Cotton-feeding cubing-roll device of cover plate type carding machine

A technology of carding machine and licker-in roller, which is applied in deburring devices, fiber treatment, textiles and papermaking, etc. It can solve the problems of difficulty in controlling the blending ratio of hemp fiber, affecting the uniformity of strips, and reducing the utilization rate of hemp fiber. Achieve the effect of stable blending ratio, reducing trash burden and good yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

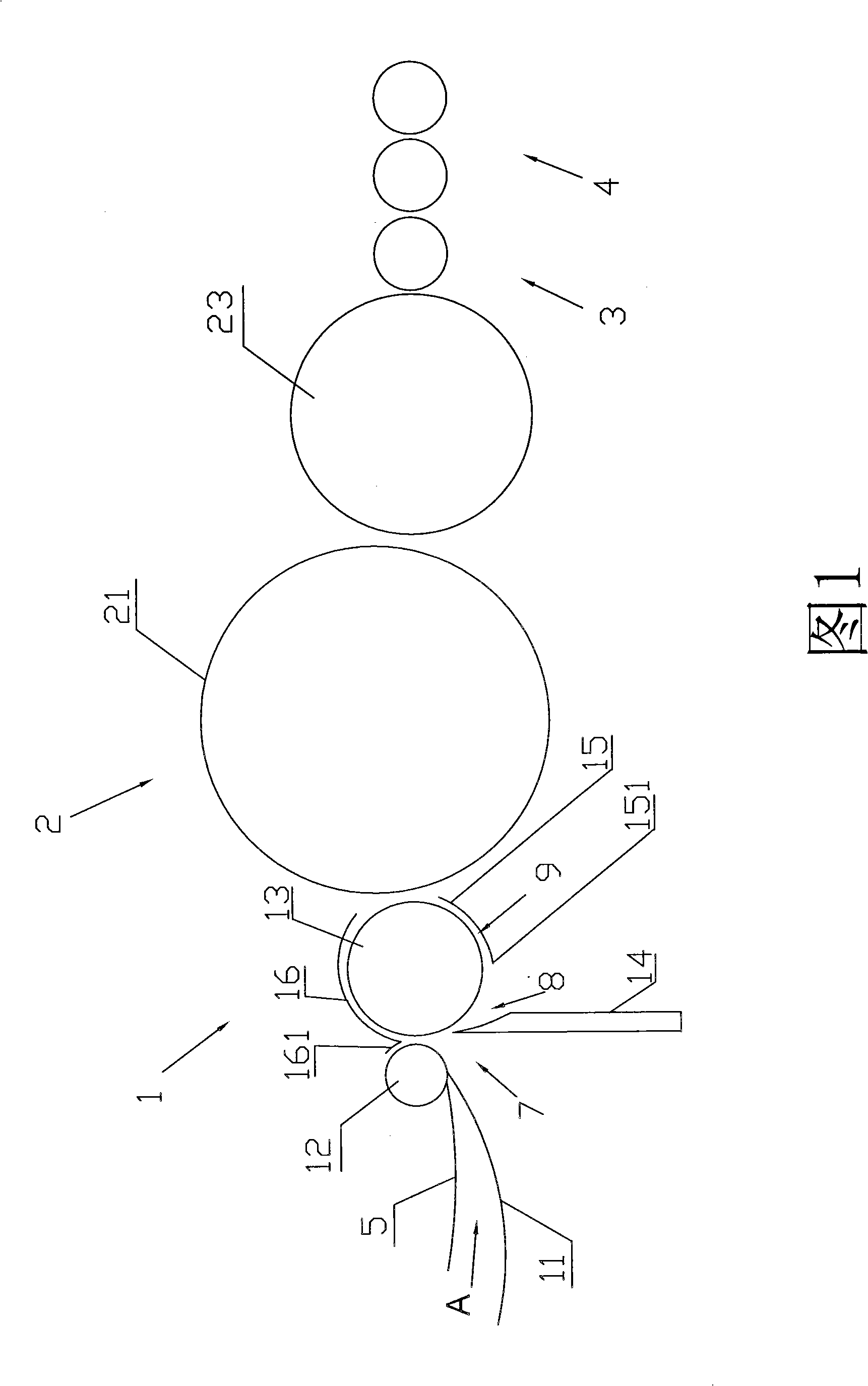

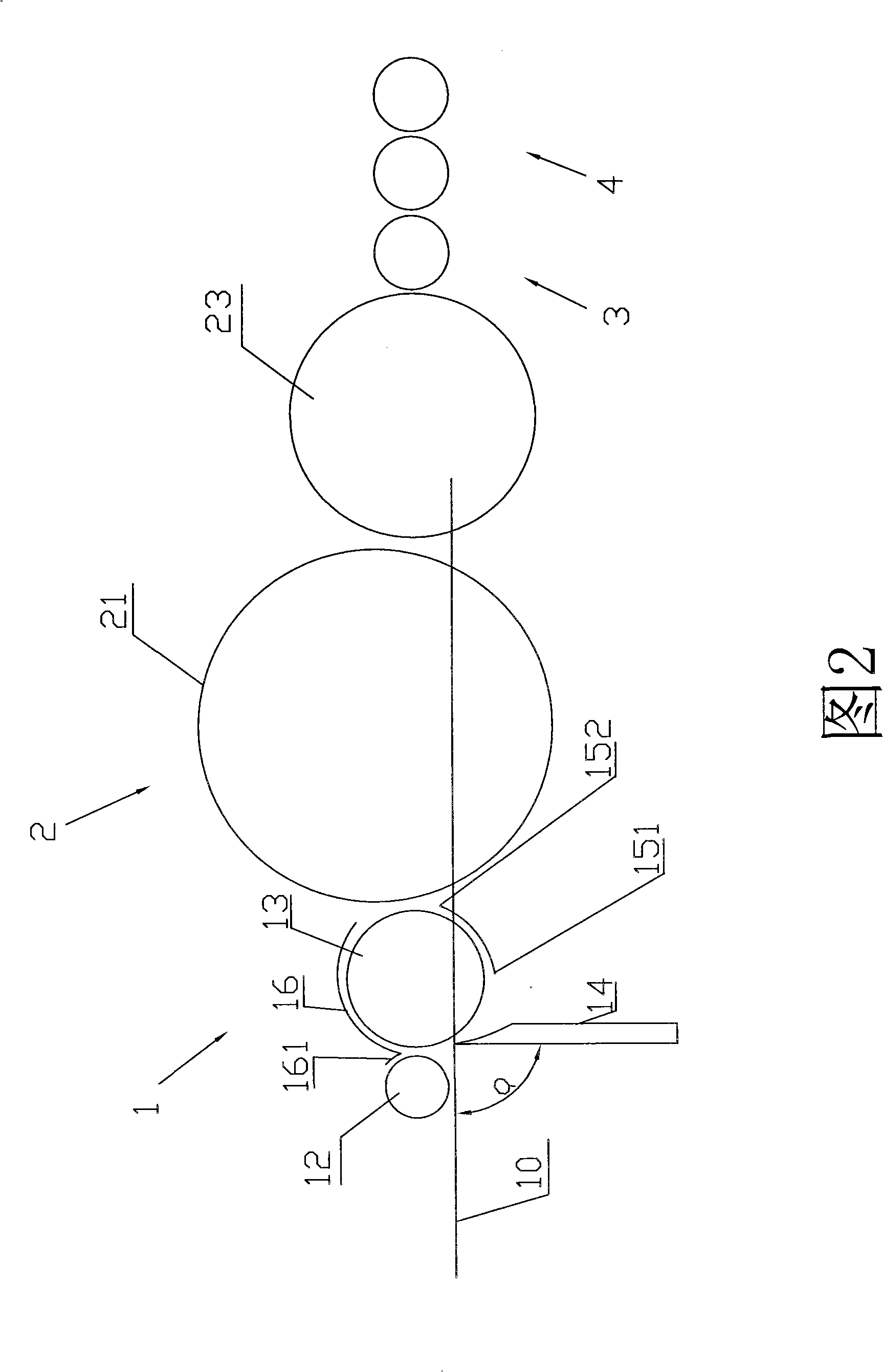

[0021] As shown in Fig. 1 and Fig. 2, the cover plate type carding machine that is used for hemp fiber carding comprises the hemp licker-in roller device 1, the carding device 2 that are arranged successively according to the direction of motion of hemp fiber 5 (arrow A direction in Fig. 2) , stripping device 3 and slivering device 4, described licker-in roller device 1 for hemp comprises fiber feed plate 11, roller 12, licker-in roller 13, and described fiber feed plate 11 is arranged on described roller 12 below, and described The licker-in roller 13 is arranged on one side of the roller 12, the licker-in roller cover plate 16 is arranged above the licker-in roller 13, and the dust removal knife 14 and the small drain bottom 15 are arranged below, and the dust removal knife 14 is arranged near the roller 12. side. The carding device 2 includes a cylinder 21, a doffer 23, etc., the stripping device 3 includes a stripping roller, a transfer roller, a pair of light rollers, an ...

Embodiment 2

[0025] The cotton-feeding licker-in roller device of the flat carding machine used for hemp fiber carding of the present embodiment is basically the same as that in Embodiment 1, and its difference is that: the inclination angle of the dust removal knife 14 is 90 °, and the dust removal knife The distance between 14 and the said licker-in roller 13 is 1.2mm; the enveloping angle a of the small drain bottom 15 is 130° (chord length d is 235mm); The distance between the rollers 13 is 10 mm, and the distance between the outlet end 152 and the licker-in roller 13 is 1.6 mm.

[0026] Of course, in other embodiments, the inclination angle of the dust removal knife 14 can also be 92°, and the distance between the dust removal knife 14 and the licker-in roller 13 can be 1.5 mm; The angle a can be 109° (the corresponding chord length d is 210mm), or 140° (the corresponding chord length d is 250mm) or 125° (the corresponding chord length d is 230mm) or between 109°-140° (corresponding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com