Bolt tightening system

A bolt and bolt hole technology, applied in the field of bolt tightening, can solve the problems of asymmetric distribution of the positions to be tightened, unreasonable bolt sequence setting, low control flexibility of the tightening system, etc. Avoid warping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

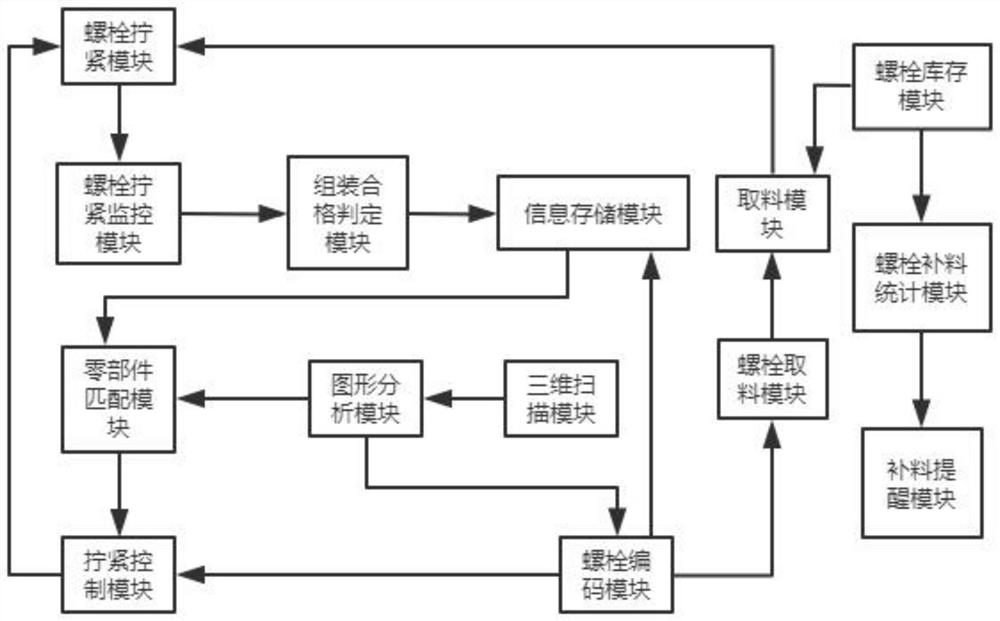

[0036] A bolt tightening system, comprising: a three-dimensional scanning module, a graphic analysis module, a bolt encoding module, an information storage module, a bolt retrieving module, a bolt inventory module, a retrieving module, a bolt tightening module, a tightening control module, and a bolt tightening monitoring module; The three-dimensional scanning module, the graphic analysis module, and the bolt encoding module are connected in sequence, the bolt encoding module, the bolt retrieving module, the retrieving module, and the bolt tightening module are connected in sequence, and the bolt inventory module and the retrieving module are connected. The bolt encoding module is connected to the tightening control module, the bolt tightening module is connected to the bolt tightening monitoring module, and the information storage module is directly or indirectly connected to the bolt encoding module and the bolt tightening monitoring module respectively;

[0037] The three-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com