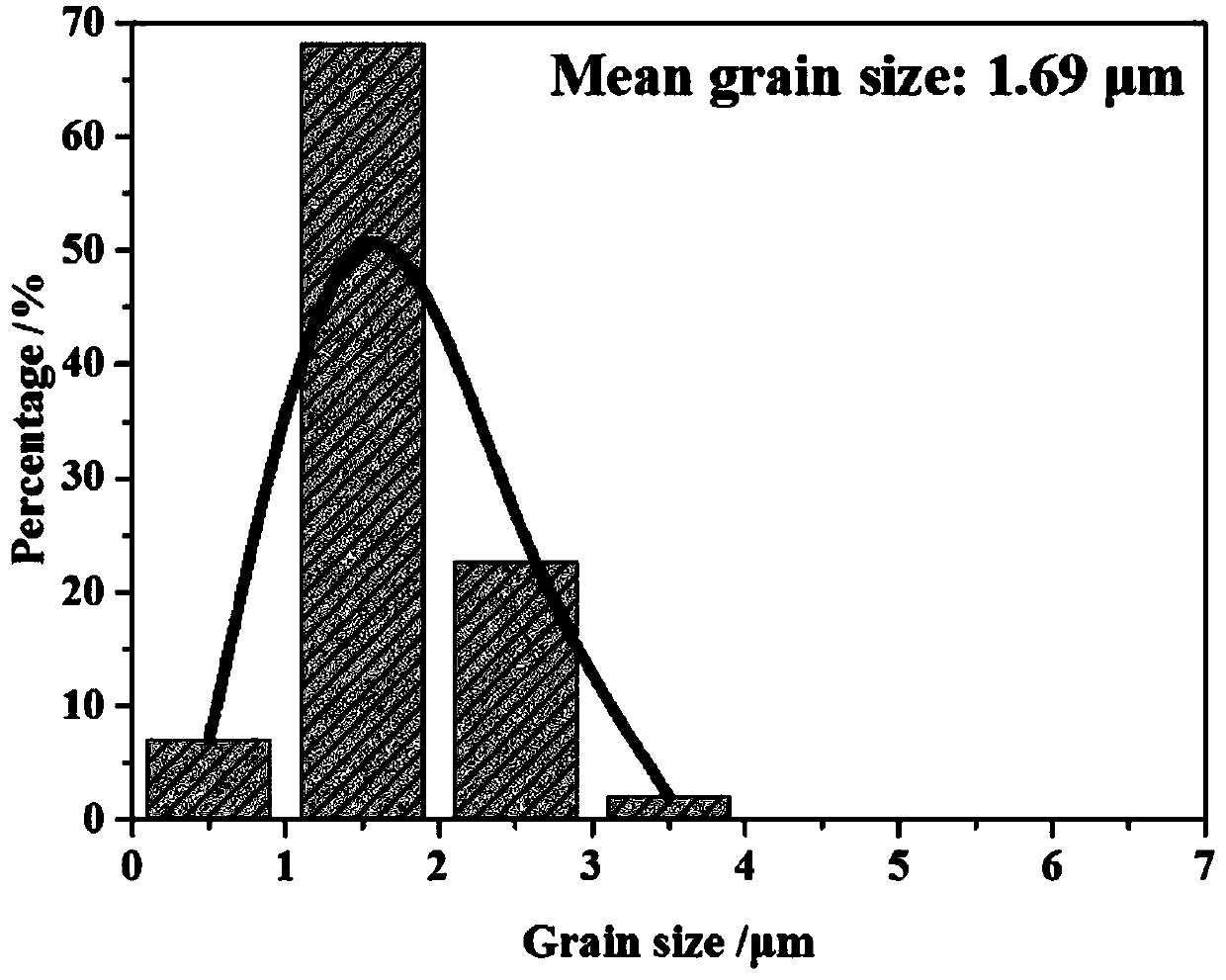

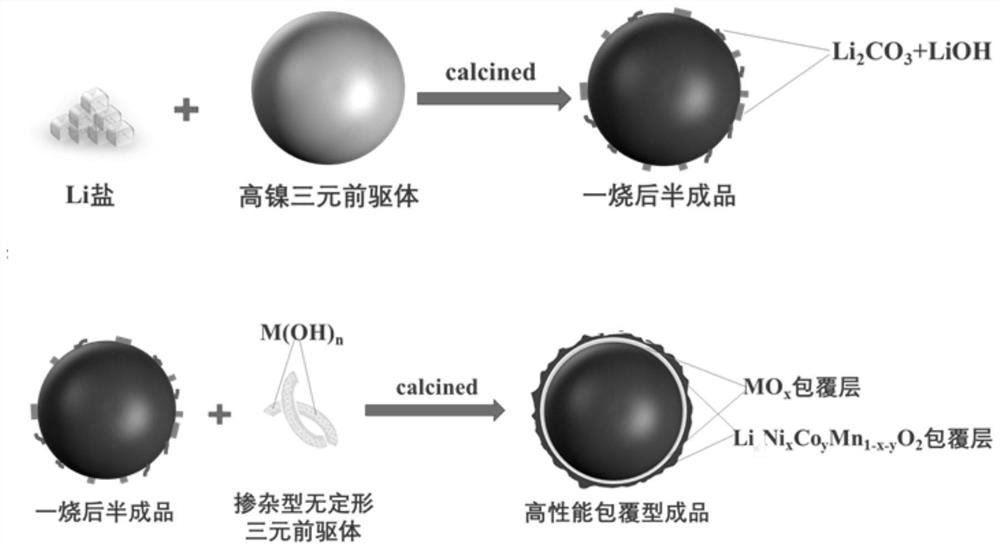

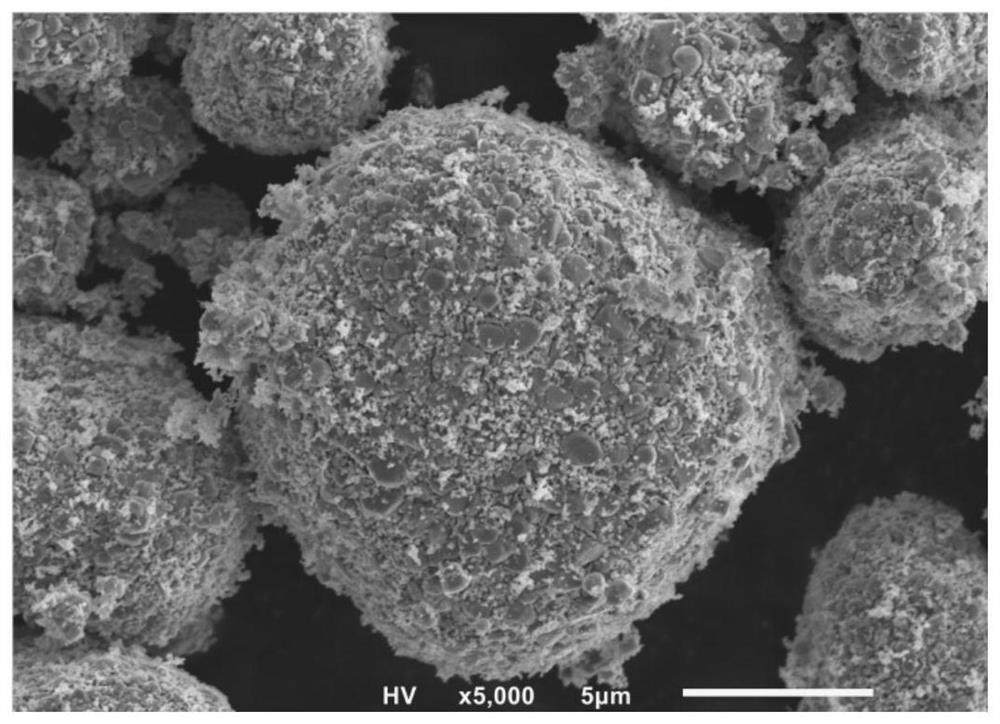

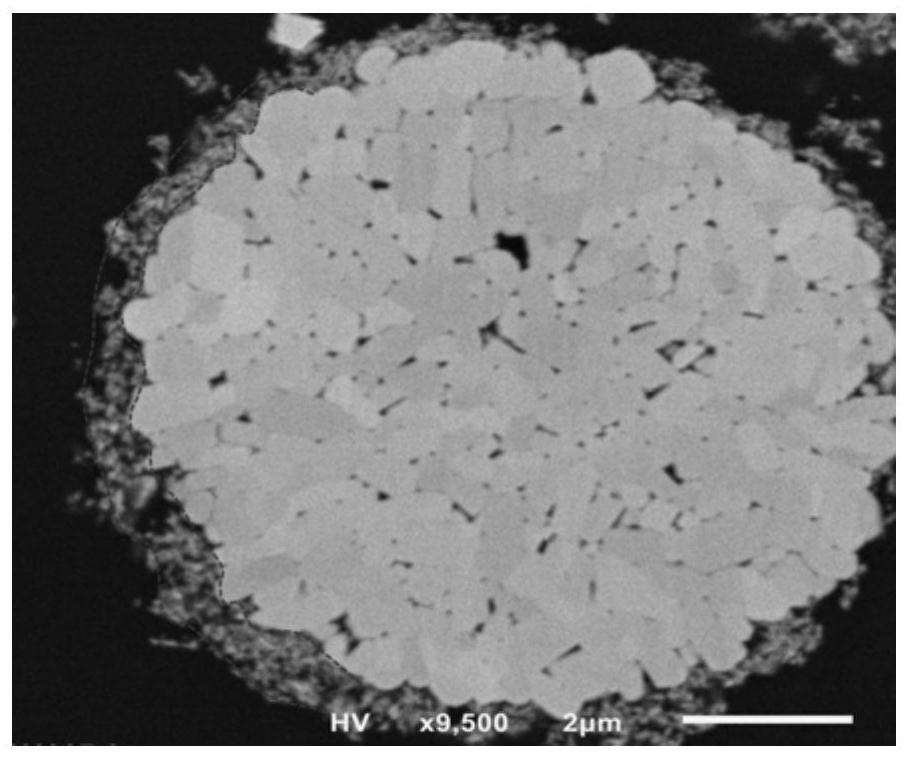

ActiveCN112117454AImprove electrochemical activityImprove performanceSecondary cellsPositive electrodesElectrical batteryPhysical chemistry

The invention provides a ternary positive electrode material, a preparation method thereof, a lithium ion battery and electric equipment. The ternary positive electrode material comprises a core layerand a shell layer coating the core layer, the core layer comprises lithium nickel cobalt manganate, and the shell layer comprises oxides of LiNixCoyMn (1-x-y) O2 and M. The preparation method of theternary positive electrode material comprises the following steps: mixing raw materials including a lithium source and a ternary precursor, and performing first sintering to obtain a substrate material; and mixing materials including a substrate material and a doped amorphous coating agent, and then carrying out second sintering to obtain the ternary positive electrode material. The lithium ion battery is prepared from raw materials including the ternary positive electrode material. The electric equipment comprises the lithium ion battery. According to the ternary positive electrode material provided by the invention, the shell layer comprises oxides of LiNixCoyMn (1-x-y) O2 and M, and the ternary positive electrode material has good electrochemical activity due to the double-coating structure, so that the ternary positive electrode material has excellent cycle performance.

