Wind turbine generator variable-pitch bearing bolt tightening method

A pitch bearing and wind turbine technology, applied in the control of wind turbines, wind power generation, wind turbines, etc., can solve the problems of high labor intensity, potential safety hazards, inconvenience, etc., to reduce labor intensity, eliminate potential safety hazards, and improve The effect of tightening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

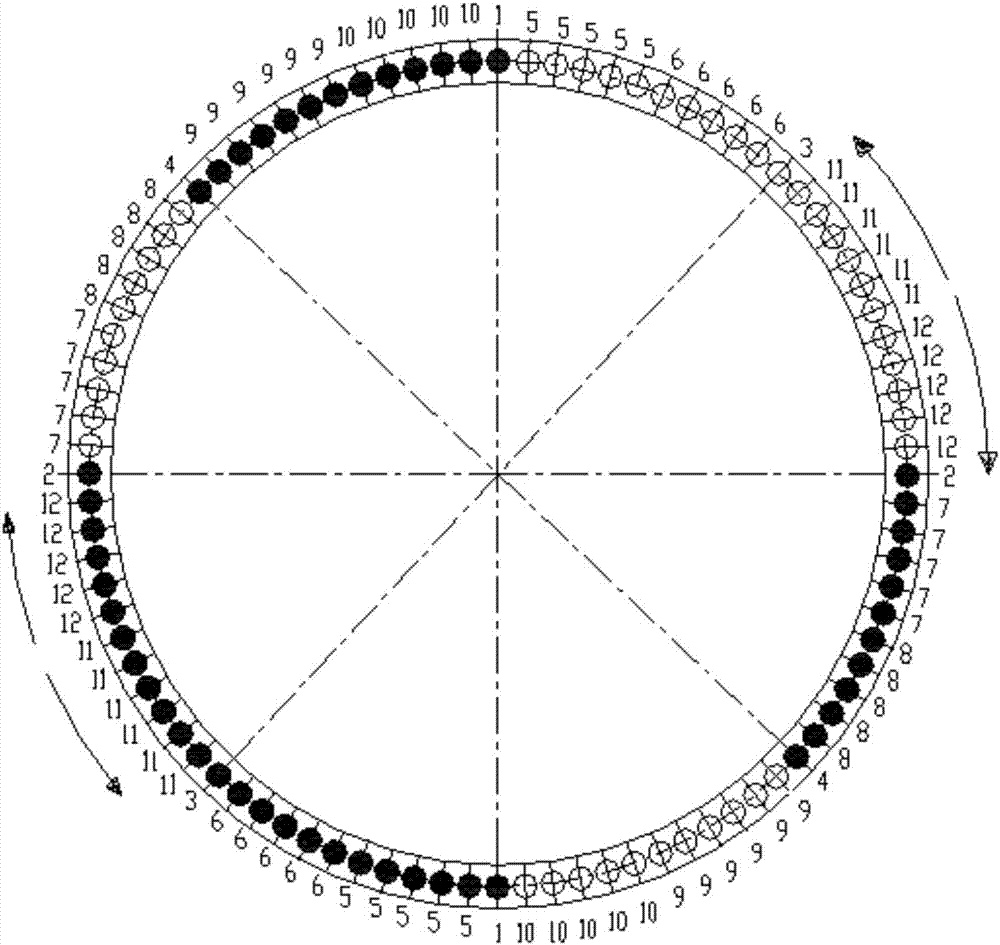

[0022] Refer to attached image 3 As shown, the method for tightening the pitch bearing bolts of wind turbines of the present invention comprises the following steps:

