Benzoxazine resin composition, prepreg made from same, copper-clad laminate and circuit board

A technology of resin composition and benzoxazine, which is applied in the fields of copper clad laminates and circuit boards, prepregs, and benzoxazine resin compositions, and can solve the dielectric constant and dielectric loss of undisclosed circuit board substrate materials, etc. problem, to achieve the effect of maintaining stable temperature coefficient of dielectric constant, fast information transmission rate, and good transmission signal integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0045] This manufacturing example is a preparation example of cage-type dendritic silicone resin, including the following steps:

[0046] (1) Synthesis of cage silicone resin:

[0047] Put 60g of trimethoxysilane, 28.4g of water, 1.32g of potassium hydroxide, and 100ml of ethanol into a 500ml three-necked flask, and perform a hydrolysis reaction with magnetic stirring at 25°C for 24 hours. After the reaction, the isopropanol was removed by rotary evaporation under reduced pressure at 50° C., and the hydrolyzate was dissolved with toluene. Then wash the toluene solution with saturated brine until neutral, remove the water layer after liquid separation, add anhydrous magnesium sulfate to the oil layer to remove water, filter the magnesium sulfate, remove the toluene at 65°C to obtain the cage-type hydrolyzate without catalyst impurities Silicone.

[0048] (2) 0.01mol of cage-type silicone resin obtained by step (1), 0.078mol of single-end vinyl silicone oil with benzene ring c...

Embodiment 1-3 and comparative example 1-3

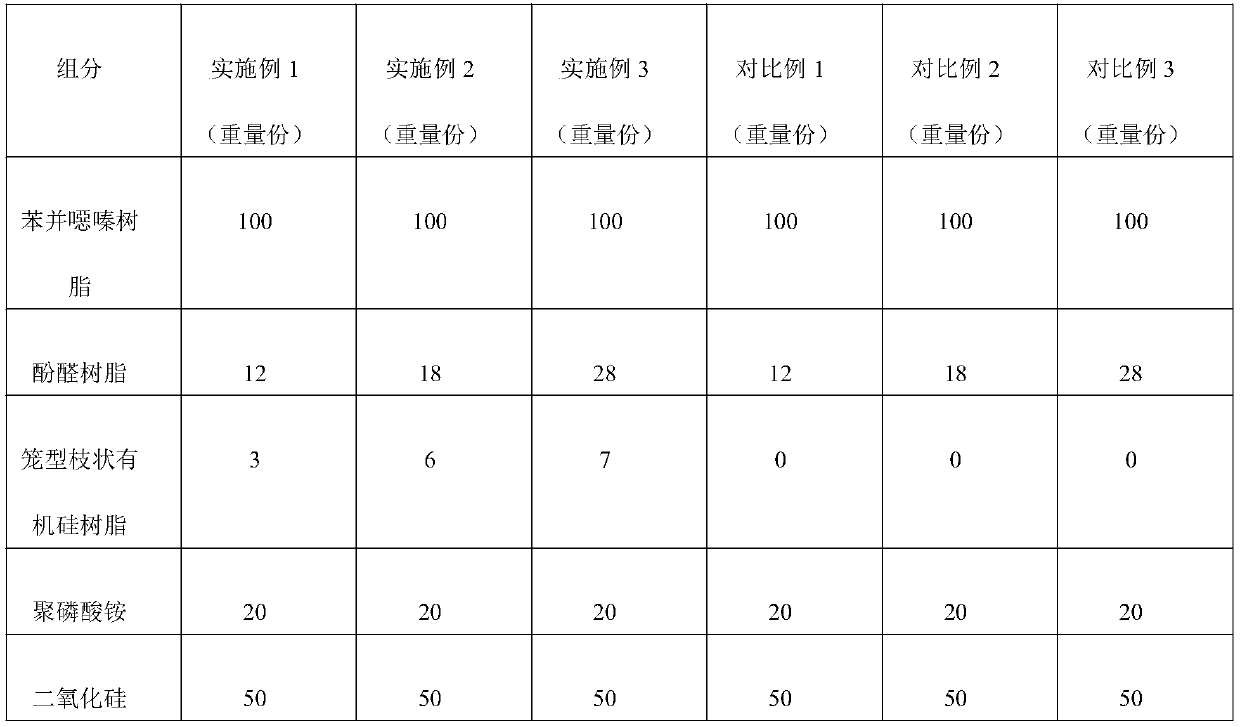

[0062] Mix benzoxazine resin, phenolic resin, cage-type dendritic silicone resin, flame retardant, and inorganic filler according to the mixing ratio shown in Table 1, and obtain a molded body of 80mm×80mm×1.5mm by hot pressing.