Owner:CNGR ADVANCED MATERIAL CO LTD

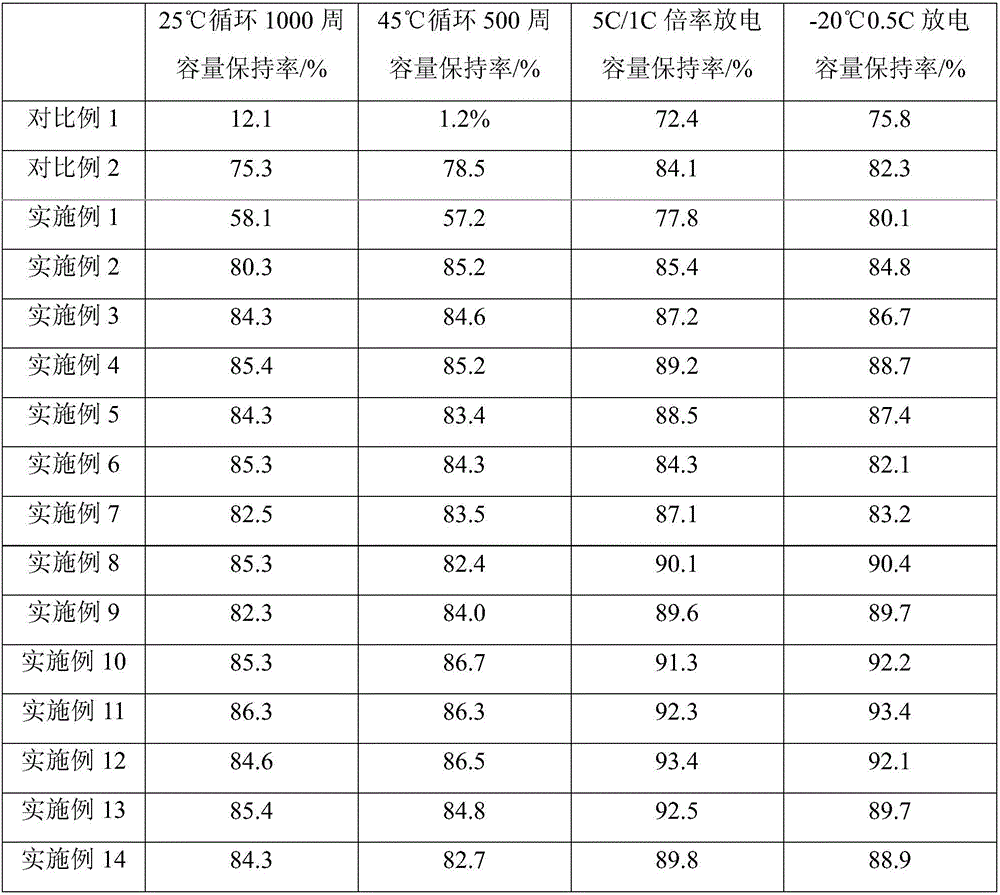

Coated multi-element positive electrode material for lithium ion battery, preparation method and application thereof

ActiveCN111564606AImprove poor conductivityImprove cycle performanceCell electrodesSecondary cellsDischarge efficiencyChemical composition

The invention discloses a coated multi-element positive electrode material for a lithium ion battery, a preparation method and application thereof. The coated multi-element positive electrode materialcomprises a multi-element positive electrode material and a coating layer coating the surface of the multi-element positive electrode material, wherein the chemical composition of the coating layer is element-doped In2O3 and / or element-doped CeO2, the element-doped In2O3 is Sr and / or Te element-doped In2O3, and the element-doped CeO2 is Te and / or Ge element-doped CeO2. The method comprises the step of coating a multi-element positive electrode material with a coating material, or introducing the coating material into preparation raw material components for synthesizing the multi-element positive electrode material to prepare the coated multi-element positive electrode material. The method provided by the invention can improve the first charge-discharge efficiency and cycle performance ofthe material, especially the high-temperature cycle performance.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

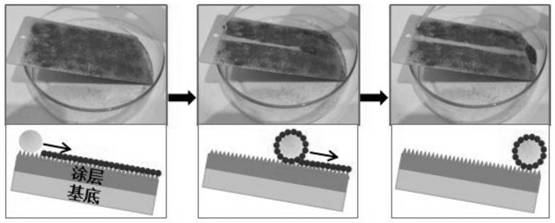

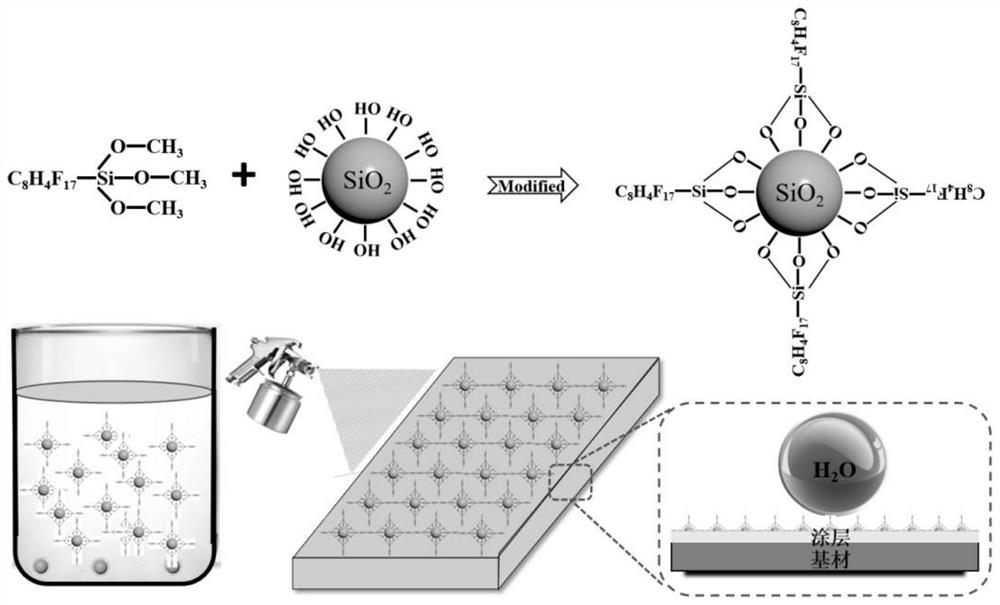

Anti-corrosion and anti-icing self-cleaning super-hydrophobic coating as well as preparation method and application thereof

PendingCN113372803ALower surface energyBlock deliveryAnti-corrosive paintsPolyurea/polyurethane coatingsPolyesterThermoplastic polyurethane

The invention belongs to the technical field of metal corrosion prevention, and particularly relates to an anti-corrosion and anti-icing self-cleaning super-hydrophobic coating as well as a preparation method and application thereof. According to the invention, 1H, 1H, 2H, 2H-perfluorodecyl trimethoxysilane is adopted to carry out hydrophobic modification on SiO2, the surface energy of SiO2 is reduced, and then modified SiO2 is doped with a polyester type thermoplastic polyurethane elastomer to prepare the anti-corrosion anti-icing self-cleaning super-hydrophobic coating with good hydrophobic performance. When the coating is coated on the surface of metal equipment, the icing time of the surface of the metal equipment can be effectively prolonged, the icing resistance of the surface of the metal equipment can be improved, the corrosion resistance of a metal substrate in acid, alkali and salt corrosive media can be improved, the coating has good wear resistance and chemical stability, the safety risk of equipment and components is reduced, and the service life is prolonged.

Owner:NORTHWEST UNIV(CN)

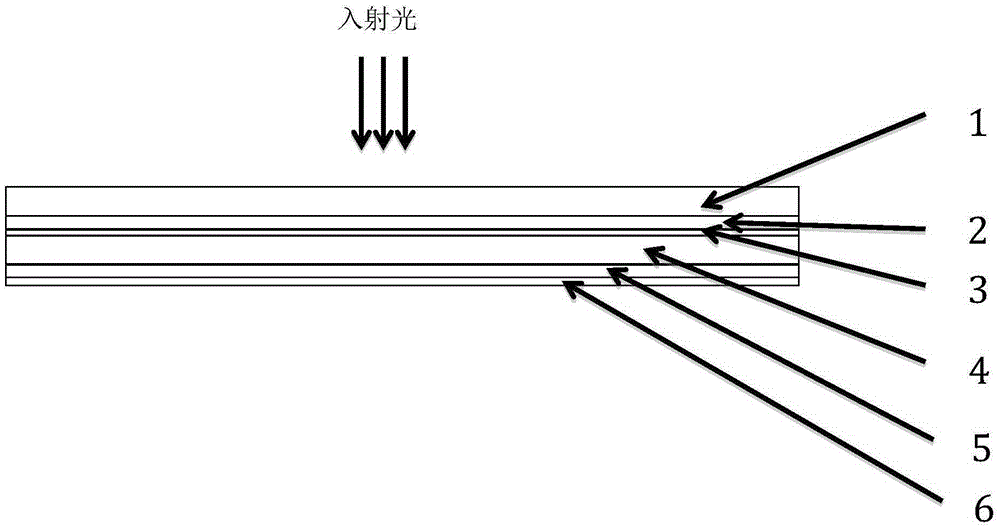

Manufacturing method for thin film crystal silicon perovskite heterojunction solar cell

InactiveCN105428535AHighlight substantive featuresImprove efficiencyFinal product manufactureSolid-state devicesHeterojunctionLight energy

The invention relates to semiconductor devices specially suitable for converting light energy into electric energy, in particular to a manufacturing method for a thin film crystal silicon perovskite heterojunction solar cell which has an electron hole recombination inhibition structure layer and adopts a high-temperature-resistant and non-transparent conductive substrate. The method comprises the steps of: preparing a P-type crystal silicon thin film layer on the high-temperature-resistant and non-transparent conductive substrate; preparing the electron hole recombination inhibition structure layer on the P-type crystal silicon thin film layer; spin-coating the electron hole recombination inhibition structure layer with a perovskite light absorption layer; making an electron transmission layer composed of dense titanium dioxide on the perovskite light absorption layer; and preparing a top electrode on the electron transmission layer composed of dense titanium dioxide. According to the method, the defects of current leakage, internal short circuit and limitation of a glass substrate to a high-temperature link of a subsequent preparation process possibly existent in a thin film crystal silicon perovskite heterojunction solar cell in the prior art are overcome.

Owner:HEBEI UNIV OF TECH

Ternary composite material and preparation method thereof and lithium-ion battery

InactiveCN106654201AAvoid direct contactInhibition of catalytic decomposition reactionsCell electrodesSecondary cellsOxalateCatalytic decomposition

The invention discloses a ternary composite material and a preparation method thereof and a lithium-ion battery. The method comprises the steps of adding a vanadium source to an oxalic acid solution, adding a phosphorus source and a lithium source, adding a ternary material for stirring evenly and then dropwise adding ethylene glycol and ethanediamine for reaction at 150-200 DEG C for 2-4 hours to obtain a precursor; carrying out vacuum drying on the precursor at 80-120 DEG C for 6-10 hours, grinding the precursor evenly and then sintering at 800-860 DEG C for 8-15 hours; and carrying out furnace cooling to obtain NLiNi<x>Co<y>Mn<z>O<2> / (1-N)Li<3>V<2>(PO<4>)<3> / C, wherein x+y+z is equal to 1 and N is smaller than 1 and greater than or equal to 0.5. A coating layer is formed on the surface of the ternary material, so that direct contact of the ternary material and an electrolyte can be blocked and catalytic decomposition of the ternary material on the electrolyte is inhibited. Catalytic reaction of the ternary material on the electrolyte is retarded by the coating layer, instantaneous accumulation of heat is relieved and a dangerous condition of the battery is inhibited.

Owner:深圳市鑫永丰科技有限公司

Cutting oil

InactiveCN101724497AImprove adsorption capacityInhibit wearAdditivesBase-materialsParaffin waxBenzotriazole

The invention discloses cutting oil, which comprises the following components in percentage by mass: 40 to 60 percent of liquid paraffin, 20 to 50 percent of oiliness improver, 4 to 18 percent of extreme-pressure additive and 0.1 to 2 percent of benzotriazole, wherein the oiliness improver is a mixture of 30 to 90 percent of tricaprylin and 10 to 70 percent of glycol ethyl ether. The invention provides the cutting oil which has good effects of lubricating, cooling, rust protection and cleaning and has good environment-friendly performance.

