Automatic turnover system of die assembly bolt of pipe pile

An automatic turning and bolting technology, which is applied in the direction of ceramic molding machines and manufacturing tools, to reduce labor intensity, avoid manual rotation, and improve tightening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

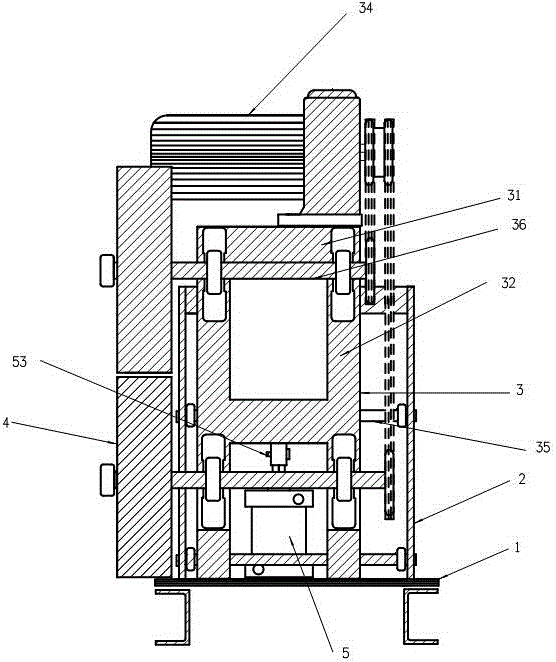

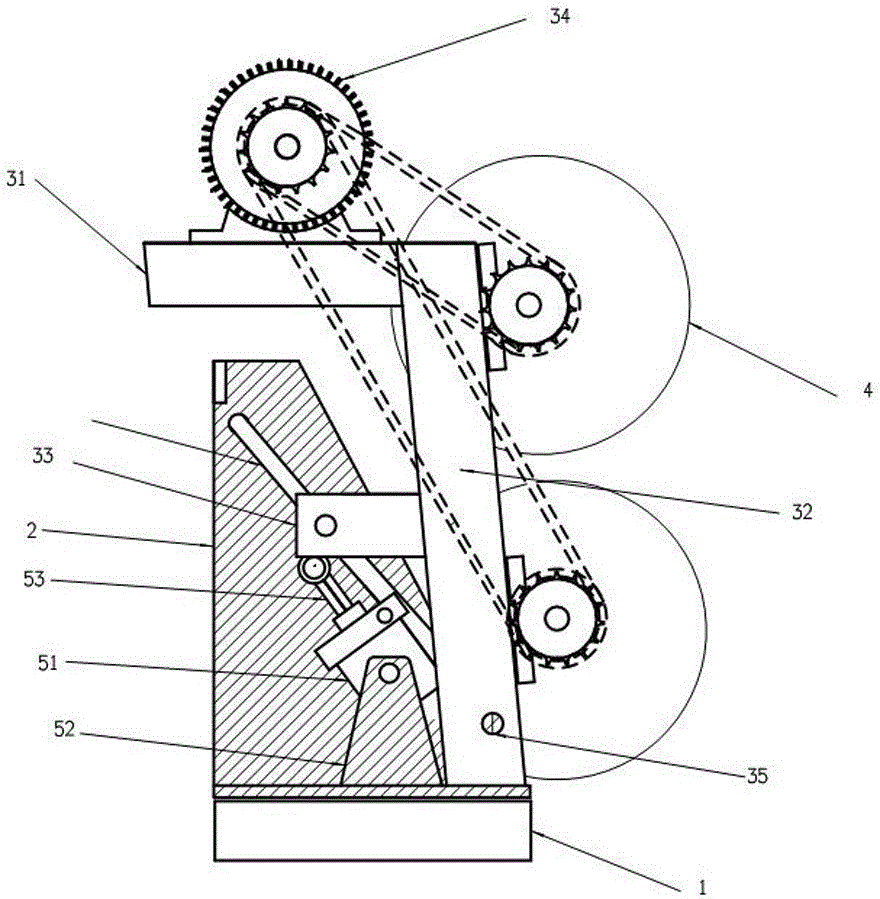

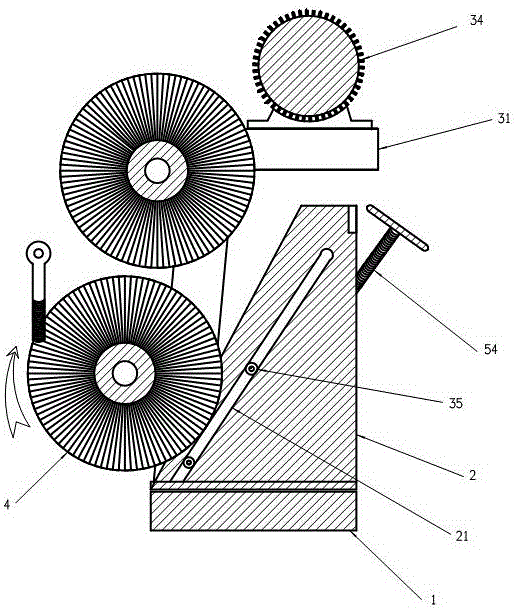

[0019] Such as Figure 1 to Figure 3 Shown is an automatic overturning system for mold clamping bolts of pipe piles. The overturning system includes a support base 1 , a guide plate 2 , a mounting frame 3 , a nylon brush 4 and an adjustment mechanism 5 .

[0020] Guide plate 2 is a right-angled trapezoidal shape, and guide plate 2 has two, and the bottom surface of guide plate 2 is respectively fixedly installed on the upper surface of support base 1 and is positioned at both sides, and guide plate 2 is perpendicular to support base 1, and the upper surface of guide plate 2 A guide groove 21 parallel to the hypotenuse is provided;

[0021] The mounting frame 3 is located between the two guide plates 2. The mounting frame 3 includes a horizontal top plate 31, a bearing fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com