Patents

Literature

38results about How to "Avoid manual rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

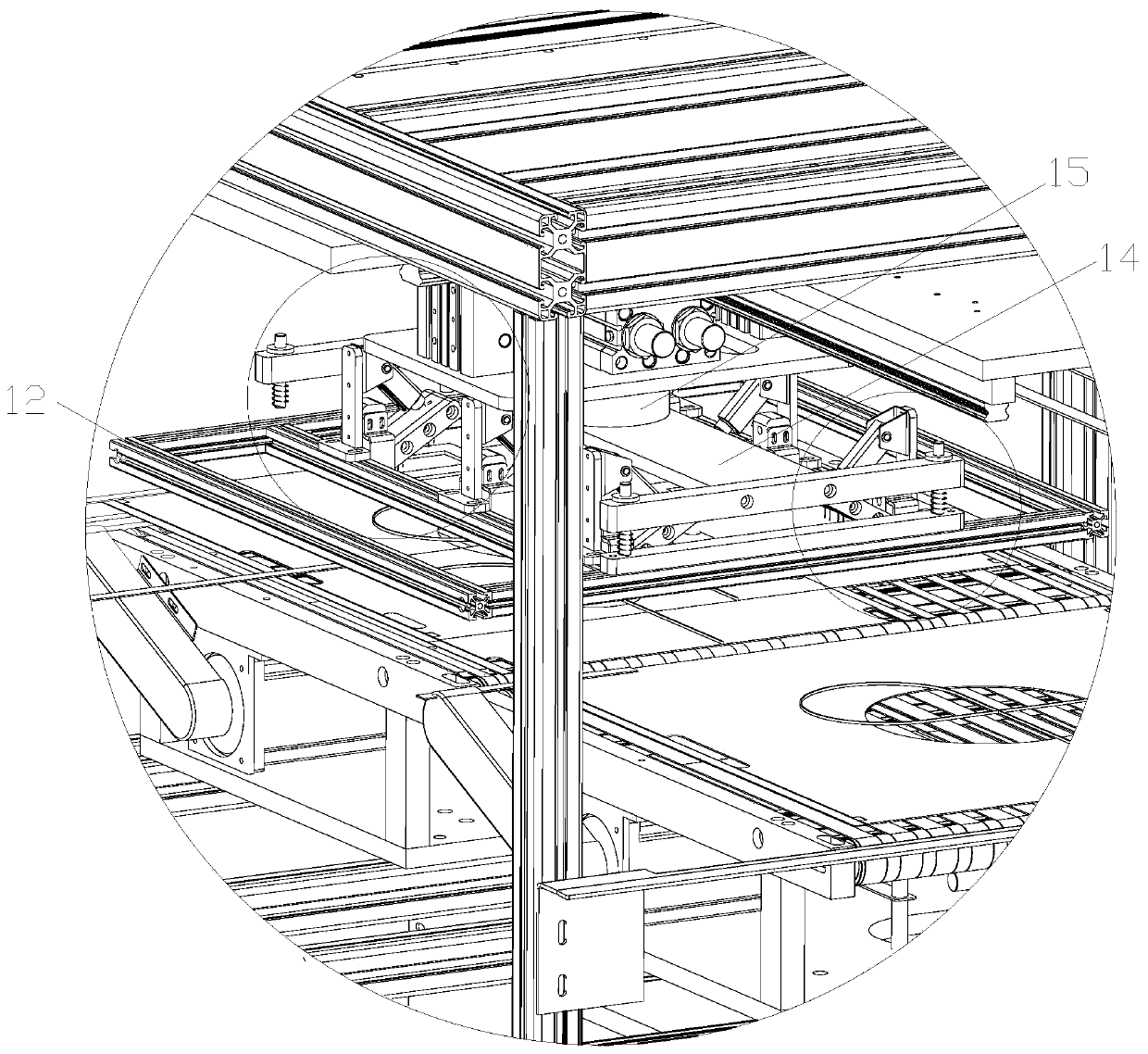

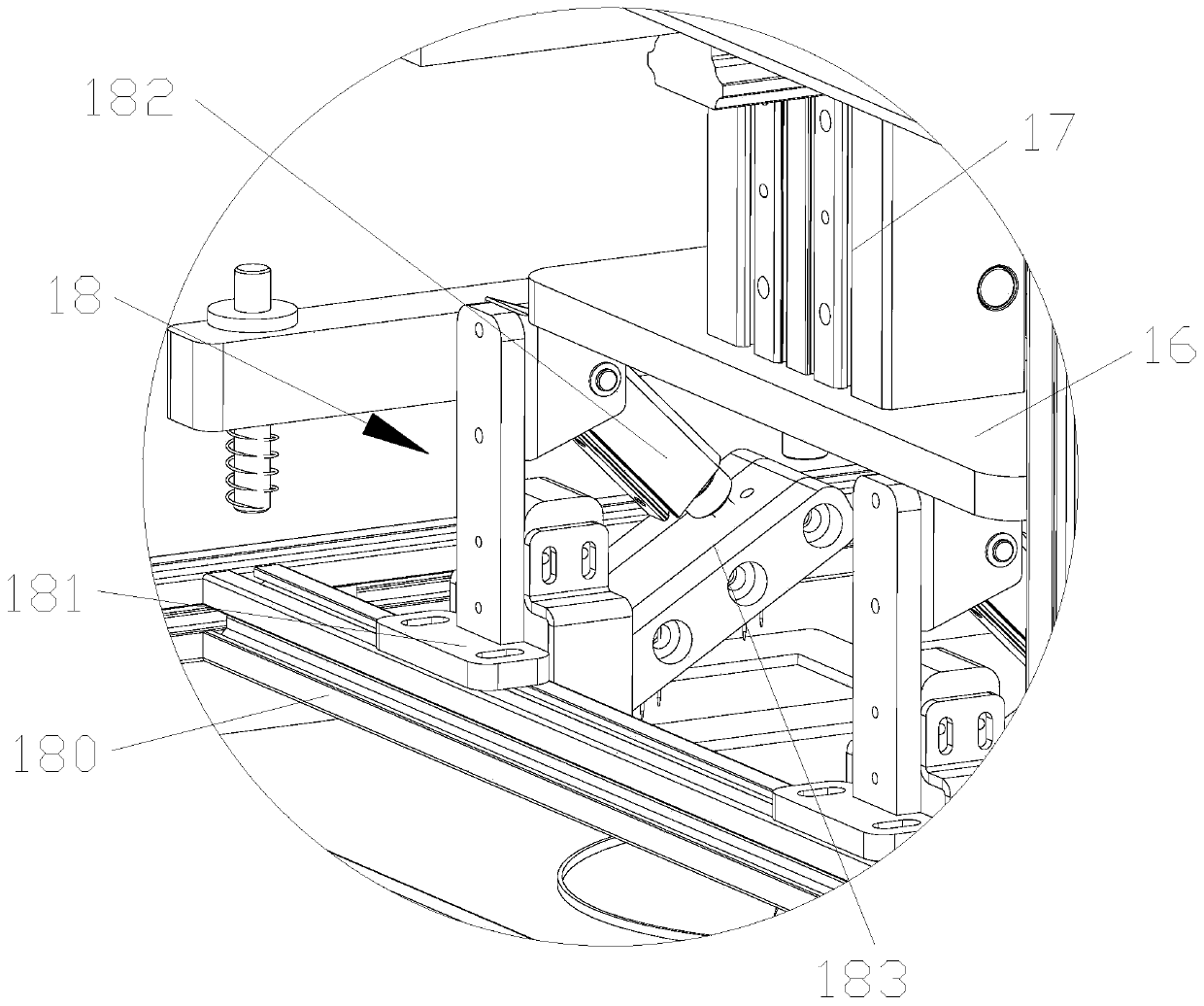

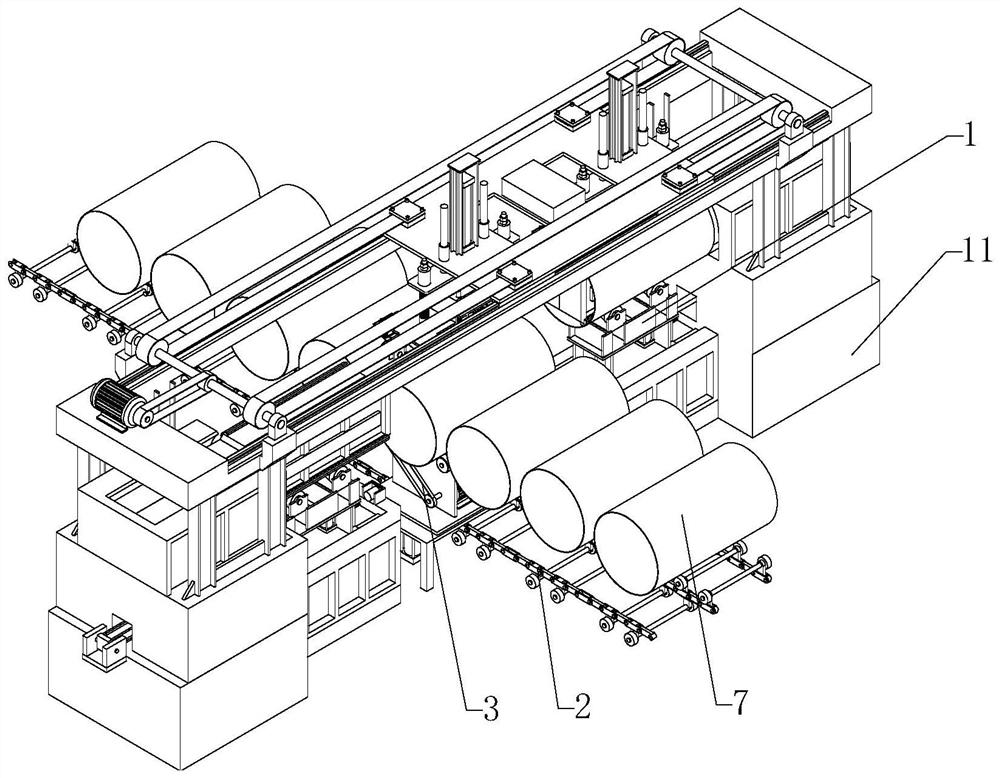

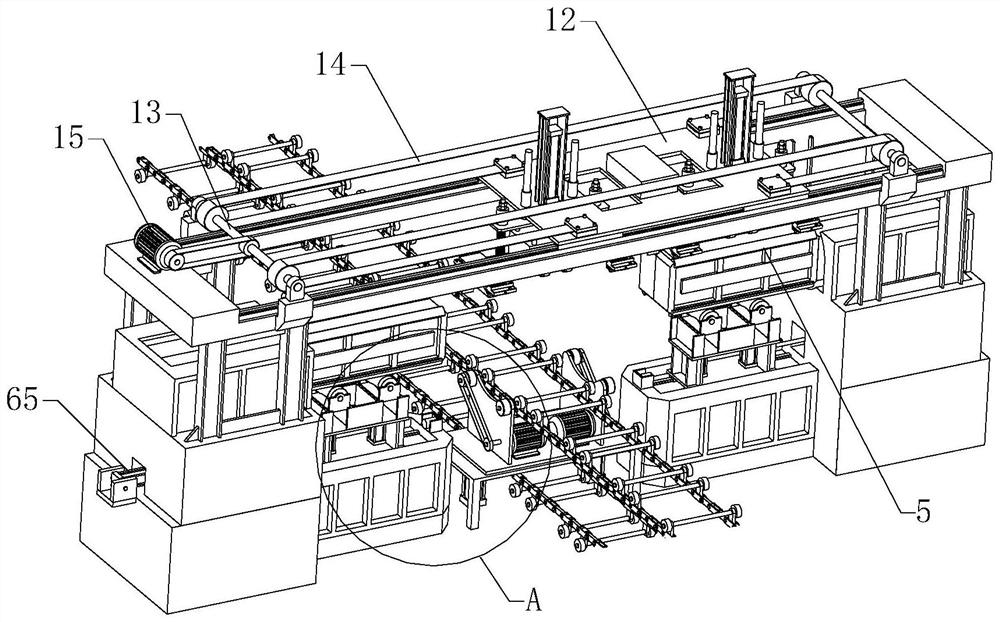

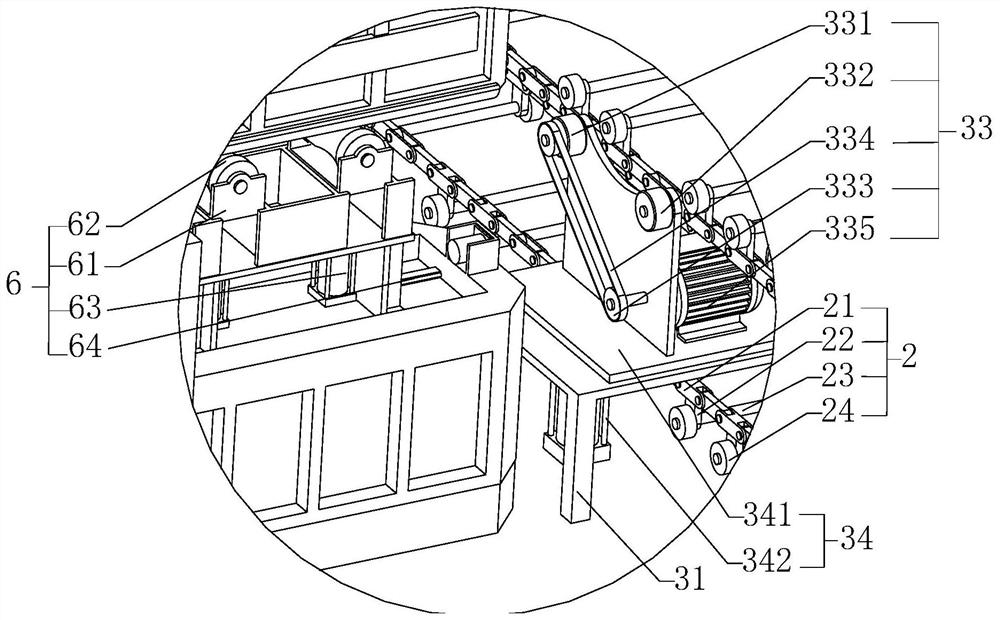

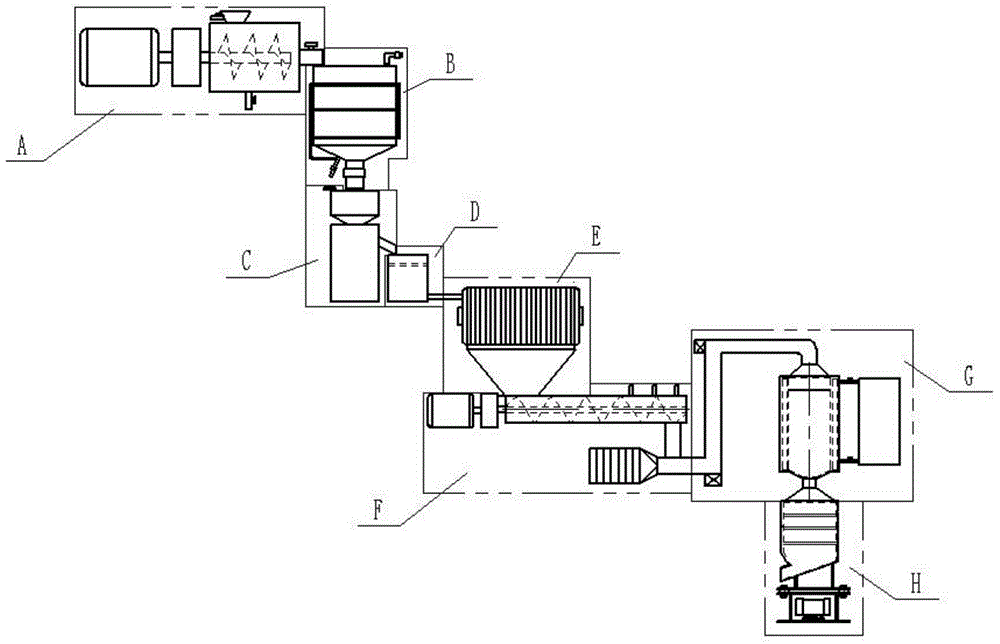

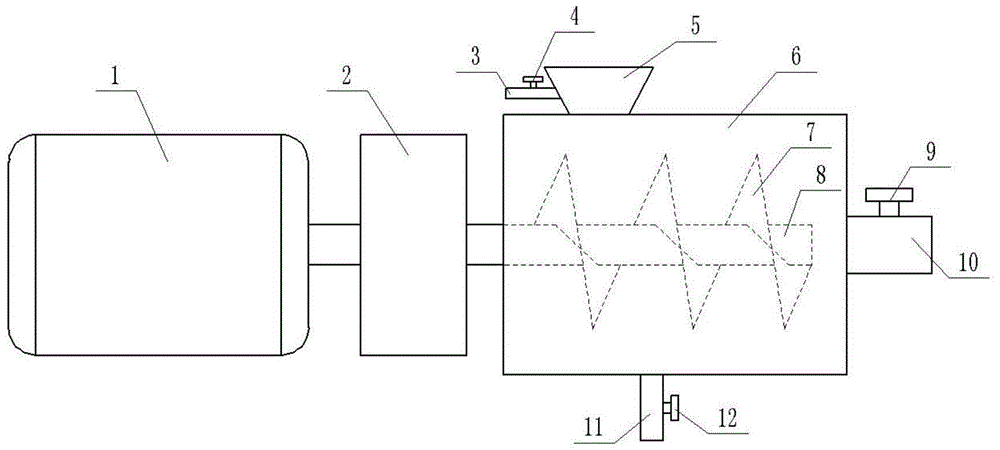

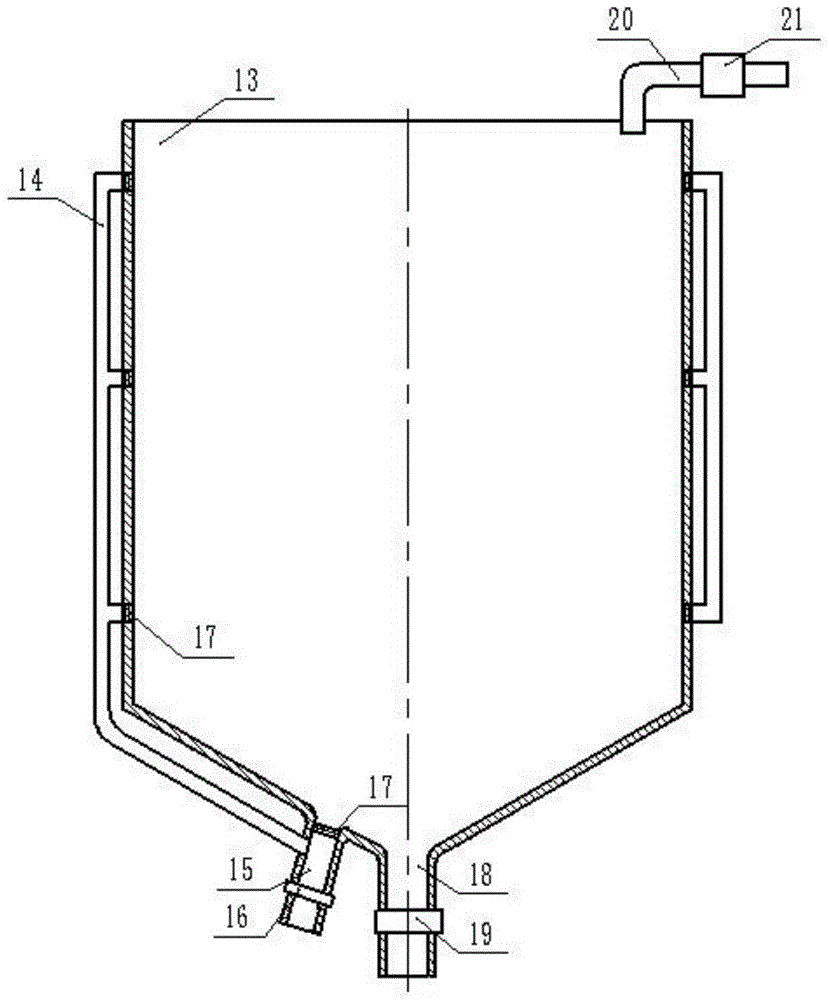

Water grinding rice flour processing system and process method

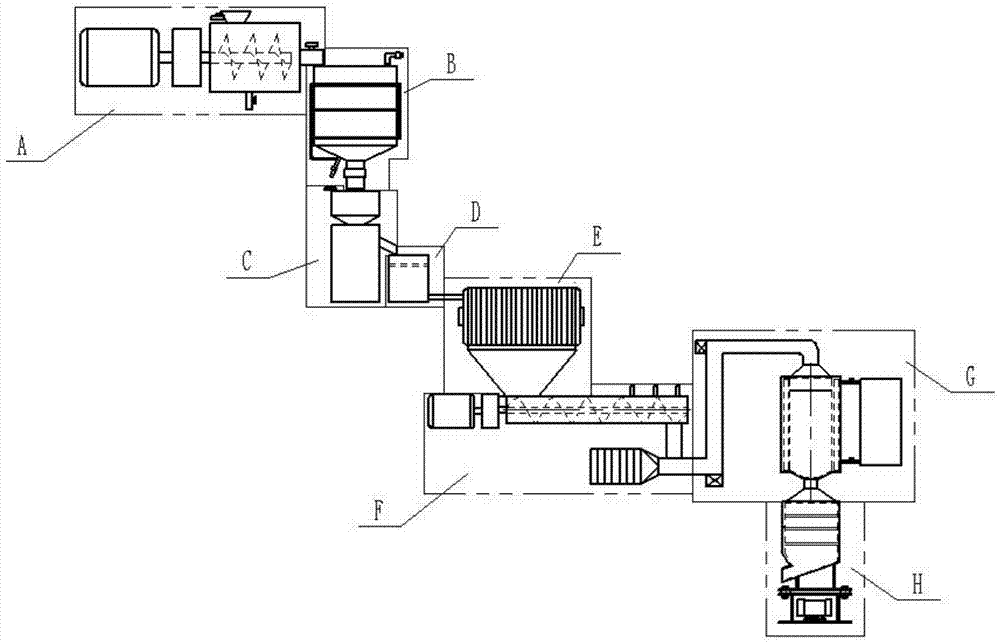

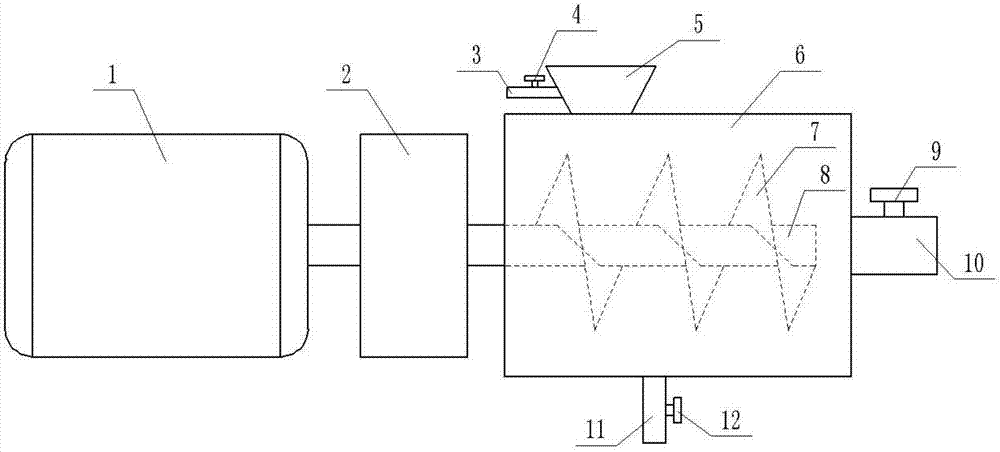

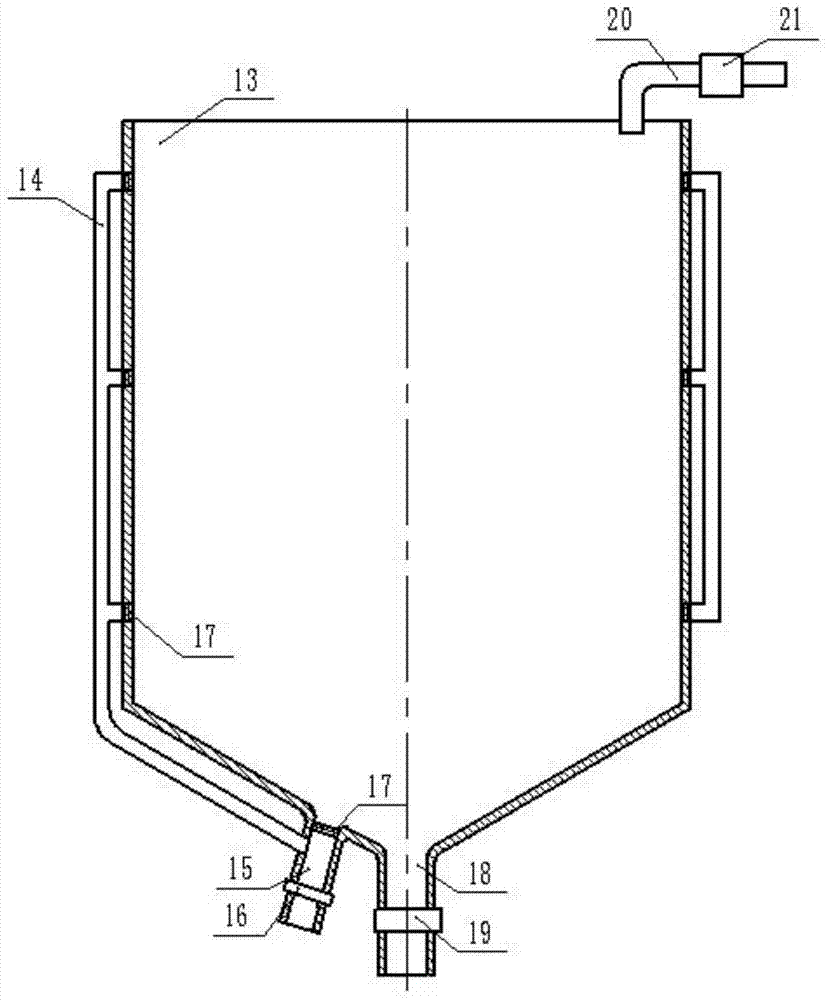

The invention discloses a water grinding rice flour processing system. The water grinding rice flour processing system comprises a washing device, an immersing device, a grinding machine, a filtering device, a dehydrating device, a drying device, a cooling device and a sieving device, wherein the immersing device is arranged under a discharging hole of the washing device; the grinding machine is arranged under a discharging hole of the immersing device; the filtering device is arranged under a pulp outlet of the grinding machine; the dehydrating