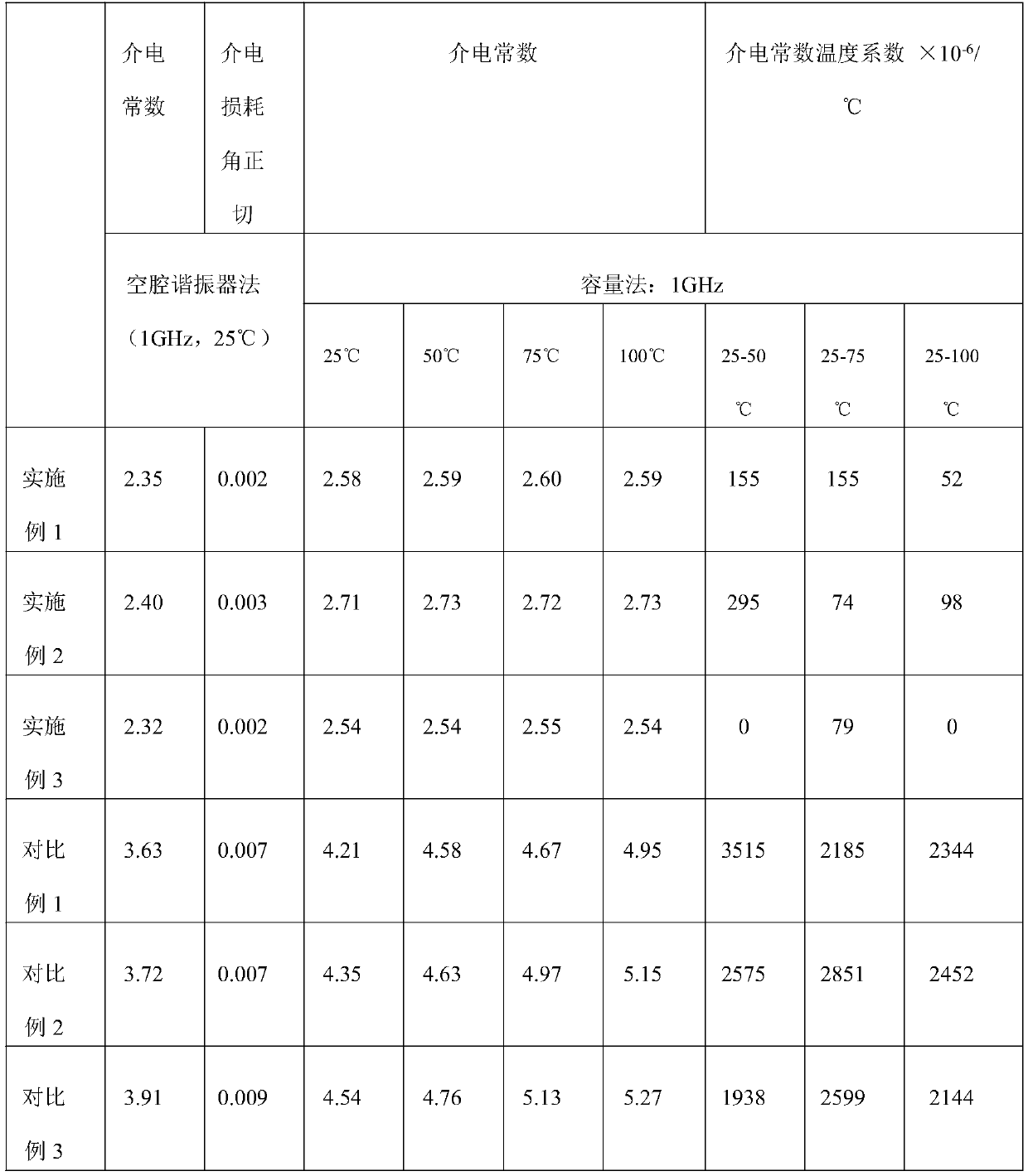

[0063] The dielectric constant and dielectric loss tangent of the molded body obtained were measured according to Test Method 1 above. In addition, the above-mentioned test method 2 was used to measure the dielectric constant at various temperatures, and the temperature coefficient of dielectric constant ɑ was obtained through conversion. The measurement results are shown in Table 2, respectively.

[0064] Table 1

[0065]

[0066] Table 2

[0067]

[0068] As can be seen from Table 2, compared with the benzoxazine resin composition without adding cage-type dendritic silicone resin, the dielectric constant and dielectric constant of the benzoxazine resin composition adding cage-type dendritic silicone resin The electrical loss tangent is low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com