Fiber combining clamp for multi-channel optical fiber splitter

A multi-channel optical fiber and splitter technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of low fault tolerance, increased workload, and fiber prolapse, and achieve the goal of simplifying the operation process and increasing the fault tolerance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

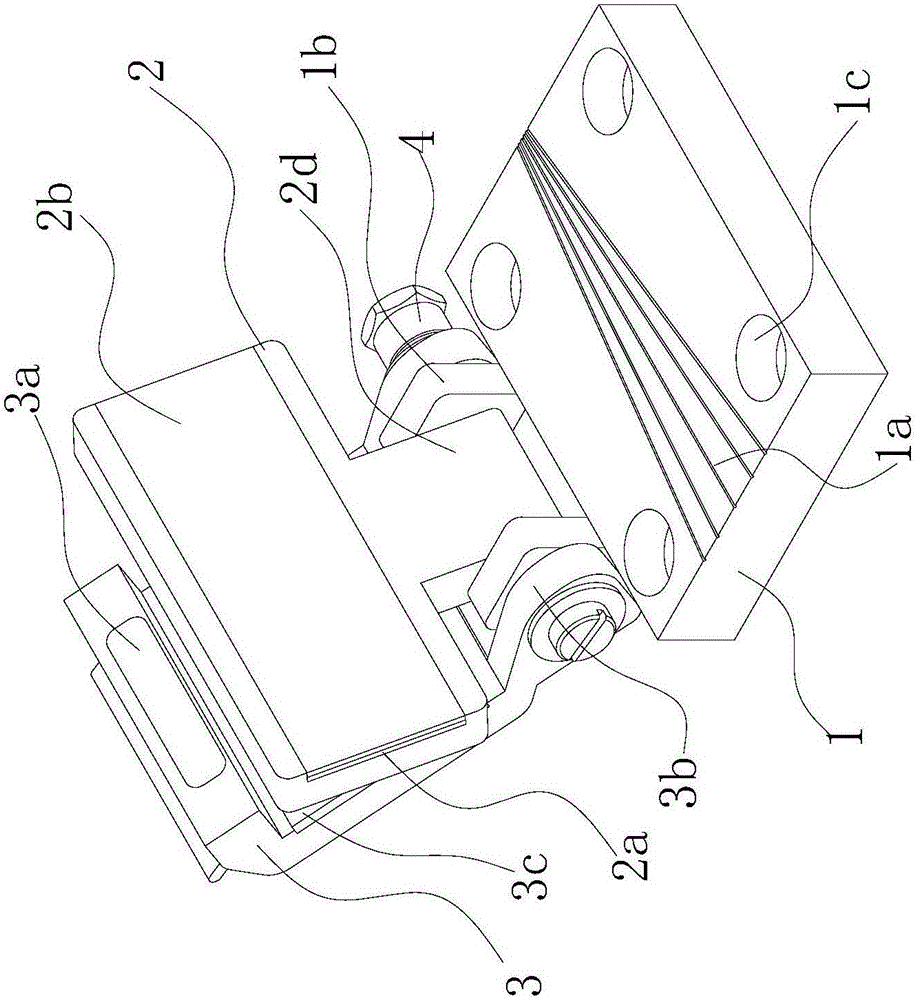

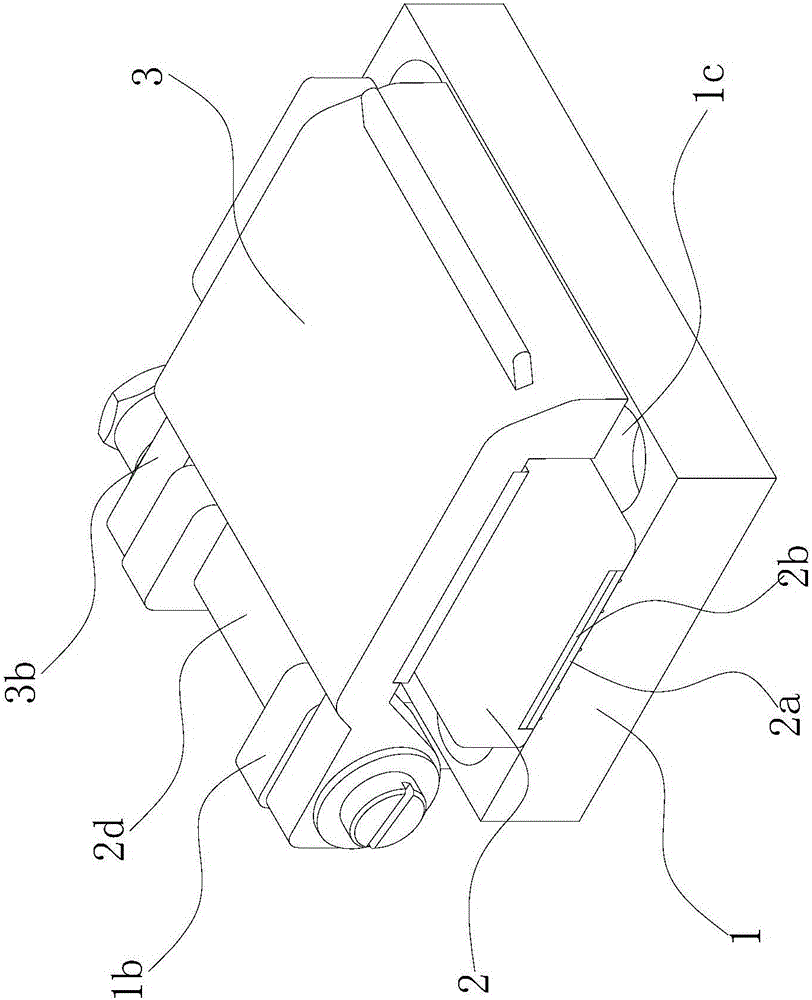

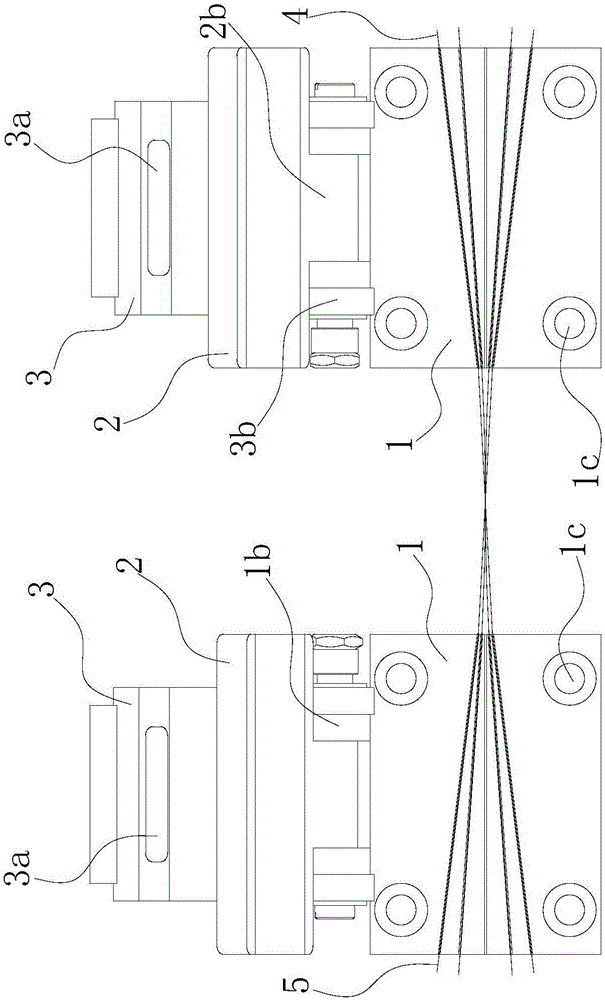

[0015] A parallel fiber fixture for multi-channel fiber splitters, such as figure 1 — image 3 As shown, it includes a metal base 1, a middle laminated fiberboard 2 and an upper laminate 3. Five optical fiber accommodation grooves 1a distributed in a radial shape and having a semicircular cross-section are evenly distributed on the upper surface of the metal base 1. The rear side of the metal base 1 has two A vertically upward ear plate 1b, pin holes are arranged on the ear plate 1b, and there are four mounting holes 1c on the four corners of the metal base 1, and the mounting holes 1c are used to fix the metal base 1 on the tapering machine;

[0016] There is a protrusion 2d in the middle on the rear side of the middle fiber laminate 2, and there is also a pin hole on the protrusion 2d. There is an inverted U-shaped groove at the bottom of the middle fiber laminate 2, and the groove can cover all the optical fiber receiving grooves 1a. There is a flexible magnet 2a in the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com