Preparation method of high-temperature-resistant and impact-resistant UPVC pipe fitting

A technology of impact resistance and high temperature resistance, which is applied in the production field of UPVC pipe fittings. It can solve the problems of low temperature resistance, impact strength, inability to fix automatically, poor fixing effect, etc., and achieve the goal of prolonging service life, clamping firmly and ensuring life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method for high-temperature-resistant and impact-resistant UPVC pipe fittings, comprising the following steps:

[0035] Step 1: In parts by weight, weigh 100 parts of polyvinyl chloride resin, 0.1 part of heat stabilizer, 1 part of toughening agent, 10 parts of metal hydroxide flame retardant, 1 part of metal compound flame retardant synergist, process 0.5 parts of additives, 1.1 parts of lubricants, 0.01 parts of antioxidants, 0.03 parts of colorants, and 0.1 parts of ultraviolet absorbers, and the above-mentioned raw materials in parts by weight are mixed in a high-mixer to prepare a high-mixture;

[0036] Step 2: Add the above-mentioned high-mixture into a twin-screw extruder, and after extrusion, it is vacuum-shaped and cooled to form a semi-finished pipe fitting;

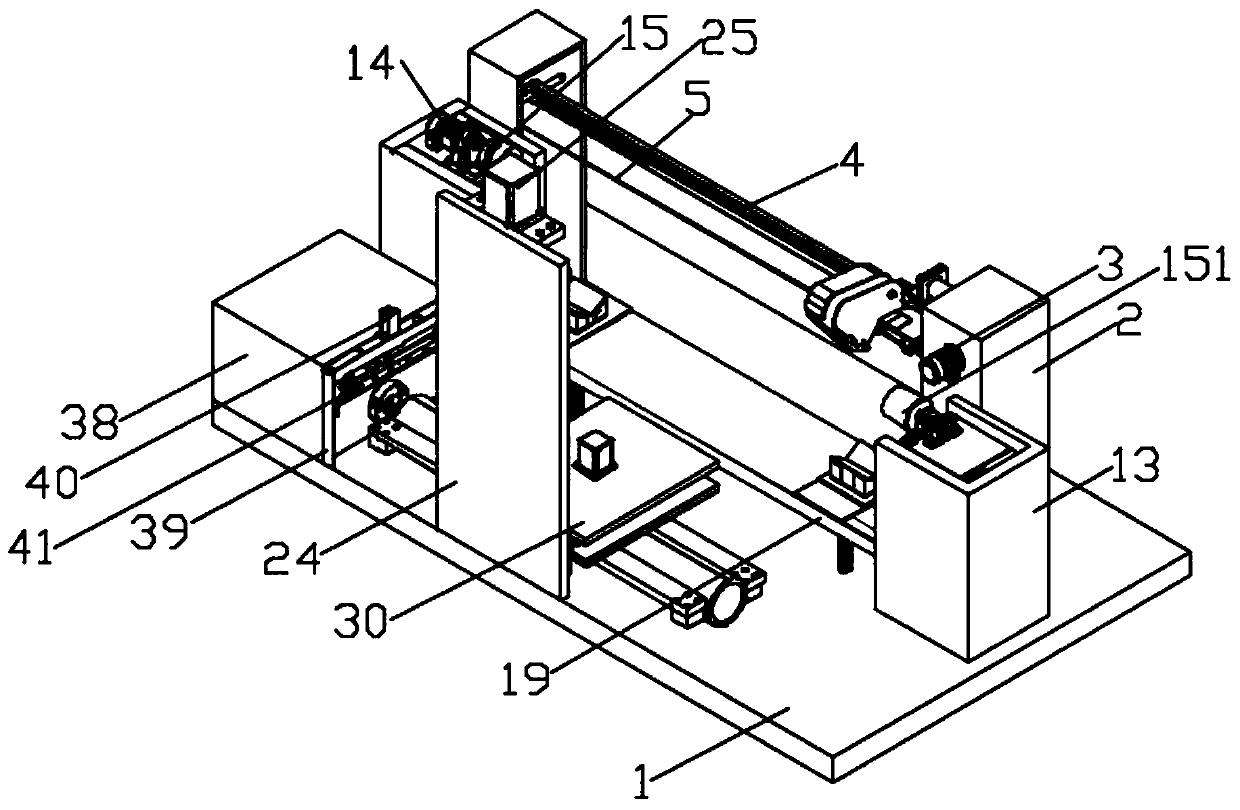

