Variable valve timing control apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments are described below. The embodiments are not limited to configurations including those described below, but may be changed or altered as appropriate.

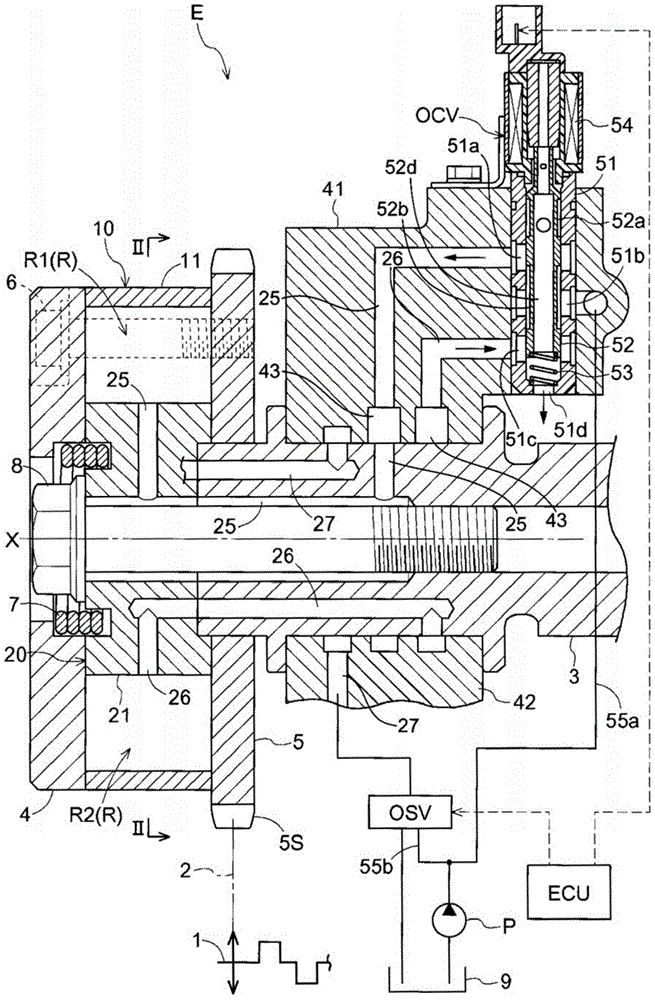

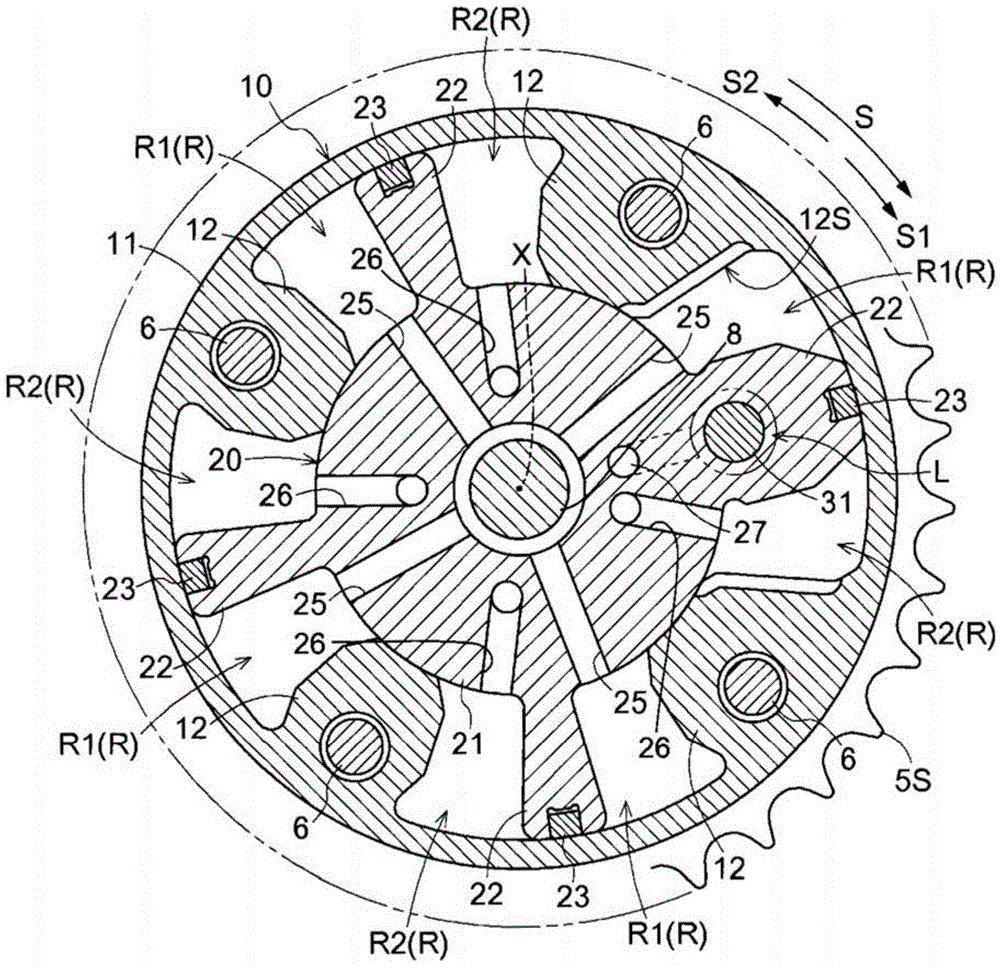

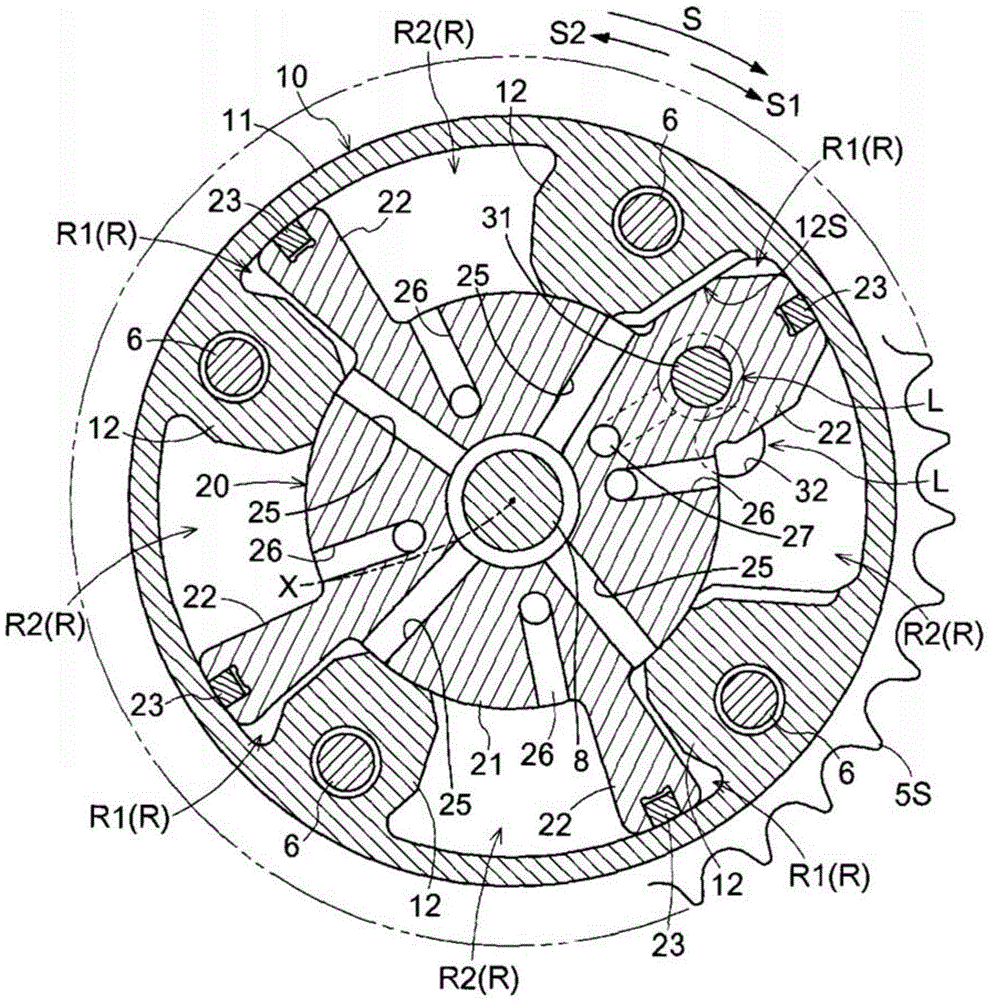

[0026] A first embodiment will be described with reference to the drawings. Such as figure 1 and figure 2 As shown, the valve opening and closing timing control device according to the first embodiment includes: an outer rotor 10 serving as a driving side rotating member; an inner rotor 20 serving as a driven side rotating member; and locking the relationship between the outer rotor 10 and the inner rotor 20 The relative rotation between the middle locking mechanism L. The outer rotor 10 rotates synchronously with a crankshaft 1 of an engine E serving as an internal combustion engine via a power transmission member 2 . The inner rotor 20 is connected to a camshaft 3 for opening and closing intake valves in the combustion chambers of the engine E. The inner rotor 20 is provided coaxially with a rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com