device is arranged on the right side of the filtering device; a pulp outlet of the filtering device is connected with the inlet of a plate frame filter press of the dehydrating device; the drying device is arranged under the dehydrating device; the outlet of a collection hopper of the dehydrating device is connected with a feeding hole of the drying device; the cooling device is arranged on the right side of the drying device; a feeding hole of the cooling device is connected with a hot air pipe of the drying device; and the sieving device is arranged just under a trumpet-shaped discharging hole of the cooling device. According to the water grinding rice flour processing system, all the devices are integrally designed and an automatic rice flour production line is provided; and the automatic degree is high, the production efficiency is high, the manpower is saved and the production quality is reliable.

Owner:CHANGSHA XUEHUANG GRAIN & OIL

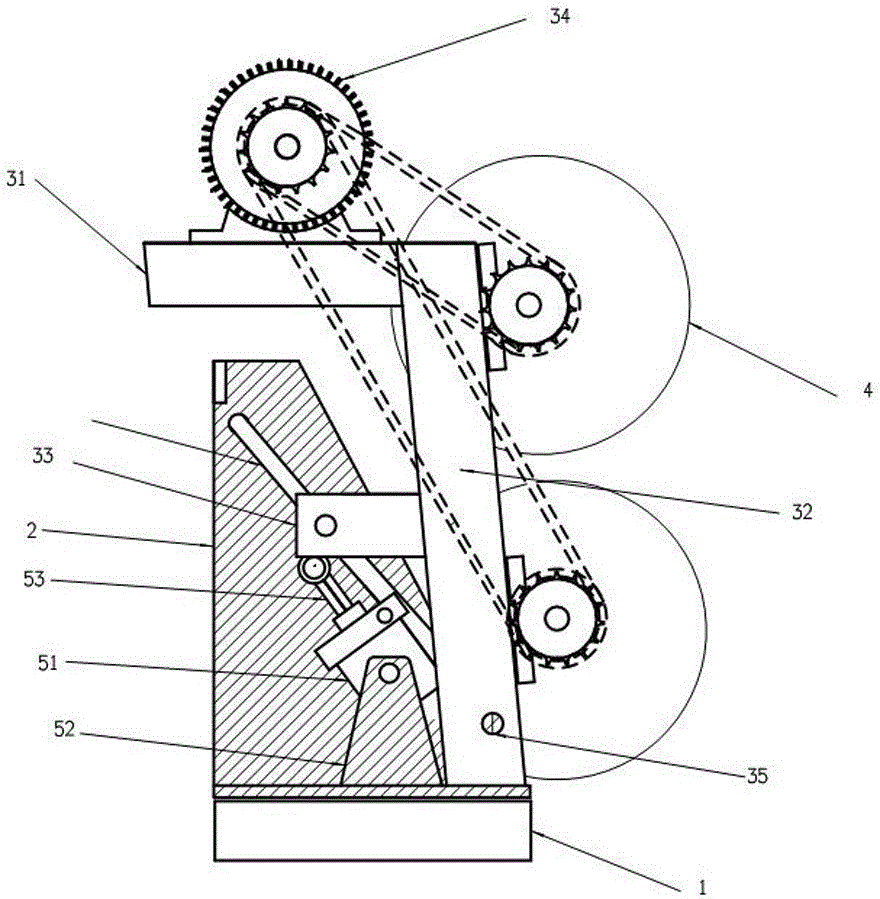

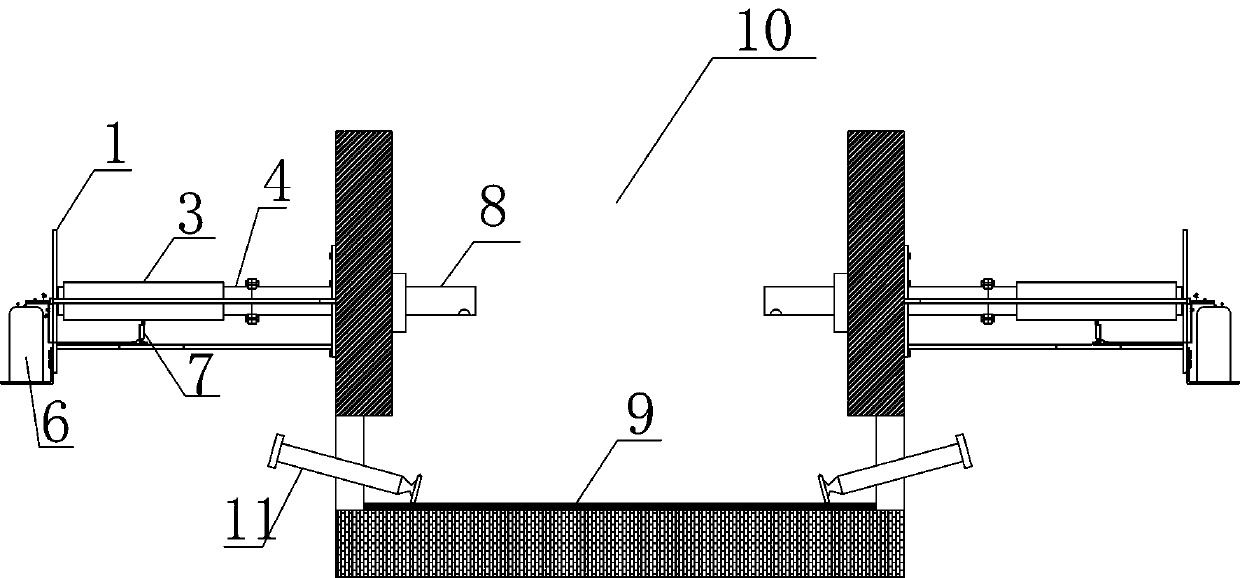

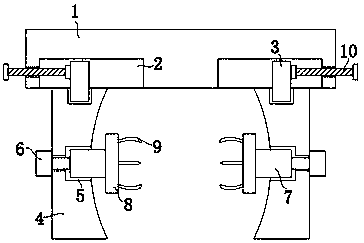

Automatic turnover system of die assembly bolt of pipe pile

InactiveCN106003414AAchieve rotationImprove tightening efficiencyCeramic shaping apparatusDrive motorEngineering

The invention relates to an automatic turnover system of a die assembly bolt of a pipe pile. According to the innovation point, the turnover system comprises a supporting base, guide plates, a mounting rack, nylon brushes and an adjusting mechanism; the automatic turnover system of the die assembly bolt of the pipe pile is mounted on the two sides of a pipe pile die rail; the nylon brush on the lower portion of the turnover system is obliquely located below the die assembly bolt in a vertical state and is closely attached to the die assembly bolt; and when a die assembly procedure is carried out after pipe pile dies are filled with concrete, a drive motor drives the nylon brushes to rotate, the nylon brush on the lower portion enables the die assembly bolt to rotate around the lower pipe pile die and then ascend to be in contact with the nylon brush on the upper portion of the turnover system, and therefore the die assembly bolt is driven by the nylon brush on the upper portion to continue to rotate, 180-degree rotation is achieved, and the die assembly bolt can be screwed down by workers conveniently.