Owner:SHAANXI UNIV OF SCI & TECH

Thin film crystalline silicon perovskite heterojunction solar cell and preparation method thereof

ActiveCN105449103AHighlight substantive featuresImprove efficiencyFinal product manufactureSolid-state devicesElectronic transmissionHeterojunction

The invention provides a thin film crystalline silicon perovskite heterojunction solar cell and a preparation method thereof, relates to a semiconductor device for converting optical energy to electric energy, and particularly provides a thin film crystalline silicon perovskite heterojunction solar cell having an electronic cavity composite suppression structure layer. The solar cell includes a transparent conductive substrate, a P-type thin film crystalline silicon layer, an electronic cavity composite suppression structure layer, a perovskite light absorption layer, an electronic transmission layer formed by compact titanium dioxide, and a back electrode. The perovskite light absorption layer and the P-type thin film crystalline silicon layer have matched energy levels, and the electronic cavity composite suppression structure layer formed by SiO2 is added between the P-type thin film crystalline silicon layer and the perovskite light absorption layer. The solar cell provided overcomes the defects of current leakage and internal short circuit of a thin film crystalline silicon perovskite heterojunction solar cell in the prior art.

Owner:HEBEI UNIV OF TECH

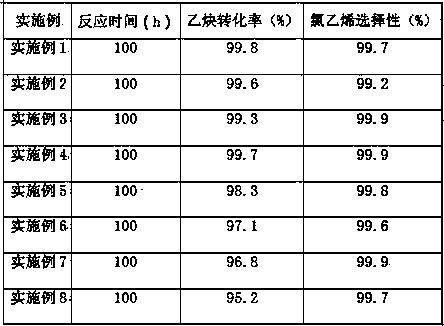

Mercury-free catalyst for acetylene hydrochlorination

ActiveCN104001524AReduce dosageImprove wear resistancePreparation by halogen halide additionMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementPtru catalyst

The invention provides a mercury-free catalyst for acetylene hydrochlorination and a preparation method thereof. The mercury-free catalyst comprises a carrier, a metal oxide film and catalyst active components, wherein the catalyst active components are distributed on the metal oxide film, and the catalyst active components include a main catalyst of gold and promoters including copper, bismuth and at least one rare earth element; the metal oxide film is applied to the surface of the carrier and the inner wall of a large hole channel, the thickness of the metal oxide film is 1 to 100 nm, and the specific surface area of the metal oxide film is 1 to 50 m<2> / g; the weight percent of the main catalyst of gold and the carrier is 0.01 to 0.2%. The mercury-free catalyst provided by the invention has the advantages of high activity and good selectivity and is suitable for the production process of a vinyl alcohol monomer with a calcium carbide acetylene method.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

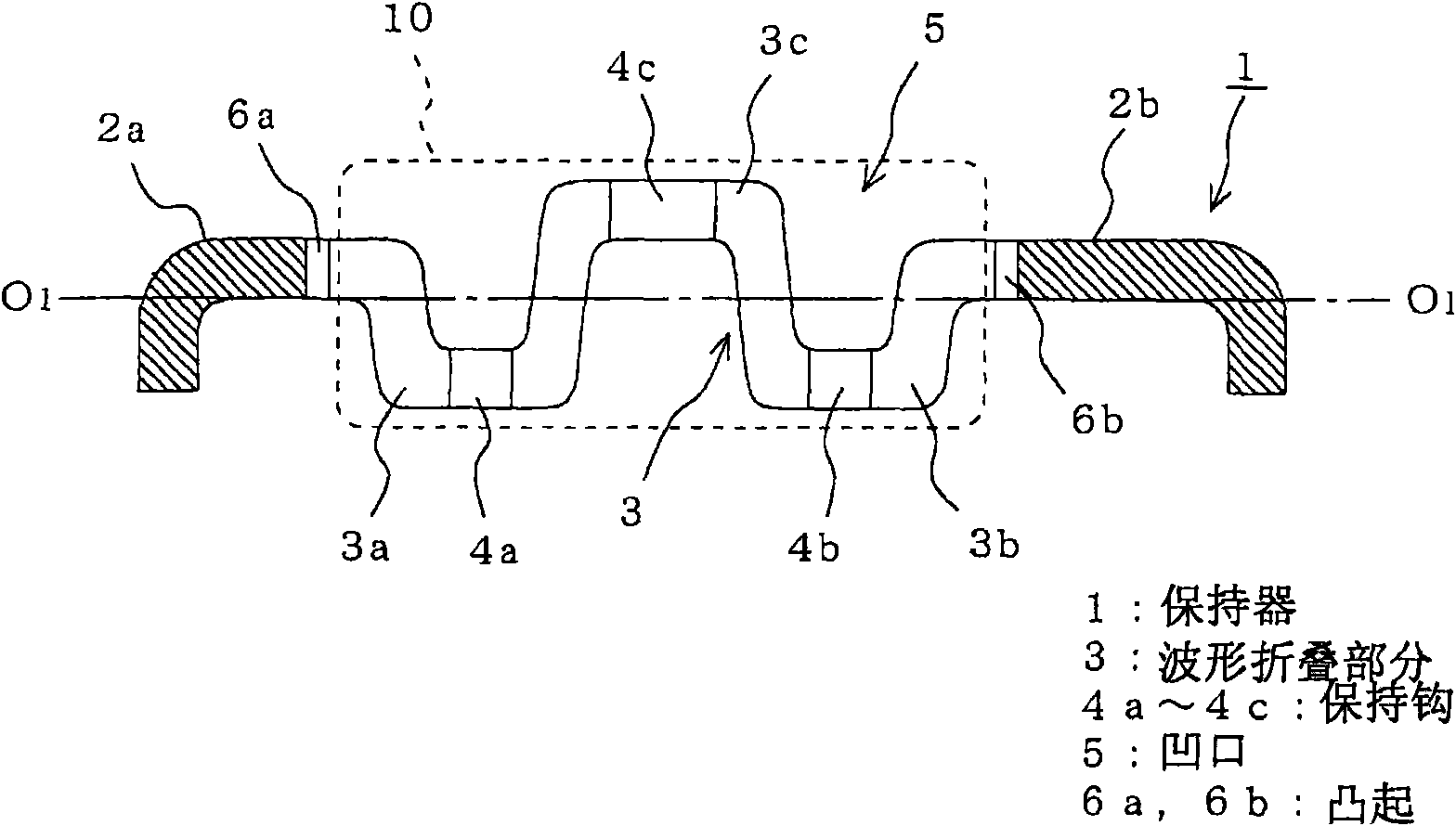

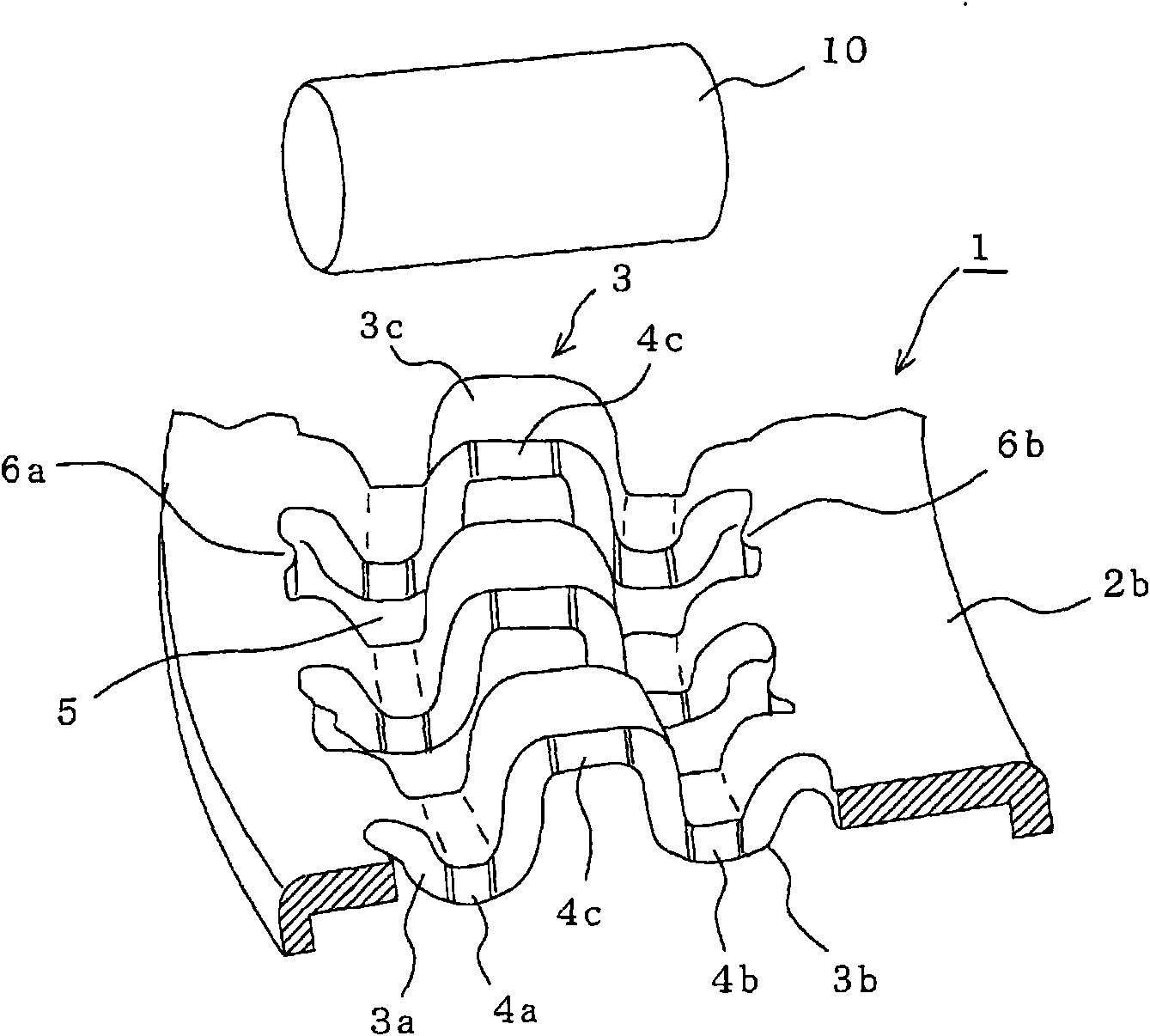

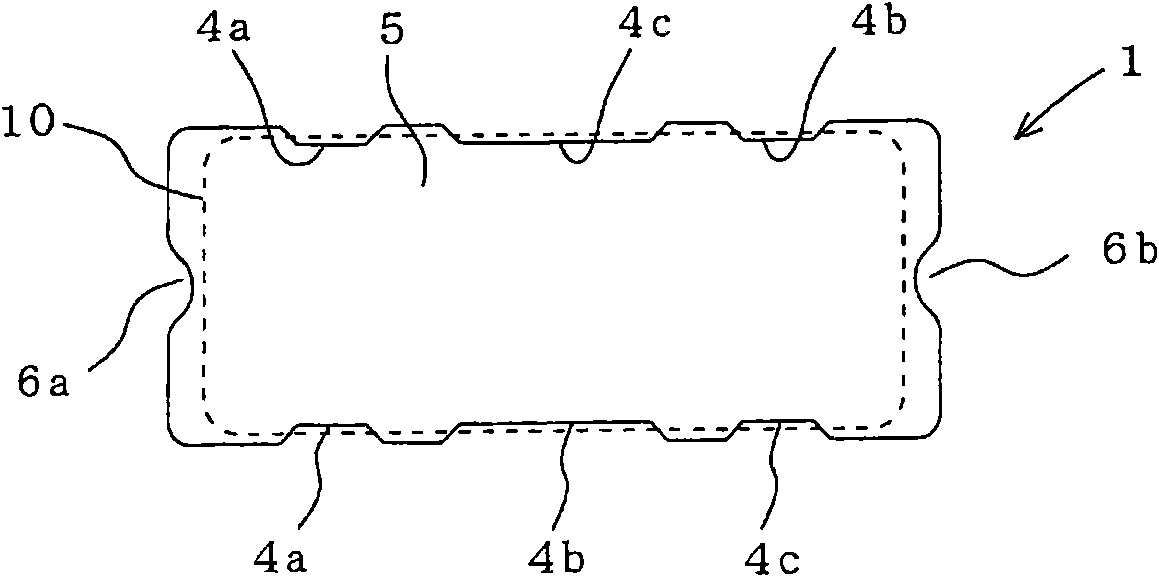

Thrust roller bearing

ActiveCN101573544AInhibit direct contactImprove reliabilityRoller bearingsBearing componentsThrust bearingEngineering

A thrust roller bearing comprises a retainer (1) having pockets (5) provided in the circumferential direction between the outer diameter side race guide part (2a) and the inner diameter side race guide part (2b) at predetermined intervals, and rollers (10) so contained in the pockets (5) as to be capable of performing rolling motion. Projections (6a, 6b) are formed on each of the pockets (5) at a substantially lateral center of its outer diameter side end surface. The roller (10) is so contained in the pocket (5) that the roller (10) is opposed to the projections (6a, 6b) at the peripheral side of the axial end surface outer from its center.

