Casing pipeline structure

A casing and pipeline technology, which is applied in the field of casing pipeline structure, can solve the problems of bleeding without any countermeasures and the decline of concrete structure strength, and achieve the effects of simplification, strength maintenance and corrosion inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

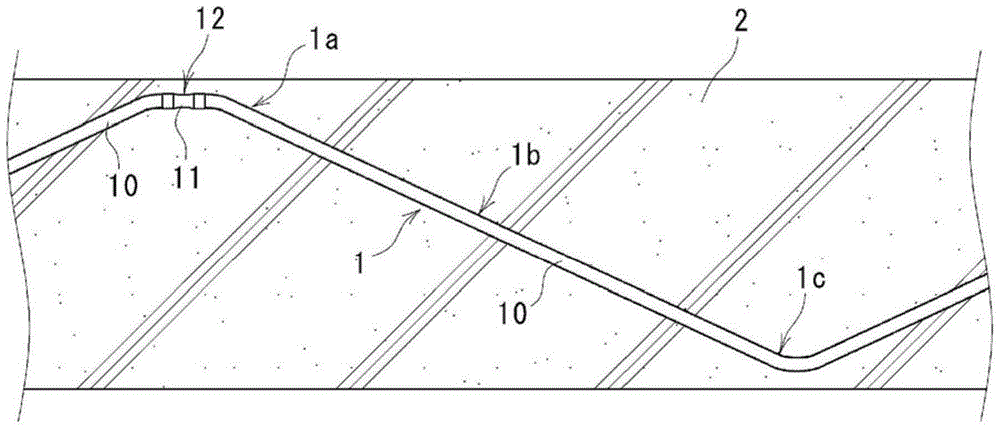

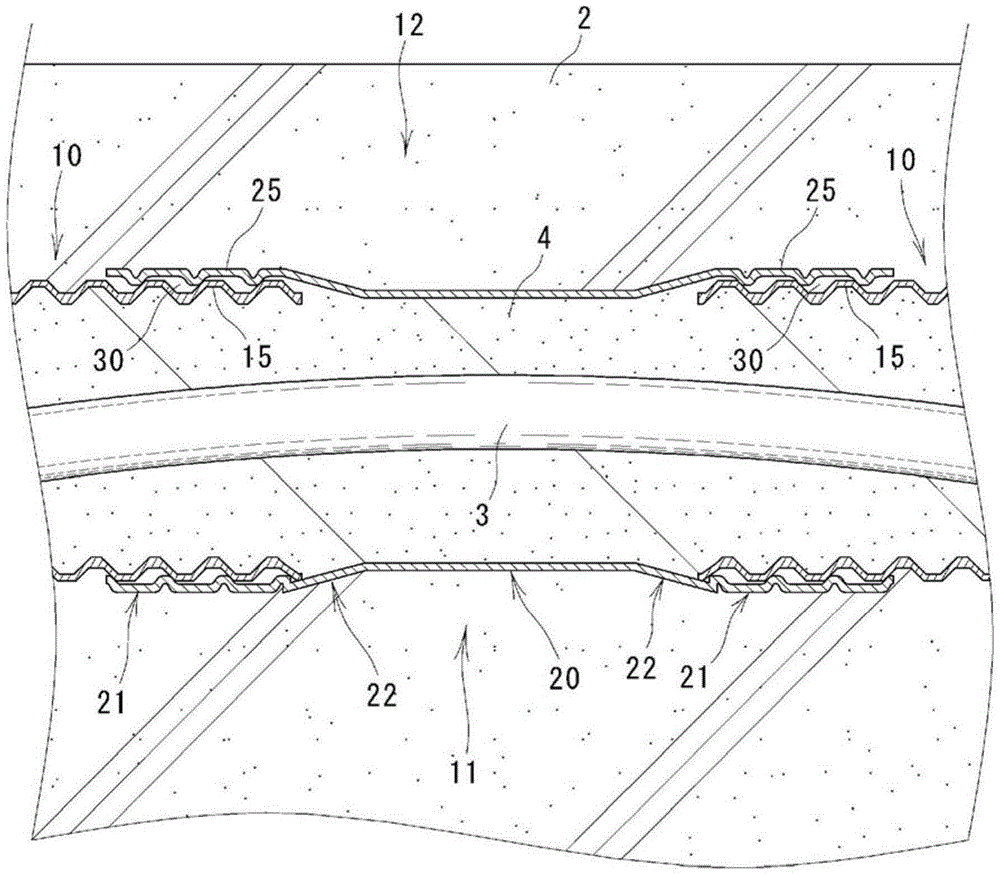

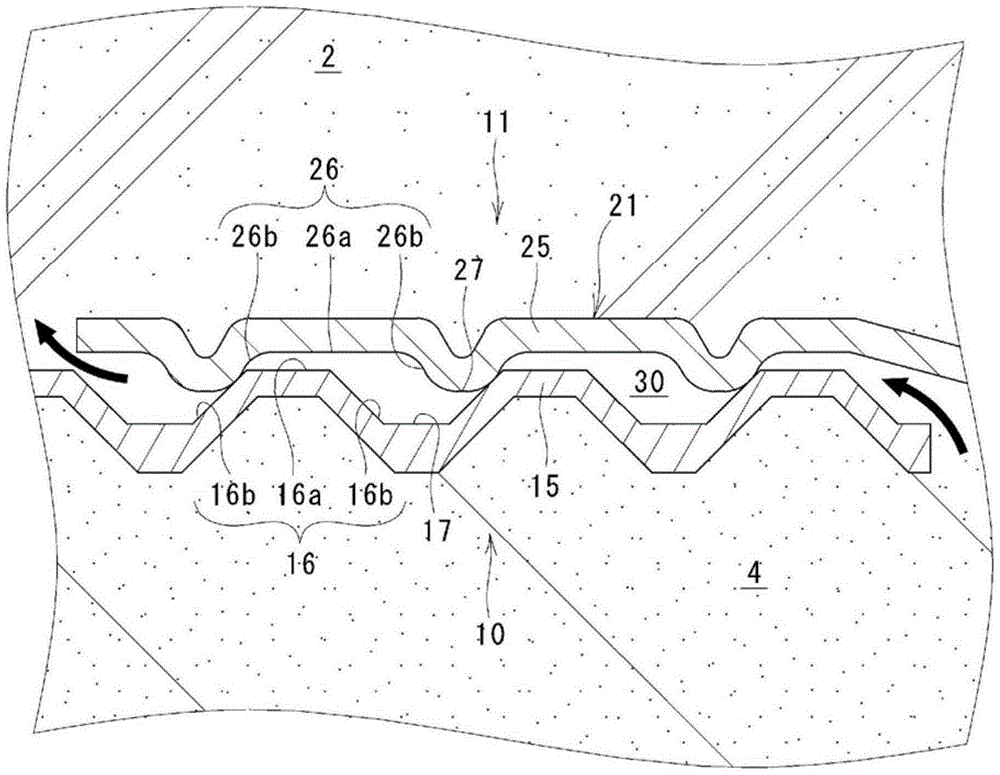

[0056] Embodiments of this invention will be described in detail below with reference to the drawings. The casing pipe structure according to one embodiment of the present invention is suitable for construction of prestressed concrete structures such as PC girder bridges produced by post-tensioning methods.

[0057] Such as figure 1 as well as figure 2 As shown, the casing pipeline 1 is buried in the concrete structure 2, and the PC steel material 3 for introducing prestress to the concrete structure 2 is inserted through the casing pipeline 1, and the casing pipeline 1 The inside is filled with cement slurry4. In addition, as the cement slurry 4, general cement slurry composed of a mixture of Portland cement, water, admixture, and the like is used.

[0058] The bushing pipeline 1 is buried in the concrete structure 2 in a meandering state in the up-down direction, and a connecting portion 12 is provided near the top 1 a of the casing pipeline 1 . The connection between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com