Owner:国鼎(南通)管桩有限公司

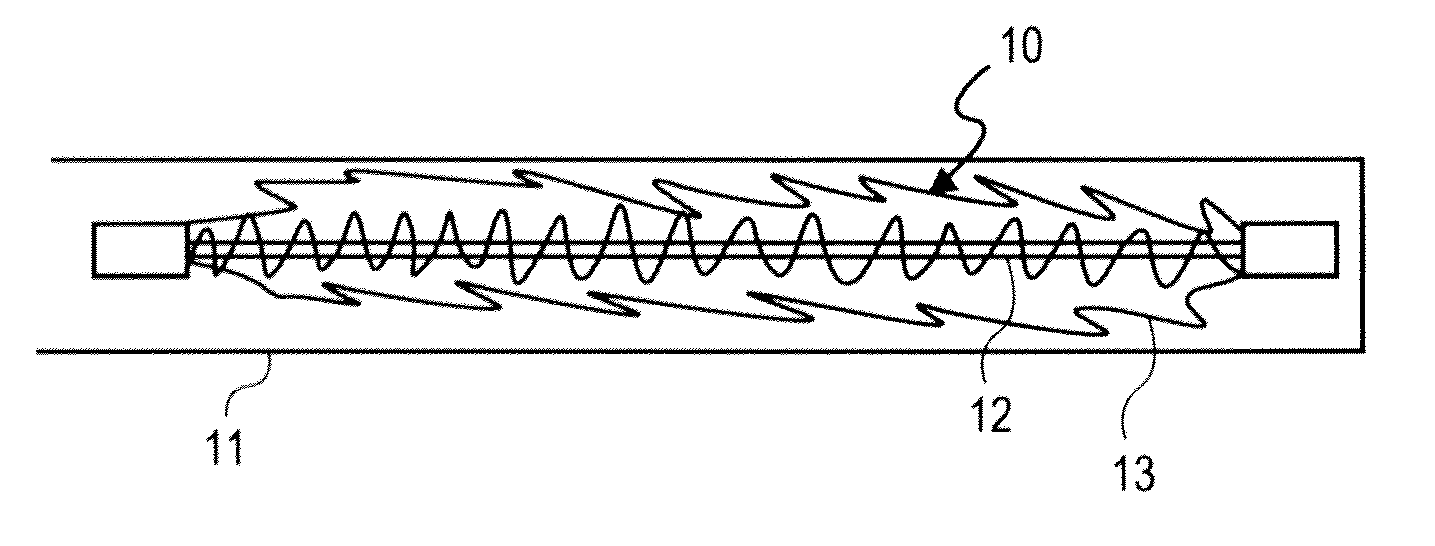

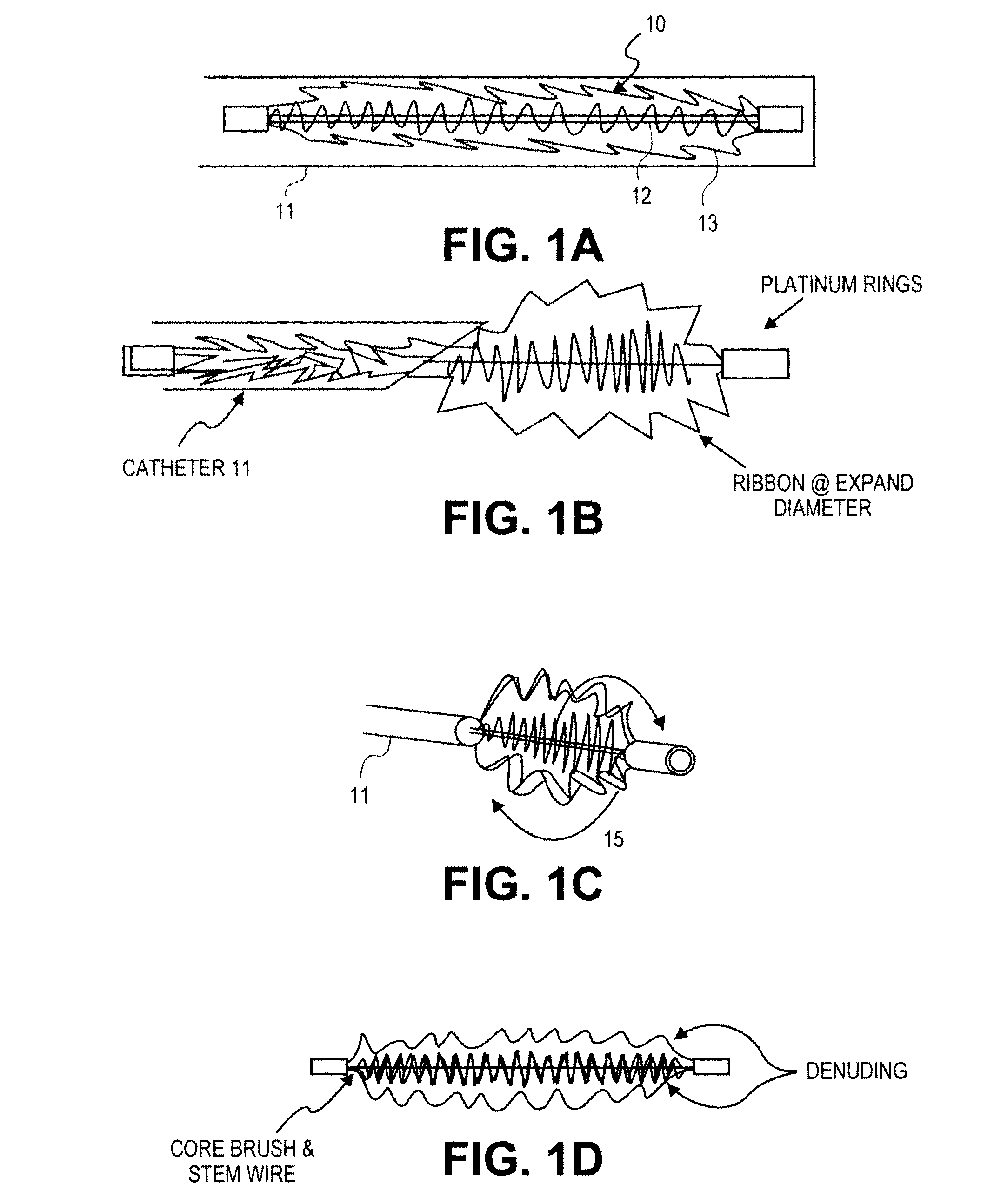

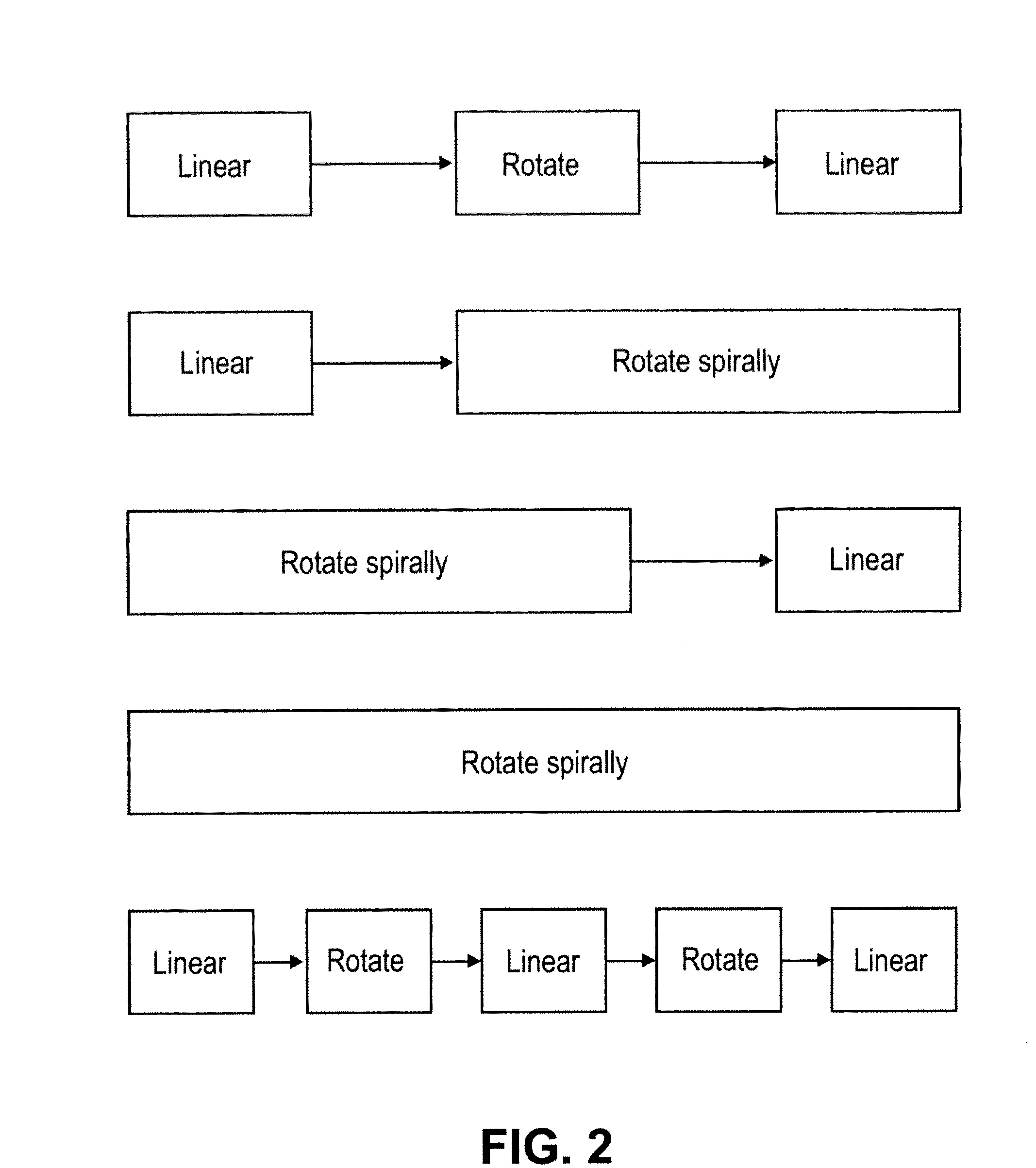

Methods and devices for deployment into a lumen

InactiveUS20100114151A1Efficient configurationDelay deploymentFallopian occludersDilatorsLinear motionFree rotation

The present invention is directed to an intracorporeal occlusion device having denuding elements, motion transfer converter or anti-migration features or a combination of one or more of these features. The disclosed occlusion device can denude the body lumen through a rotational motion of the denuding elements within a lumen. The delivery system can transfer a linear motion of a handle to a combination of linear and rotational movements of the occlusion device for placement and denuding action. Anti-migration features provide free spinning of the main body of the occlusion device to prevent migration of the deployed occlusion device, especially with rotatable denuding elements.