Owner:JTEKT CORP

Compound anode material used for lithium ion battery, preparation method of compound anode material, and lithium ion battery

ActiveCN106410169AIncrease contact interfaceGood synergyCell electrodesSecondary cellsLithium iron phosphatePhysical chemistry

The invention discloses a compound anode material used for a lithium ion battery, a preparation method of the compound anode material, and a lithium ion battery. The preparation method comprises the following steps: according to a situation that the molar ratio of Ni to Co to Mn is equal to X to Y to Z, preparing solution, and carrying out coprecipitation to prepare precursor oxide under an alkaline condition; preparing an Li source and the precursor oxide; after the above materials are evenly mixed, carrying out high-temperature sintering to obtain an Li-rich ternary material; carrying out coprecipitation on a P source and an Fe source to prepare FePO4; preparing the Li-rich ternary material and the FePO4 according to a certain molar ratio, evenly mixing in a solvent, and evenly grinding after drying; sintering the above mixed powder at a high temperature; cooling with a furnace to obtain the compound anode material used for the lithium ion battery. According to a compound system of the ternary material and lithium iron phosphate, a contact interface for material compounding is effectively improved, and the synergistic effect of the compound material is better performed. Meanwhile, side reaction generated by the contact of the ternary material and electrolyte is inhibited, and the safety of the lithium ion battery is greatly improved.

Owner:深圳市鑫永丰科技有限公司

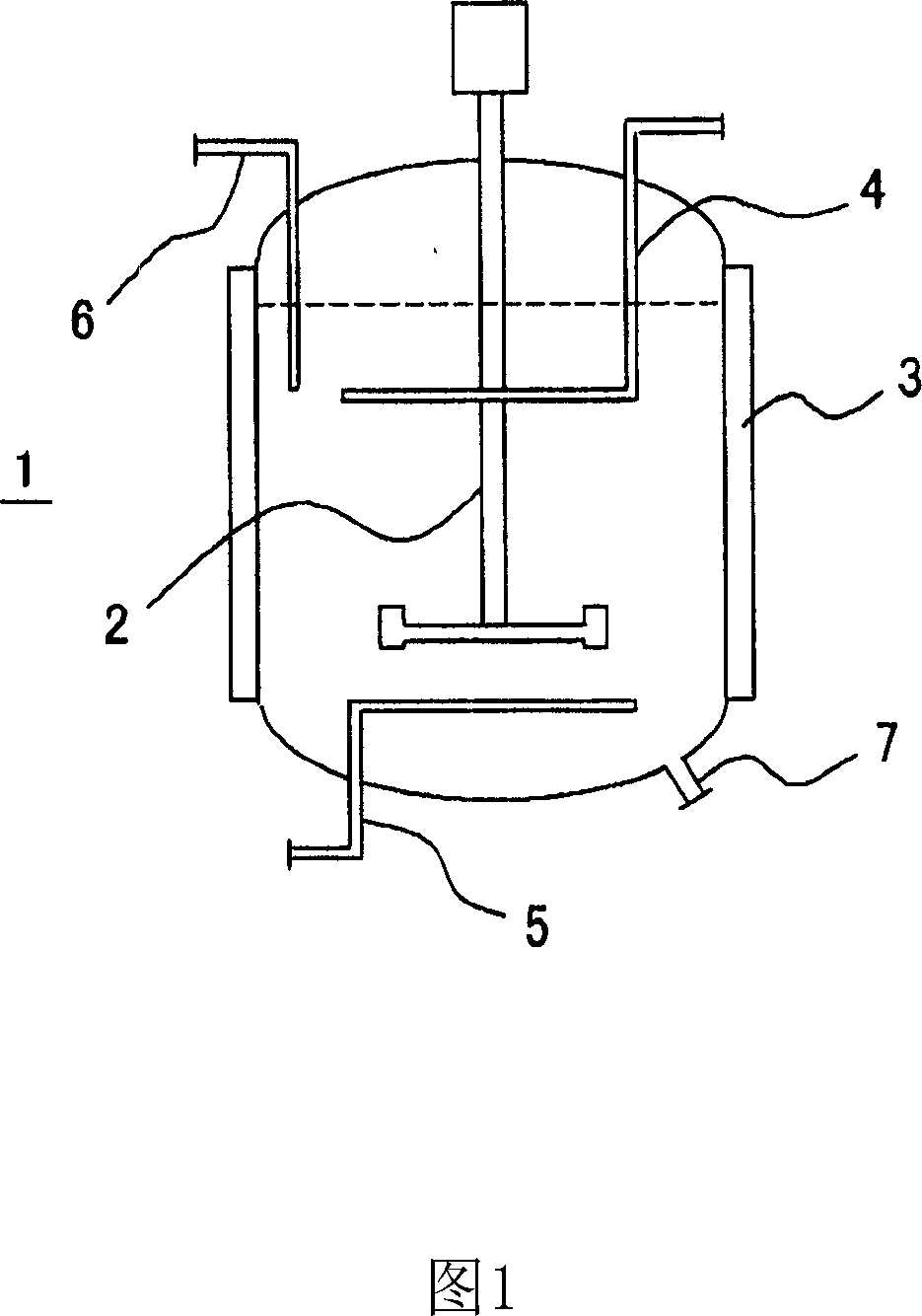

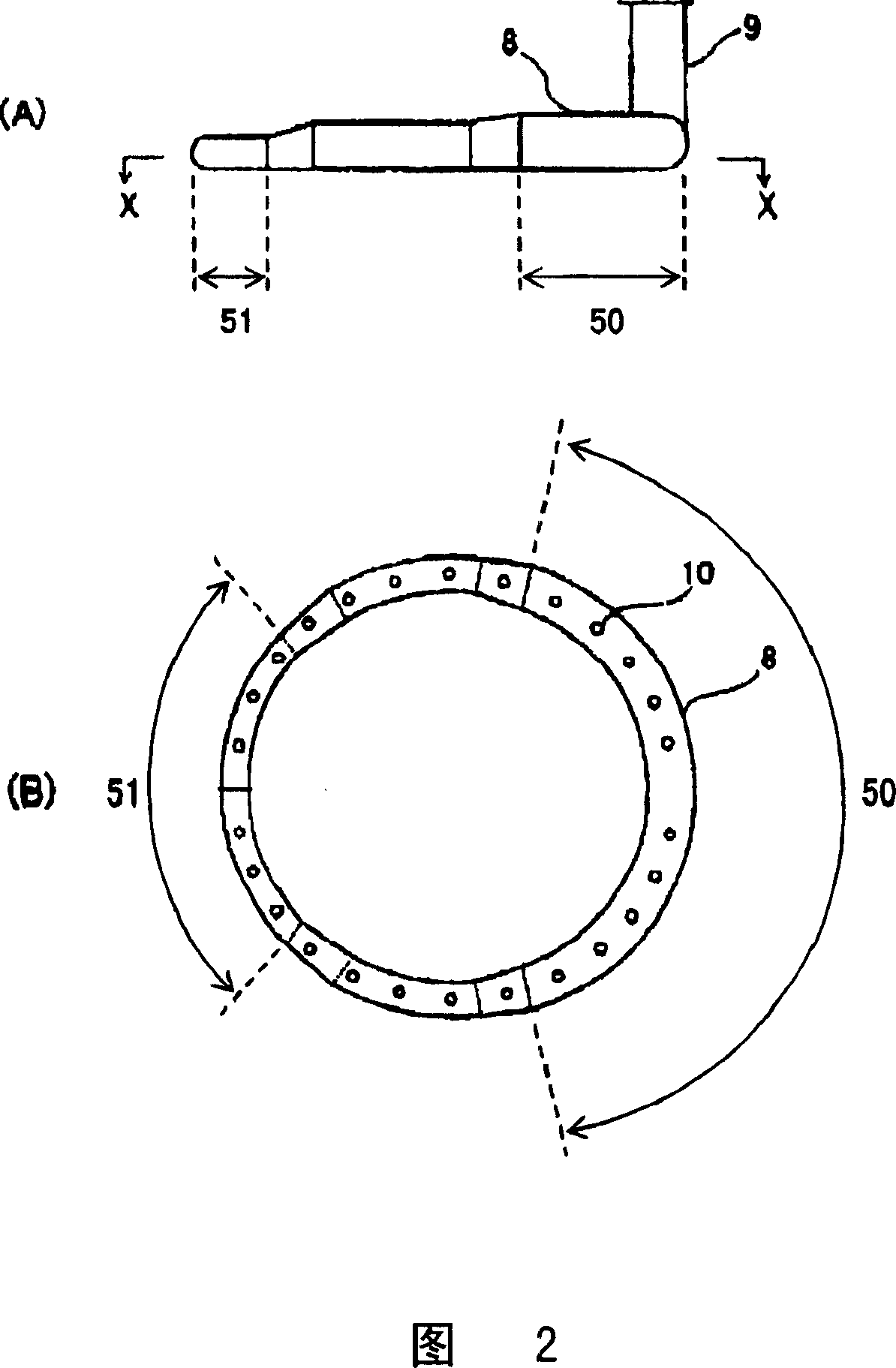

Fogger, reactor using same and method for preparation of oxime

ActiveCN101011649AInhibit direct contactAvoid decompositionChemical/physical/physico-chemical nozzle-type rreactorsOximes preparationChemistryKetone

The present invention provides a nebulizer, a reactor using the nebulizer, and a method for producing an oxime, which are difficult for catalyst particles to enter and can be easily discharged even if they are used in a reaction in which catalyst particles are suspended. The sprayer of the present invention is characterized in that the pipe diameter decreases gradually or substantially continuously along the direction of the front end, and is preferably used in a reactor in which at least a part of the reaction raw material is supplied by the sprayer to suspend the catalyst particles for reaction, and is particularly preferably used It is used to make oximes by reacting ketones, ammonia and hydrogen peroxide.

Owner:SUMITOMO CHEM CO LTD

Film forming solution for adelomorphic protecting film

InactiveCN101195041AEasy to useStay hydratedCosmetic preparationsToilet preparationsAqueous solutionPhosphatidic acid

The invention relates to a film-forming solution of conceal protecting films, and is characterized in that the invention contains a water solution which is provided with acrylic hydroxyethyl phosphatidic acid choline with weight ratio of 1%-10% and acrylic n-butyl polymer components, the pH value of the solution is 6-8, wherein, the average molecular weight of acrylic hydroxyethyl phosphatidic acid choline and acrylic n-butyl polymer components is 600 thousand, and 2- mahogany-1 and 4-naphthoic polymer components are further contained in the solution. After the film-forming solution of conceal protecting films is daubed on the skin, a layer of protecting films which are tightly clung to the skin can be quickly formed, the protecting function of inhibiting viruses and microorganisms such as HIV and herpes from infecting is provided, and the functions of removing oily soil and delaying skin aging and the like are further provided.

