Circuit board and preparation method thereof

A technology of circuit boards and substrates, which is applied in the direction of circuit substrate materials, printed circuit manufacturing, printed circuits, etc., can solve the problems of insufficient stability of circuit board resistance and dielectric constant, large environmental pollution, long processing time, etc., and achieve shortened processing time, reduce environmental pollution, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

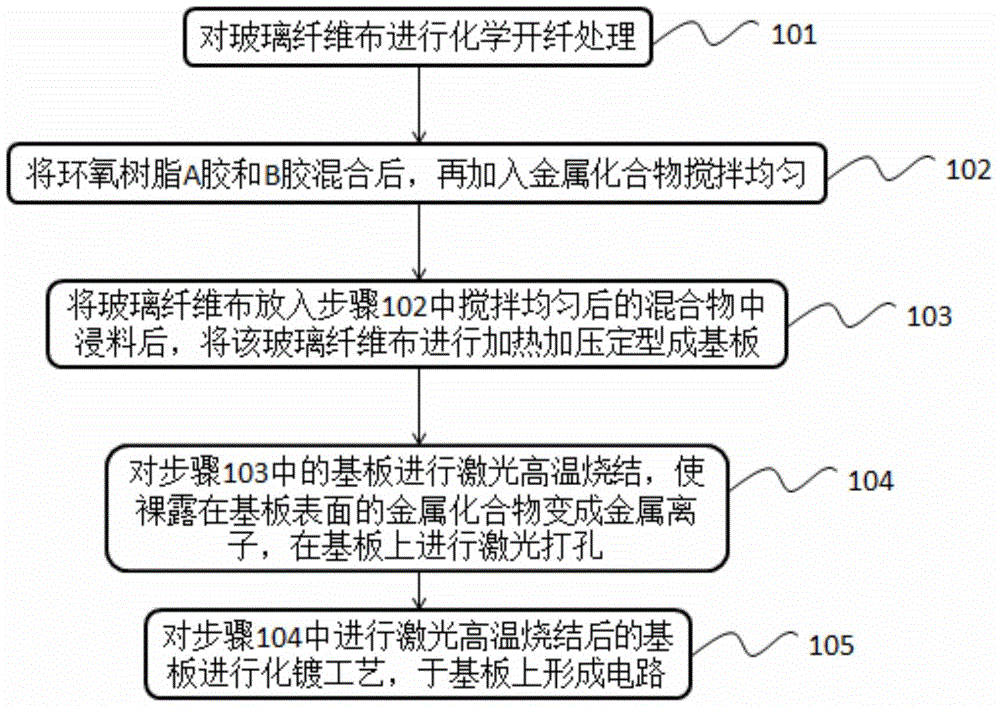

[0024] Please refer to figure 1 Shown is a flow chart of the method for preparing the circuit board of the present invention.

[0025] The invention proposes a circuit board and its preparation method, which not only solves the technical problems of large environmental pollution, long processing time and low efficiency in the current traditional circuit board production process, but also the resistance value and dielectric constant of the produced circuit board are not stable enough, Moreover, a circuit board with more stable resistance value and dielectric constant is provided.

[0026] Wherein, the present invention provides a kind of preparation method of circuit board, wherein, this preparation method comprises the following steps:

[0027] Step 101: performing chemical fiber opening treatment on the glass fiber cloth;

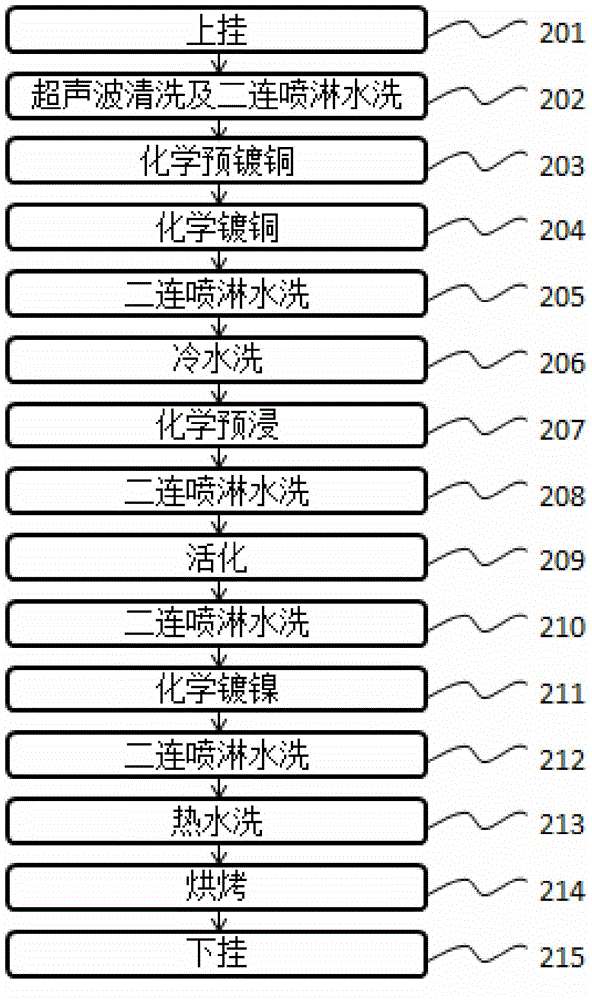

[0028] Step 102: After mixing the epoxy resin glue A and glue B, add the metal compound and stir evenly; Step 103: Put the glass fiber cloth into the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com