Tower drum frame

A technology of a tower tube and an inner connecting end, which is applied in the field of tower tube, can solve the problems of increasing the manufacturing cost of the tower tube frame, increasing the processing cost of the flange, and prolonging the processing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution provided by the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not be regarded as limiting the technical content disclosed in the present invention.

[0029] It should be explained that the tower frame generally includes multi-section towers. In order to save space, this document only specifically describes the connection structure of the two-section towers, and does not describe the connection structure of each tower separately; The connection structure can be connected in the same way.

[0030] In this document, the orientation words "outside" and "inside" are relative to the centerline of the tower frame, the position close to the centerline is "inside", and the position away from the centerline is "outside".

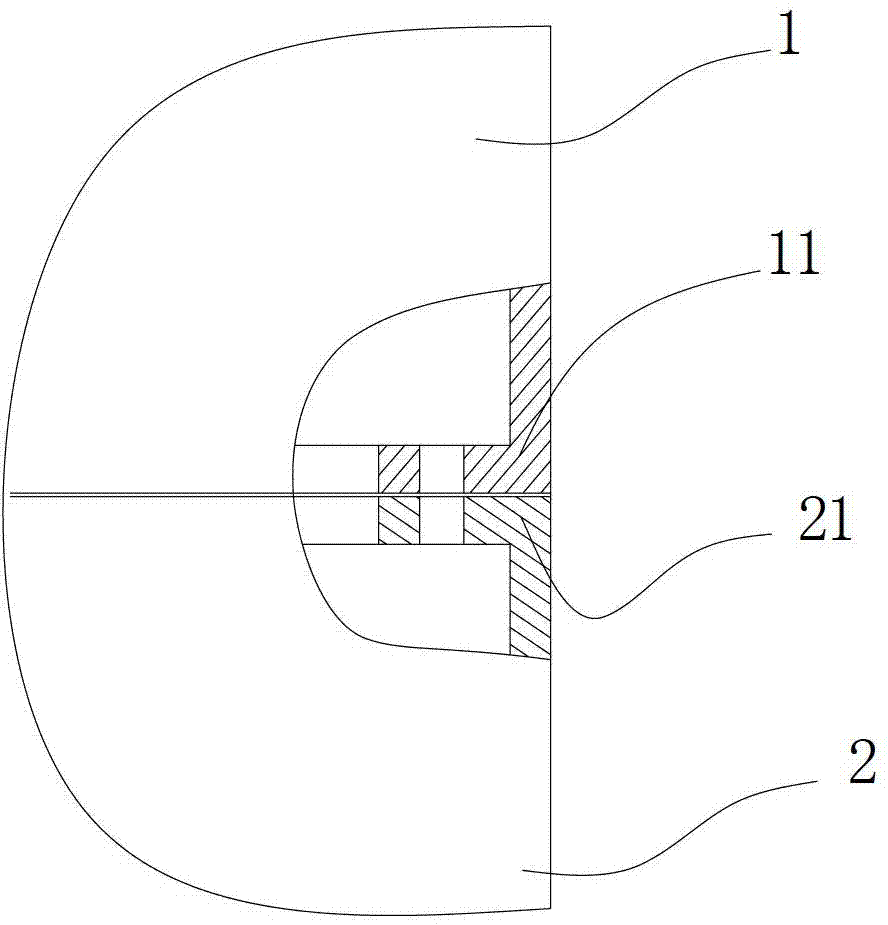

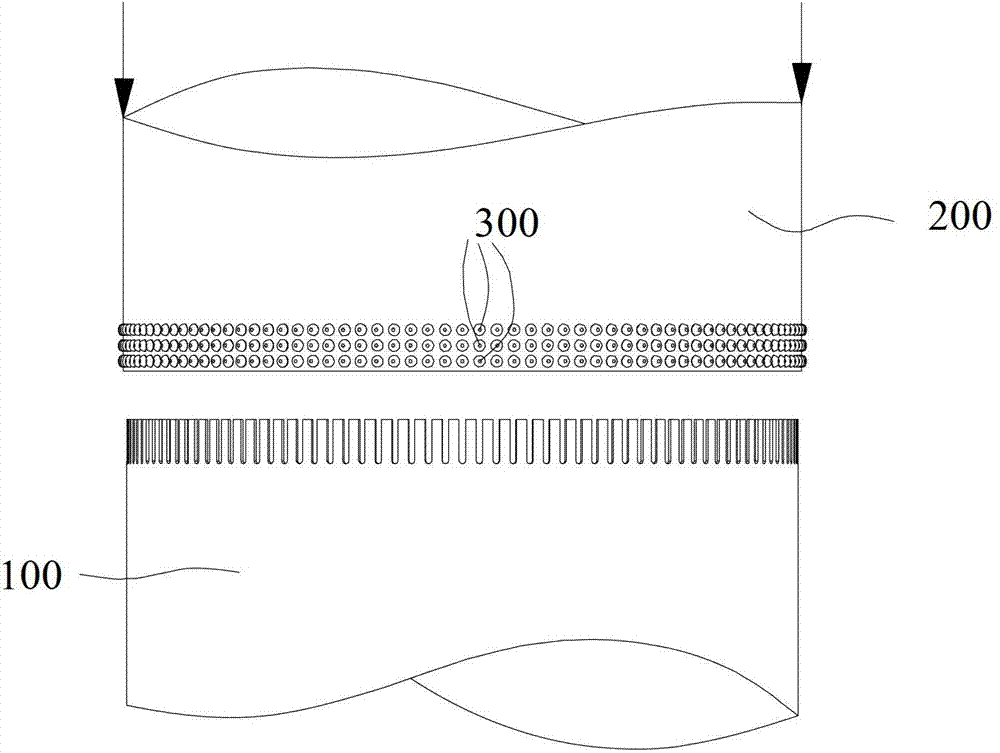

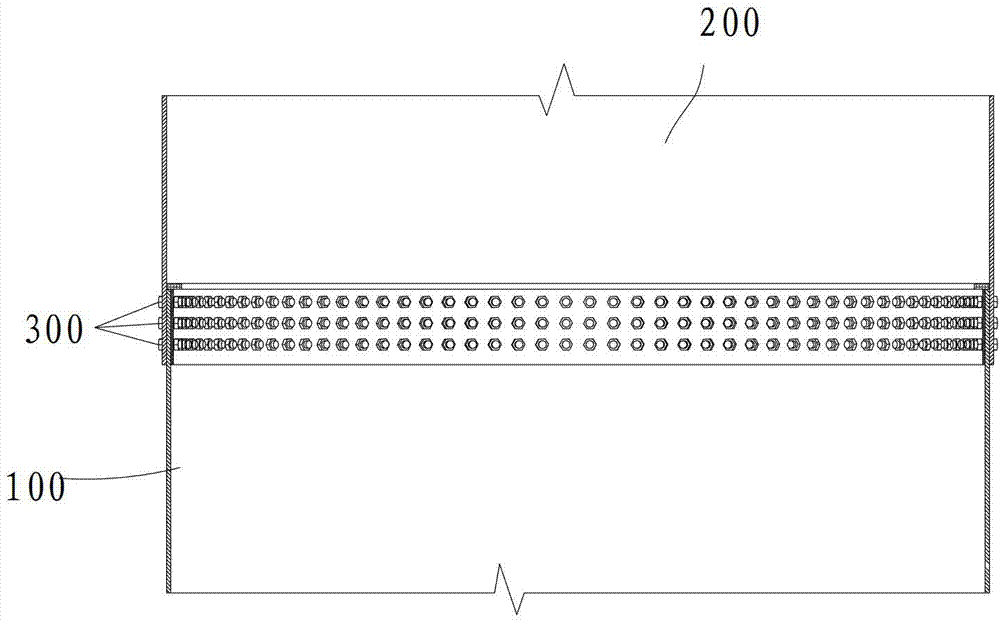

[0031] Please refer to Figure 2 to Figure 5 , figure 2 It is a docking diagram of two towers in the tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com