Owner:DONGGUAN TAILI BIOTECH

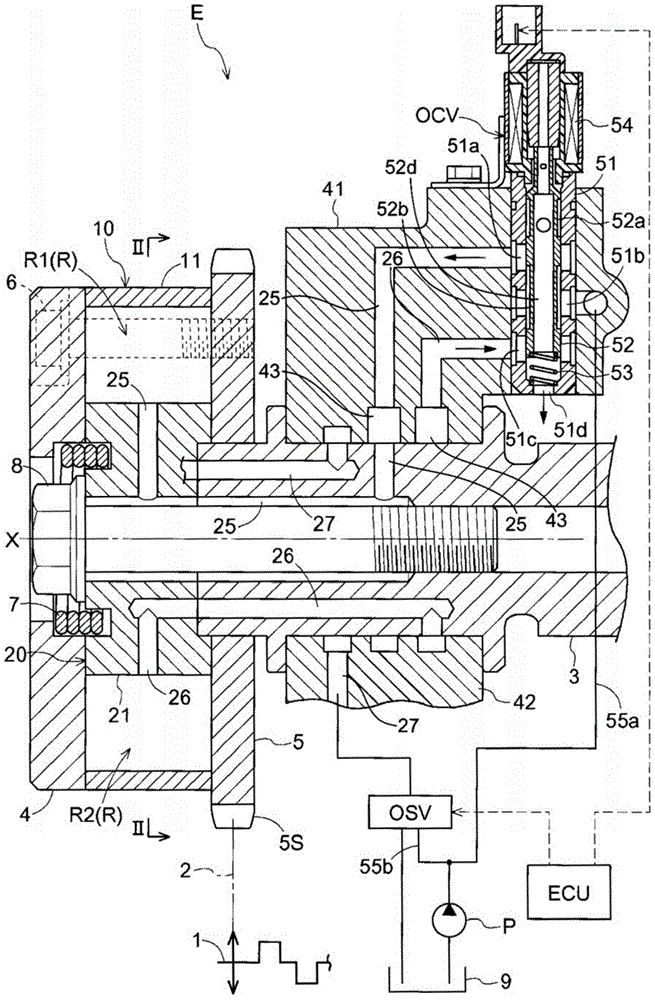

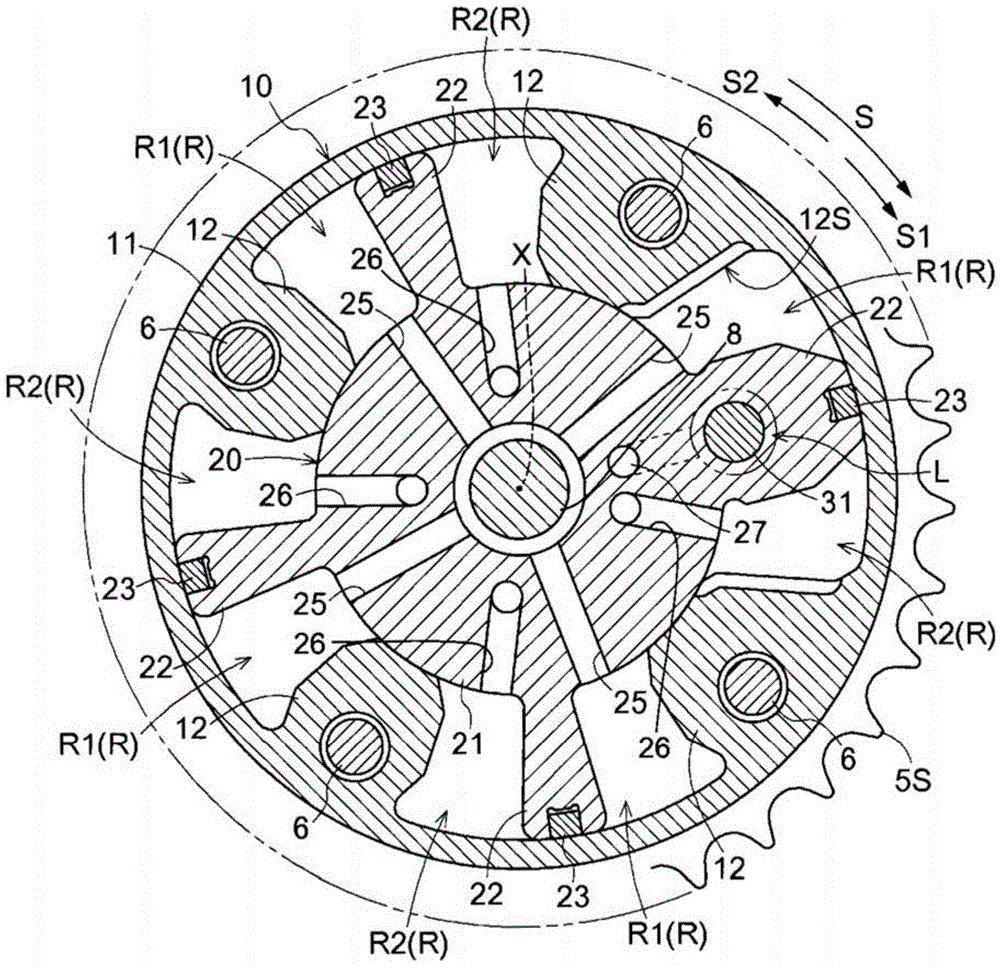

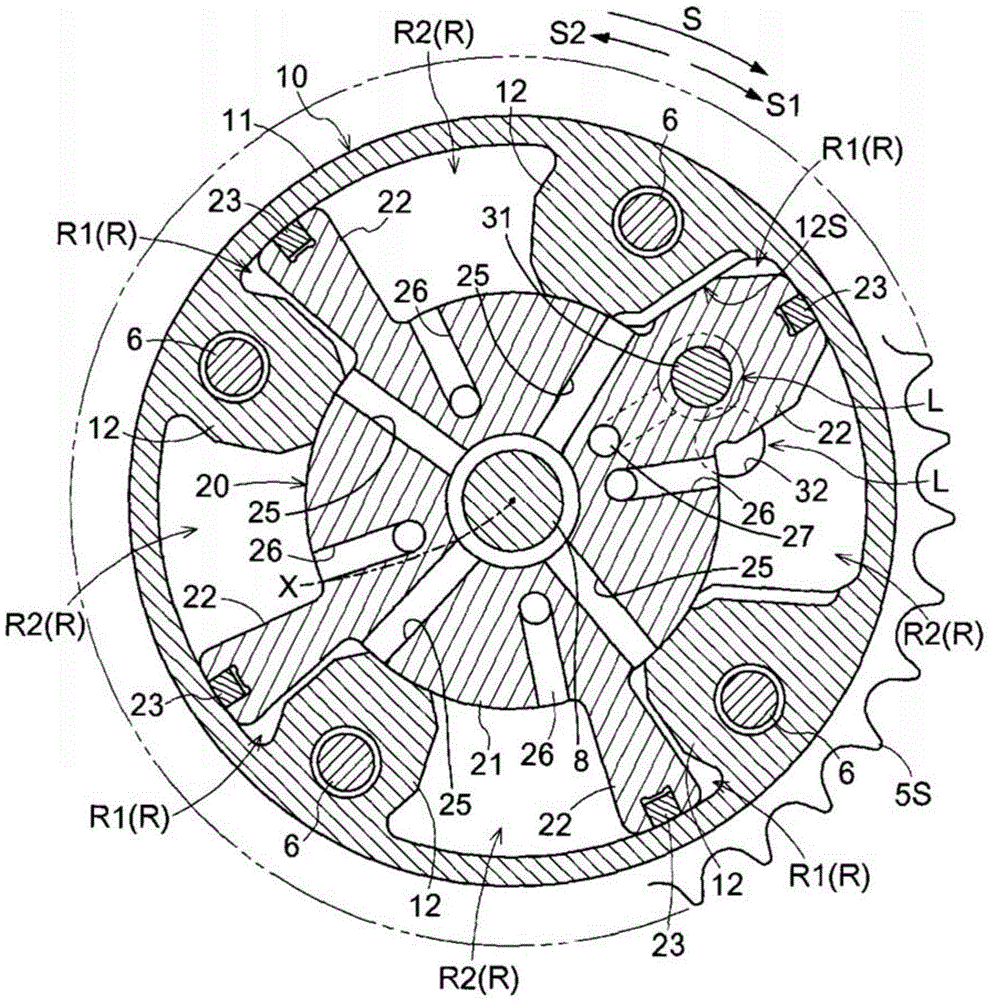

Variable valve timing control apparatus

A variable valve timing control apparatus includes a driving-side rotation member rotating in synchronization with a crankshaft of an internal combustion engine, a driven-side rotation member integrally rotating with a camshaft of the internal combustion engine, an intermediate lock mechanism being selectively switchable between a locked state and an unlocked state, a plurality of hydraulic chambers, at least one of the plurality of hydraulic chambers being positioned at a lower side than an axis of the camshaft, a plurality of partition portions, each of the plurality of partition portions dividing each of the hydraulic chambers into an advanced angle chamber and a retarded angle chamber, an electromagnetic valve including a supply and discharge port that is positioned at an upper side than the axis of the camshaft and switching supply and discharge of fluid relative to the hydraulic chambers, and a pump supplying fluid to the electromagnetic valve.

Owner:AISIN SEIKI KK

Method for preparing transition metal oxide composite electrode for lithium battery

InactiveCN111883749AImprove electrochemical performanceInhibit direct contactElectrode collector coatingLi-accumulatorsElectrolytic agentPyrrolidinones

The invention discloses a method for preparing a transition metal oxide composite electrode for a lithium battery, and the method comprises the following steps: S1, taking nickel nitrate hexahydrate,iron nitrate nonahydrate and metal oxide as raw materials, and obtaining a mixed solution; S2, performing alkalizing and drying to obtain a precursor material; S3, sintering the precursor material ina tubular furnace to obtain a coated material; S4, taking Nmethyl pyrrolidone as a solvent and taking polyvinylidene fluoride as a binder to prepare the composite electrode. According to the invention, the self-made coating material is used as the main substance of the motor, and the ferronickel compound is used as the coating layer, so the lithium manganate base material is protected from being corroded by electrolyte, the cycle performance of the motor is improved, the transmission rate of ions or electrons can be improved to a certain extent, and the electrochemical performance of the material is improved; the preparation method disclosed by the invention is simple and convenient, easy to operate and suitable for large-scale production, and a battery assembled by adopting the electrodematerial is high in specific capacity and excellent in cycle performance.