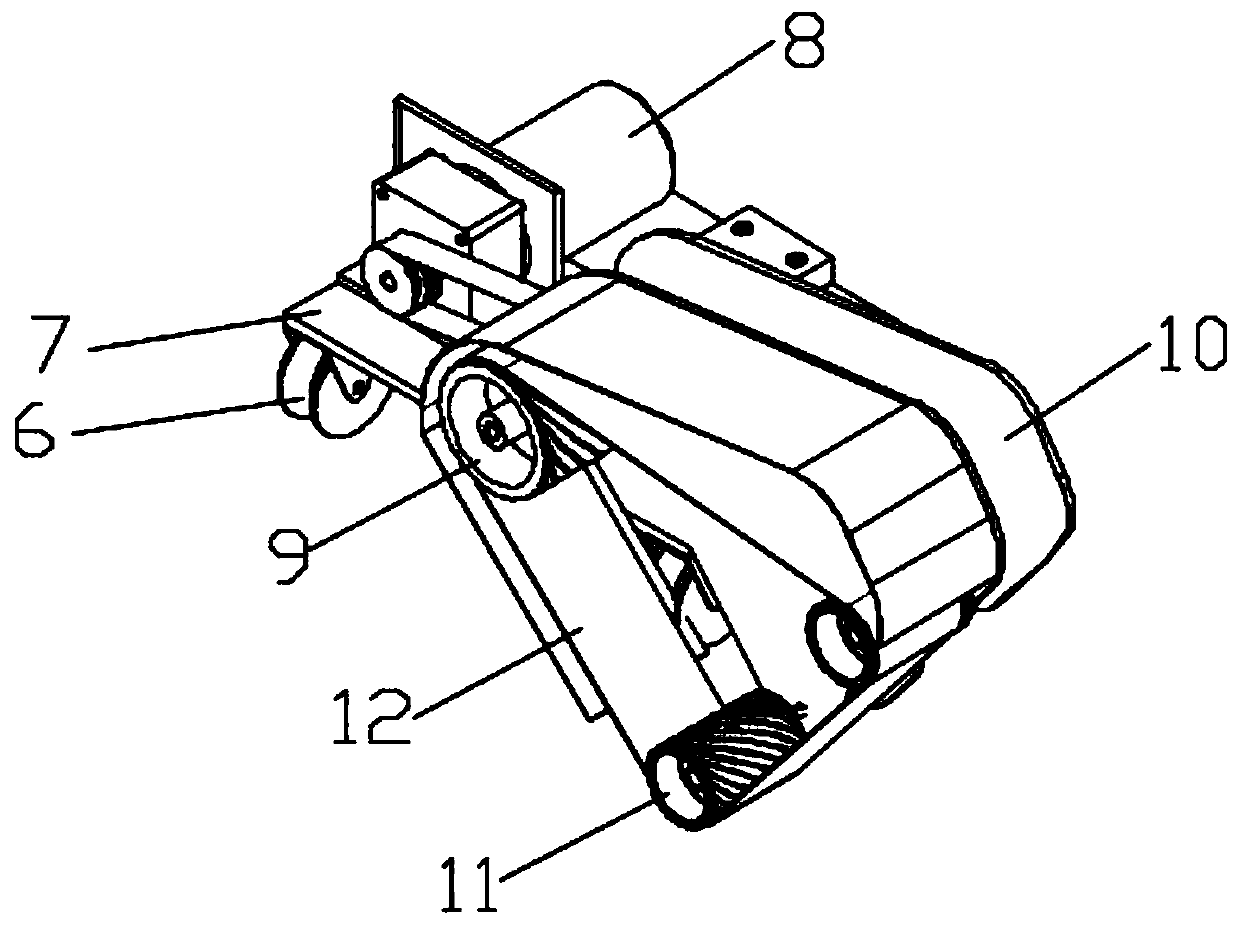

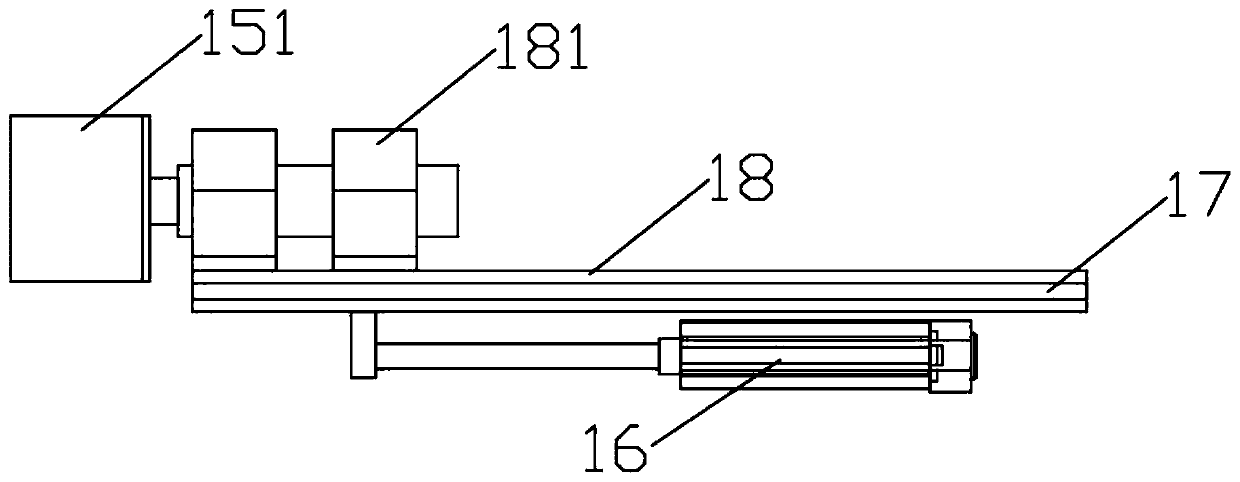

[0037] Step 3: put the above-mentioned semi-finished pipe fittings into the traction box 38 of the grinding equipment on one side of the traction opening 381, the output shaft of the sixth ...

Embodiment 2

[0041] Step 1: In parts by weight, weigh 150 parts of polyvinyl chloride resin, 10 parts of heat stabilizer, 20 parts of toughening agent, 80 parts of metal hydroxide flame retardant, 20 parts of metal compound flame retardant synergist, process 3.0 parts of auxiliary agent, 5 parts of lubricant, 5 parts of antioxidant, 5 parts of colorant, 5 parts of ultraviolet absorber, and the above-mentioned raw materials in parts by weight are put into a high-mixer and mixed to prepare a high-mixture; step 2, Three all are identical with embodiment 1;

[0042] Specifically, the metal hydroxide flame retardant is aluminum hydroxide. The metal compound flame retardant synergist is magnesium oxide. The toughening agent is nitrile rubber; the processing aid is maleic acid-acrylic acid copolymer. The heat stabilizer is calcium zinc stabilizer. The lubricant is oxidized polyethylene wax. The antioxidant is antioxidant lU1U; the ultraviolet absorber is propyl salicylate. In step 1, the rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com