Microwave ceramic dielectric filter and processing forming method thereof

A technology of dielectric filter and microwave ceramics, applied in the field of communication, can solve the problems of inconsistent dimensional shrinkage, uneven density of green body, complex shape, etc. in dry pressing, and achieve the effects of superior performance, excellent mechanical properties, and small sintering deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

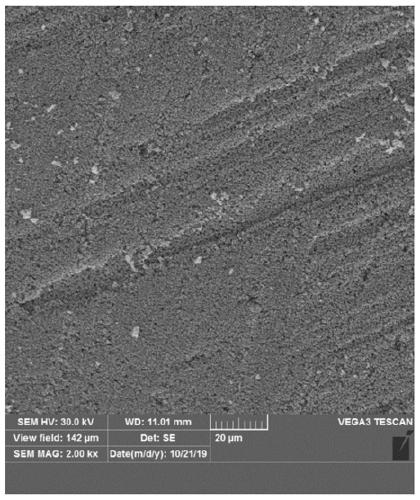

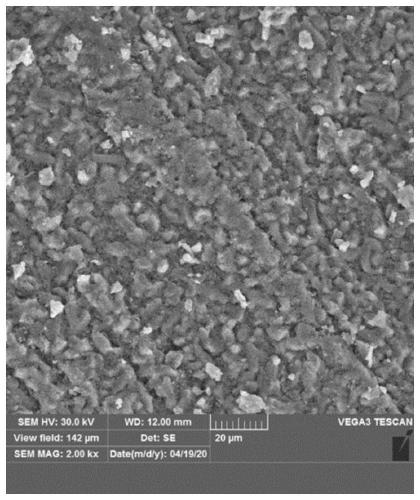

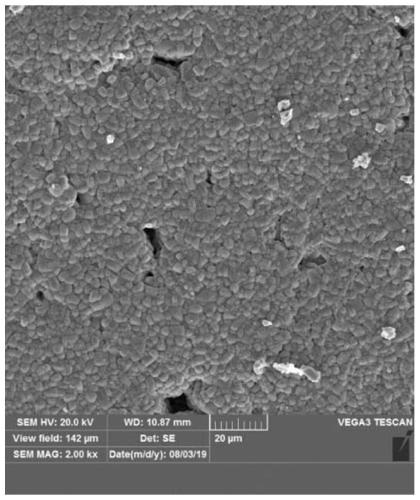

Image

Examples

Embodiment 1

[0059] A microwave ceramic dielectric filter, comprising a ceramic dielectric body and a metal layer attached to the surface of the ceramic dielectric body, the feeding material for preparing the ceramic dielectric body includes 24kg of microwave ceramic powder, 4.2kg of polyoxymethylene, 0.9kg of polypropylene, and 0.6kg of paraffin wax. kg, dioctyl phthalate 0.012kg, oleic acid 0.06kg, silicone oil 0.06kg;

[0060] Its preparation method is as follows:

[0061]Mixing and granulation steps: put the ceramic forming agent in the internal mixer to preheat and melt, the mixing temperature is 165°C, the speed is 5r / min, add microwave ceramic powder for kneading, the kneading temperature is 185°C, and the speed is 5r / min. 25r / min, knead and mix evenly to form a milky white mud mass, and then use a granulator to granulate to obtain microwave ceramic feed;

[0062] Injection molding steps: put the above-mentioned microwave ceramic feed into an injection molding machine, and inject a...

Embodiment 2

[0072] A microwave ceramic dielectric filter, comprising a ceramic dielectric body and a metal layer attached to the surface of the ceramic dielectric body, the feed material for preparing the ceramic dielectric body includes 24.6kg of microwave ceramic powder, 3.51kg of polyoxymethylene, and 1.08kg of low-density polyethylene , paraffin 0.54kg, dioctyl phthalate 0.108kg, oleic acid 0.081kg, sorbitan monostearate 0.054kg, polyamide 0.027kg;

[0073] Its preparation method is as follows:

[0074] Microwave ceramic powder pretreatment: dry the microwave ceramic powder at 500°C for 2 hours, and keep it warm at 150°C;

[0075] Mixing and banburying granulation steps: After mixing the ceramic forming agent and microwave ceramic powder evenly, put it in the internal mixer for preheating and melting. The preheating temperature is 165°C and the speed is 5r / min. Kneading, the kneading temperature is 180°C, the speed is 25r / min, kneading and mixing evenly to form a milky white muddy ma...

Embodiment 3

[0082] A microwave ceramic dielectric filter, comprising a ceramic dielectric body and a metal layer attached to the surface of the ceramic dielectric body, the feed material for preparing the ceramic dielectric body includes 24kg of microwave ceramic powder, 4.2kg of polyaldehyde base, 0.9kg of polypropylene, paraffin wax 0.6kg, dioctyl phthalate 0.012kg, oleic acid 0.06kg, silicone oil 0.06kg;

[0083] Its preparation method is as follows:

[0084] Mixing and granulation steps: put the ceramic forming agent in the internal mixer to preheat and melt, the mixing temperature is 165°C, the speed is 5r / min, add microwave ceramic powder for kneading, the kneading temperature is 185°C, and the speed is 5r / min. 25r / min, knead and mix evenly to form a milky white mud mass, and then use a granulator to granulate to obtain microwave ceramic feed;

[0085] Injection molding steps: put the above-mentioned microwave ceramic feed into an injection molding machine, and inject and mold a ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com