Inverted-arch interlocked girder and construction method thereof

A technology of interlocking and anti-bottom arching, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve problems such as bulging floor rock blocks, bottom arch failure, and small contact surface, so as to increase the uniformity of force, The effect of increasing the contact area and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below in conjunction with the accompanying drawings.

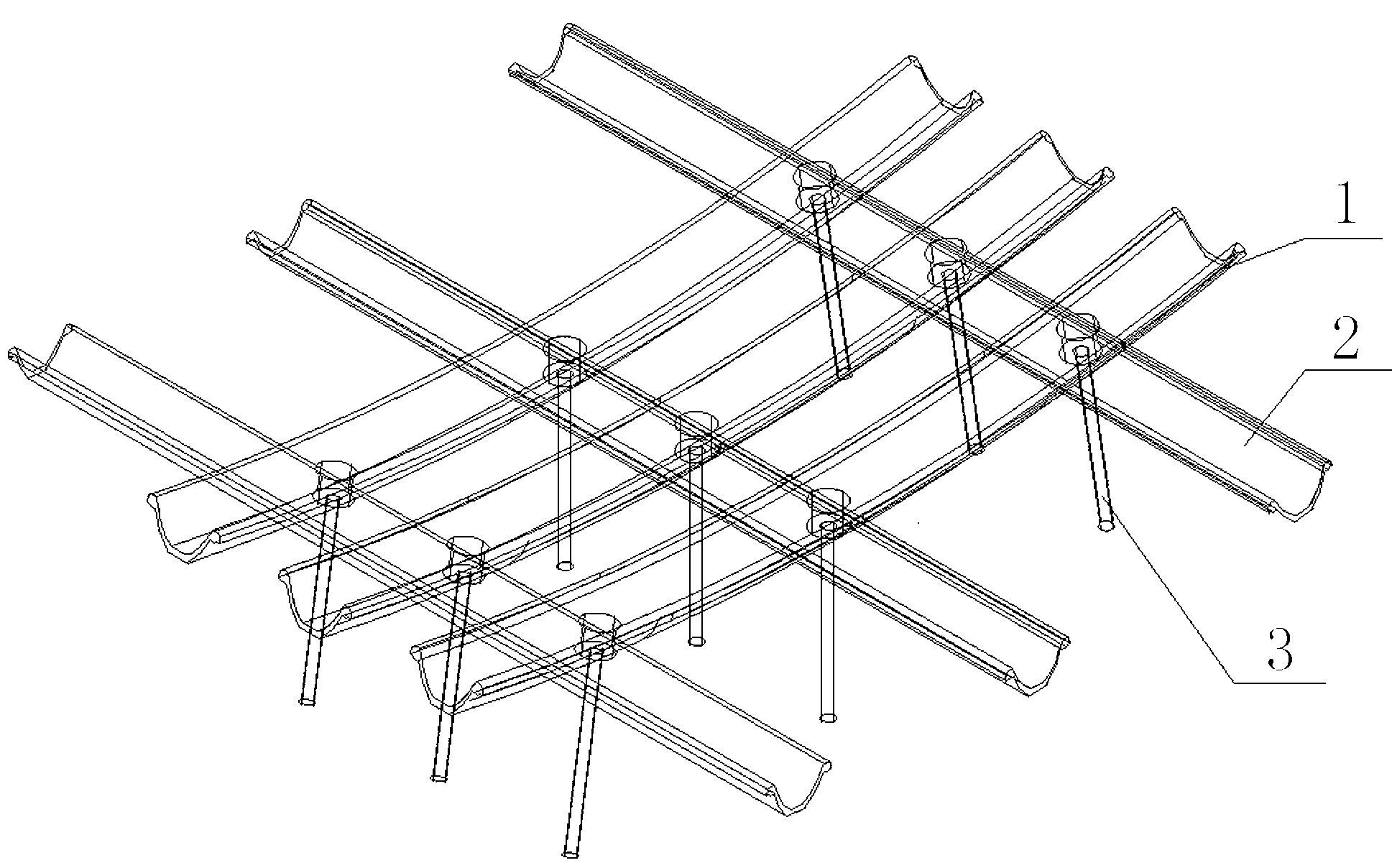