Owner:BAYER HEALTHCARE LLC

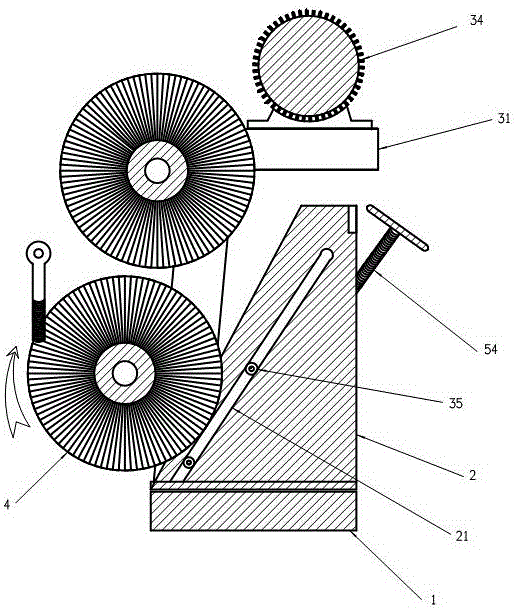

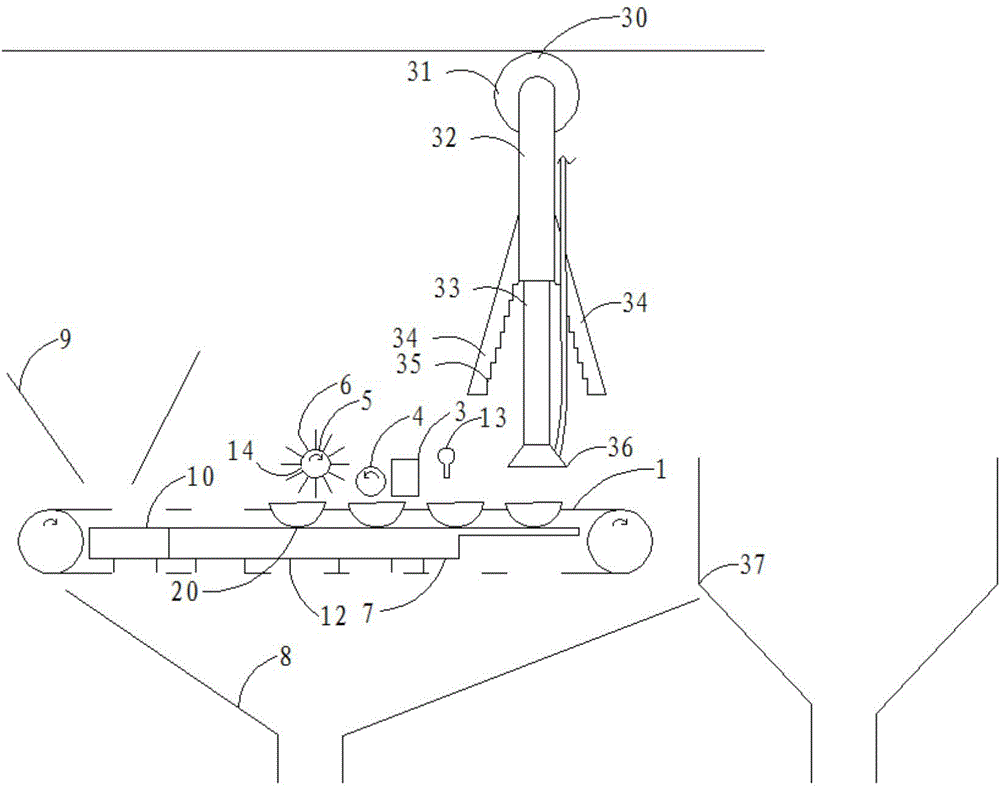

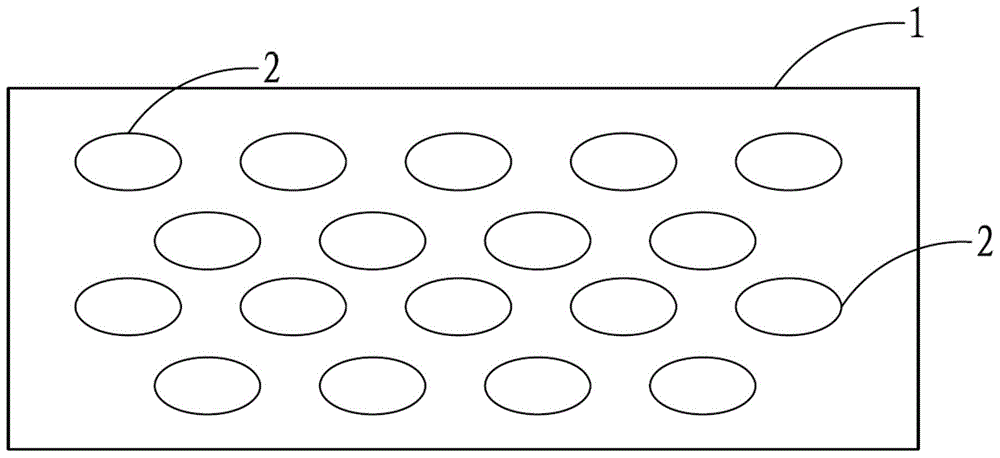

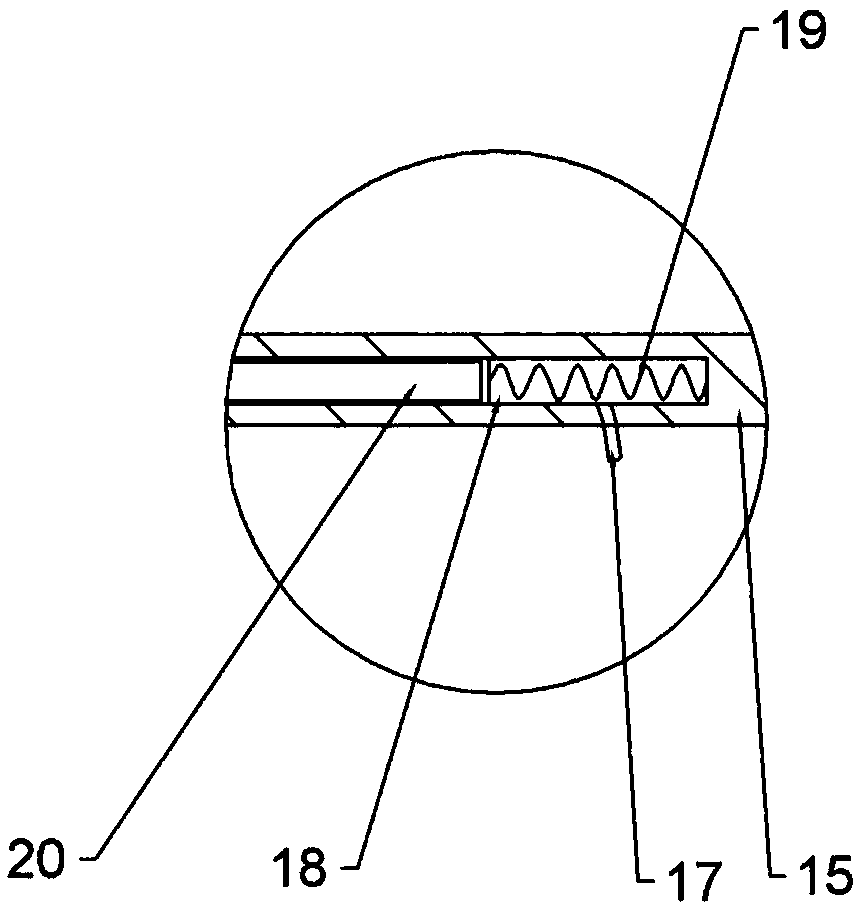

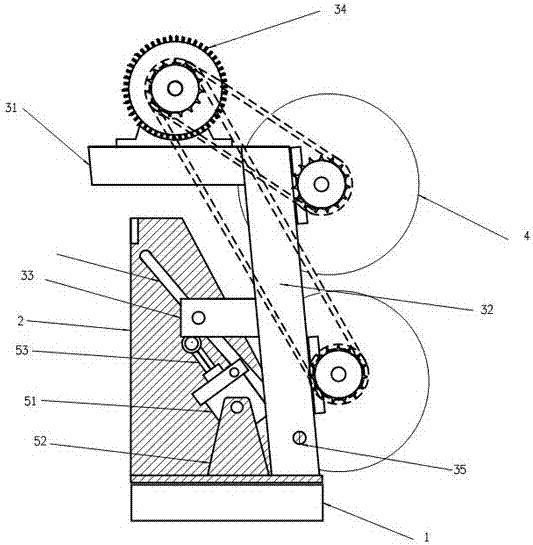

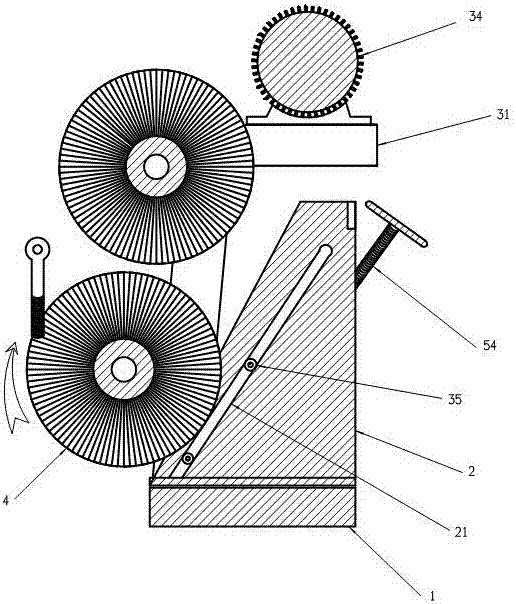

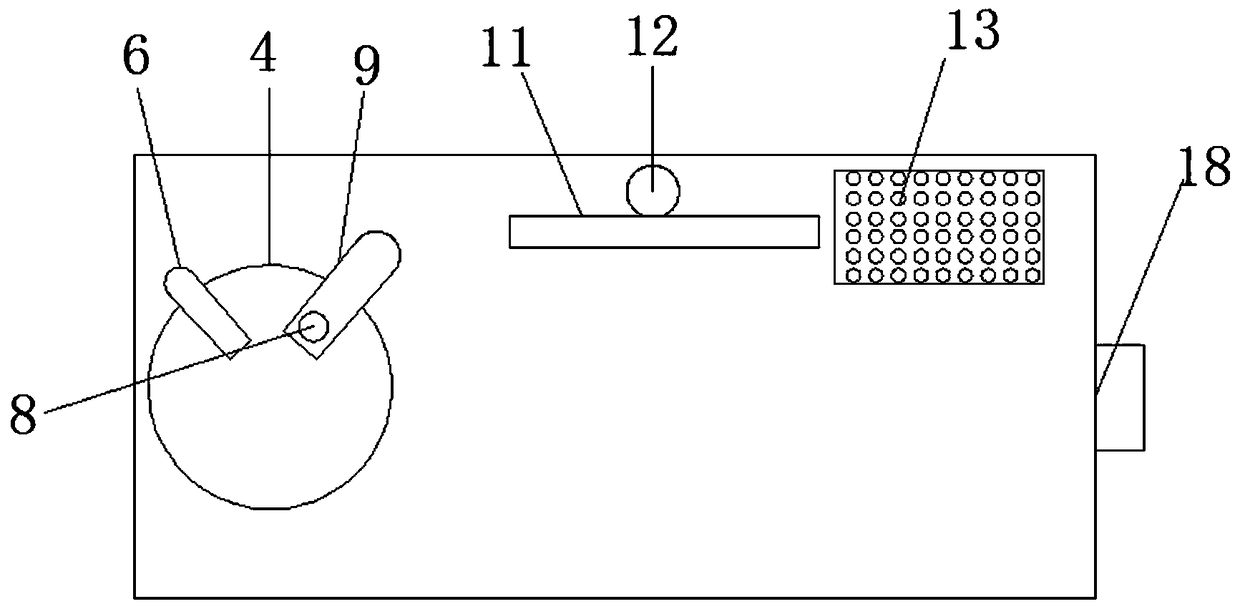

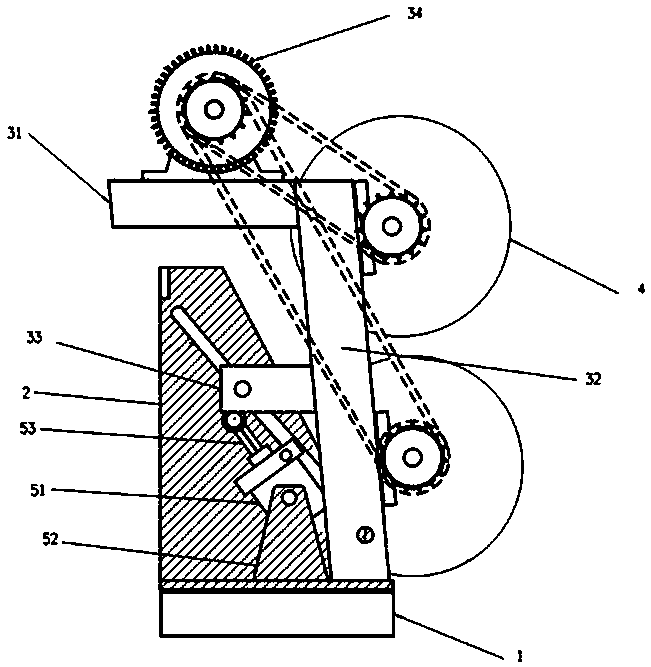

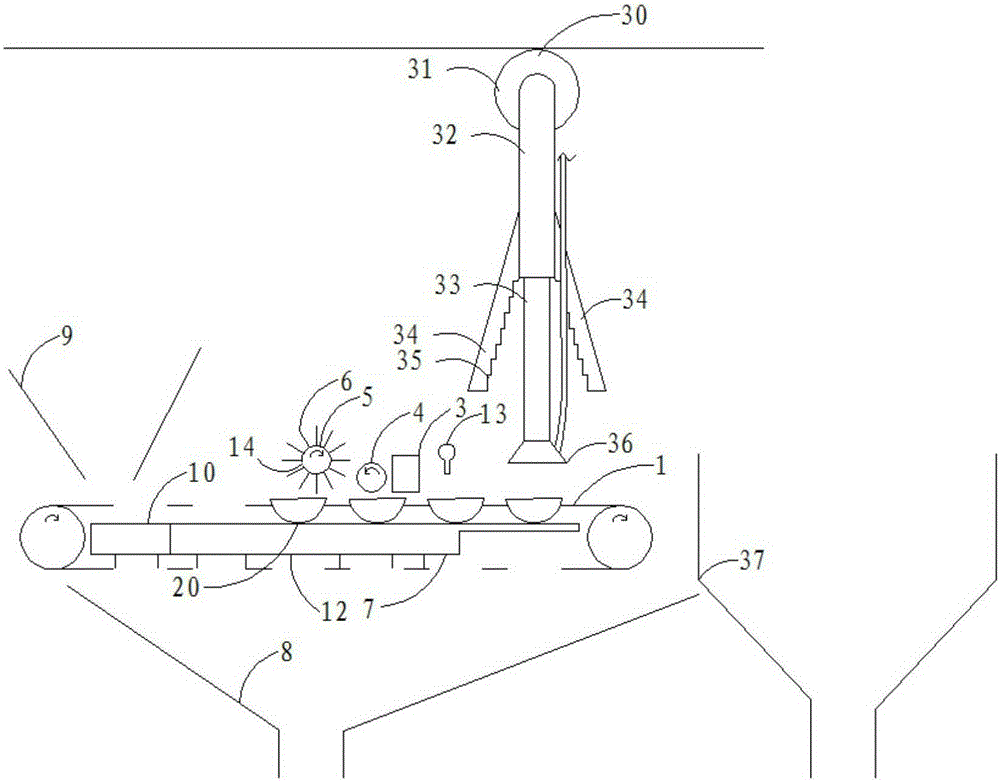

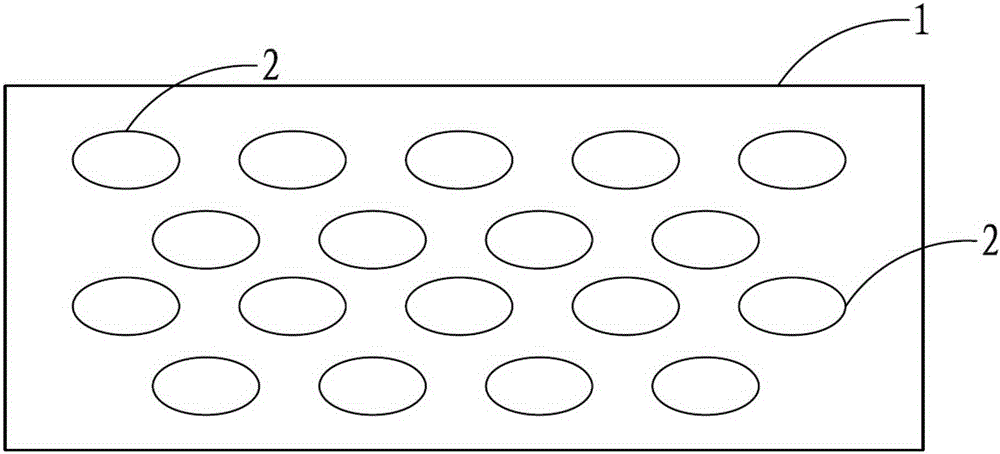

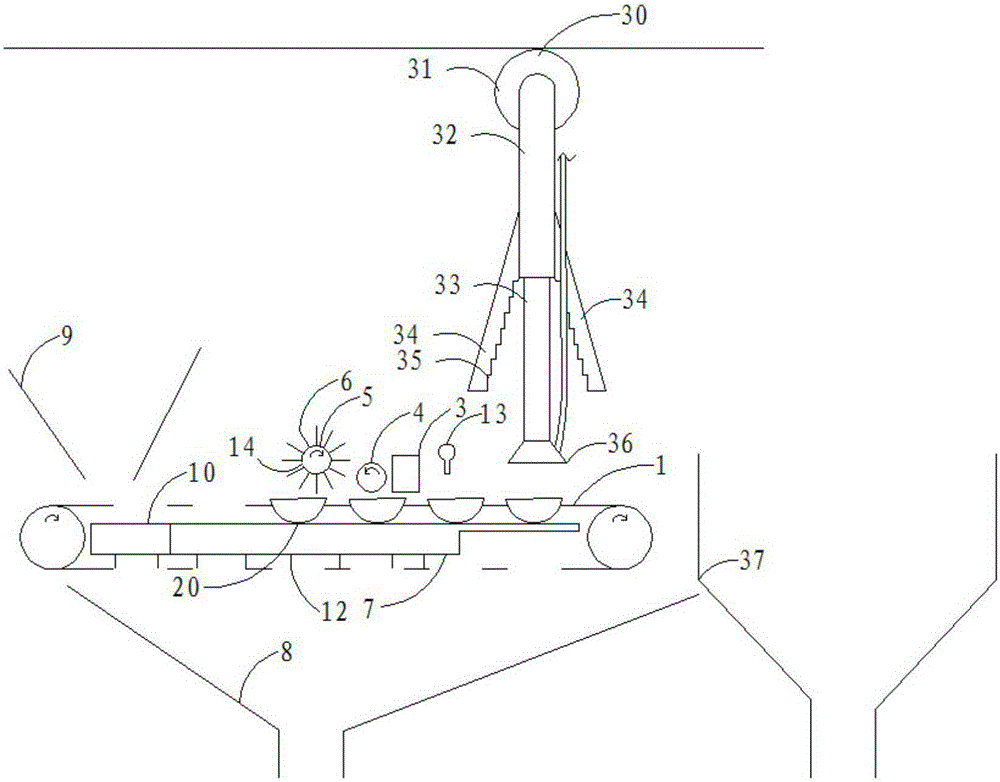

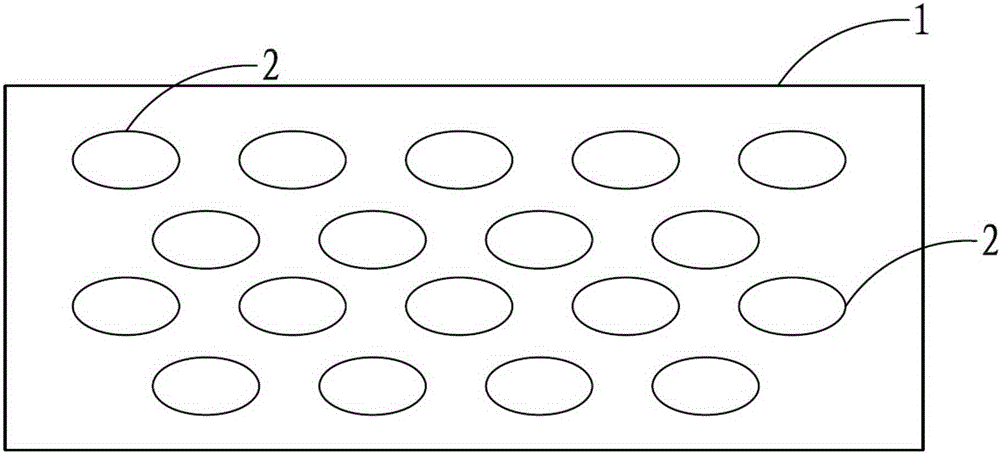

Efficient fully-automatic abalone processing equipment

InactiveCN104920577AAvoid manual rotationReduce processing stepsShellfish processingTransmission beltLong axis

The invention provides efficient fully-automatic abalone processing equipment. The efficient fully-automatic abalone processing equipment comprises a conveyor belt, wherein oval holes are formed in the conveyor belt, and the direction of long axes of the oval holes is consonant with the movement direction of a transmission belt; a blocking limited block is arranged above the transmission belt, a rotating wheel is arranged on the left side of the limited block, a cylindrical rotary brush is arranged on the left side of the rotating wheel, and brush finish is arranged on the side surface of the circumference of the rotary brush; a platform is arranged in the transmission belt, a collecting hopper is arranged under the transmission belt, and a feed hopper is arranged on the upper left side of the transmission belt; the transmission belt and the rotary brush are driven by a motor, and the conveyor belt and the rotary brush rotate in a clockwise direction. According to the efficient fully-automatic abalone processing equipment disclosed by the invention, abalones can automatically rotate to positions where abalone meat faces upwards, the abalones can be automatically processed, the problem of manually rotating and processing the abalones is solved, the working efficiency is improved, and the labor cost is reduced.

