GaAs enhancing/depletion type strain high mobility of electron transistor material structure

A technology with high electron mobility and material structure, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as low noise tolerance threshold voltage changes, and achieve the effect of good ohmic contact and high doping rate characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

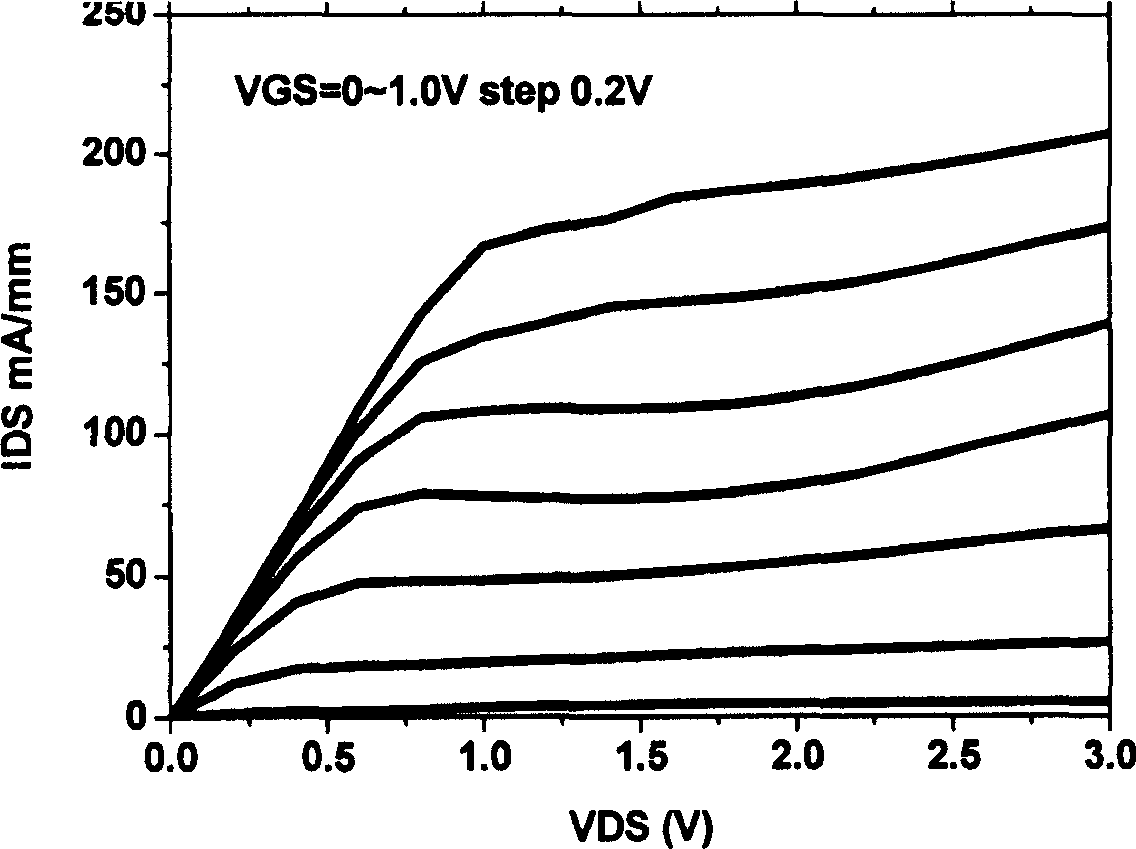

[0025]A gallium arsenide (GaAs) based monolithic integrated enhancement / depletion type strained high electron mobility transistor (MHEMT) device material structure of the present invention, as shown in Table 2, adopts InGaAs / InAlAs / InGaAs Arsenic material structure, on the upper surface of the semi-insulating gallium arsenide (100) substrate material, a linear slow-change InAlGaAs epitaxial layer is grown by slow-change growth technology as a buffer layer with a thickness of 1.5 μm, and then on the buffer layer Sequential growth: the third layer: undoped indium aluminum arsenic layer with a thickness of 500 angstroms; the fourth layer: undoped indium gallium arsenic layer with a thickness of 200 angstroms, indium composition X = 0.53±0.02, gallium group Point Y=0.47±0.02, X+Y=1, as a channel layer; the fifth layer: an undoped indium aluminum arsenic layer, with a thickness of 40 angstroms, as an isolation layer; the sixth layer: a planar doped layer, its The doping concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com