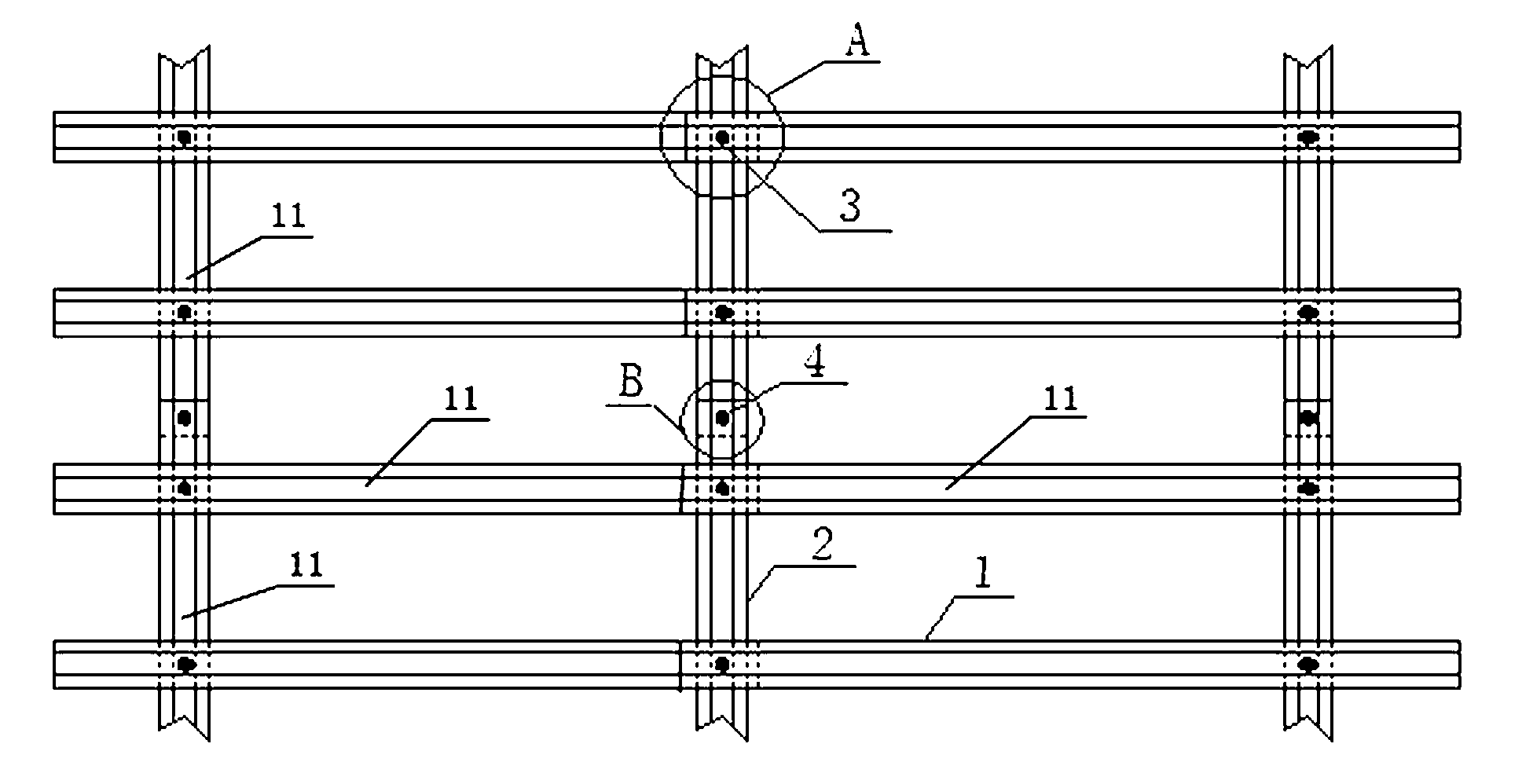

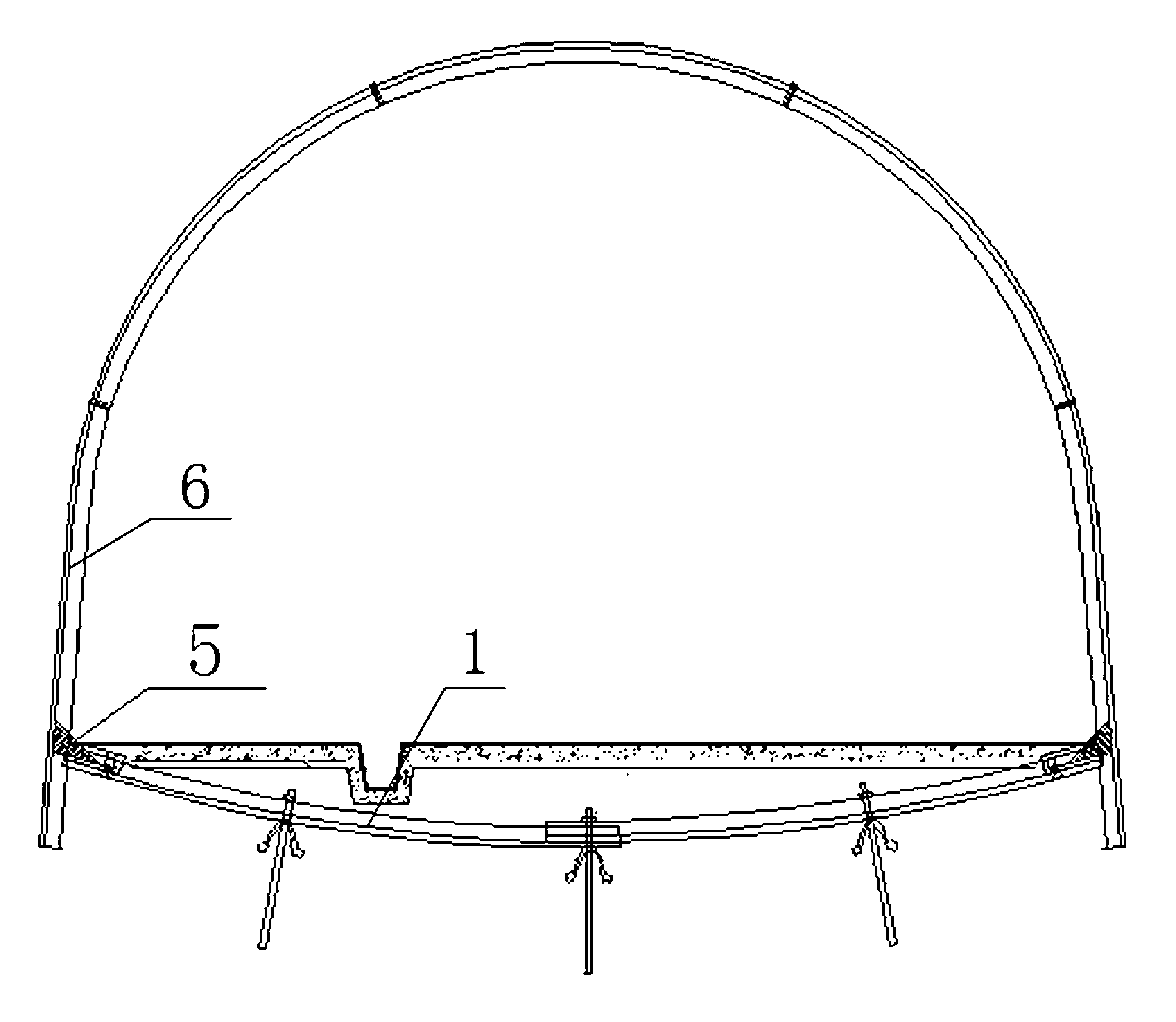

[0022] like figure 1 As shown, the bottom arch chain beam of the present invention includes a plurality of chain beams 2 and a plurality of reverse bottom arches 1, and a plurality of chain beams 2 are arranged in parallel, and a plurality of reverse bottom arches 1 are vertically overlapped with the chain beams 2, and the overlapping points Fixed by the anchor rod 3 and the nut 4, the anti-bottom arch 1 is located above the chain beam 2. The vertical overlap between the chain beam 2 and the anti-bottom arch 1 is fastened by the anchor rod 3 and the nut 4, which not only ensures the stability of the bracket, but also effectively increases the contact area between the anti-bottom arch 1 and the bottom plate, and changes the line contact. It is a mesh contact, which increases the uniformity of the force and effectively prevents the broken rock mass of the bottom plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com