Owner:安徽南都华铂新材料科技有限公司 +1

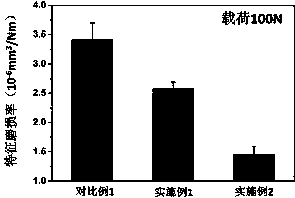

Preparation method of epoxy resin-based nano-composite material suitable for oil lubrication working condition

The invention relates to a preparation method of an epoxy resin-based nano-composite material suitable for an oil lubrication working condition. The method comprises the following steps: (1) preparingcobalt-aluminum hydrotalcite by a hydrothermal technology; (2) stirring and mixing the cobalt-aluminum hydrotalcite and epoxy resin for 5-30 min under a vacuum condition, then adding a curing agent,and continuously stirring and mixing for 4-8 min to obtain a mixed solution; and (3) pouring the mixed solution into a mold, carrying out high-temperature curing, and demolding and shaping to obtain the epoxy resin-based nano-composite material suitable for the oil lubrication working condition. The method is low in cost, simple and easy to implement and capable of achieving mass production, and the obtained epoxy resin-based nano-composite material is good in friction and abrasion resistance and has good application prospects as a moving part under the oil lubrication working condition.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ternary positive electrode material, preparation method and application thereof

PendingCN114094067AInhibit direct contactReduce side effectsSecondary cellsPositive electrodesElectrolytic agentLithium

The invention provides a ternary positive electrode material and a preparation method and application thereof. The ternary positive electrode material comprises a coating layer arranged on the surface, and the coating layer comprises a tungsten-containing compound and a co-coating layer of at least one effective element compound; the effective elements comprise any one or a combination of at least two of B, Mg, Al, Si, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Sr, Y, Zr, Nb, Mo, Ru, Sn, Sb, Ba, Hf, Ta, Re or Bi. The ternary positive electrode material is coated by taking the tungsten-containing compound and the at least one effective element compound as the coating source, so that the side reaction between the ternary positive electrode material and electrolyte is reduced, the diffusion of lithium ions is promoted, the power performance and the cycle performance of the material are improved, and the gas production problem is effectively improved; according to the preparation method, the surface of the ternary positive electrode material is coated through one-time sintering treatment, the preparation method is simple, and industrial production is facilitated.

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD +1

Electrolyte for metal-sulfur secondary battery and metal-sulfur secondary battery containing electrolyte

PendingCN113937357APromote circulationInhibit direct contactElectrolytesLi-accumulatorsElectrolytic agentCerium nitrate

The invention discloses an electrolyte for a metal-sulfur secondary battery and the metal-sulfur secondary battery containing the electrolyte. The electrolyte for the metal-sulfur secondary battery comprises metal salt, an organic solvent and a cerium (IV)-based additive. The cerium (IV)-based additive is one or more of cerium nitrate, cerium fluoride, cerium chloride, cerium iodide, ceric ammonium nitrate and cerium trifluoromethanesulfonate; the concentration of the metal salt in the electrolyte is 0.5-2.0 mol / L, and the addition amount of the cerium (IV)-based additive is 0.1-5 wt% of the total mass of the metal salt and the organic solvent; and the water content in the electrolyte is less than 100 ppm. The invention provides a metal-sulfur secondary battery comprising the electrolyte. The cerium (IV)-based additive in the electrolyte can effectively protect the negative electrode of the battery and ensure the stability of the negative electrode structure; and the additive can also act on a positive electrode, has good adsorption and catalysis effects on sulfur and sulfide, can effectively inhibit the shuttle effect of polysulfide, and improves the cycle performance of the battery.

Owner:ZHEJIANG UNIV OF TECH

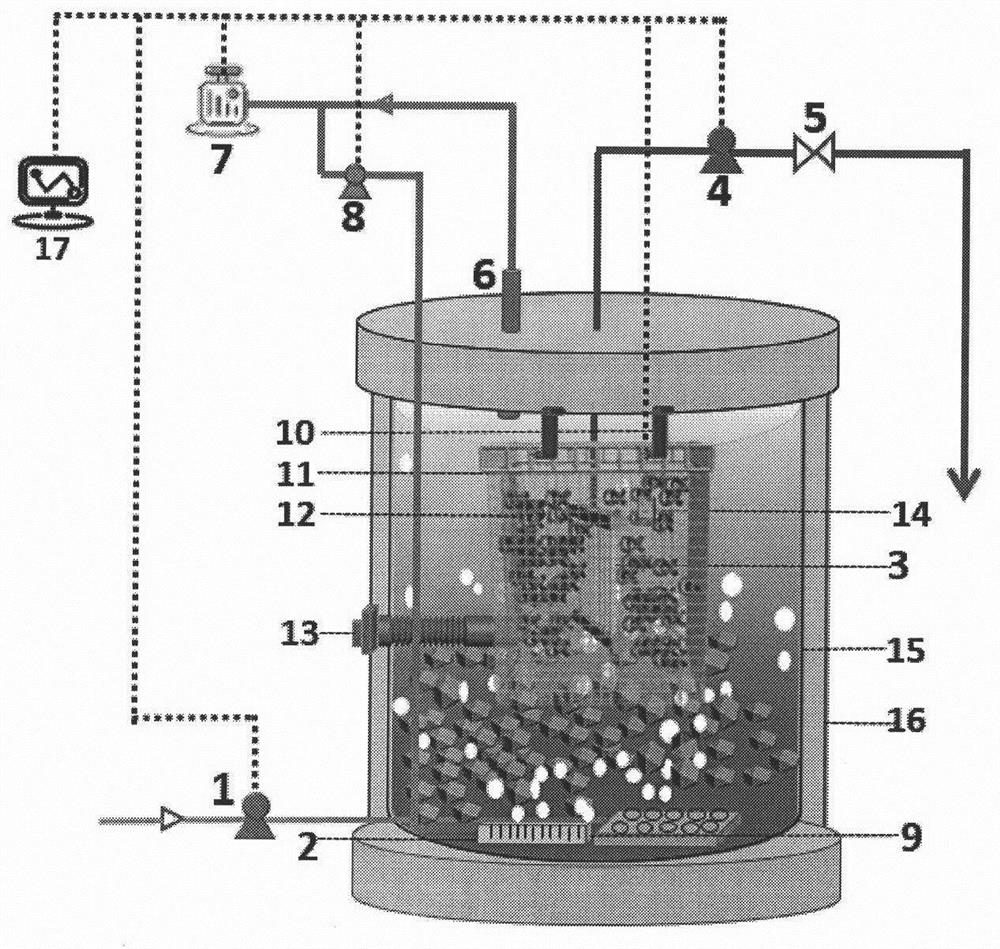

Novel intelligent dynamic anti-pollution anaerobic membrane bioreactor

ActiveCN112661262AReduce usageEffective protectionTreatment with anaerobic digestion processesSustainable biological treatmentEnvironmental engineeringMembrane bioreactor

The invention relates to a novel intelligent dynamic anti-pollution anaerobic membrane bioreactor, and belongs to the technical field of anaerobic membrane bioreactors. The novel intelligent dynamic anti-pollution anaerobic membrane bioreactor is characterized in that a membrane assembly is located in an intelligent dynamic anti-pollution module, the module is composed of an outer frame, an intelligent composite carrier of a biological membrane inhibitor D-amino acid, a D-amino acid concentration monitoring system and a carrier replacement system, the upper end of the module is fixed with a reactor through a fixing device, a reactor water inlet is positioned at the bottom of an anaerobic tank, a water outlet is internally connected with the membrane assembly, a biogas collecting pipe is connected to a biogas collecting device through a gas pipe, and an aeration device is positioned at the bottom of the reactor. According to the invention, D-amino acid is released through the intelligent dynamic anti-pollution module to inhibit membrane biological pollution, after the D-amino acid is released, a new composite carrier can be rapidly replaced and supplemented so as to regenerate the biological pollution resistance of the module, and the aeration effect and the hydrodynamic property in the reactor can be improved through the module so as to improve the anti-pollution effect, so that continuous control of membrane biological pollution is realized, and the system operation cost is reduced.

Owner:NANKAI UNIV

A low-temperature anti-sulfur denitrification catalyst and preparation method thereof

ActiveCN104056658BStrong water resistanceImprove low temperature denitrification performanceMolecular sieve catalystsDispersed particle separationChemical formulaMolecular sieve

The invention discloses a low-temperature sulfur-resistant denitration catalyst and a preparing method of the low-temperature sulfur-resistant denitration catalyst. The low-temperature sulfur-resistant denitration catalyst is formed by mixing, by weight, 15%-100% of active sites and 0-85% of carbon-based carriers; the active sites are formed by mixing one or two of the first active sites and the second active sites; the first active sites are composed of Mn(0.1-0.8)Ce(0.2-0.9)Ox or Mn(0.1-0.8)Mg(0.2-0.9)Ox dispersed into a 3A molecular sieve, and the value of the x is determined according to the content and the oxidation valence state of metallic elements in the chemical formula; the second active sites are composed of Mn (0.1-0.8)Mg(0.2-0.9) or Mn (0.1-0.8)Ce (0.2-0.9)Ox with the surface coated with a TiO2 or SiO2 protecting layer. According to the method, one or more of the first active sites and the second active site are mixed with carbon-based carriers to obtain the low-temperature sulfur-resistant denitration catalyst. As surface dewatering is performed on the catalyst, water molecules contained in flue gas are attached in an open-framework structure of the catalyst to form capillary condensation very difficultly or form vitriol or sulphurous acid ammonium salt with NH3 and SO2 or SO3 to cause deactivation of the catalyst.

