Method for manufacturing integral wire mesh

A technology of wire mesh and manufacturing method, which is applied in metal material coating process, liquid chemical plating, coating, etc., can solve problems affecting normal use, edge shedding of warp or weft threads, and difficult realization of wire mesh, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The specific method of electroplating to prepare stainless steel wire mesh is as follows:

[0019] Use the existing weaving technology to weave stainless steel wire mesh, chemically degrease the woven stainless steel wire mesh, wash it with hot and cold water, put it into the plating tank for electroplating nickel, take it out after a certain period of reaction, wash it with water, dry it, and coil it. Can.

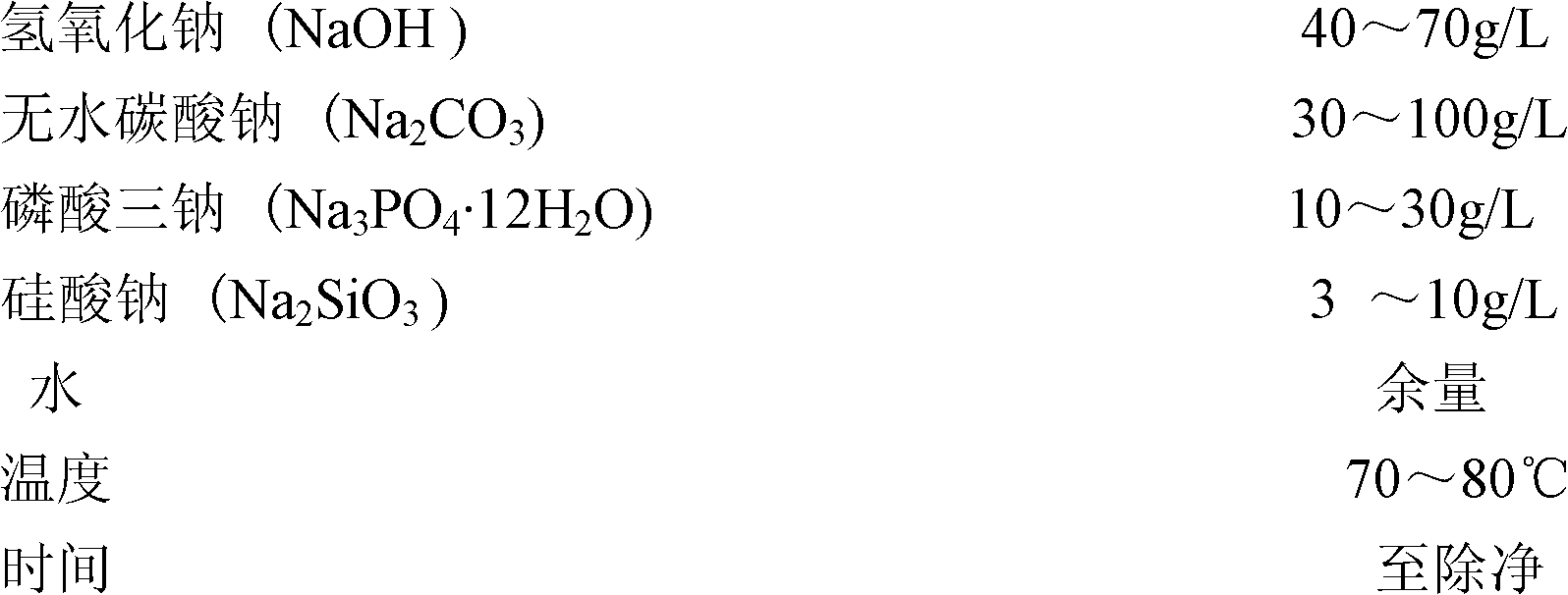

[0020] 1. Chemical degreasing: bath composition and working conditions are as follows

[0021]

[0022] 2. Hot and cold water washing: first rinse with hot water (40-50 degrees Celsius) to prevent residual degreasing liquid on the surface of the stainless steel wire mesh, and then rinse with cold water (room temperature).

