Large-overload stop structure of diaphragm type pressure signal device

A pressure signal and large overload technology, which is applied in the field of aviation and airborne, can solve the problems that the shape cannot be completely matched, the product structure is complicated, and the unloading effect is poor, so as to achieve the effect of completely consistent performance, high production efficiency and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

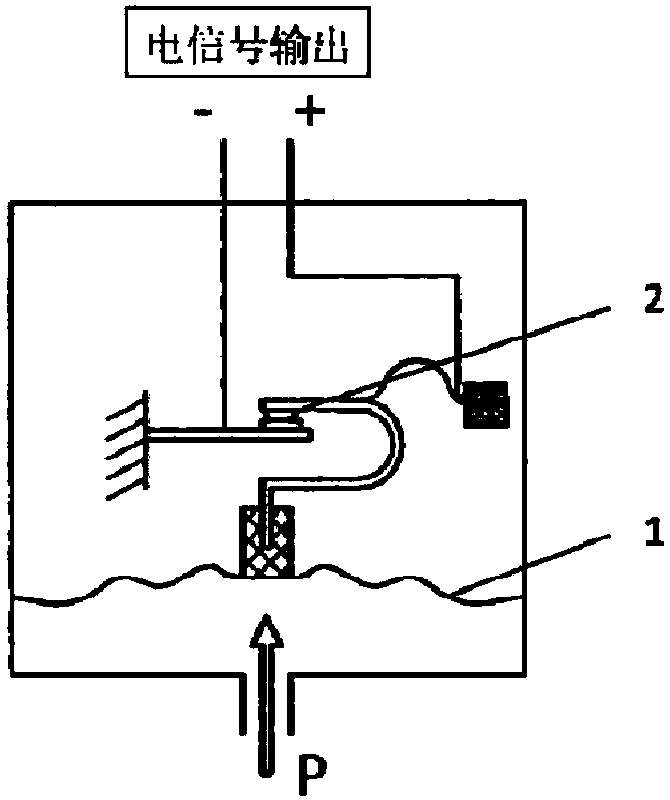

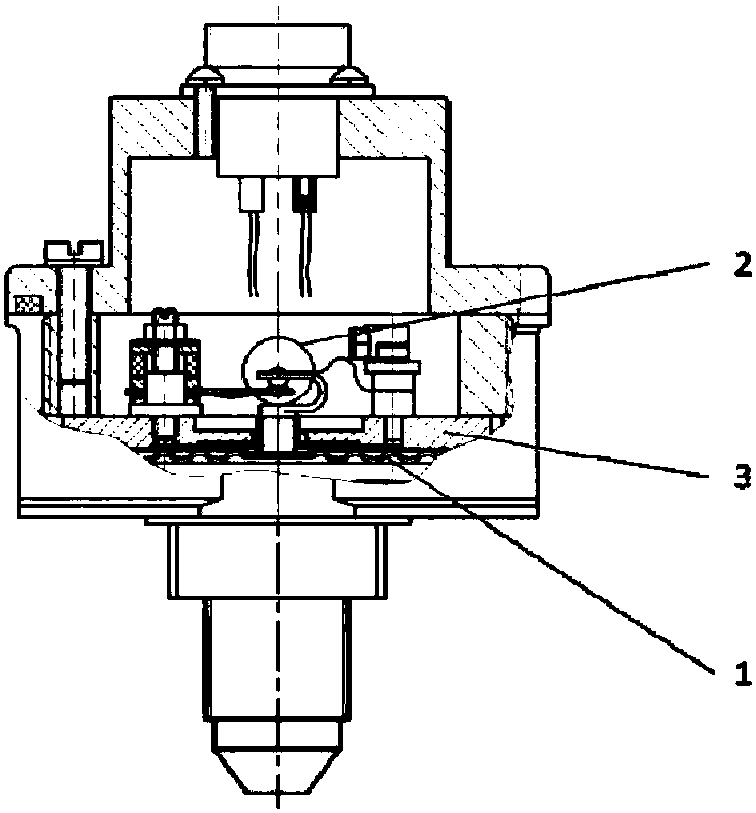

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

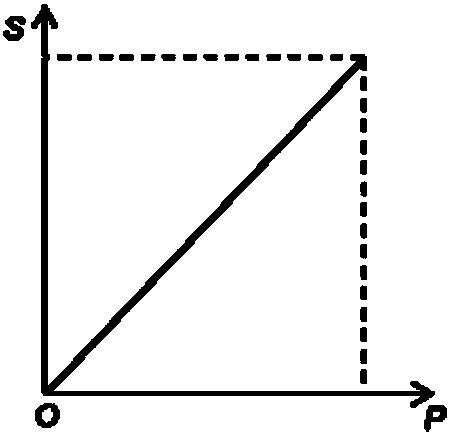

[0022] The invention discloses a large overload stop structure of a diaphragm pressure signal device, which is a stop plate with a stepped surface, and the sensing part of the pressure signal device is composed of a corrugated diaphragm with 3 to 5 corrugations and a stop plate The peaks of the corrugated diaphragm correspond to the steps of the stop plate one by one, and the height of each step of the stop plate corresponds to the displacement value of each peak of the corrugated diaphragm under the working pressure state. see Figure 5 , which is a structural schematic diagram of a specific embodiment of the present invention, the number of corrugations is 3, and the number of steps of the corresponding stop plate is also 3. The present invention can be applied to corrugated diaphragms with 4, 5 or even more corrugations at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com