Bismuth barium sodium niobate-based glass ceramic material with high energy storage density, and preparation method and application thereof

A bismuth barium sodium niobate-based technology with high energy storage density is applied in glass manufacturing equipment, glass forming, manufacturing tools, etc. high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of bismuth barium sodium niobate base glass-ceramic material with high energy storage density adopts the following steps:

[0036] (1) with BaCO 3 、 Bi 2 o 3 、Na 2 CO 3 , Nb 2 o 5 , SiO 2 As raw material, the molar ratio is 21.6BaCO 3 -2.4Bi 2 o 3 -6Na 2 CO 3 -30Nb 2 o 5 -40SiO 2 After the ingredients are mixed evenly, the temperature is controlled at 1450-1550°C and melted at a high temperature for 1-2 hours to obtain a high-temperature melted slurry;

[0037] (2) Pour the high-temperature melt prepared in step (1) into a mold preheated at 600-650°C to form and maintain the preheating temperature for 5-6 hours to remove the residual stress in the glass to prepare a transparent uniform glass, and slice it to obtain glass flakes;

[0038] (3) Perform controlled crystallization on the glass flakes prepared in step (3). During the controlled crystallization, the heating rate is controlled to be 3°C / min, the crystallization temperature...

Embodiment 1

[0041] The preparation method of bismuth barium sodium niobate base glass-ceramic material with high energy storage density adopts the following steps:

[0042] (1) BaCO with a purity greater than 99wt% 3 、 Bi 2 o 3 、Na 2 CO 3 , Nb 2 o 5 , SiO 2 For raw material batching, the molar percentage of each component is 21.6%, 2.4%, 6%, 30%, 40%, mixed by ball mill for 24 hours, dried at 100°C for 6 hours, and melted at 1550°C for 2 hours; (The above-mentioned ball mills all use absolute ethanol as the medium, and the ball-to-material ratio is 1.5:1).

[0043] (2) Pouring the high-temperature melt obtained in step (1) into a square metal mold, annealing for stress relief at 650° C. for 6 hours, and then cutting to obtain glass flakes with a thickness of 1.0 to 1.5 mm;

[0044] (3) Put an equal amount of the glass flakes prepared in step (2) into a crucible, heat up to 850° C. at a rate of 3° C. / min, and keep warm for 3 hours to obtain glass ceramics.

