Preparation of wood-like sulfuration resistant material for polyether type polyurethane shoes

A polyether polyurethane, vulcanization-resistant technology, applied in footwear, applications, apparel, etc., can solve the problems of restricting the application of polyurethane materials, poor thermal stability, low hardness, etc., and achieve good product performance repeatability and thermal stability. The effect of good performance and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

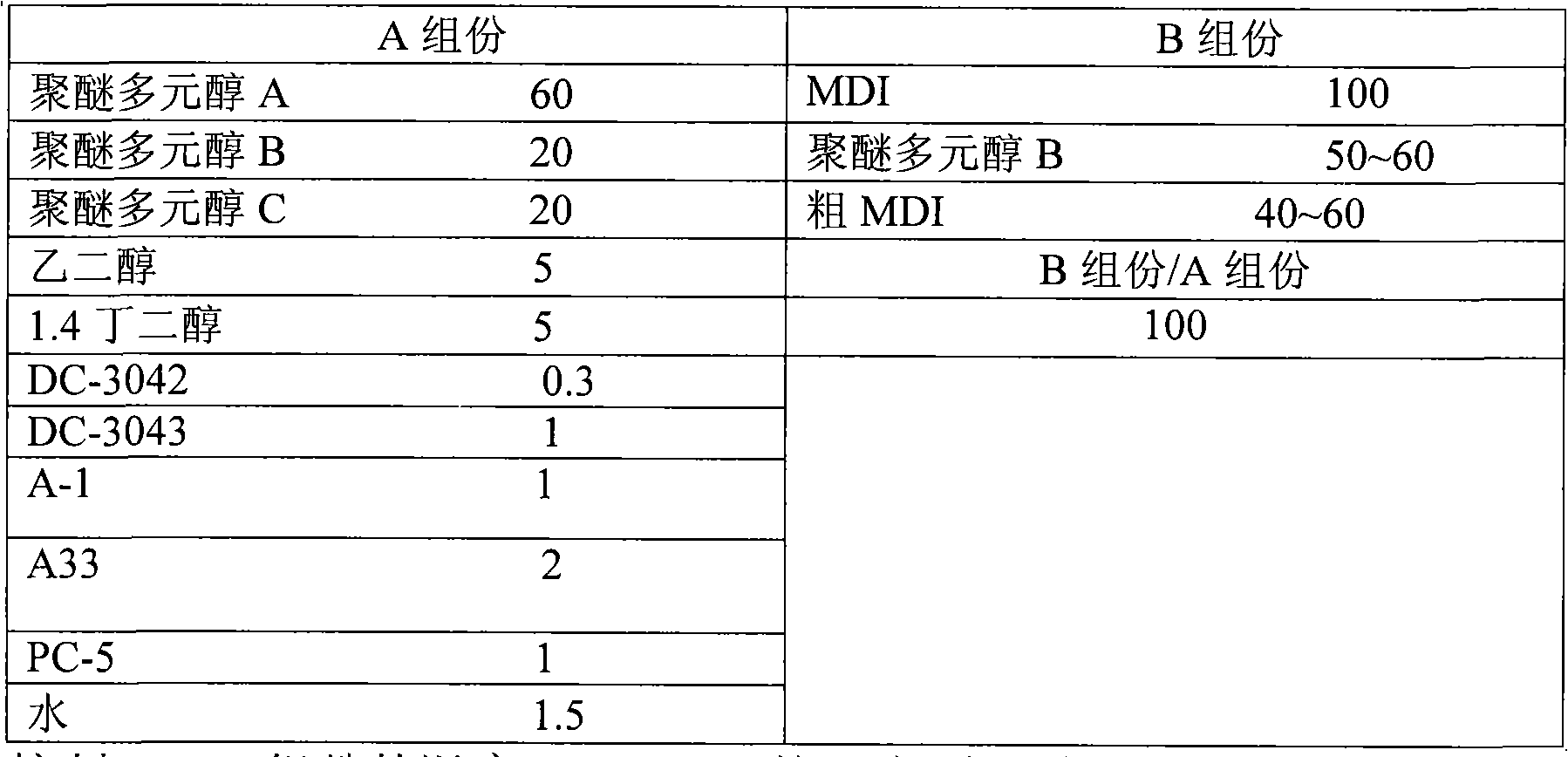

Embodiment 1

[0032]

[0033] Control the temperature of components A and B at 40-42°C, foam through a polyurethane foam machine according to the mass ratio of component B / A = 100, inject into the shoe mold, mold temperature is 40°C, demould in 3 minutes, that is A finished product of wood-like vulcanization-resistant material for polyether polyurethane shoes was obtained.