Owner:XIAN SINO GREEN HI TECH CO LTD

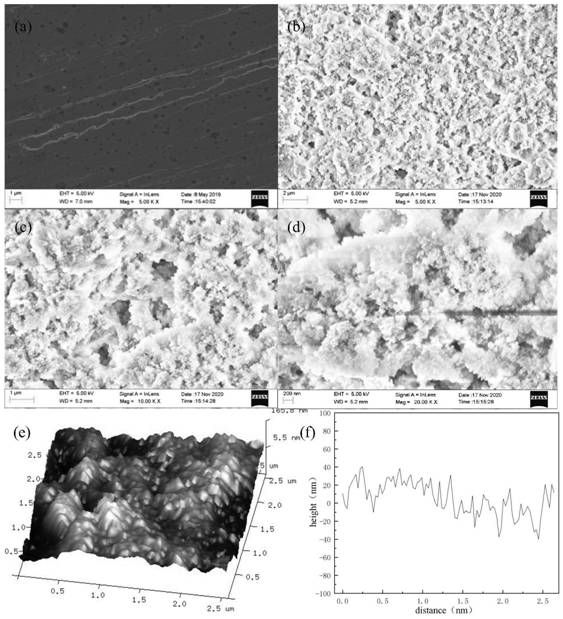

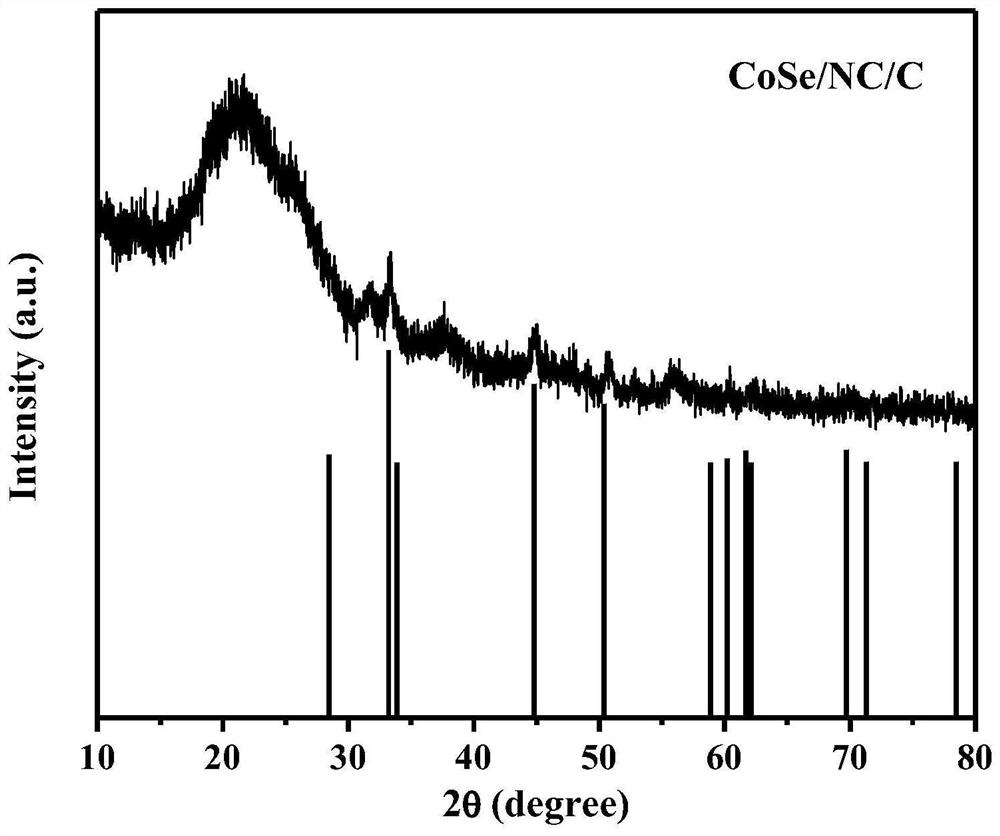

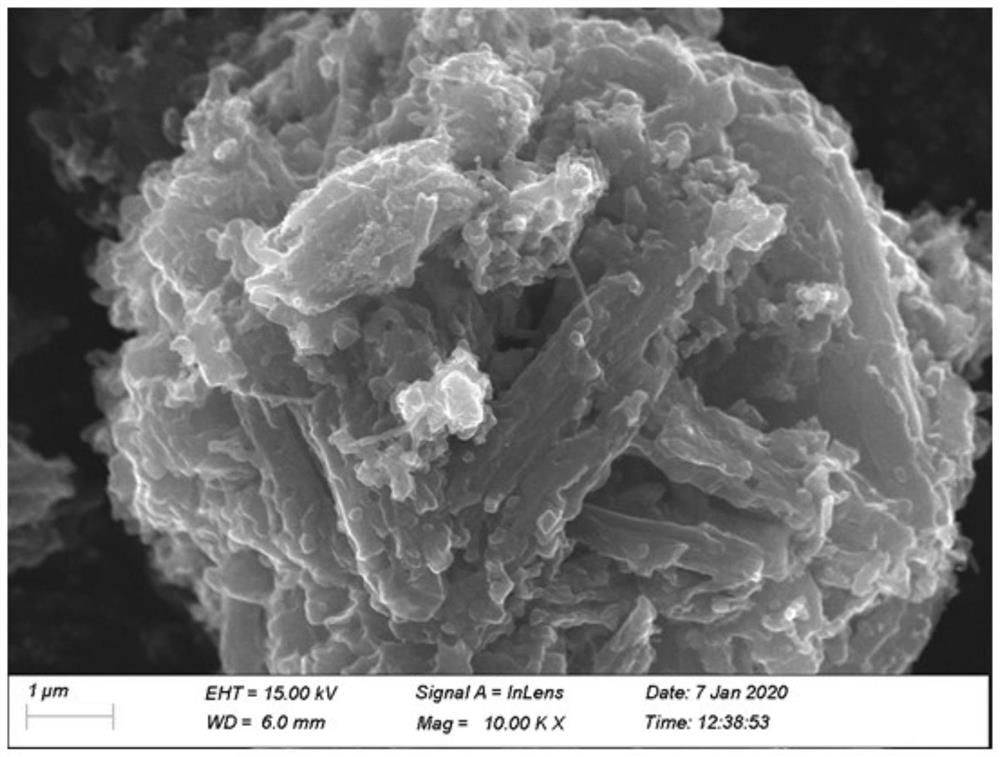

A kind of double-layer carbon-coated-metal selenide composite electrode material and preparation method thereof

ActiveCN111785970BImprove performanceInhibit direct contactSecondary cellsNegative electrodesCarbon coatingOrganosolv

The invention relates to a double-layer carbon-coated-metal selenide composite electrode material and a preparation method thereof. Selenium powder and phthalocyanine salt are used as raw materials for preparation, and the addition weight ratio of the two is controlled, so that the prepared composite electrode material has high cycle stability and rate performance. In the preparation process, the raw materials are firstly ground and mixed, and then heat-treated in a tube furnace in two steps, accompanied by chemical vapor deposition of organic solvents, so that the prepared metal selenide composite electrode material forms a double-layer dual-function electrode material. Carbon-coated metal selenide, and by controlling the process parameters such as reaction temperature and organic solvent loading rate during the whole reaction process, the prepared composite electrode material has good comprehensive performance. The preparation process of the invention is simple, the cycle is short, easy to control, and convenient for industrialized popularization and production.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

