Wafer-level low-temperature packaging method based on gold-tin alloy bonding

An encapsulation method and tin alloy technology, which are applied in the process of producing decorative surface effects, decorative arts, microstructure devices, etc., can solve the problems of high cost, complex process, incompatibility, etc., and achieve reliable industrialization and commercialization , The process is simple to implement, and the effect of reducing the total thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below by taking the bonding of Si cover sheet and Si back sheet as an example and referring to the accompanying drawings.

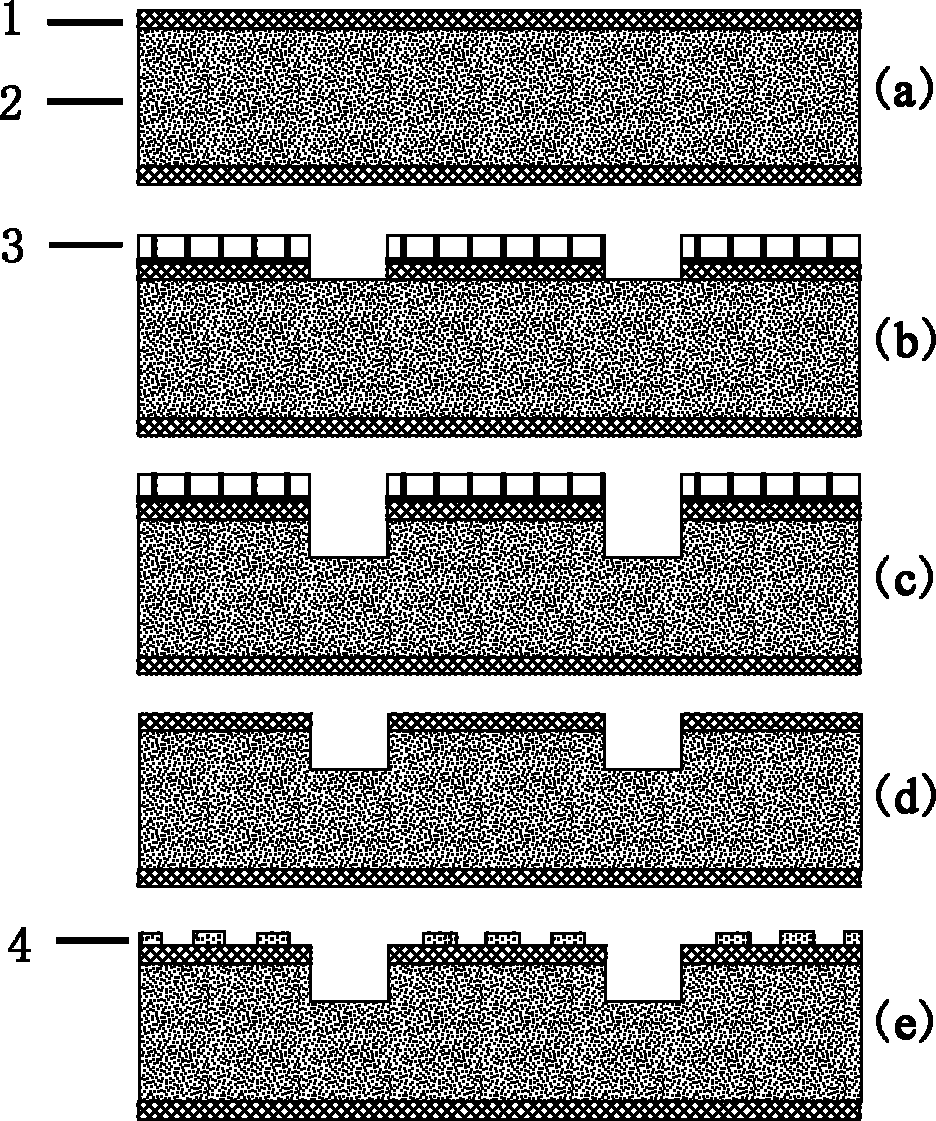

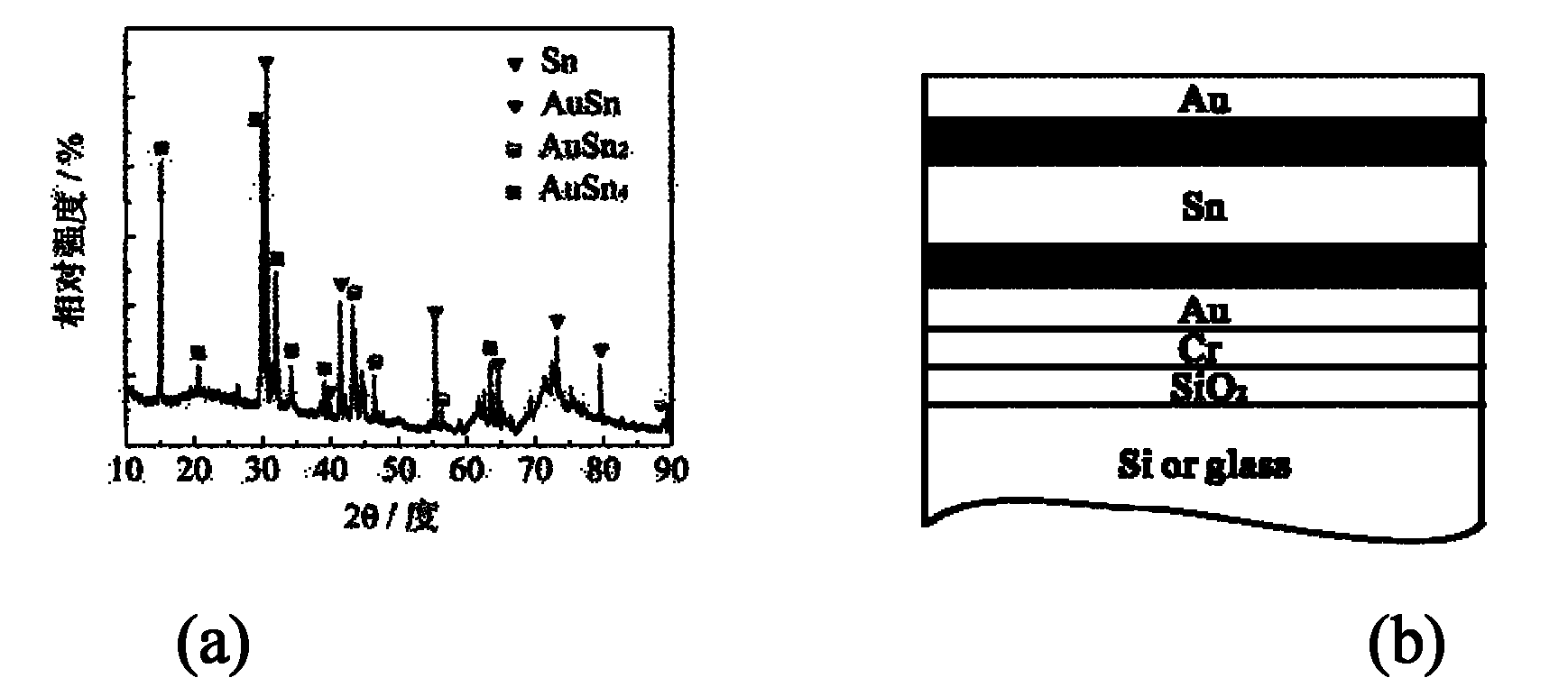

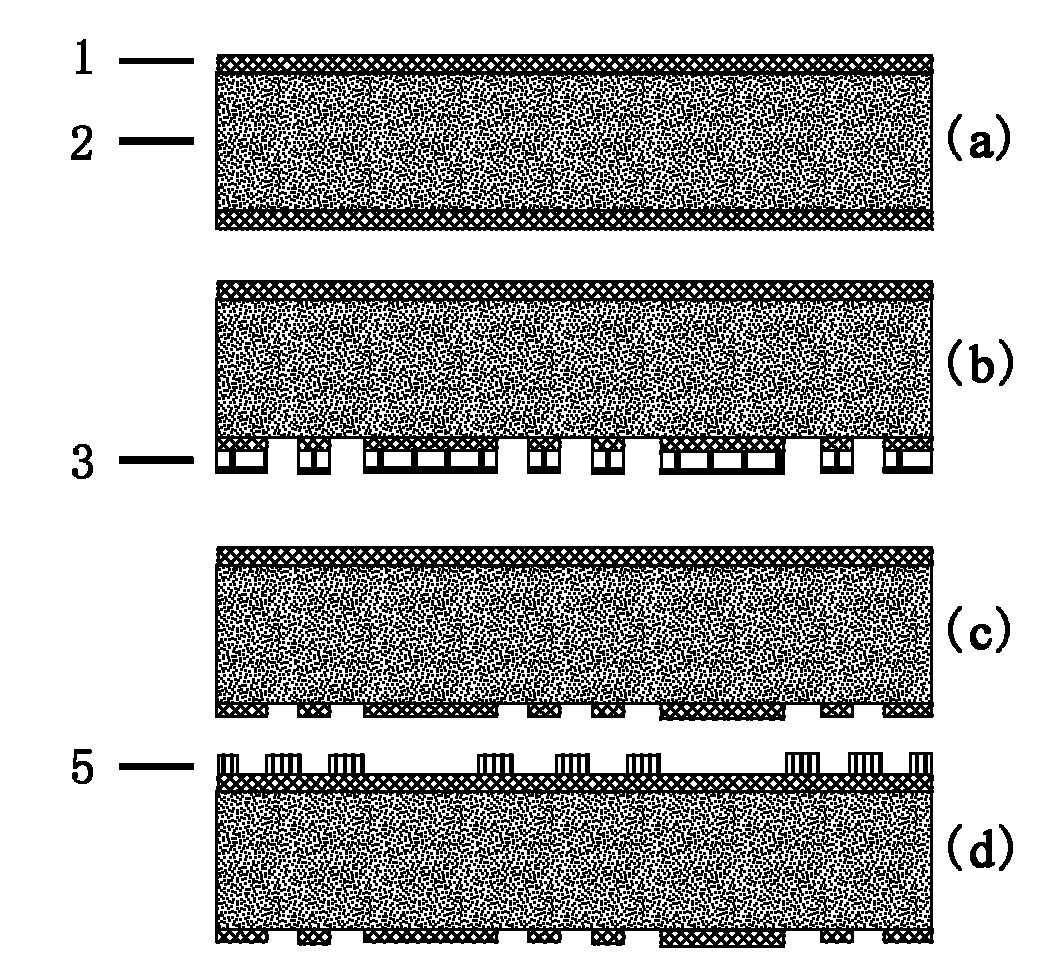

[0048] The invention provides a wafer-level low-temperature packaging method based on Au-Sn alloy bonding. The method includes: selecting a substrate as a cover sheet and a bottom sheet; performing photolithography on the front of the cover sheet for the first time, through etching and Etching creates a cavity as a placement space for the packaged device or structure; performs a second photolithography on the front of the cover sheet; evaporates a multilayer metal film of Cr / Au / Sn / Au according to the designed weight percentage of Au and Sn; Peel off the multi-layer metal film to make the metal bonding structure on the cover sheet; carry out the first photolithography on the back of the negative, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com