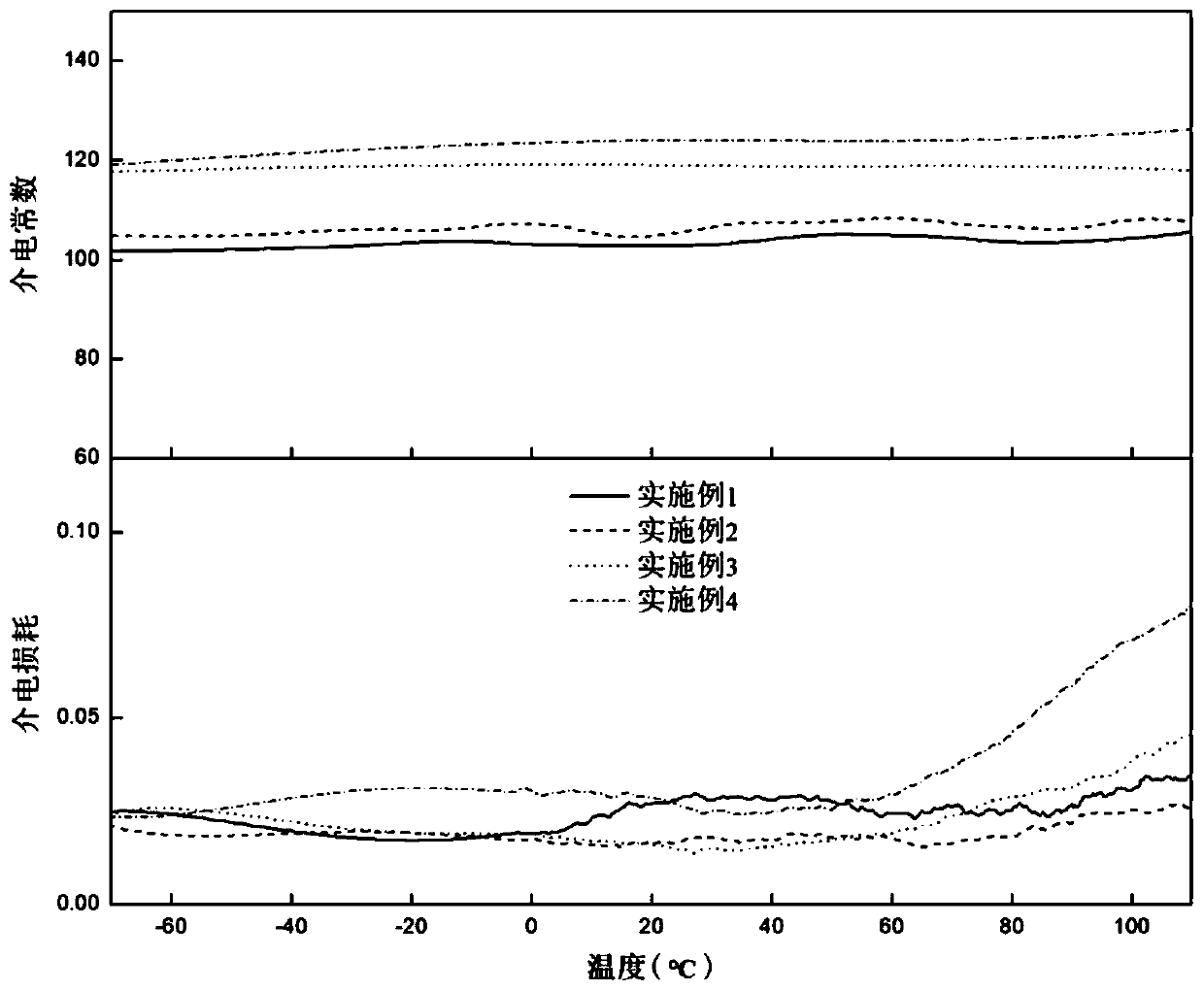

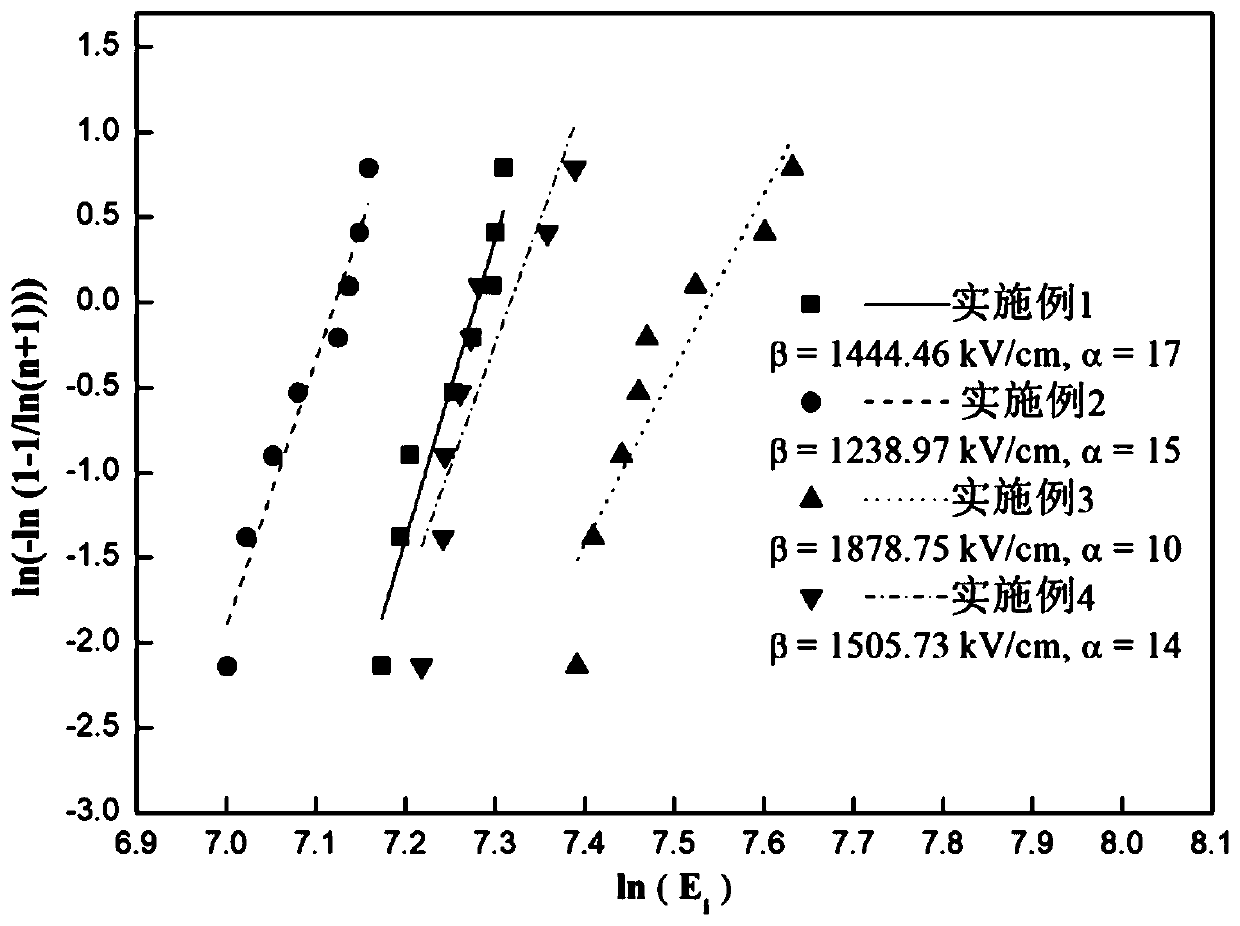

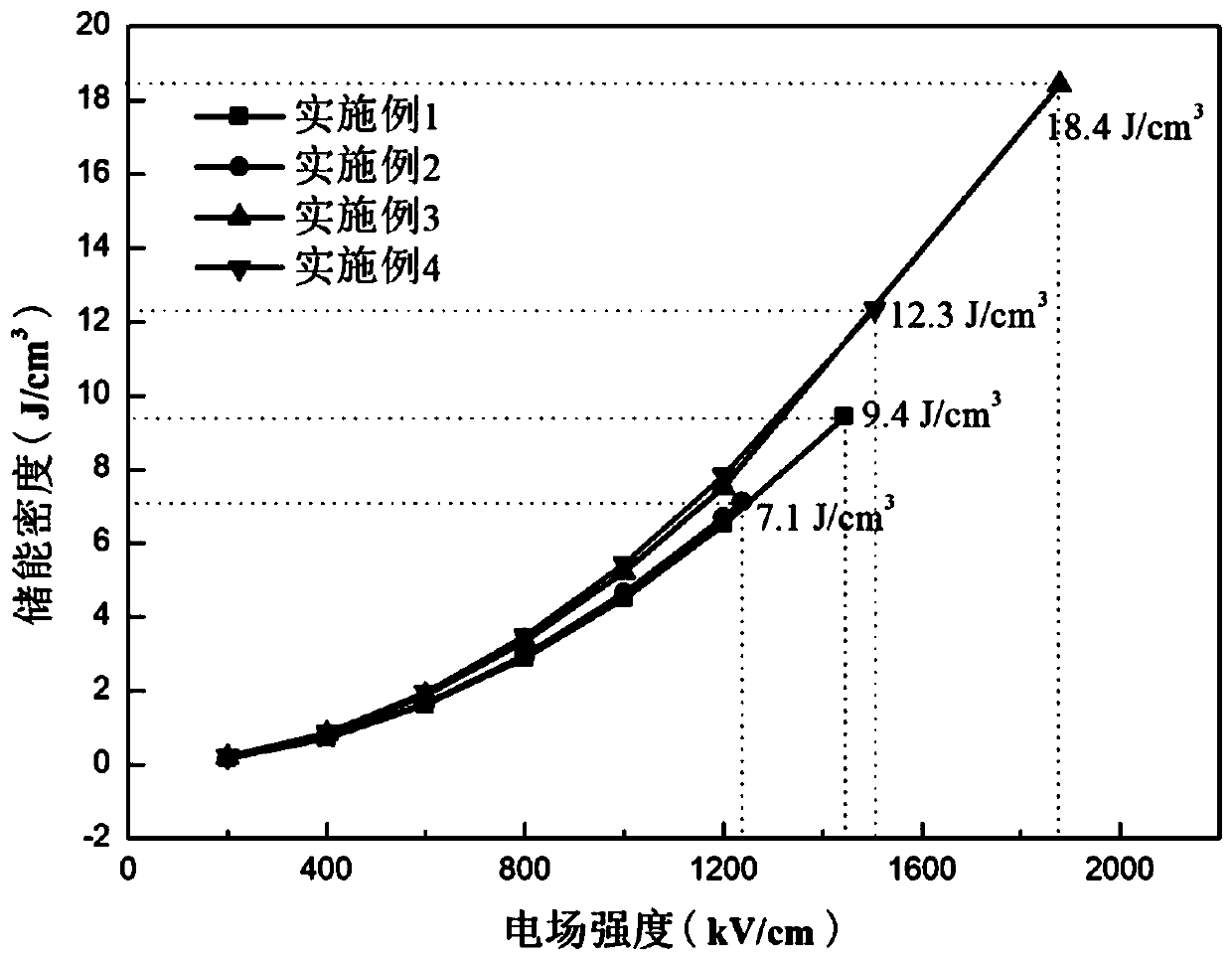

[0045] The dielectric ...

Embodiment 2

[0048] The preparation method of bismuth barium sodium niobate base glass-ceramic material with high energy storage density adopts the following steps:

[0049] (1) BaCO with a purity greater than 99wt% 3 、 Bi 2 o 3 、Na 2 CO 3 , Nb 2 o 5 , SiO 2 For raw material batching, the molar percentage of each component is 21.6%, 2.4%, 6%, 30%, 40%, mixed by ball mill for 24 hours, dried at 100°C for 6 hours, and melted at 1550°C for 2 hours; (The above-mentioned ball mills all use absolute ethanol as the medium, and the ball-to-material ratio is 1.5:1).

[0050] (2) Pouring the high-temperature melt obtained in step (1) into a square metal mold, annealing for stress relief at 650° C. for 6 hours, and then cutting to obtain glass flakes with a thickness of 1.0 to 1.5 mm;

[0051] (3) Put an equal number of glass flakes prepared in step (2) into a crucible, heat up to 900° C. at a rate of 3° C. / min, and keep warm for 3 hours to obtain glass ceramics.

[0052] The dielectric proper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com