Preparation method of epoxy resin-based nano-composite material suitable for oil lubrication working condition

A technology of nanocomposite materials and epoxy resin, applied in the field of polymer materials, to achieve the effect of low cost and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

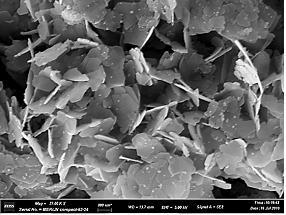

Image

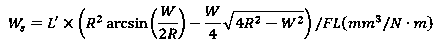

Examples

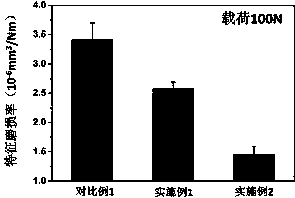

Embodiment 1

[0033] Embodiment 1 The preparation method of the epoxy resin-based nanocomposite material suitable for oil lubrication working conditions comprises the following steps:

[0034] ⑴Preparation of cobalt-aluminum hydrotalcites (Co-Al LDHs):

[0035] ① Cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) be dispersed in deionized water to obtain a solution A with a concentration of 0.1mol / L;

[0036] ②Add 1L solution A to 1L containing sodium hydroxide (NaOH) and sodium carbonate (NaOH) 2 CO 3 ) in an aqueous solution, which is fully dissolved by magnetic stirring to obtain solution B;

[0037] ③Add 1L 0.1mol / L Al(OH) to 1L Solution B 3 Solution, after stirring, transfer the mixed solution to a hydrothermal reaction kettle, conduct a hydrothermal reaction at 120°C for 4 hours, and then cool naturally to obtain an off-white solution C containing suspended solid particles;

[0038] ④ Solution C was centrifuged and washed with deionized water at a speed of 2000r / min to obtain a precipitate, ...

Embodiment 2

[0041] Example 2 The preparation method of epoxy resin-based nanocomposites suitable for oil lubrication conditions, comprising the following steps:

[0042] (1) Preparation of cobalt-aluminum hydrotalcites (Co-Al LDHs) is the same as in Example 1.

[0043] ⑵According to the mass fraction, 10.0wt.% cobalt-aluminum hydrotalcite (Co-Al LDHs) and 90.0wt.% epoxy resin have a vacuum degree of -1×10 5 Pa, rotating speed is 2000r / min under the condition of stirring and mixing 30min, add the curing agent of epoxy resin volume content 10% again, continue to stir and mix 8min with the rotating speed of 4000r / min, obtain mixed solution;

[0044] (3) The mixture is poured into the mold, and cured at 120°C for 8 hours at a high temperature. After demoulding and shaping, the epoxy resin-based nanocomposite material suitable for oil lubrication conditions is obtained.

Embodiment 3

[0045] Example 3 The preparation method of epoxy resin-based nanocomposites suitable for oil lubrication conditions, comprising the following steps:

[0046] ⑴Preparation of cobalt-aluminum hydrotalcites (Co-Al LDHs):

[0047] ① Cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) be dispersed in deionized water to obtain a solution A with a concentration of 3mol / L;

[0048] ②Add 1L solution A to 100L solution containing sodium hydroxide (NaOH) and sodium carbonate (NaOH) 2 CO 3 ) in an aqueous solution, which is fully dissolved by magnetic stirring to obtain solution B;

[0049] ③Add 100L 0.1mol / L Al(OH) to 1L solution B 3 Solution, after stirring, transfer the mixed solution to a hydrothermal reaction kettle, conduct a hydrothermal reaction at 120°C for 24 hours, and then cool naturally to obtain an off-white solution C containing suspended solid particles;

[0050] ④ Solution C was centrifuged and washed with deionized water at a speed of 2000r / min to obtain a precipitate, which was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com