High dielectric constant thin film-aluminum oxide laminated structure insulating film and preparation method thereof

A technology of high dielectric constant and high dielectric constant materials, applied in the field of microelectronics, can solve problems such as harsh production conditions, high cost, and low utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

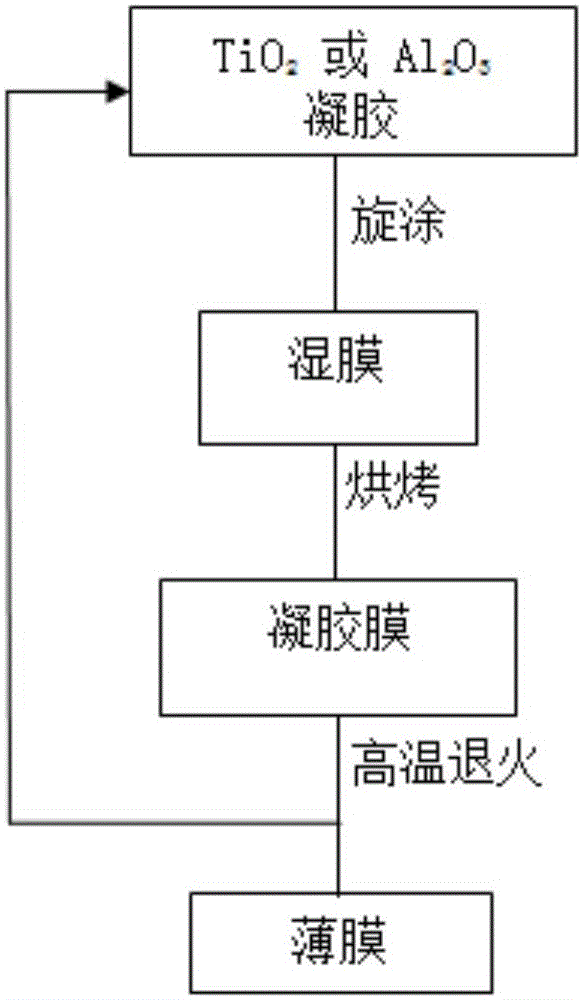

[0031] The preparation method of the high dielectric constant film-alumina laminate structure insulating film of the present invention comprises:

