Wire twisting device for conductive wire terminal

A wire and wire device technology, applied in the field of wire twisters, can solve the problems of increased product defect rate, increased labor cost, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

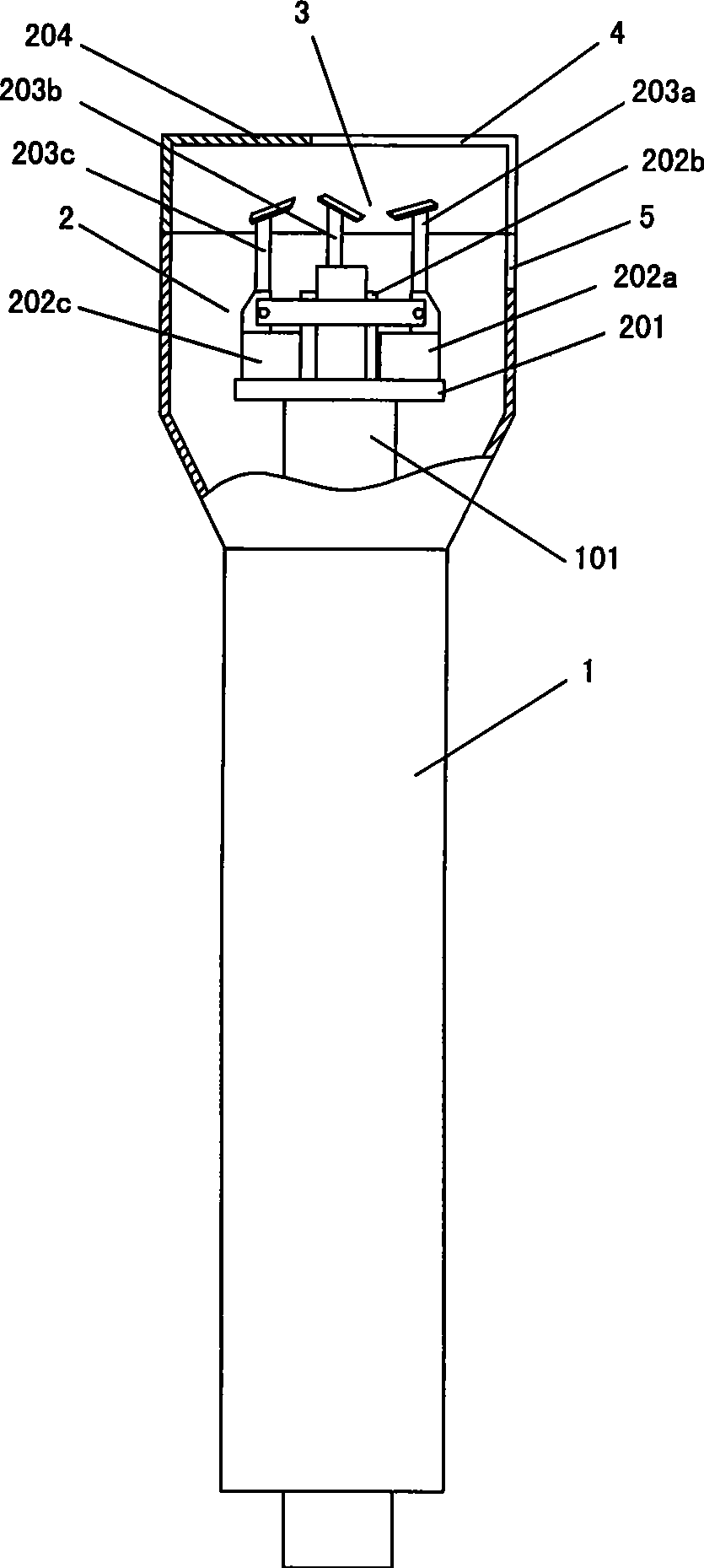

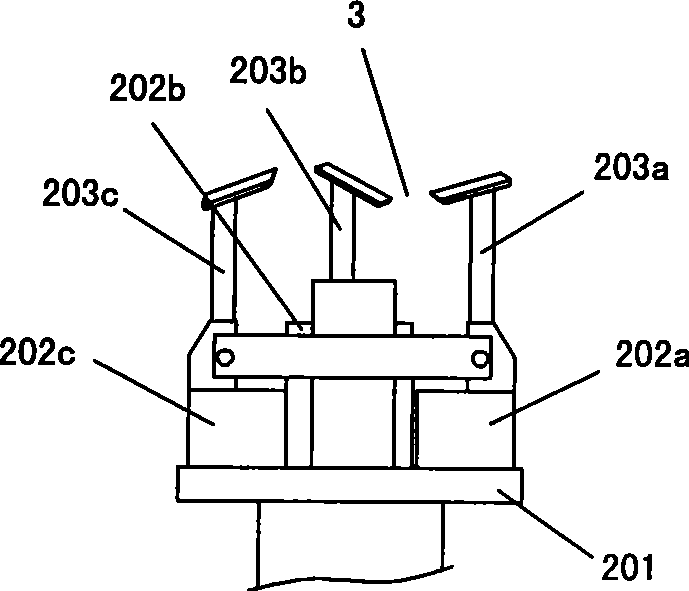

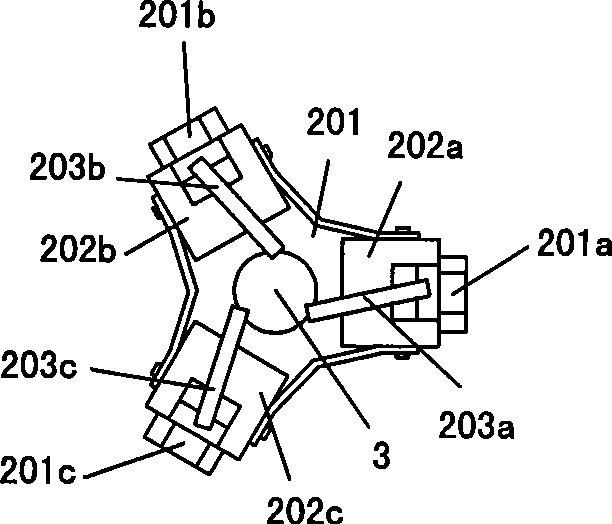

[0017] like Figure 1 to Figure 3 As shown, a wire end twister includes a driving device 1. The driving device 1 can be a pneumatic or electric bit, or other driving tools. The output shaft of the pneumatic or electric bit is used as the output end of the driving device. 101, the output end 101 is equipped with a thread twisting head 2 that can tighten the bare wire end, and the thread twisting head includes a rotating seat 201, a linkage seat 202a, 202b, 202c, thread twisting arms 203a, 203b, 203c and its housing 204 The lower part of the rotating base 201 is provided with a drive interface for the output end 101 of the driving device to be plugged in, and the upper part is fixed with three moving seats 202a, 202b, 202c arranged in a circular shape, and the moving seats 202a, 202b, 202c are fixed with Approximate "7"-shaped twisting arms 203a, 203b, 203c, the gaps between several twisting arms 203a, 203b, 203c constitute the wire twisting port 3, and the housing 204 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com