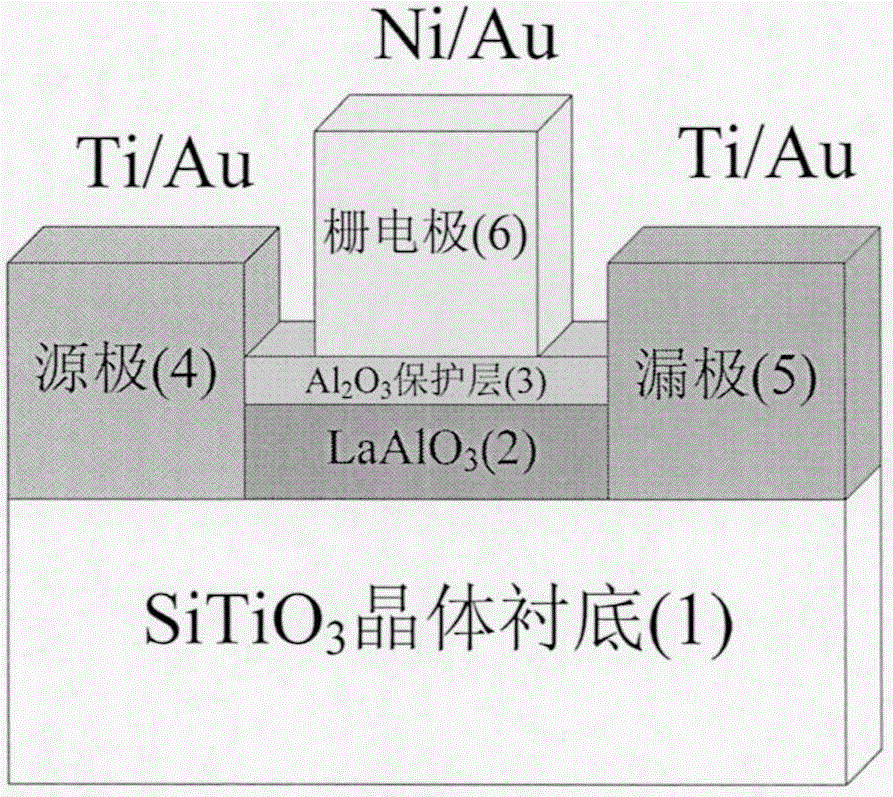

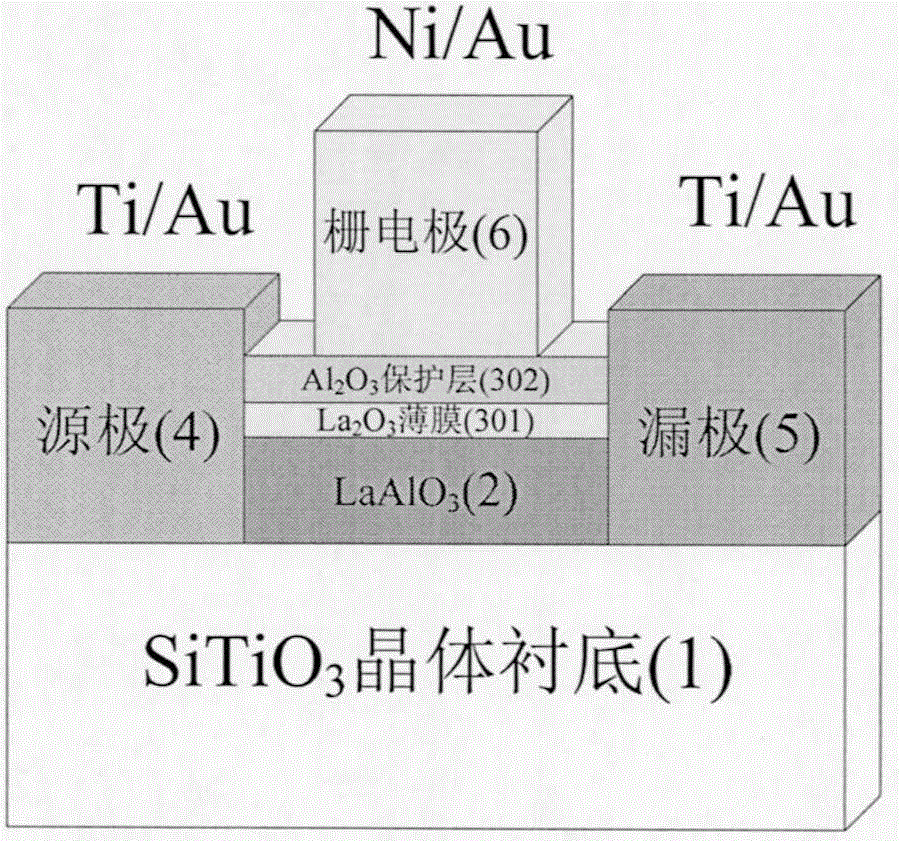

LaAlO3/SrTiO3 heterojunction field effect transistor based on La-based gate and manufacturing method

A heterojunction field effect, transistor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem that device performance and reliability are difficult to meet requirements, device channel charge control is weakened, device channel Problems such as weak charge control force, to achieve the effect of stable dielectric constant, large forbidden band width, and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: making La 2 o 3 The film thickness is 2nm, Al 2 o 3 LaAlO with stacked gate structure with protective layer thickness of 2nm 3 / SrTiO 3 heterojunction transistors.

