Method for improving coulombic efficiency and cycling stability of lithium-rich positive electrode material

A lithium-rich cathode material and cycle stability technology, applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of capacity and magnification reduction, small effect, low initial Coulombic efficiency, etc., to improve cycle stability, Easy to operate and increase the effect of reversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

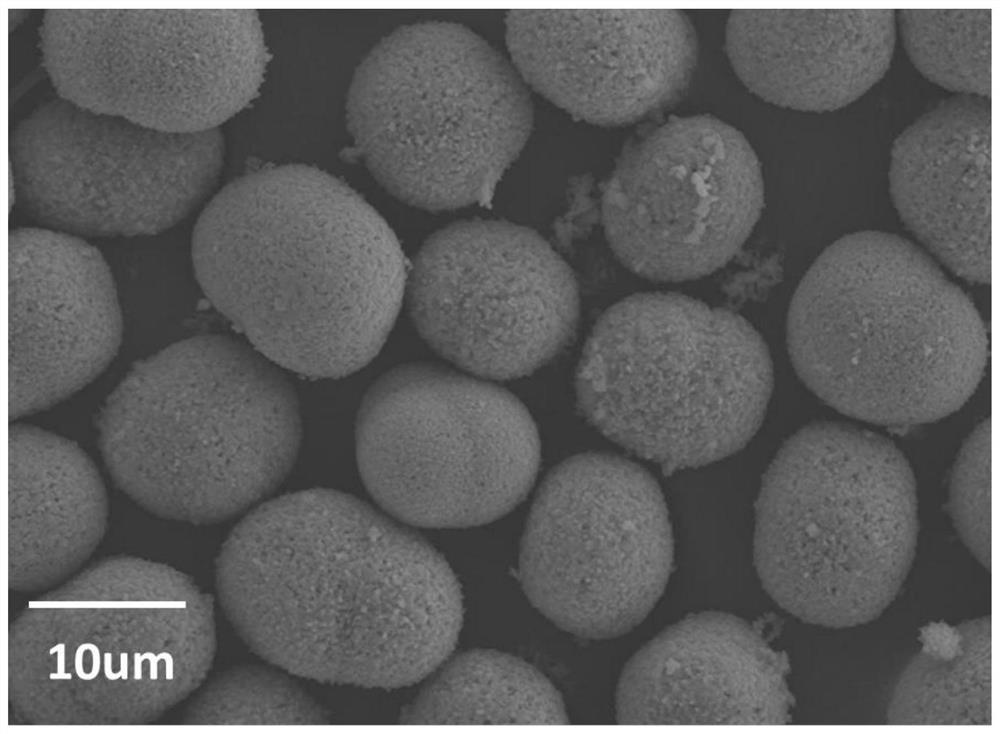

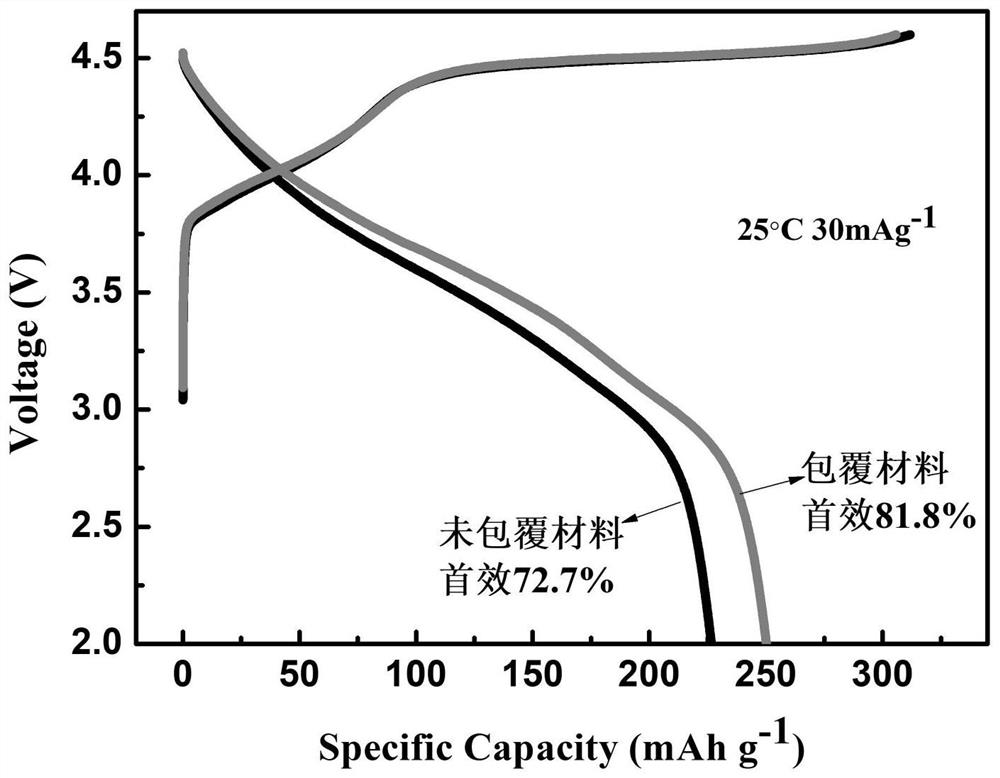

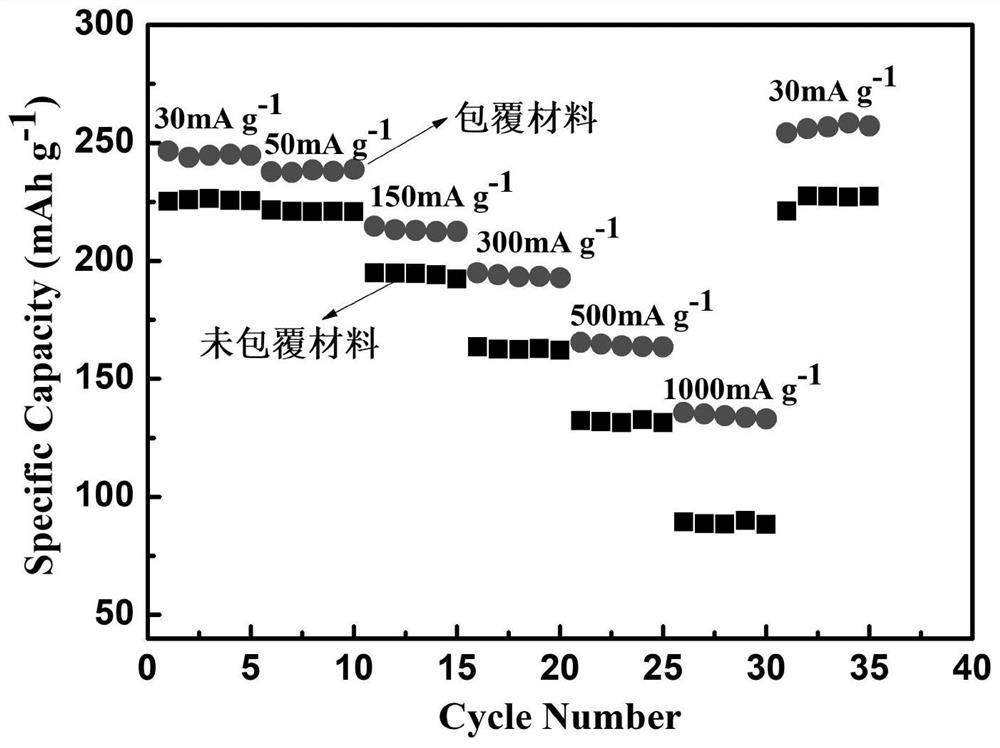

[0045] A kind of adopting dry method to mix promote lithium-rich manganese-based cathode material (chemical formula is 0.5Li 2 MnO 3 0.5LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 ) the method for coulombic efficiency and cycle stability, specifically comprises the following steps:

[0046] S1 Place the lithium-rich manganese-based positive electrode material and the lithium-intercalable organic compound in a stirring device and mix for 5 minutes;

[0047] S2 Add an organic solvent to the stirring device, and continue stirring for 30 minutes to obtain a mixture A, wherein the mass of the organic solvent is 1% of the total mass of the lithium-rich manganese-based positive electrode material and the lithium-intercalable organic compound;

[0048] S3 vacuum-heating the stirring equipment equipped with the mixture A, and continuing to stir until the organic solvent is completely volatilized, and sieved to obtain a lithium-rich manganese-based positive electrode material capable of coating a...

Embodiment 6-10

[0054] A kind of adopting dry method to mix promotes lithium-rich manganese-based cathode material (chemical formula is Li 1.4 mn 0.61 Ni 0.18 co 0.18 Al 0.0 3 o 2.4 ) the method for coulombic efficiency and cycle stability, specifically comprises the following steps:

[0055] S1 Put the lithium-rich manganese-based positive electrode material and the lithium-intercalable organic compound in a stirring device and mix for 30 minutes;

[0056] S2 Add an organic solvent to the stirring device, and continue stirring for 120 minutes to obtain a mixture A, wherein the mass of the organic solvent is 30% of the total mass of the lithium-rich manganese-based positive electrode material and the lithium-intercalable organic compound;

[0057] S3 vacuum-heating the stirring equipment equipped with the mixture A, and continuing to stir until the organic solvent is completely volatilized, and sieved to obtain a lithium-rich manganese-based positive electrode material capable of coatin...

Embodiment 11-15

[0063] A kind of adopting dry method to mix promotes lithium-rich manganese-based cathode material (chemical formula is Li 1.2 mn 0.56 Ni 0.16 co 0.08 o 2 ) the method for coulombic efficiency and cycle stability, specifically comprises the following steps:

[0064] S1 Place the lithium-rich manganese-based positive electrode material and the lithium-intercalable organic compound in a stirring device and mix for 10 minutes;

[0065] S2 Add an organic solvent to the stirring device, and continue stirring for 80 minutes to obtain a mixture A, wherein the mass of the organic solvent is 10% of the total mass of the lithium-rich manganese-based positive electrode material and the lithium-intercalable organic compound;

[0066] S3 vacuum-heating the stirring equipment equipped with the mixture A, and continuing to stir until the organic solvent is completely volatilized, and sieved to obtain a lithium-rich manganese-based positive electrode material capable of coating and modify...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com