Preparation method for improving surface hydrophilicity of nanometer polyethylene terephthalate (PET) films

A hydrophilic and thin-film technology, which is applied in the field of preparation of improving the surface hydrophilicity of nano-PET films, can solve the problems of insignificant modification effect, no cross-linked layer, insufficient surface layer, etc., and achieves electron density distribution and space The effect of uniform density publication, good uniformity and performance repeatability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

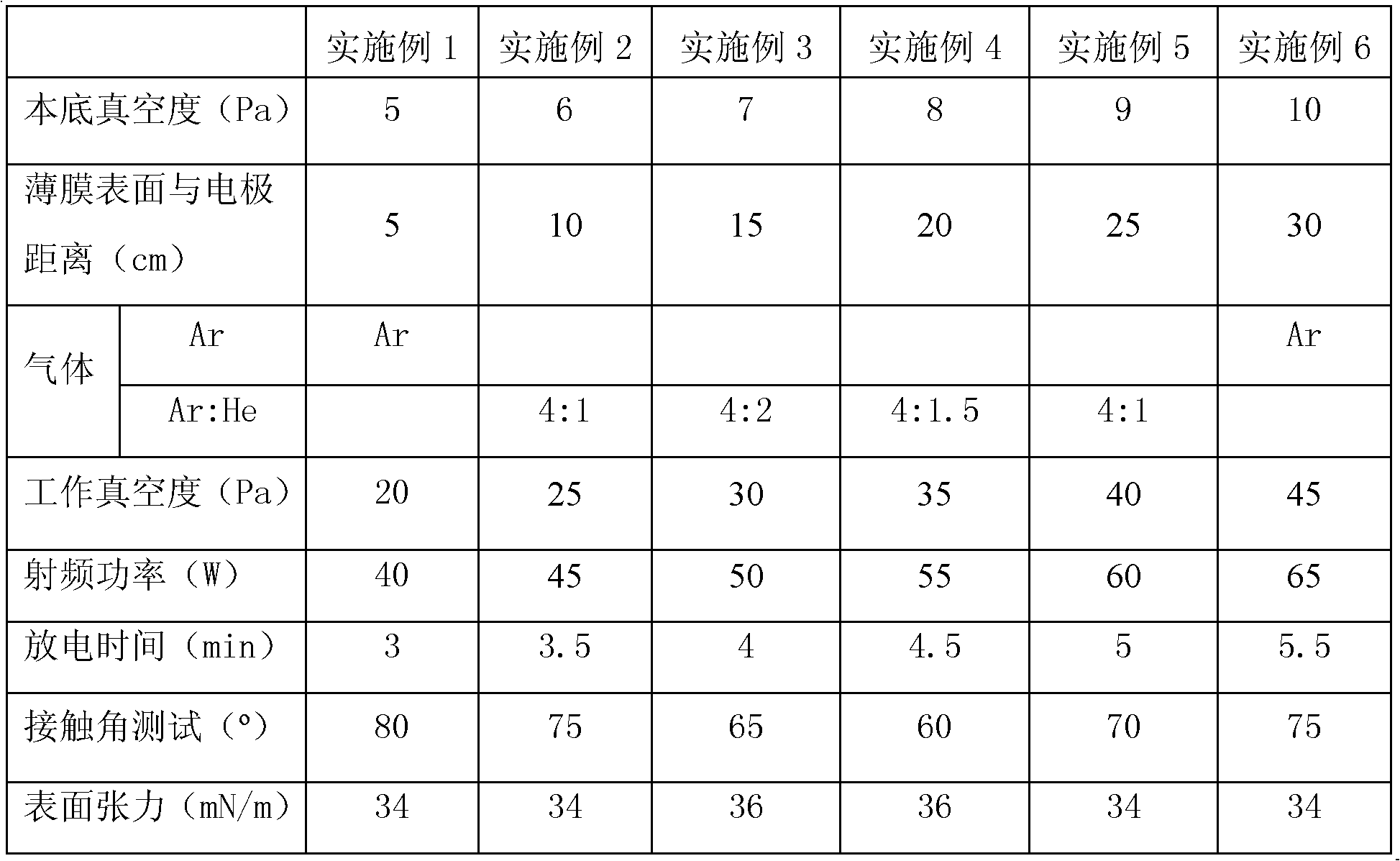

[0011] The present invention improves the preparation method of the surface hydrophilicity of the nano-PET film. First, the nano-PET film is cleaned with deionized water, and then dried with hot nitrogen or vacuum-dried; the nano-PET film after surface cleaning is placed in a radio frequency plasma generator In the middle of the two electrodes of the generation chamber, the RF plasma generator can use the commercially available J-A2500 or JS-45 plasma RF generator, etc., and the generation chamber is cleaned by degreasing, rust removal, etc., and has relatively good gas tightness, the radio frequency power supply frequency of the radio frequency plasma generator is 13.56MHz, the working power of the radio frequency power supply during the first modification is 40~65W, the nano-PET film of the present invention can select the thin film that thickness is 0.1mm~0.3mm , the distance between the two surfaces of the nano-PET film and the two electrodes is controlled at 5-30cm, such a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com