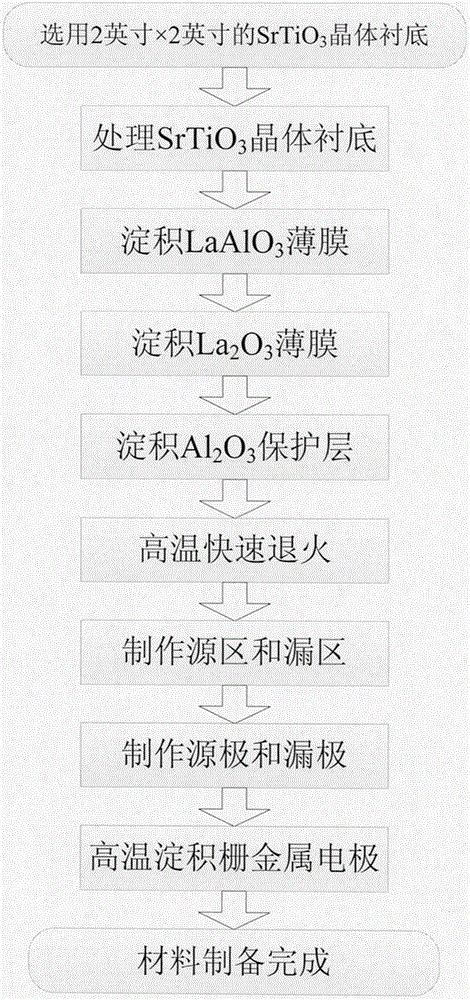

[0037] refer to image 3 , the production steps of this example are as follows:

[0038] Step 1, select SrTiO with a diameter of 1 inch 3 crystal as the substrate, and it is pretreated to obtain the (100) crystal plane, that is, TiO 2 noodle.

[0039] 1a. SrTiO 3 The crystal substrate was placed in deionized water for 20 minutes;

[0040] 1b. Take out SrTiO 3 The crystal substrate, which is placed in a buffer solution consisting of HF at a concentration of 49% and NH at a concentration of 40% 4 Mixture of F, HF and NH 4 The volume ratio of F is 1:5, the pH value is 4.7, soaking for 30 seconds;

[0041] 1c. Take out the SrTiO 3 crystal substrate, the O 2 Under the atmosphere, the temperature was raised to 950°C, and annealing was performed for 1 hour;

[0042] 1d. The annealed ...

Embodiment 2

[0082] Embodiment 2: making La 2 o 3 The film thickness is 3nm, Al 2 o 3 LaAlO with stacked gate structure with protective layer thickness of 1nm 3 / SrTiO 3 heterojunction transistors.

[0083] refer to image 3 , the production steps of this example are as follows:

[0084] Step 1, choose SrTiO with a diameter of 1 inch 3 crystal as the substrate, and it is pretreated to obtain the (100) crystal plane, that is, TiO 2 noodle;

[0085] The process of pretreatment is identical with step 2 of example 1.

[0086] Step two, in the pretreated SrTiO 3 Deposit LaAlO with a thickness of 7nm on the crystal substrate 3 film.

[0087] refer to Figure 4 , the specific implementation of this step is as follows:

[0088] 2.1. In the ultra-clean room environment, the pretreated SrTiO 3 Put the crystal substrate into the reaction chamber of the atomic layer deposition equipment, then evacuate the pressure of the chamber to 10hPa, heat the temperature to 320°C, set the nitrogen ...

Embodiment 3

[0119] Embodiment 3: making La 2 o 3 The film thickness is 2nm, Al 2 o 3 LaAlO with stacked gate structure with protective layer thickness of 3nm 3 / SrTiO 3 heterojunction transistors.

[0120] refer to image 3 , the production steps of this example are as follows:

[0121] Step A, select SrTiO with a diameter of 1 inch 3 crystal as the substrate, and it is pretreated to obtain the (100) crystal plane, that is, TiO 2 noodle;

[0122] The process of pretreatment is identical with step 2 of example 1.

[0123] Step B, in the pretreated SrTiO 3 Deposit LaAlO with a thickness of 9 nm on the crystal substrate 3 film.

[0124] refer to Figure 4 , the specific implementation of this step is as follows:

[0125] B1. In the ultra-clean indoor environment, the pretreated SrTiO 3 Put the crystal substrate into the reaction chamber of the atomic layer deposition equipment, then evacuate the pressure of the chamber to 9hPa, heat the temperature to 300°C, set the nitrogen f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com