Gum dipping glove and manufacturing process thereof

A technology for making crafts and gloves, which is applied to gloves, other household appliances, household components, etc. It can solve problems such as cumbersome operation steps, and achieve the effects of reducing the use of materials, improving efficiency, and reducing time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

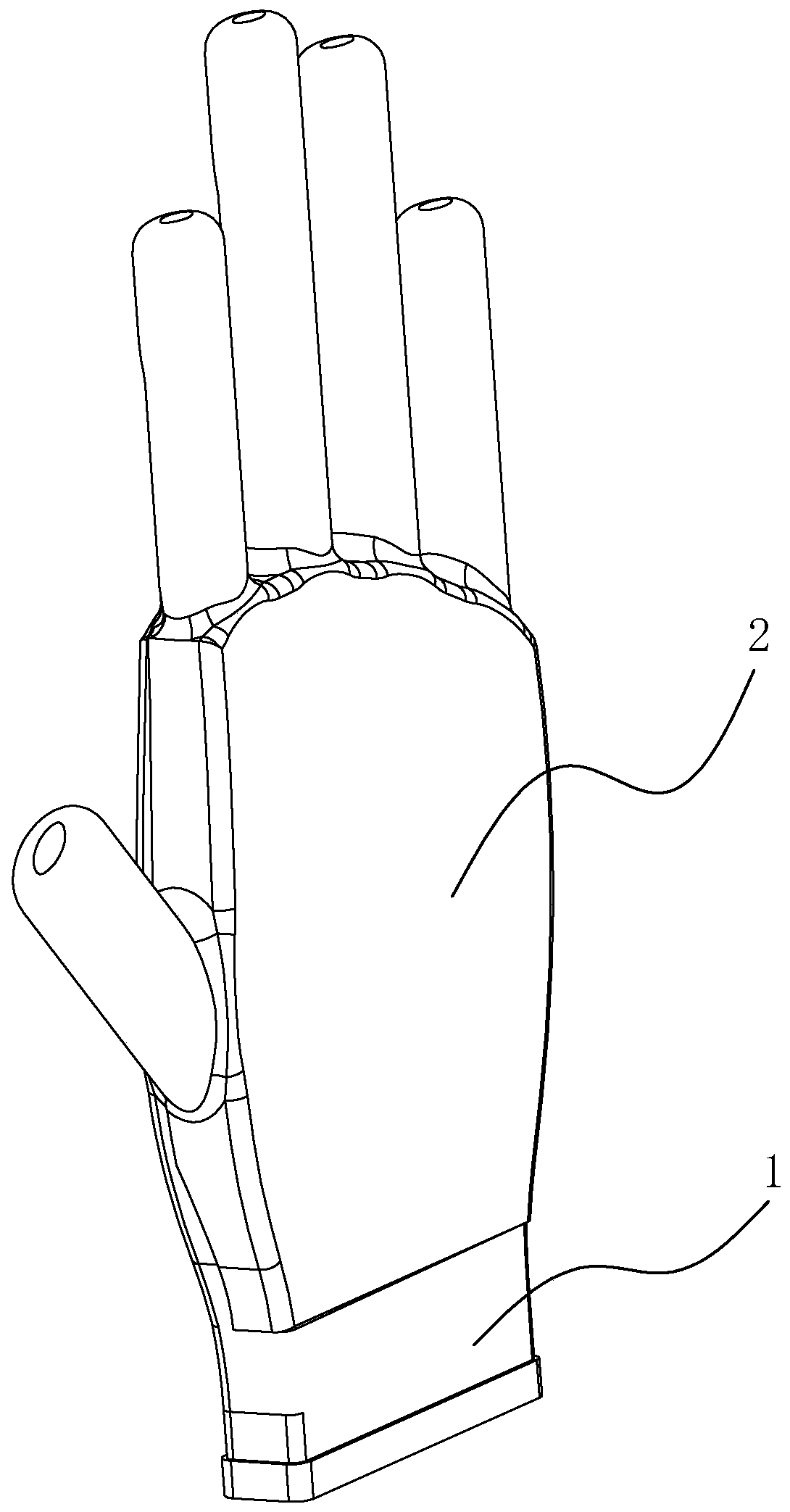

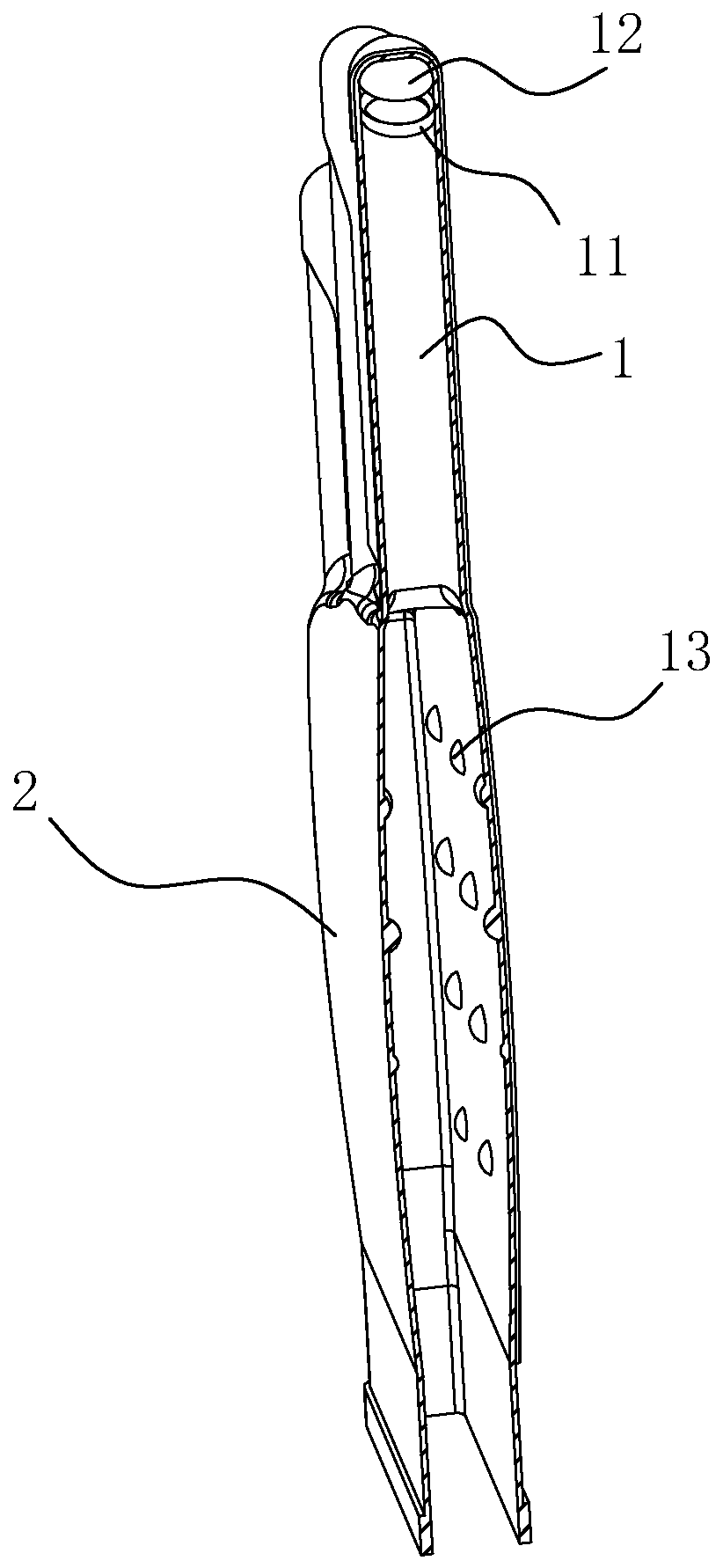

[0042] A kind of dipped glove, refer to figure 1 and figure 2 , which includes a glove core 1 and an adhesive part 2 located in the palm of the glove core 1 and fingers. The glove core 1 is preferably woven from polyester, and the rubber part 2 is adhered to the glove core 1 through a dipping process; the glove core 1 is located on several fingers. The end of the glove is sewn with an elastic ring 11, which is located on the side of the glove core 1 away from the rubber part 2. The elastic ring 11 is preferably a rubber band. Through the stretching elasticity of the elastic ring 11, the user's fingers can It can be inserted into the glove core 1 more stably.

[0043] refer to figure 1 and figure 2 The top of the glove core 1 finger is glued with a protective pad 12, the protective pad 12 is preferably made of silica gel, the protective pad 12 can be attached to the fingertips, and the fingernails of the user are easy to rub the top of the glove core 1 finger part for a lo...

Embodiment 2

[0047] A manufacturing process of rubber-dipped gloves, comprising the steps of:

[0048] S1, preheating: the glove mold is preheated to 35°C through an oven;

[0049] S2. Cover film: manually set one set of glove core on the glove mold;

[0050] S3, cooling: wait for the surface temperature of the glove core 1 to cool down to 30°C, and the cooling time for cooling is 2min;

[0051]S4. Dipping: Put the palm of the glove core 1 towards the dipping tank, which contains nitrile rubber, and make the fingers of the glove core 1 tilt towards the dipping tank by 30°, and the glove core 1 enters the dipping tank, so that the palm of the glove core 1 and the dipping tank The finger part is soaked by the glue, and the soaking time is 5S; the speed of the running chain of the glove mold is controlled by a transmission to 0.5m / min;

[0052] S5. Hanging drop: the glove core 1 after dipping is placed above the hanging drop tank for hanging drop;

[0053] S6. Heating: Send the glove core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com