Hydraulic buffer assembly production system equipment and production process thereof

A technology of hydraulic buffer and production system, applied in assembly machines, metal processing equipment, metal processing, etc., can solve problems such as low tightening efficiency, inability to absorb nuts, and reduced feeding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

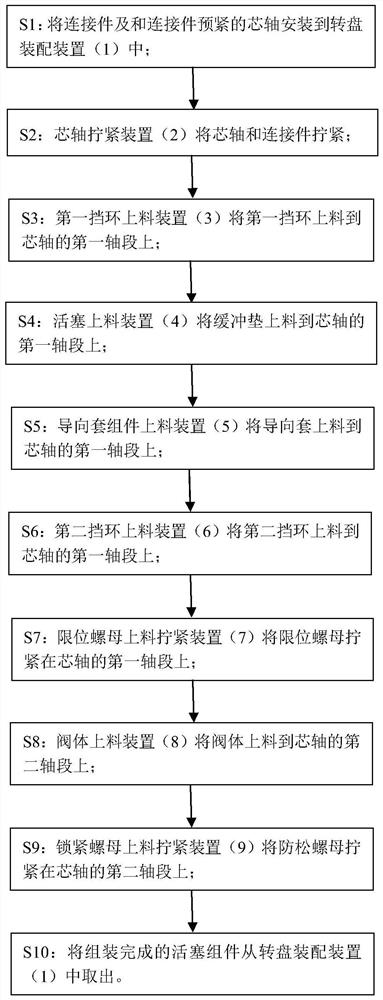

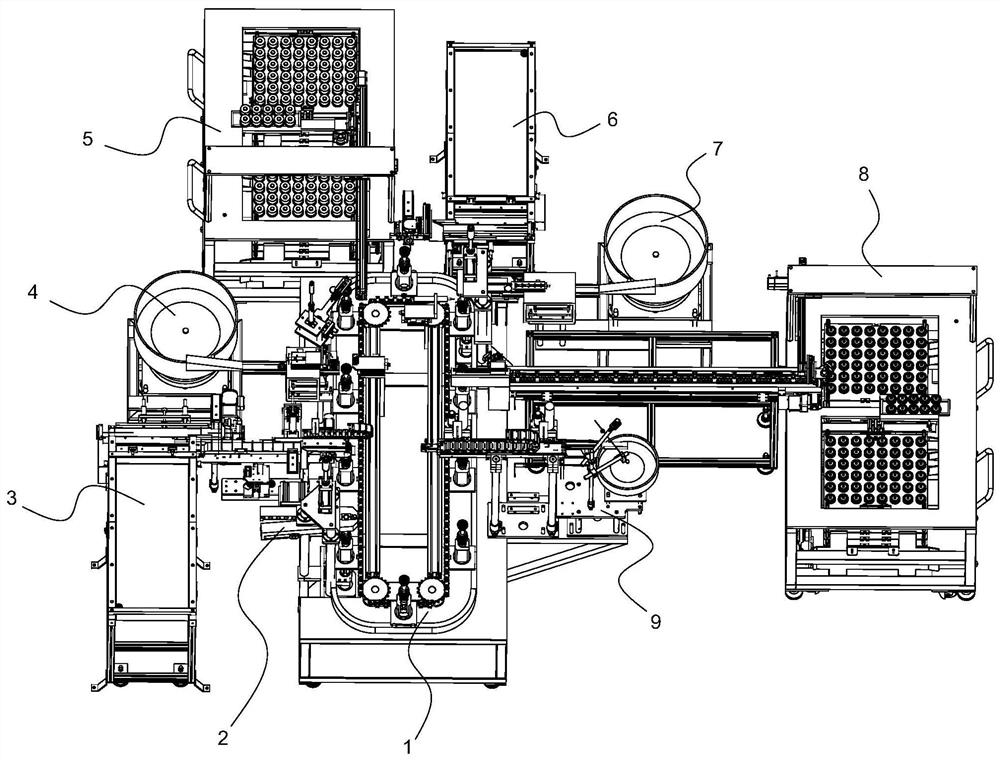

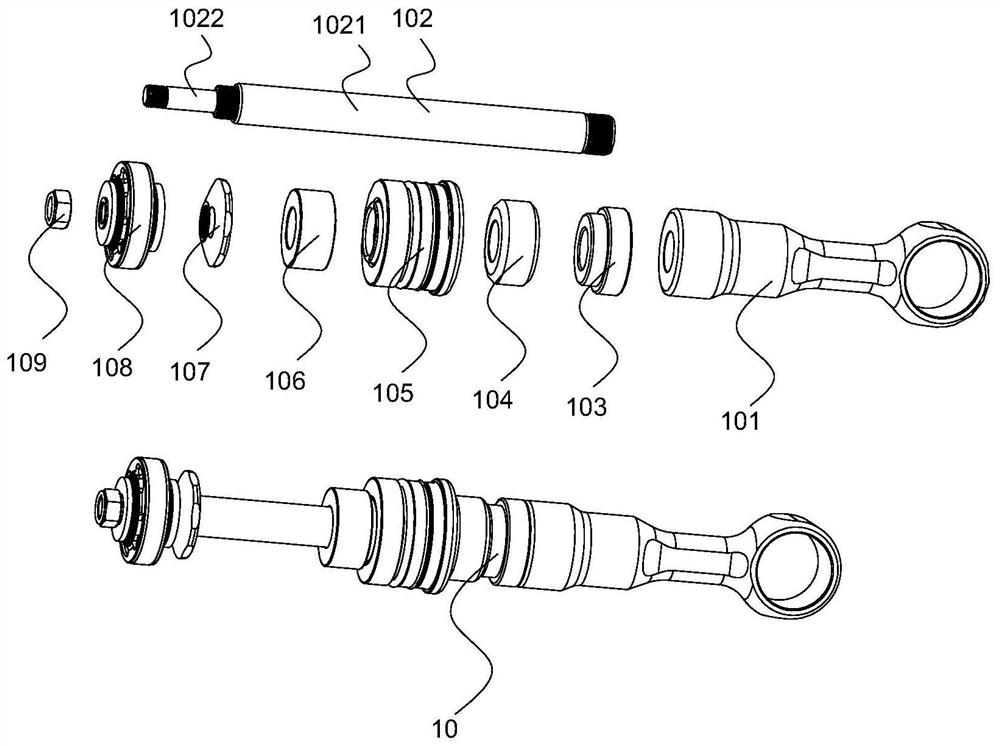

[0027] A hydraulic buffer assembly production system, the system includes piston assembly assembly production equipment, such as figure 2 The equipment shown includes a frame and a turntable assembly device 1 installed on the frame, a shaft core tightening device 2, a first retaining ring feeding device 3, a piston feeding device 4, a guide sleeve assembly feeding device 5, a second The retaining ring feeding device 6, the limit nut feeding and tightening device 7, the recovery valve feeding device 8 and the locking nut feeding and tightening device 9. The turntable assembly device 1 is sequentially provided with a connecting piece loading station, a shaft core tightening station, a first retaining ring feeding station, a piston feeding station, a guide sleeve assembly feeding station, and a second retaining ring feeding station. Station, limit nut feeding and tightening station, recovery valve feeding station and lock nut feeding and tightening station. The connector loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com