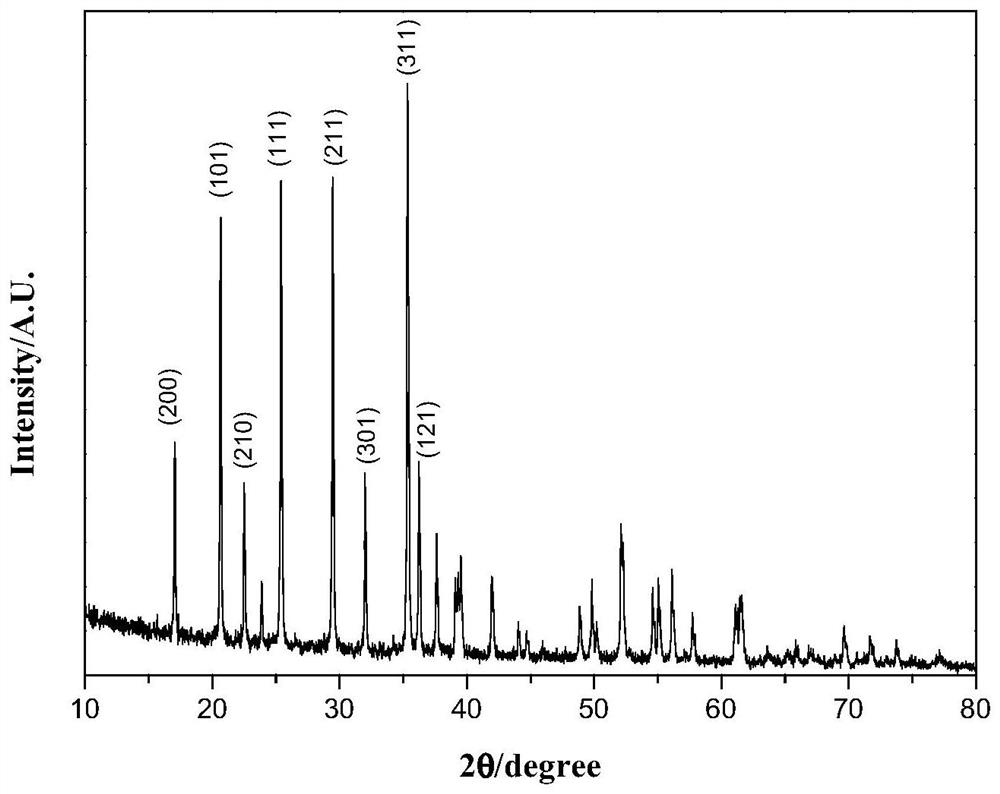

Preparation method of high-compaction-density lithium manganese iron phosphate/carbon composite positive electrode material

A technology of lithium iron manganese phosphate, positive electrode material, applied in nanotechnology, positive electrode, phosphorus compound and other directions for materials and surface science, can solve the problem of material compaction density not improving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Concrete preparation method comprises the following steps:

[0036] 1) Dilute phosphoric acid to a mass concentration of 2-55% for later use, add manganese source, iron source, dispersant and deionized water in a sealable container, and pass protective gas into the container;

[0037] 2) Slowly add the diluted phosphoric acid solution into a sealed container to produce ferromanganous phosphate precipitation, age for 10-20 days, and adjust the pH value at any time to stabilize at 2.0-5.0, so that it can nucleate uniformly;

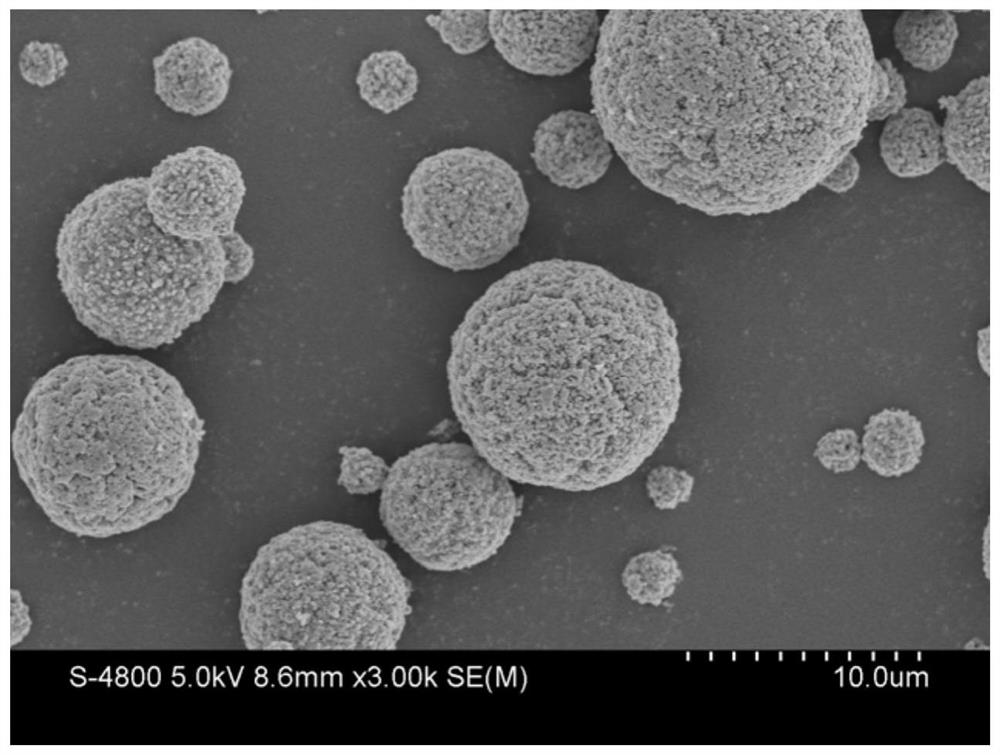

[0038] 3) Wash the formed precipitate with 5-50 times the mass of deionized water for 3-5 times, then dry it in vacuum at 60-80°C, and then sinter at high temperature in a protective gas atmosphere for the first time to form spherical particles of 1-10 μm A;