Owner:江华瑶族自治县金牛开发建设有限公司

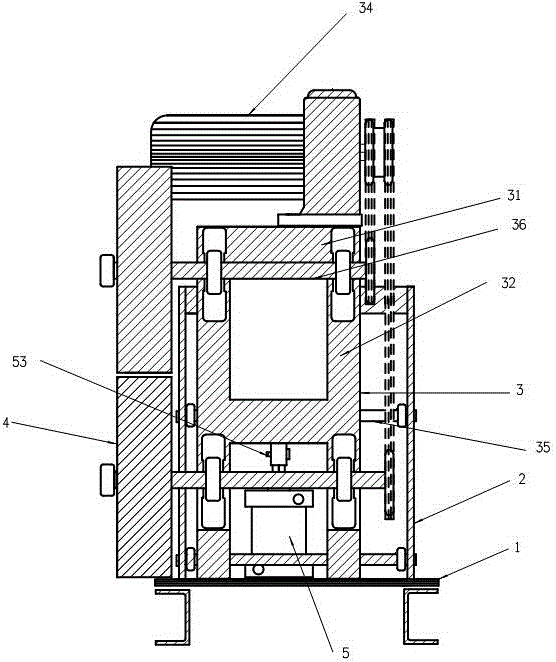

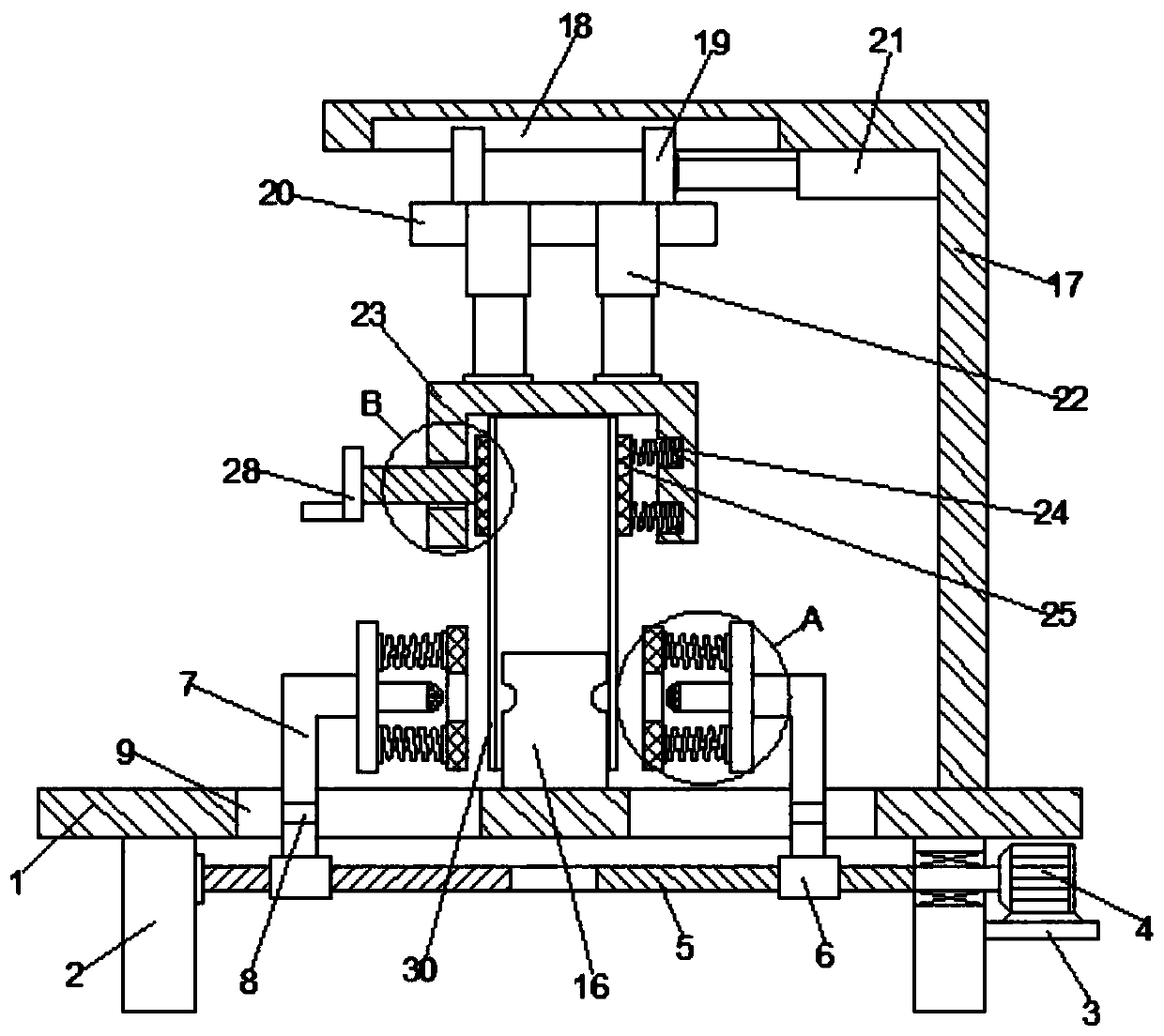

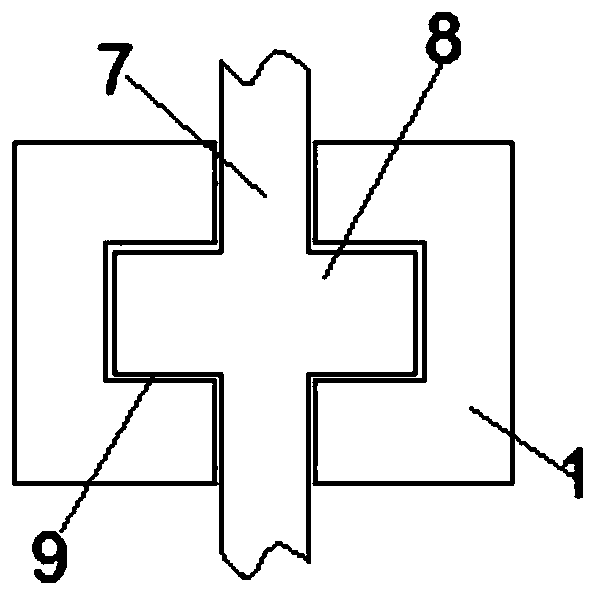

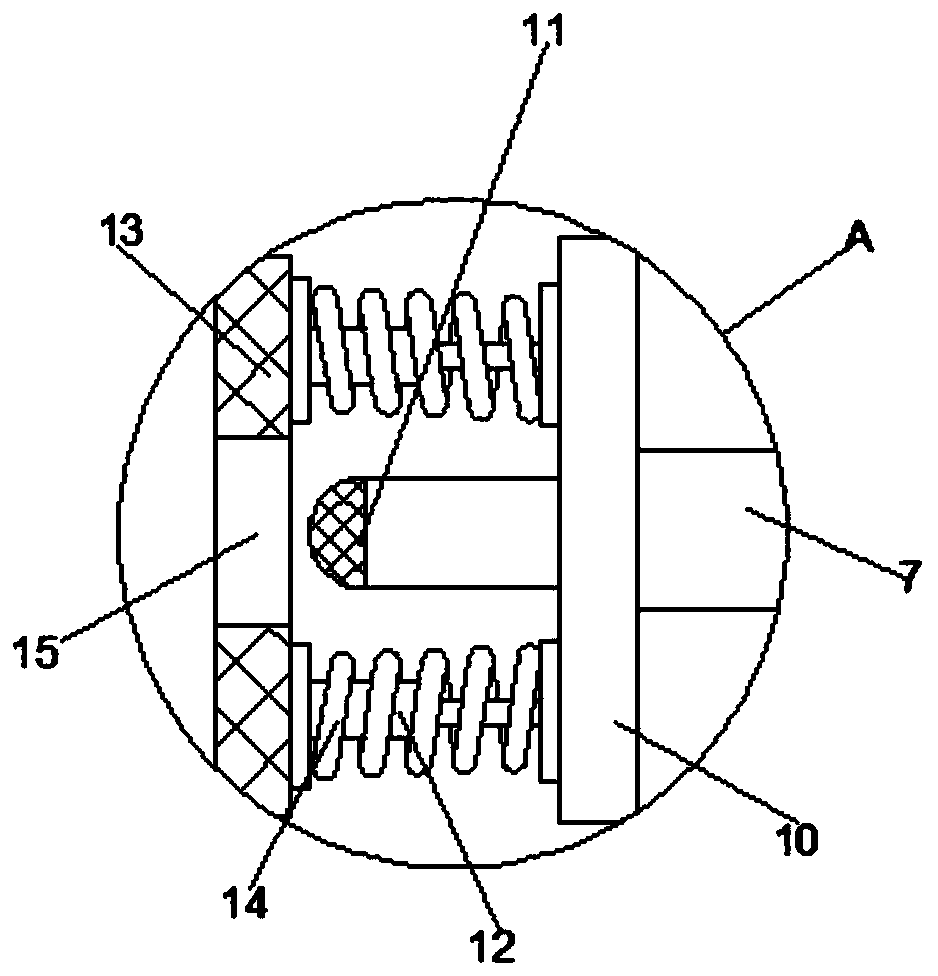

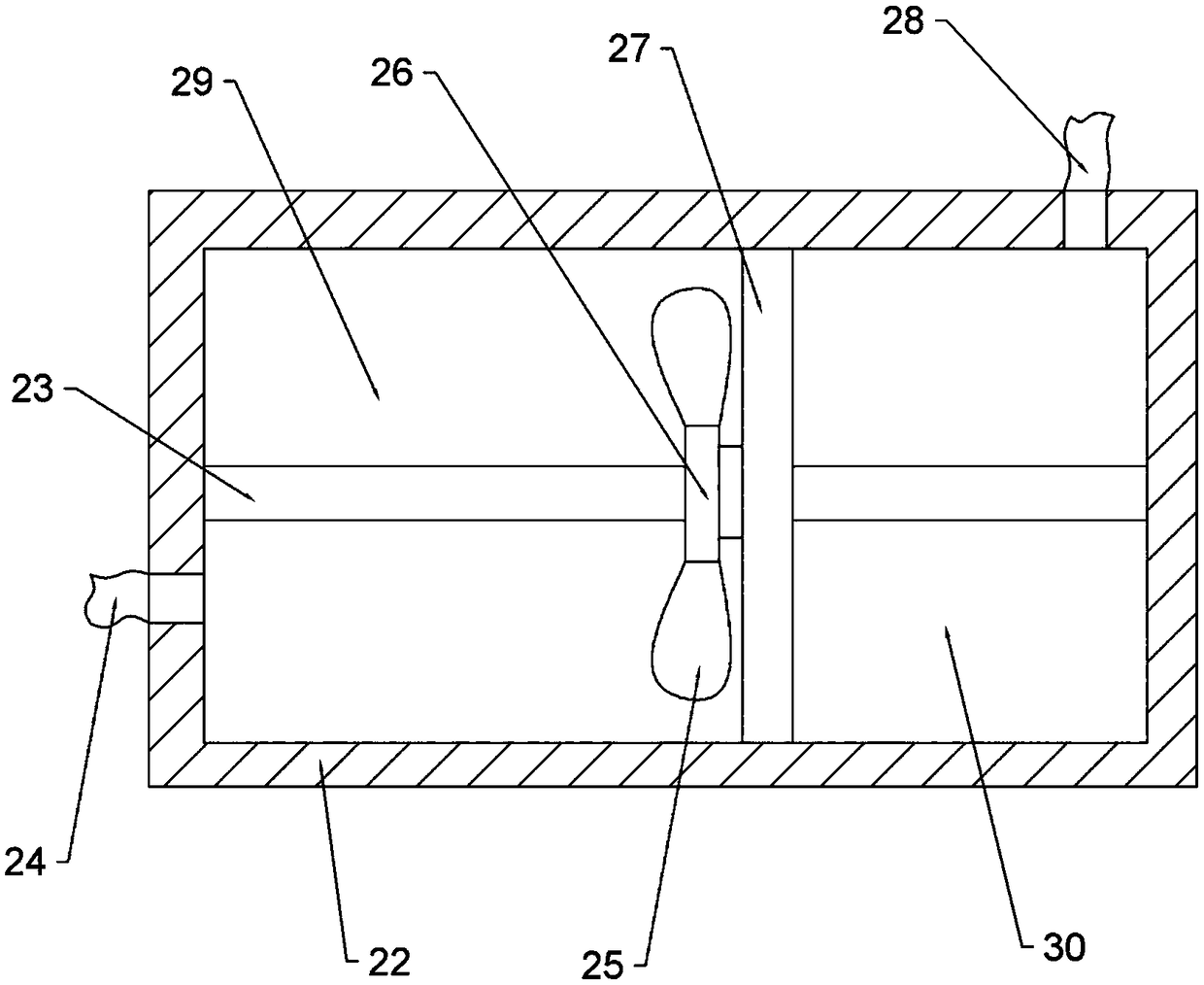

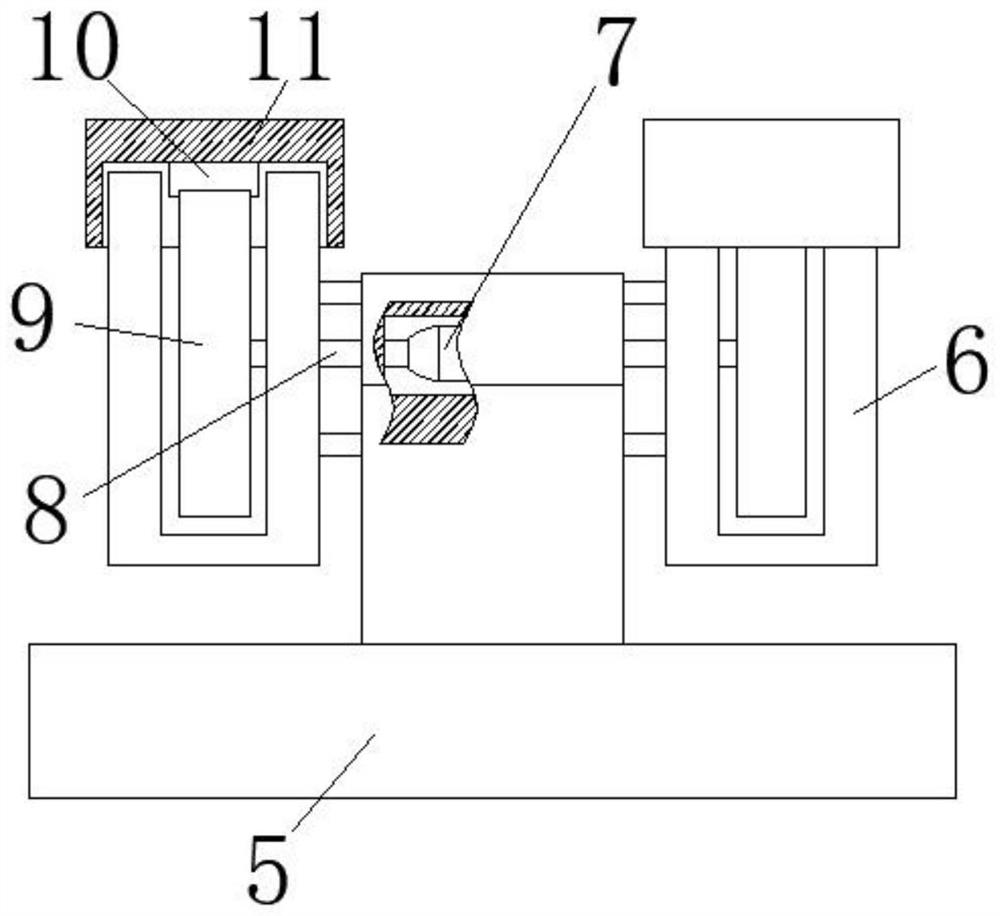

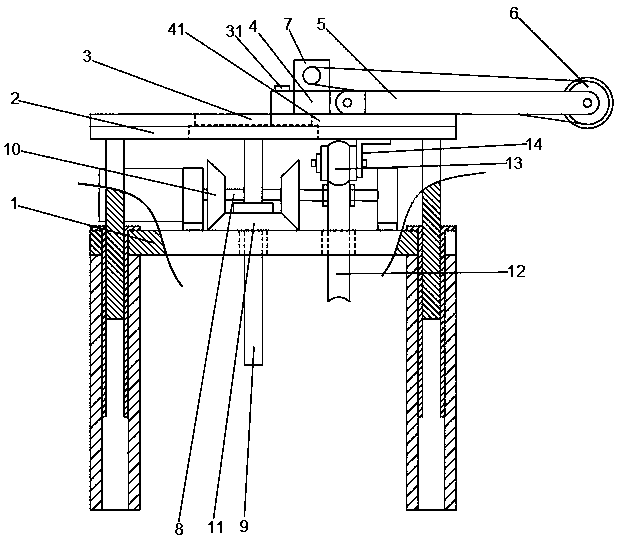

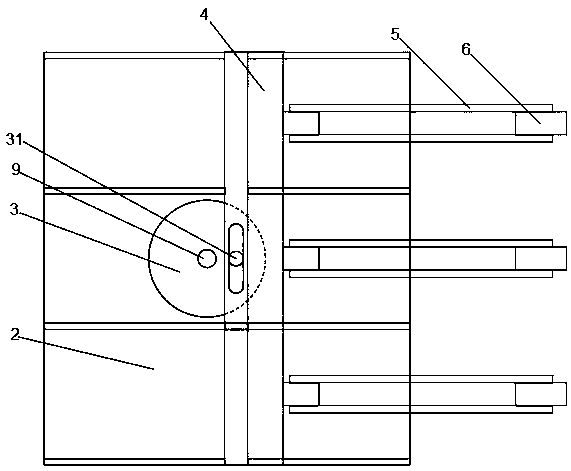

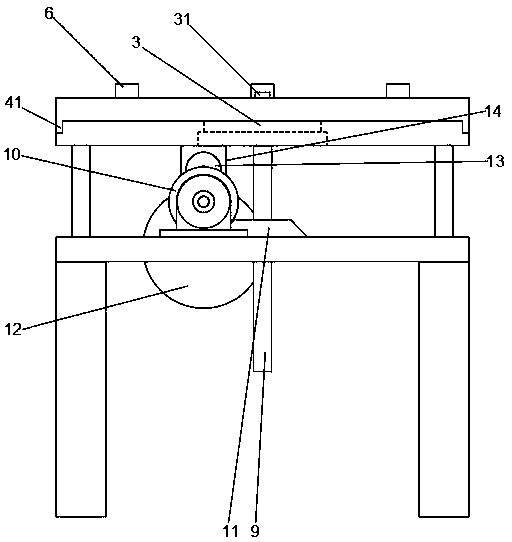

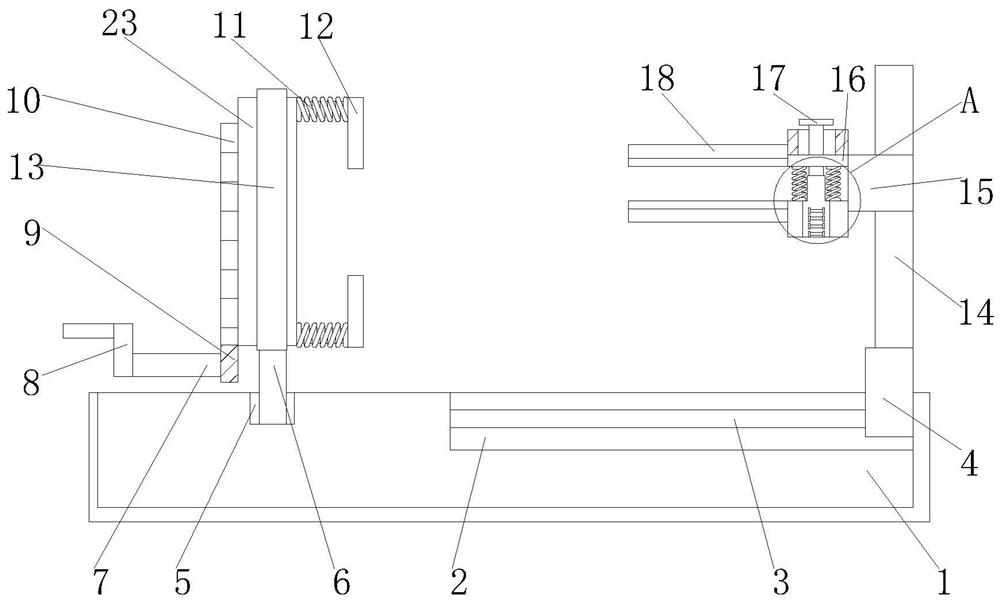

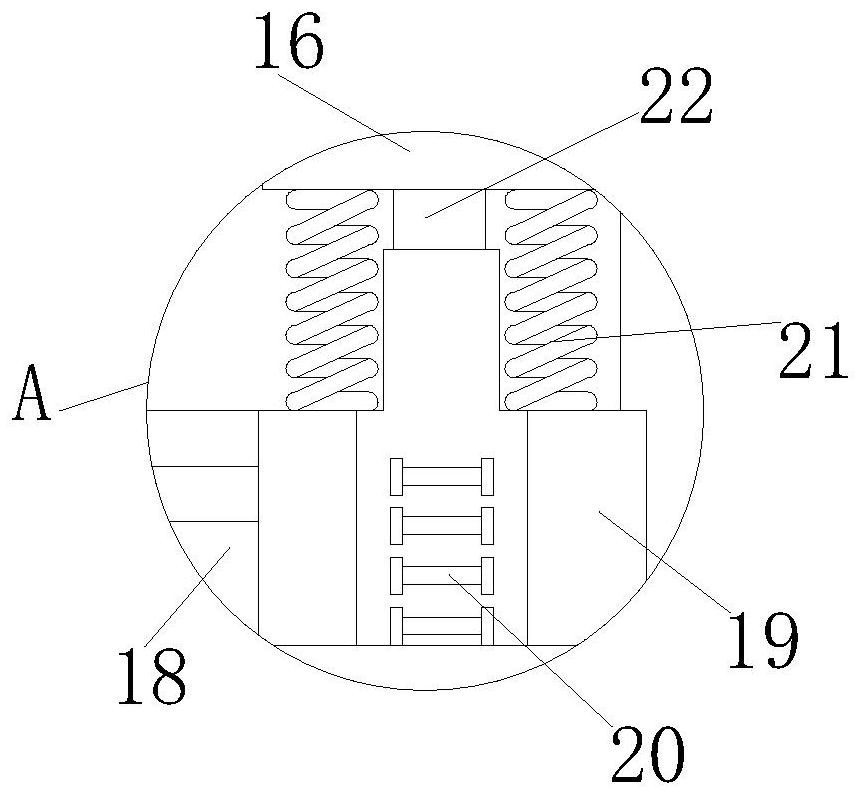

Stamping device for bicycle pipe fitting machining

InactiveCN111036751AAvoid manual rotationEasy to fixShaping toolsMetal-working feeding devicesPipe fittingElectric machinery

The invention relates to the technical field of bicycle pipe fitting machining and particularly relates to a stamping device for bicycle pipe fitting machining. The device comprises a base; supportingseats are symmetrically arranged at a bottom of the base; a fixed plate is arranged in the middle of a right supporting seat; a driving motor is mounted on the fixed plate; a screw is arranged at anoutput end of the driving motor; the screw penetrates an upper portion of the right supporting base and is rotationally connected with a left supporting base; the screw is symmetrically sleeved with nuts; and L-shaped rods are symmetrically arranged at tops of the nuts. The invention provides a stamping device for bicycle pipe fitting machining. Under the action of a first clamping block and a second clamping block, the effect of clamping a pipe fitting body is achieved; the fixing effect is good, the punching precision is improved, the effect of adjusting the punching position of the pipe fitting body is achieved under the action of a first driving air cylinder and a second driving air cylinder, an effect of adjusting a punching position of the pipe fitting body is achieved, different positions of a pipe fitting can be punched, meanwhile, punching is completed in the left direction and the right direction of the pipe fitting body, and the working efficiency is improved.