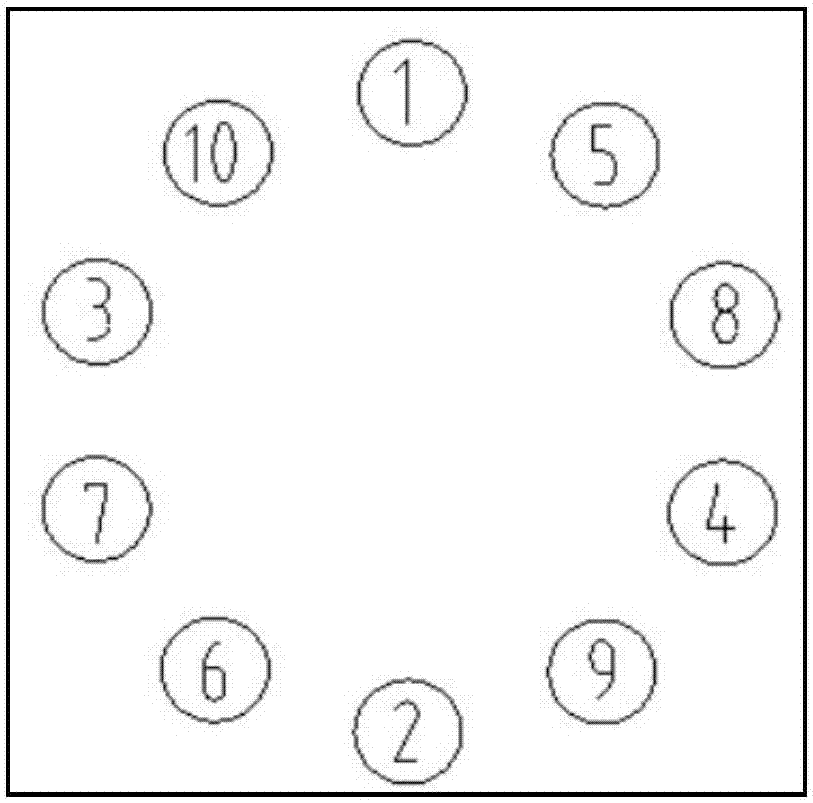

[0023] (1) The eight bolts on the pitch bearing at the positions of 0°, 45°, 90°, 135°, 180°, 225°, 270° and 315° are firstly fixed in the order of the cross method. Preload.

[0024] Wherein, the eight bolts are specifically preloaded according to the cross method: bolts corresponding to 0°, 180°, 270°, 90°, 135°, 315°, 45°, and 225°.

[0025] A more optimal pre-tightening method is to tighten two opposite bolts at the same time. And on this basis, the order of preloading is as follows: 0° and 180°, 270° and 90°, 135° and 315°, 45° and 225° corresponding bolts. For example, special tools can be used to complete the tightening of two pairs of relative bolts at the same time, or two operators can operate two pairs of relative bolts at the same time.

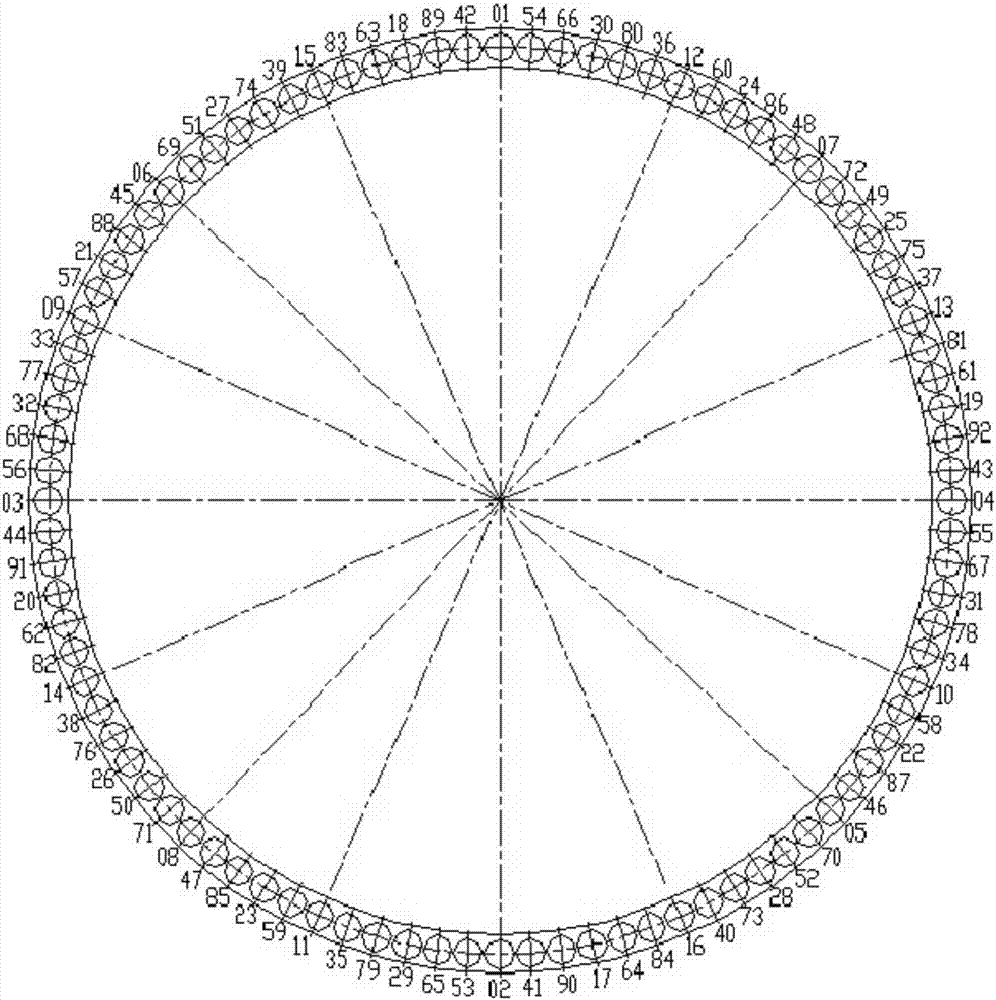

[0026] (2) Multiple bolts on the pitch bearing are equall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com