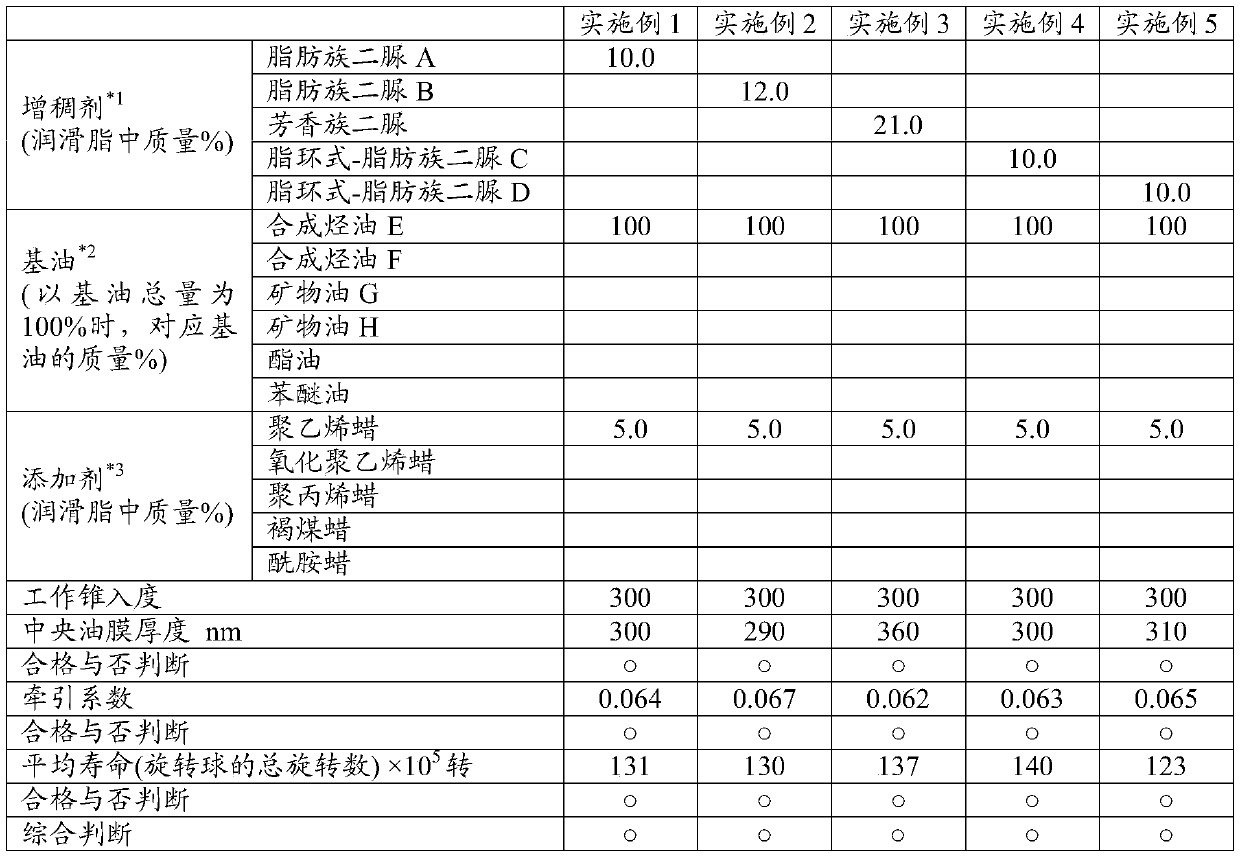

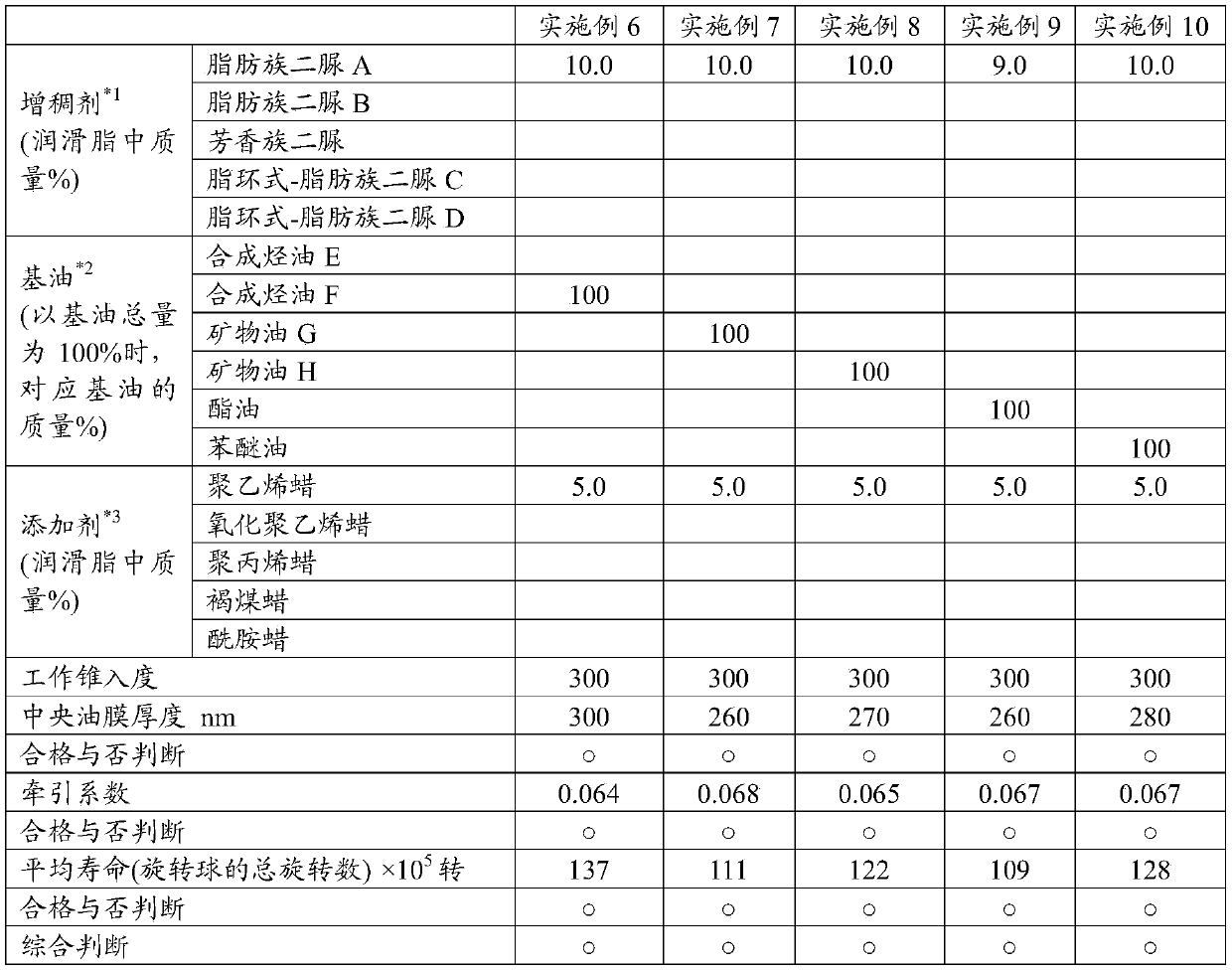

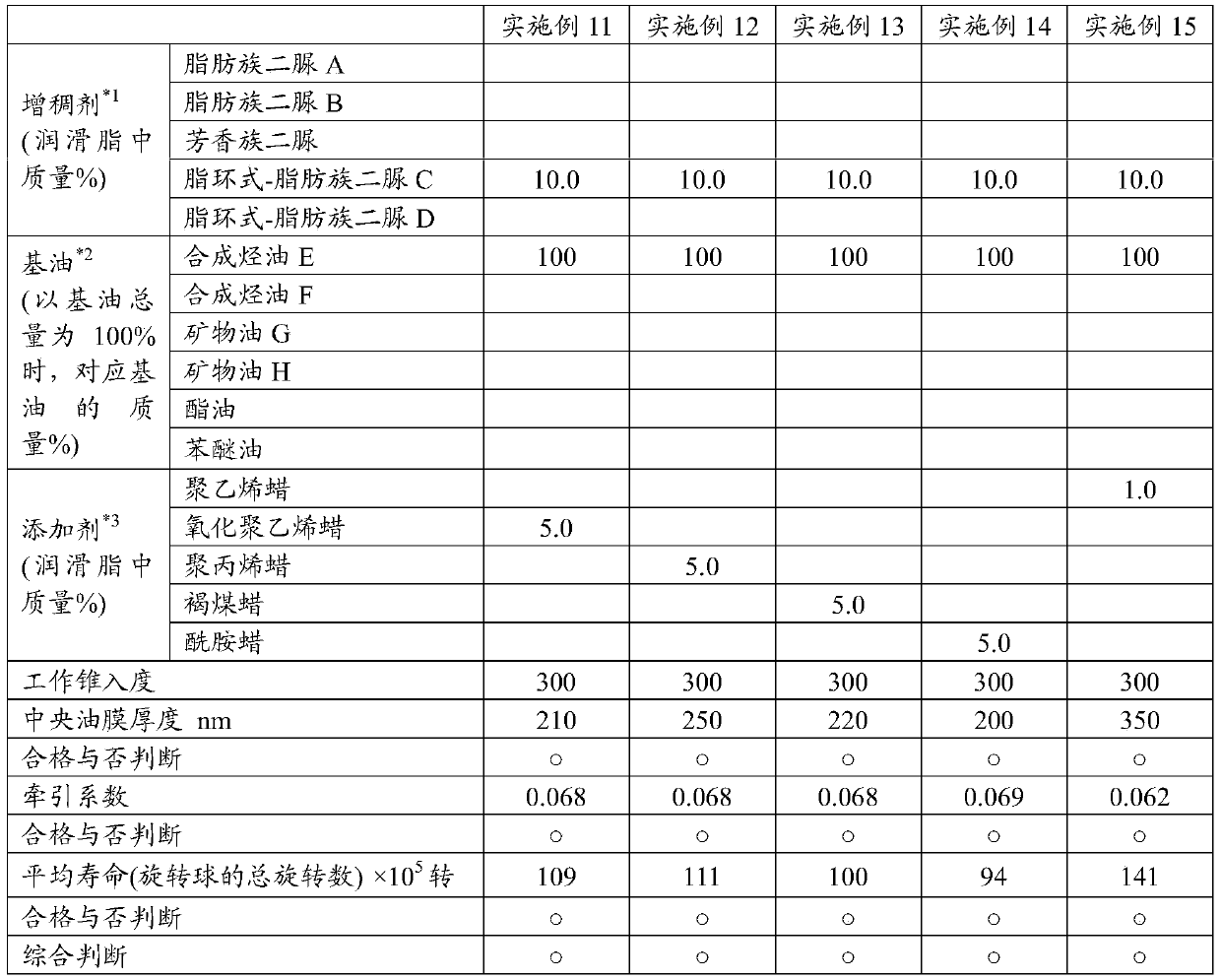

grease composition

ActiveCN106795450BInhibit direct contactReduce frictional torqueThickenersAdditivesPolymer scienceBase oil

The present invention provides a lubricating grease composition for lubricating mechanical parts having steel parts to be lubricated in rolling motion and sliding rolling motion, characterized in that it contains a base oil, a thickener, and an additive. At least one compound of ethylene wax, oxidized polyethylene wax, polypropylene wax, montan wax and amide wax.

Owner:KYODO YUSHI CO LTD

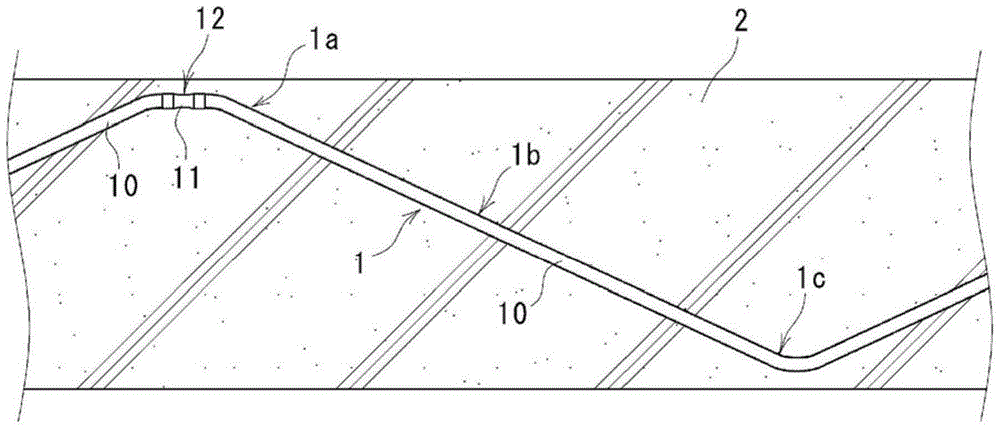

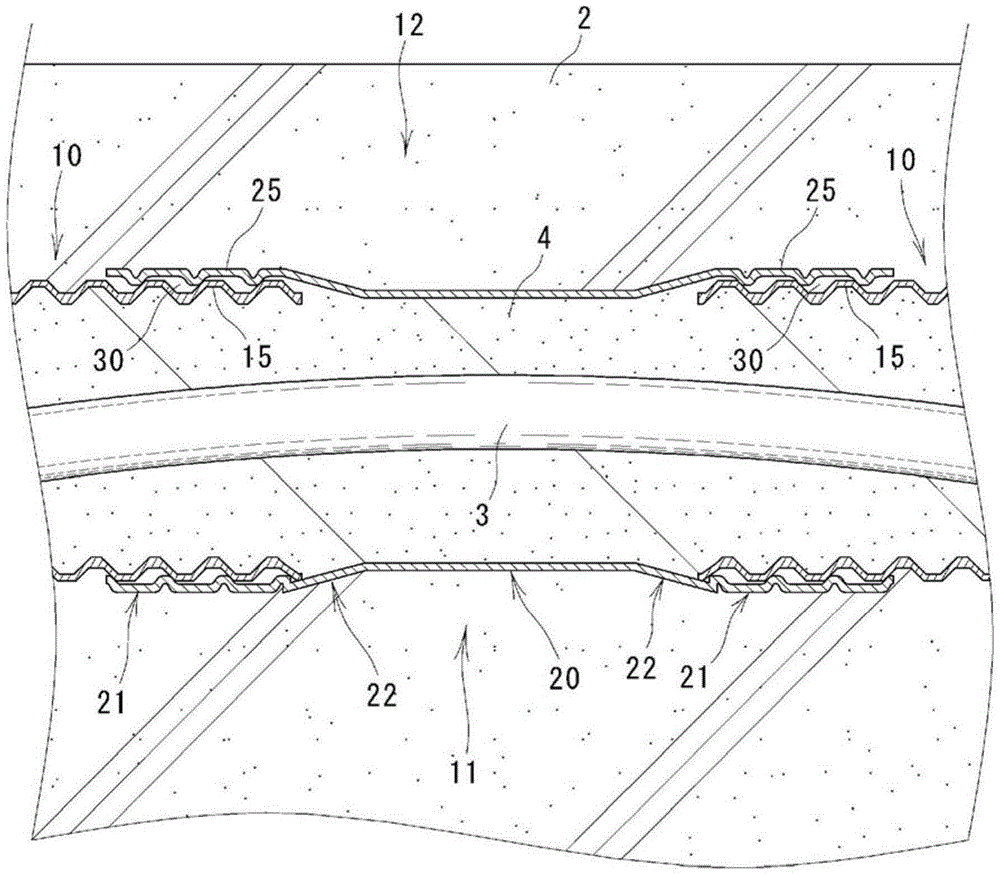

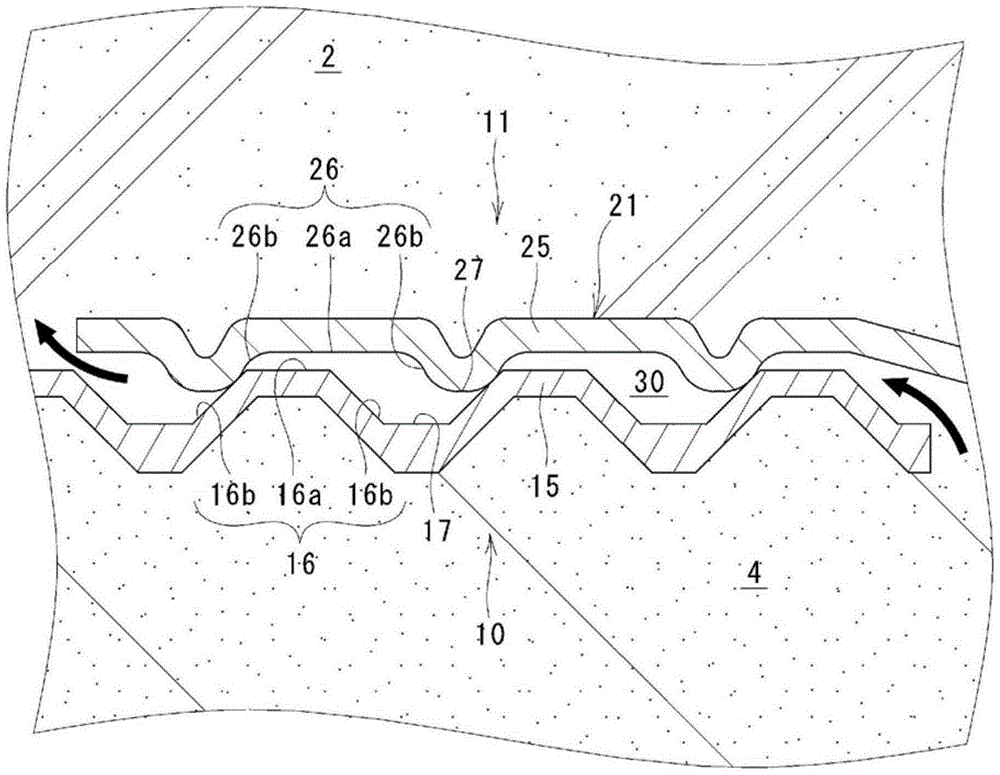

Casing pipeline structure

InactiveCN104937187BAvoid corrosionGuaranteed StrengthBridgesBuilding reinforcementsWater dischargeEngineering

The purpose of the present invention is, in a sheath conduit in which a PC steel member is inserted and that is filled with grout, to prevent corrosion of the PC steel member caused by bleed water by isolating the bleed water, which is produced inside the conduit when the grout cures, or allowing the same to escape. This sheath conduit (1) comprises connection sites (12) where ends of sheaths (10) are coupled and fixed via a joint member (11). In the connection site (12), a connecting tube (21) of the joint member (11) is fit around and fixed to the end of the sheath (10) by screwing together a ridge (15) of the sheath (10) and a projection (25) of the joint member (11) while the outer peripheral face (16) of the ridge (15) and the inner circumferential face (26) of the projection (25) are in partial contact with each other, and a water discharge channel (30) for guiding bleed water, which is produced inside the conduit when grout (4) cures, to the exterior of the conduit is formed between the end of the sheaths (10) and the connecting tubes (21) of the joint members (11).

Owner:TOTAKU IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com