Barium niobate sodium lead based glass ceramic material with high energy-storage density and preparation method thereof

A high energy storage density, glass ceramic technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of low dielectric constant and energy storage density of glass ceramic materials, and achieve high energy storage density The effect of resistance to breakdown field strength and dielectric constant improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of barium lead sodium niobate-based glass ceramic energy storage material with high energy storage density comprises the following steps:

[0035] (1) BaCO with a purity greater than 99wt% 3 , PbO, Na 2 CO 3 , Nb 2 O 5 , SiO 2 It is a raw material ingredient, and the molar percentages of its components are 21.25%, 1%, 12.75%, 34%, and 32%. The mixture is ball-milled for 24 hours, dried at 110 °C for 6 hours, and then melted at a high temperature of 1550 °C for 60 minutes; (The above ball mills all use absolute ethanol as the medium, and the ratio of ball to material is 1.5:1).

[0036] (2) pouring the high-temperature melt obtained in step (1) into a square metal mold, annealing at 650° C. for stress relief for 4 hours, and then cutting to obtain a glass flake with a thickness of 1.0-1.5 mm;

[0037] (3) Put an equal amount of the glass flakes obtained in step (2) into a crucible, and after raising the temperature to 800°C at a heating rate ...

Embodiment 2

[0041] The preparation method of barium lead sodium niobate-based glass ceramic energy storage material with high energy storage density comprises the following steps:

[0042] (1) BaCO with a purity greater than 99wt% 3 , PbO, Na 2 CO 3 , Nb 2 O 5 , SiO 2 It is a raw material ingredient, and the molar percentages of its components are 21.25%, 1%, 12.75%, 34% and 32%. After ball milling for 24 hours, drying at 110 °C for 6 hours, and melting at 1600 °C for 50 minutes; (The above ball mills all use absolute ethanol as the medium, and the ratio of ball to material is 1.5:1).

[0043] (2) pouring the high-temperature melt obtained in step (1) into a square metal mold, annealing at 650° C. for stress relief for 5 hours, and then cutting to obtain a glass flake with a thickness of 1.0-1.5 mm;

[0044] (3) Put an equal amount of the glass flakes obtained in step (2) into a crucible, raise the temperature to 850°C at a heating rate of 5°C / min, and keep the glass ceramics for 6 ...

Embodiment 3

[0048] (1) BaCO with a purity greater than 99wt% 3 , PbO, Na 2 CO 3 , Nb 2 O 5 , SiO 2 It is a raw material ingredient, and the molar percentages of its components are 21.25%, 1%, 12.75%, 34%, and 32%. The mixture is ball-milled for 24 hours, dried at 110 °C for 6 hours, and melted at a high temperature of 1580 °C for 55 minutes; (The above ball mills all use absolute ethanol as the medium, and the ratio of ball to material is 1.5:1).

[0049](2) pouring the high-temperature melt obtained in step (1) into a square metal mold, annealing at 650° C. for stress relief for 4.5 hours, and then cutting to obtain a glass flake with a thickness of 1.0-1.5 mm;

[0050] (3) Put an equal amount of the glass flakes obtained in step (2) into a crucible, and after raising the temperature to 900°C at a heating rate of 5°C / min, keep the temperature for 6 hours to obtain glass ceramics.

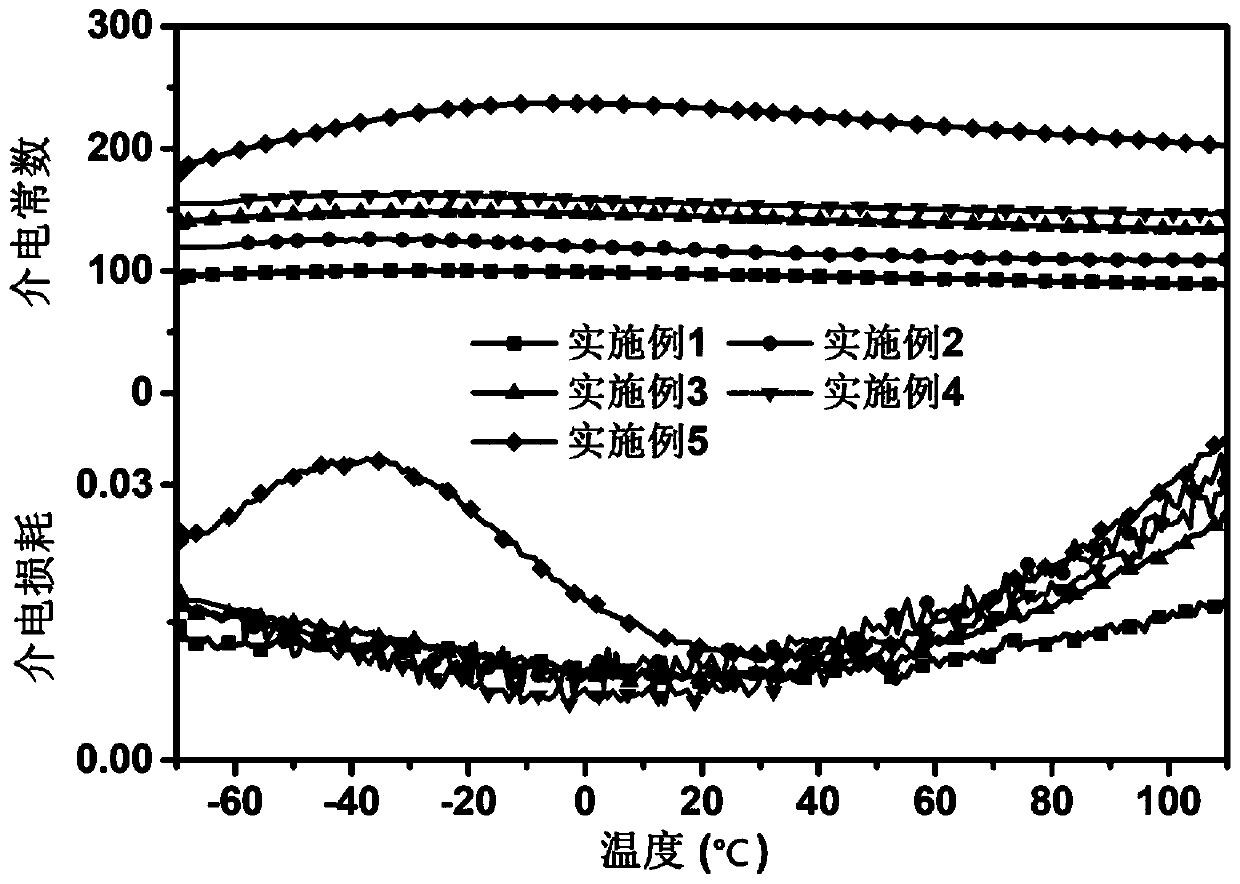

[0051] The dielectric properties of the samples prepared in this example are as follows: figure 1 As...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com