Superhigh-temperature-resistant nonpolarity radio-frequency coaxial electrical connector

A radio frequency connector, radio frequency coaxial technology, applied in the direction of connection, two-part connection device, connection device parts, etc., can solve the problem of inability to meet ultra-high temperature application conditions, increase the complexity of the whole machine system, and unfavorable equipment maintenance and repair And other problems, to achieve the effect of excellent electrical properties, high strength, good relaxation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

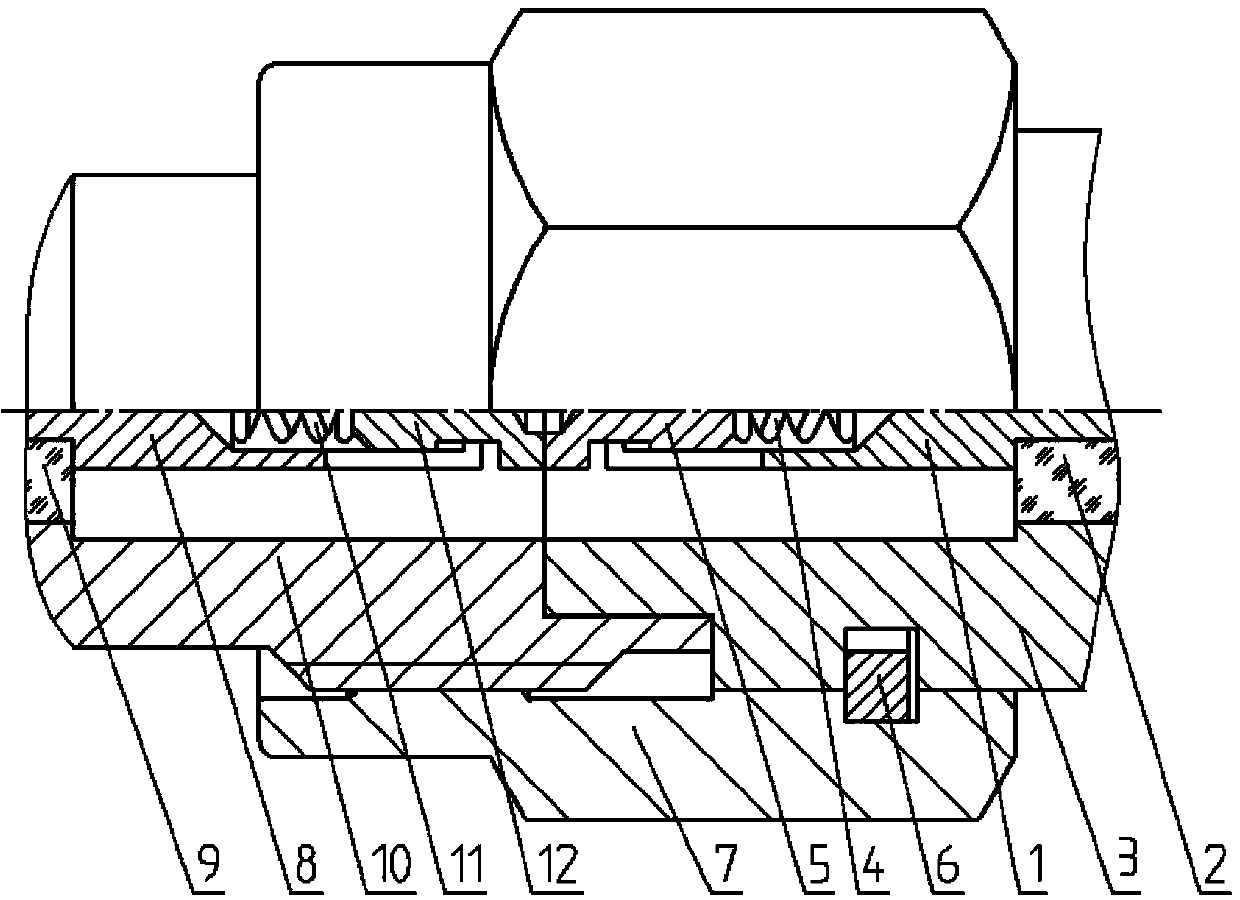

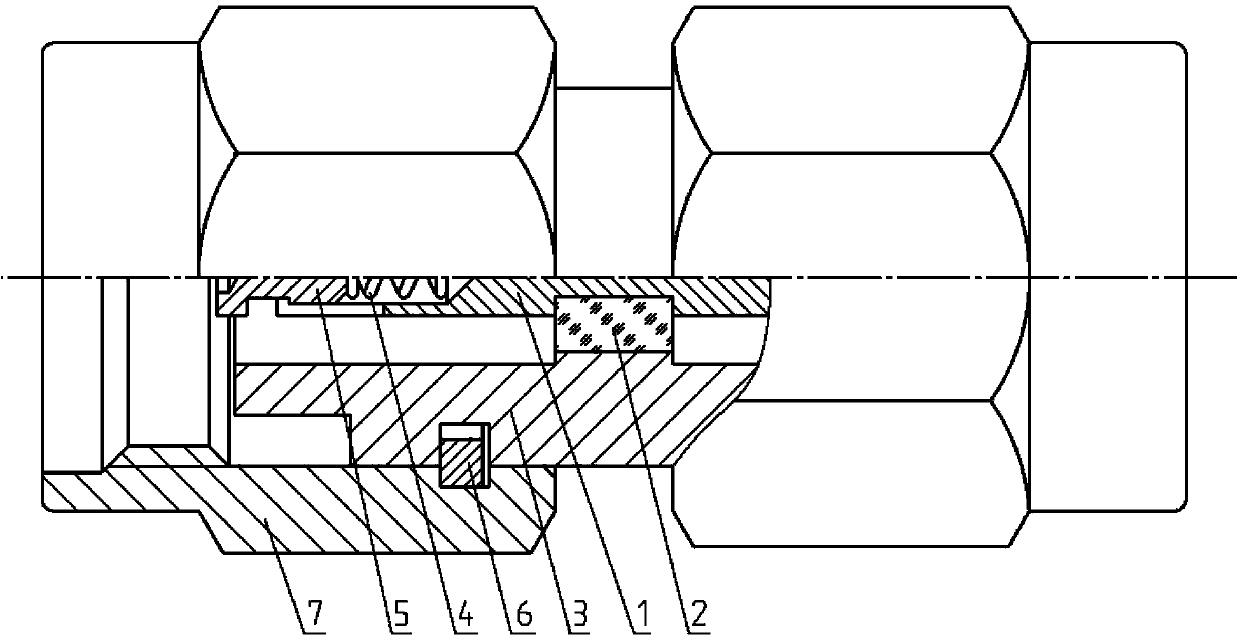

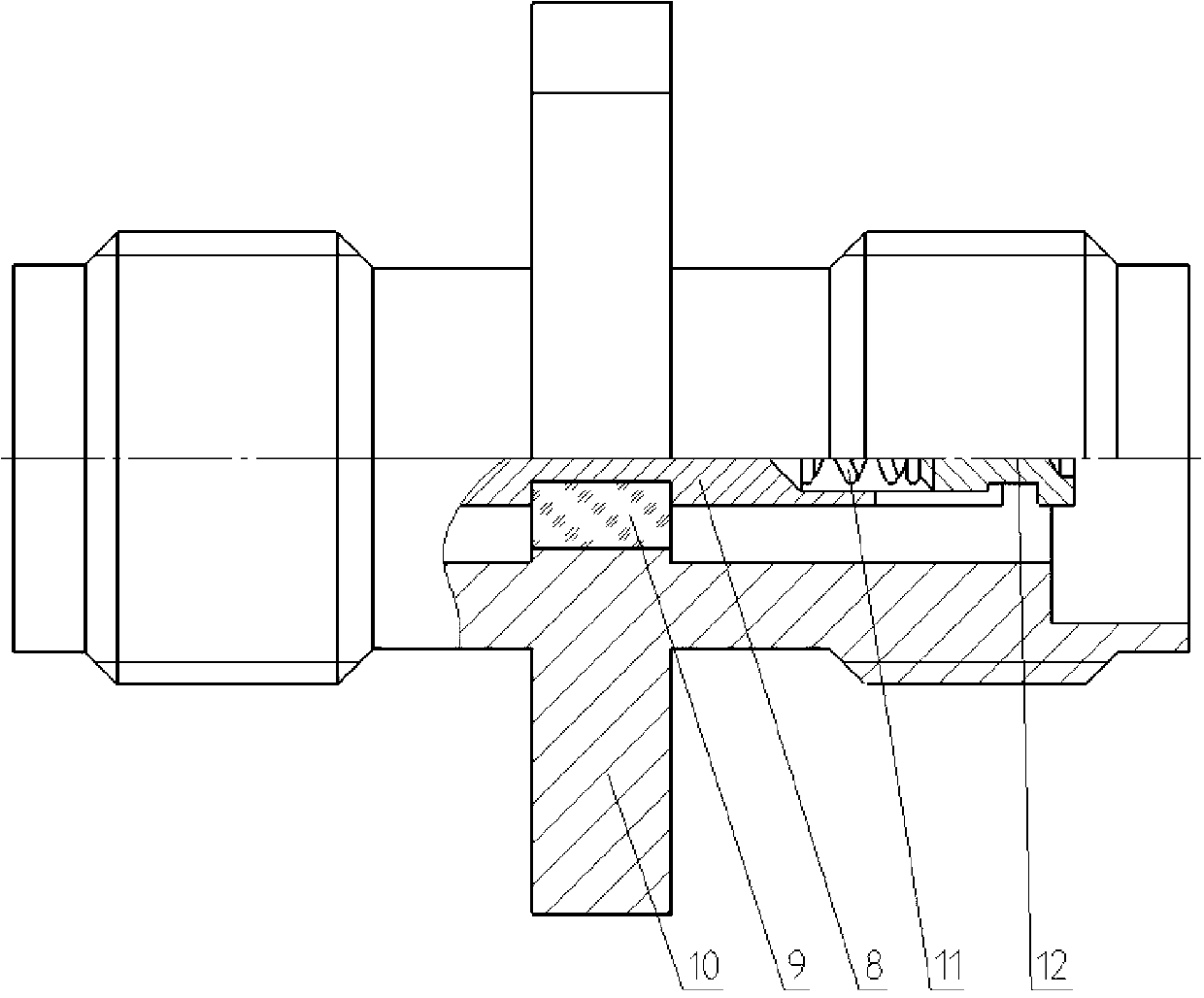

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] Such as figure 1 , figure 2 with image 3 As shown, an ultra-high temperature resistant non-polar radio frequency coaxial electrical connector includes a radio frequency connector plug and a radio frequency connector socket mated with the radio frequency connector plug; the radio frequency connector plug includes a plug inner conductor 1, a plug shell 3. The inner conductor 1 of the plug and the plug shell 3 are sintered together through the plug glass body 2 in the middle, and the connecting screw sleeve 7 is arranged outside the plug shell 3, and the snap ring 6 is placed between the connecting screw sleeve 7 and the plug shell 3. In the ring groove, the mouth of the inner conductor 1 of the plug is split inwards to form a plug step hole, and a plug spring 4 is placed in the plug step hole. In the step hole, the plug spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com