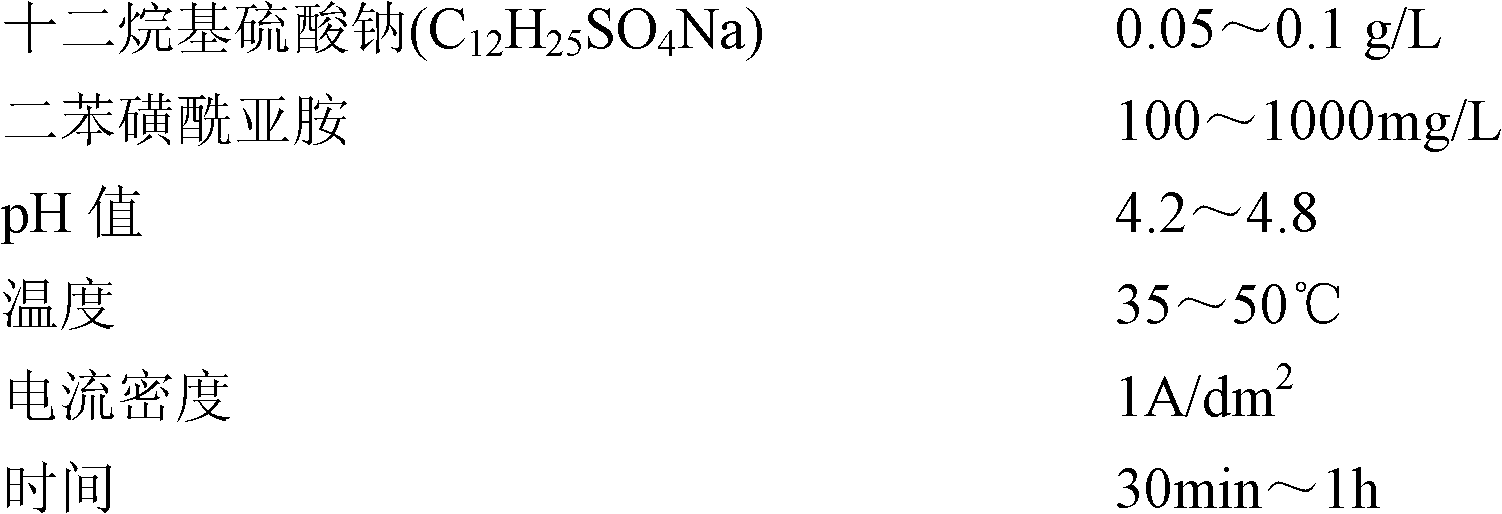

[0023] 3. Plating solution formula and process conditions:

[0024]

[0025]

[0026] The stainless steel wire mesh of this formula needs to be charged into the tank, first use 3~4A / dm 2 The impulse current is 1~3min, and then drops ...

Embodiment 2

[0029] The specific method of electroless plating to prepare copper wire mesh is as follows:

[0030] Use the existing weaving technology to weave copper wire mesh, choose copper wire or brass wire, chemically degrease, heat, cold water wash and pickle the prepared copper wire mesh, put it into the plating tank for chemical tin-lead alloy plating , Take it out after a certain period of time, wash, dry, and coil.

[0031] 1. Chemical degreasing: same as Example 1.

[0032] 2. Washing in hot and cold water: Same as Example 1.

[0033] 3. Pickling

[0034] 3-1 copper wire

[0035]

[0036] 3-2 brass wire

[0037]

[0038] 4. Wash in hot or cold water.

[0039] 5. Chemical plating solution formula and process conditions:

[0040]

[0041] 5-1. Copper alloy electroless plating is induced by clean iron wire or direct current (less than 35V) for 2 to 5 seconds, and when a large number of bubbles are generated on the surface of the wire mesh, take out the iron wire or c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com