Anti-corrosion and anti-icing self-cleaning super-hydrophobic coating as well as preparation method and application thereof

A super-hydrophobic coating and self-cleaning technology, used in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the hidden dangers of the environment, enterprise production, people's property and life safety, affect the safe operation of various equipment and components, Problems such as metal surface failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

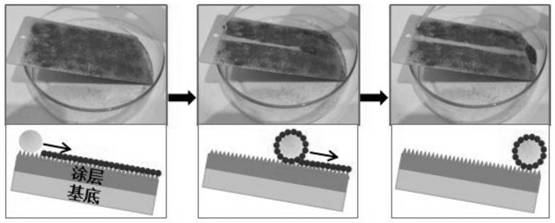

[0029] The invention provides a method for preparing an anti-corrosion and anti-icing self-cleaning superhydrophobic coating, comprising the following steps:

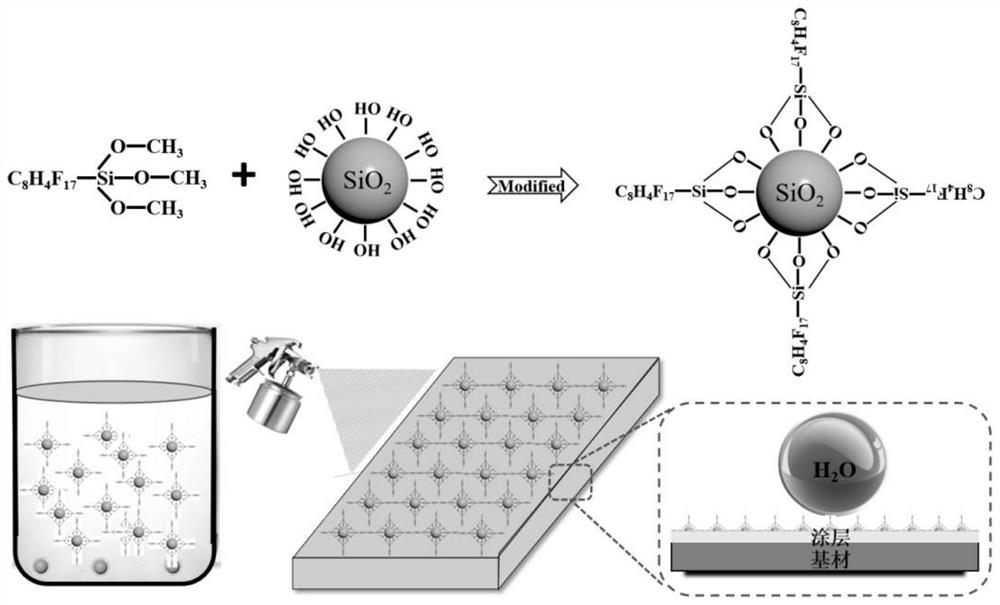

[0030] SiO 2 Perform the first mixing with 1H,1H,2H,2H-perfluorodecyltrimethoxysilanol solution, and modify it to obtain a modified silica dispersion;

[0031] The polyester thermoplastic polyurethane elastomer and the organic solvent are mixed for the second time to obtain the polyester thermoplastic polyurethane elastomer sol;

[0032] The modified silicon dioxide dispersion liquid, the polyester thermoplastic polyurethane elastomer sol and the polyurethane curing agent are mixed for a third time and doped to obtain an anti-corrosion, anti-icing and self-cleaning super-hydrophobic coating.

[0033] Unless otherwise specified, the present invention has no special requirements on the sources of the raw materials used for the preparation, and commercially available products well known to those skilled in the art can be ...

Embodiment 1

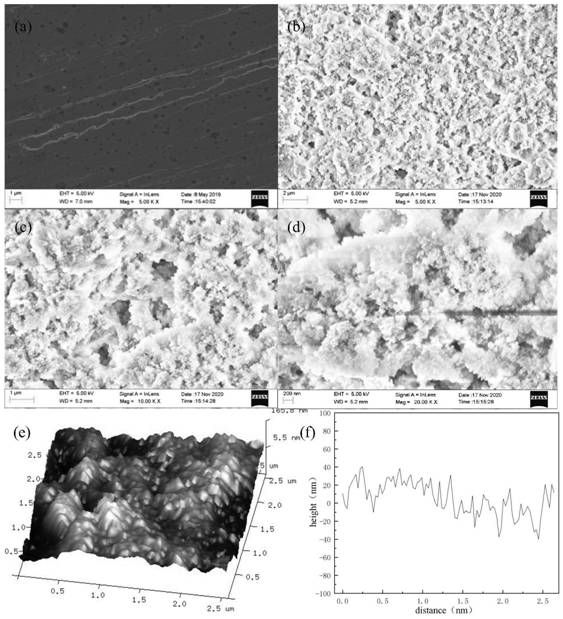

[0058] 2g nano-SiO 2 Particles (15±5nm) were added to 100mL of 1wt% 1H,1H,2H,2H-perfluorodecyltrimethoxysilane absolute ethanol solution and magnetically stirred for 2h to obtain a modified silica dispersion; Ester-type thermoplastic polyurethane elastomer was added to 60mL N,N-dimethylformamide, and magnetically stirred at 60°C for 2h until the polyester-type thermoplastic polyurethane elastomer rubber was completely dissolved to obtain polyester-type thermoplastic polyurethane elastomer sol; then The modified silica dispersion, the polyester thermoplastic polyurethane elastomer sol and 2 g of isocyanate curing agent were stirred at room temperature for 30 min to obtain an anti-corrosion, anti-icing and self-cleaning superhydrophobic coating.

Embodiment 2

[0060] 2g nano-SiO 2 Particles (15±5nm) were added to 150mL of 1wt% 1H,1H,2H,2H-perfluorodecyltrimethoxysilane absolute ethanol solution and magnetically stirred for 2h to obtain a modified silica dispersion; Ester-type thermoplastic polyurethane elastomer was added to 30mL N,N-dimethylformamide, and magnetically stirred at 60°C for 2h until the polyester-type thermoplastic polyurethane elastomer rubber was completely dissolved to obtain polyester-type thermoplastic polyurethane elastomer sol; then The modified silicon dioxide dispersion, the polyester thermoplastic polyurethane elastomer sol and 1.5 g of isocyanate curing agent were stirred at room temperature for 30 minutes to obtain an anti-corrosion, anti-icing and self-cleaning superhydrophobic coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com