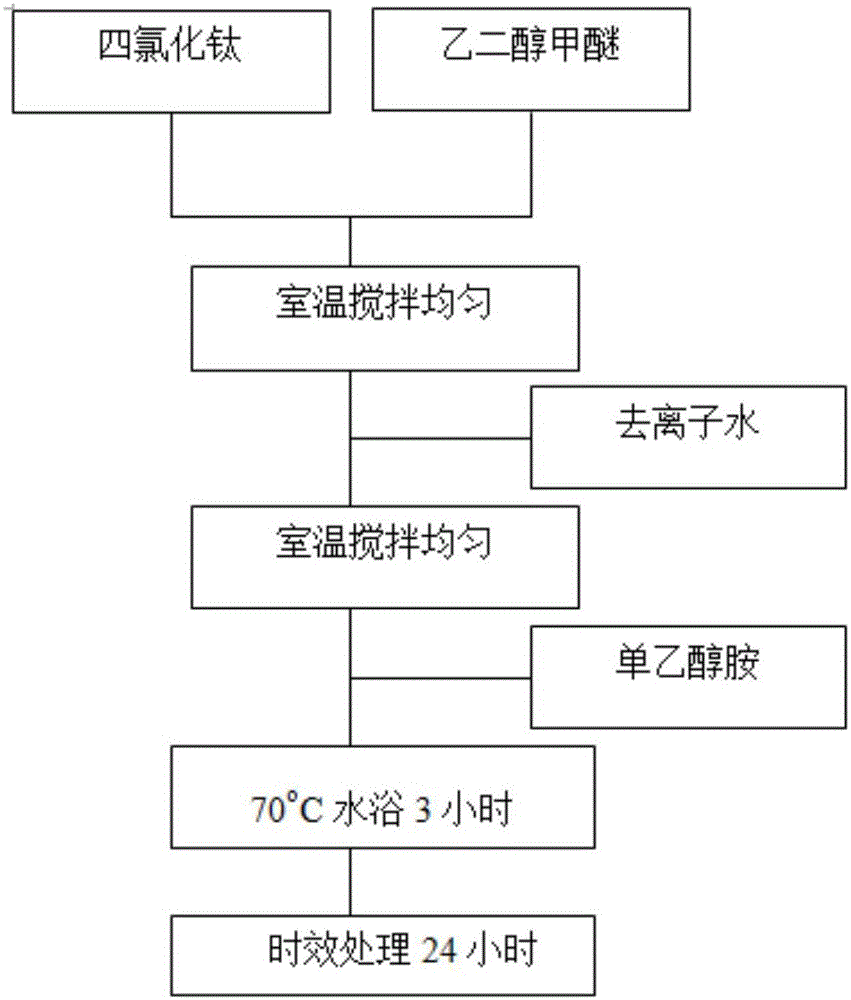

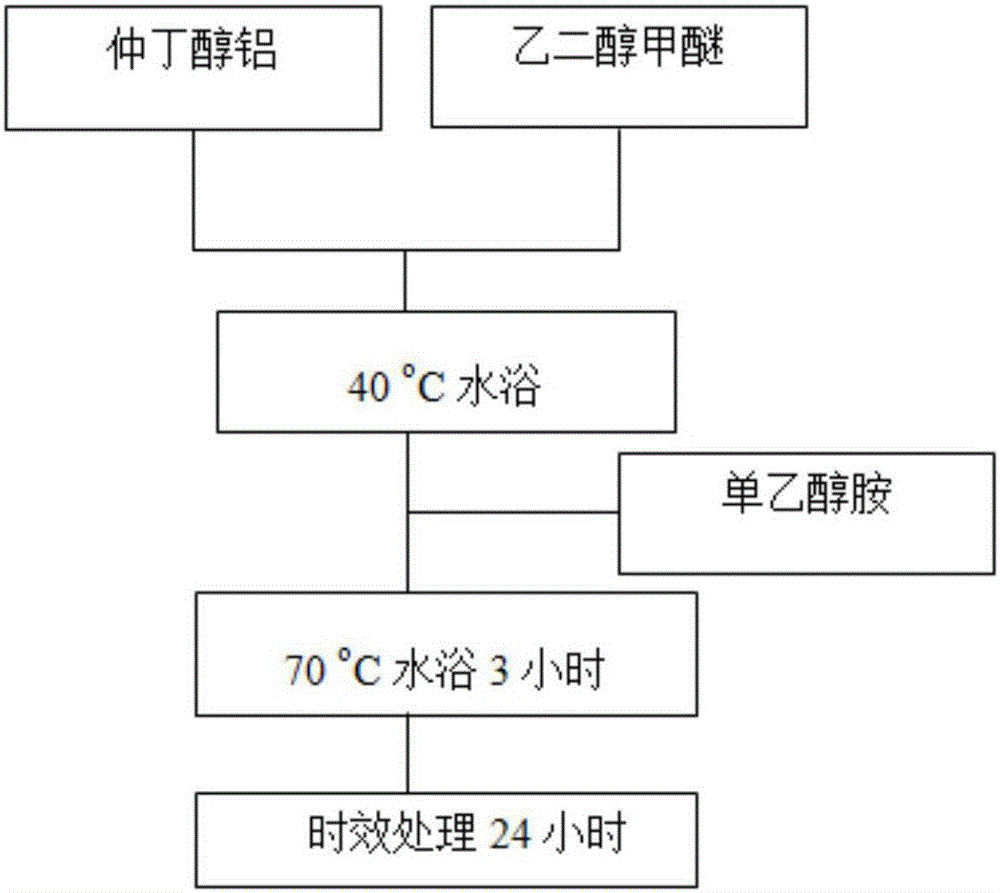

[0032] a. Preparation of high dielectric constant material precursor sol-gel: the solution containing high dielectric constant elements is dissolved in ethylene glycol methyl ether solution to form a precursor solution containing high dielectric constant elements, the high dielectric constant The molar concentration of constant elements is not more than 0.3M; after the solution containing high dielectric constant elements and ethylene glycol methyl ether solution are mixed evenly, add deionized water, and the molar concentration ratio of deionized water and high dielectric constant element ions is not greater than 5:1; then, stand still; after the deionized water and the precursor solution containing high dielectric constant elements are mixed evenly, monoethanolamine is added dropwise, and the molar concentration ratio of monoethan...

Embodiment 1

[0038] The following is attached Figure 1-5 The preparation method of the titanium oxide-alumina laminate structure insulating film of the present invention will be further described in detail with specific examples. It should be noted that the drawings are all in a very simplified form, using imprecise scales, and are only used to facilitate and clearly achieve the purpose of assisting in describing the present embodiment.

[0039] In this embodiment, in the laminated structure, both the bottom layer and the top layer are titanium oxide high dielectric constant films; the preparation method of the titanium oxide-alumina laminated structure insulating film includes:

[0040] a. see figure 1 ,TiO 2 Precursor sol-gel preparation: the TiCl 4 Dissolved in ethylene glycol methyl ether solution to form Ti precursor solution, TiCl 4 The molar concentration is not more than 0.3M, preferably 0.05M; after stirring at room temperature, TiCl 4 After mixing with ethylene glycol methy...

Embodiment 2

[0053] In this embodiment, the preparation of a zirconia-alumina laminated structure insulating film is taken as an example for illustration; the preparation method of a zirconia-alumina laminated structure insulating film includes: a.ZrO 2 Preparation of precursor sol-gel; b.Al 2 o 3 Preparation of precursor sol-gel; c. Provide a substrate, adopt spin-coating process to ZrO 2 The precursor gel is spin-coated on the surface of the substrate; then, the ZrO spin-coated on the substrate is baked 2 Precursor gel, and then, through the annealing process, the ZrO on the substrate 2 Precursor gels to form ZrO 2 thin film; d. Spin-coating Al 2 o 3 Precursor gel spin-coated on ZrO 2 film surface; then, baked and spin-coated on ZrO 2 Al on the film surface 2 o 3 precursor gel, and then, through an annealing process, the ZrO 2 Al on the film surface 2 o 3 Precursor gels to form Al 2 o 3 Thin film; e. Repeat c-d to obtain ZrO on the substrate 2 -Al 2 o 3 A laminated struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com