[0039] 4) Take lithium hydroxide monohydrate LiOH·H 2 O is prepared into a solution with a mass concentration of 1 to 15%, adding spherical particles A to it, spraying and drying, and sinteri...

Embodiment 1

[0049] 1) Weigh 28.7ml of 85% phosphoric acid and slowly add 200ml of deionized water to dilute and prepare a solution for later use. Add 45.30g of manganese sulfate MnSO in a sealed container 4 , 55.61g ferrous sulfate heptahydrate FeSO 4 ·7H 2 0, 4g Polyethylene Glycol 400 and 100ml deionized water, pass into nitrogen protective gas in this container.

[0050] 2) Slowly add diluted phosphoric acid into a sealed container to produce ferromanganous phosphate precipitation, age for 15 days, and adjust the pH value to 4.0 at any time to make it evenly nucleate.

[0051] 3) The formed precipitate was washed 4 times with 10 ml of deionized water, and then dried under vacuum at 60°C. Then sinter for the first time at a high temperature of 750° C. for 5 hours in a nitrogen protective gas atmosphere to form spherical particles A of 1-10 μm.

[0052] 4) Take 20.98g lithium hydroxide monohydrate LiOH·H 2 O is prepared into a solution with a mass concentration of 10%, adding spheric...

Embodiment 2

[0055] 1) Weigh 28.7ml of 85% phosphoric acid and slowly add 200ml of deionized water to dilute and prepare a solution for later use. Add 37.77g of manganese dichloride MnCl in a sealed container 2 , 25.35g ferrous chloride FeCl 2 , 4g Polyethylene Glycol 400 and 100ml deionized water, pass into nitrogen protection gas in this container.

[0056] 2) Slowly add diluted phosphoric acid into a sealed container to produce ferromanganous phosphate precipitation, age for 12 days, and adjust the pH value to 4.0 at any time to make it evenly nucleate.

[0057] 3) The formed precipitate was washed 4 times with 15 ml of deionized water, and then dried under vacuum at 70°C. Then sinter for the first time at a high temperature of 720° C. for 8 hours in a nitrogen protective gas atmosphere to form spherical particles A of 1-10 μm.

[0058] 4) Take 20.98g lithium hydroxide monohydrate LiOH·H 2 O is prepared into a solution with a mass concentration of 10%, adding spherical particles A to...

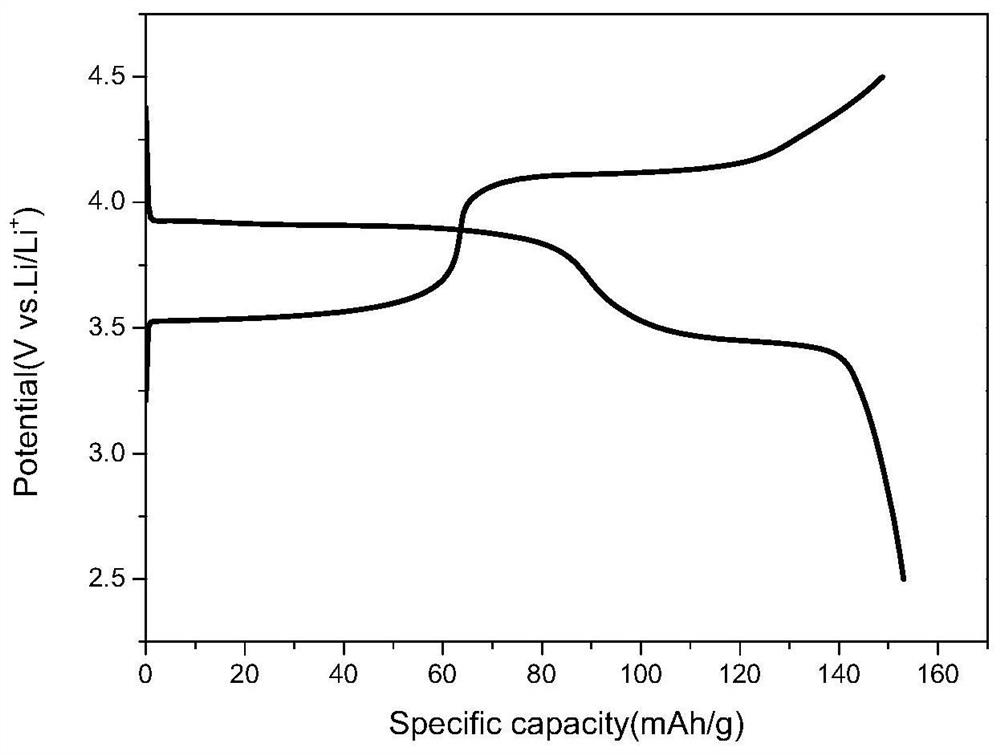

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com