[0034] When the molded product is placed for 24 hours, the performance of the product is measured as follows:

[0035] Density (g / m 3 )

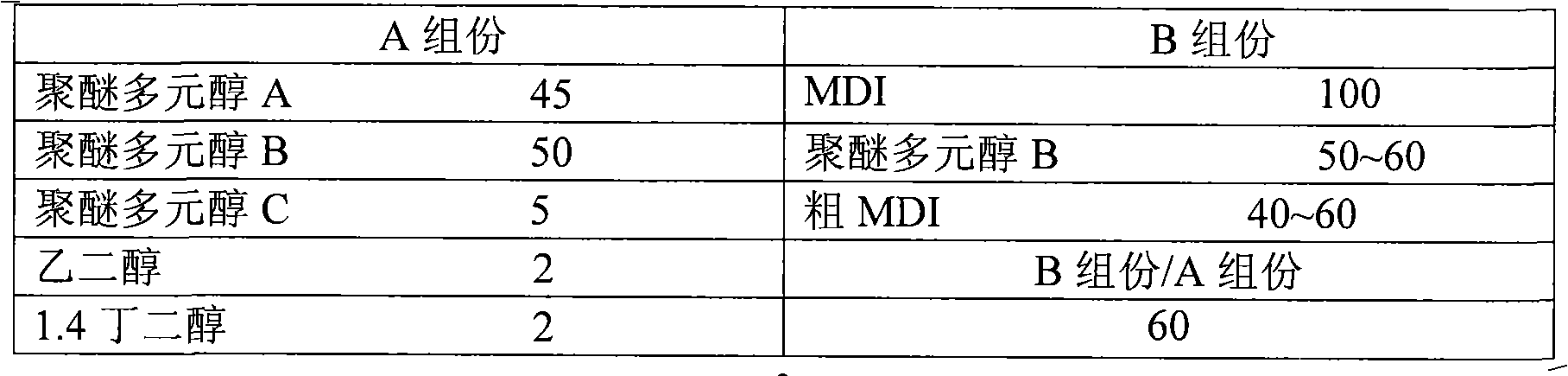

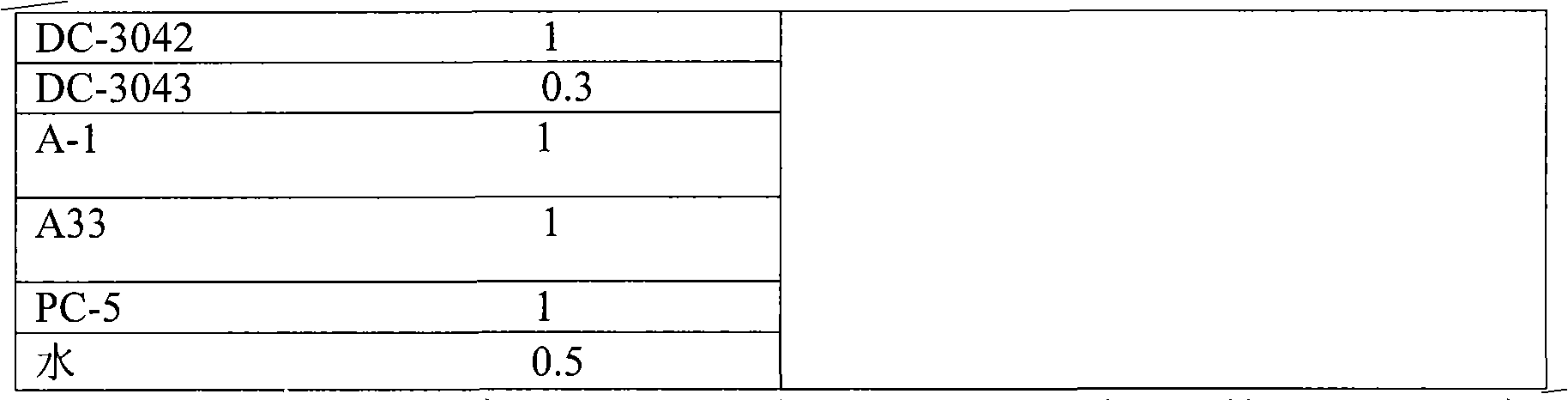

Embodiment 2

[0037]

[0038]

[0039] Control the temperature of components A and B at 40-42°C, foam through a polyurethane foaming machine according to the mass ratio of component B / component A=60, inject into the shoe mold, mold temperature is 50°C, demould in 5 minutes, that is A finished product of wood-like vulcanization-resistant material for polyether polyurethane shoes was obtained.

[0040] When the molded product is placed for 24 hours, the performance of the product is measured as follows:

[0041] Density (g / m 3 )

Embodiment 3

[0043]

[0044] Control the temperature of components A and B at 40-42°C, foam through a polyurethane foam machine according to the mass ratio of component B / A = 85, inject into the shoe mold, mold temperature is 45°C, demould in 4 minutes, that is A finished product of wood-like vulcanization-resistant material for polyether polyurethane shoes was obtained.

[0045] When the molded product is placed for 24 hours, the performance of the product is measured as follows:

[0046] Density (g / m 3 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com