Owner:湖州屹鼎自动化科技有限公司

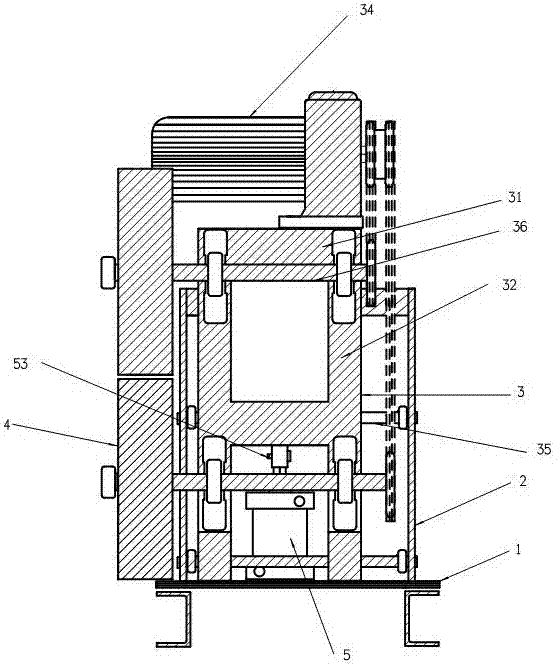

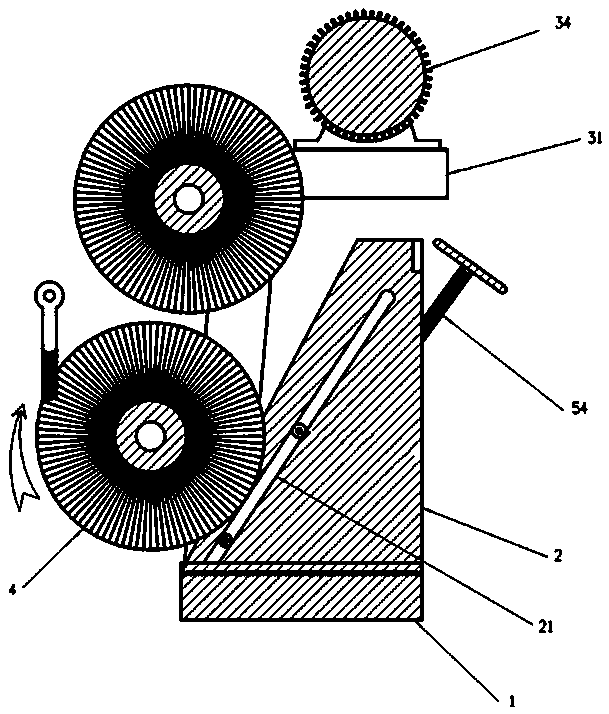

Wood polishing device

ActiveCN111015392AEasy to polishEasy to shipEdge grinding machinesRevolution surface grinding machinesCantilevered beamGear wheel

A wood polishing device comprises a polishing mechanism, a movable lifting mechanism and a bottom plate, one end of the bottom plate is connected with an incomplete gear through a motor; the device further comprises a cantilever beam, the cantilever beam is connected with a bearing seat through a pull rod, the bearing seat is connected with a gear through a shaft, one end of the shaft is connectedwith a positioning plate, the lower end of the side wall of the positioning plate is connected with an arc-shaped frame I, the top end of the positioning plate is connected with an air cylinder through a support, and the air cylinder is connected with an arc-shaped frame II. By means of the design that the incomplete gear is in meshing transmission with the gear, a log rotates intermittently, time is reserved for a polishing piece to polish the log, and a shaft pipe and a shaft rod drive the polishing piece to stretch and contract, the logs with different diameters can be polished conveniently, the motor drives the positioning plate to rotate, the polishing piece polishes the circumference of the log, and manual rotation is avoided.

Owner:雅棣木业江苏有限公司

Vehicle exhaust pipe hot end welding fixture tool

ActiveCN112589366AAchieve fixed clampingAdjust the tilt angleInternal combustion piston enginesWelding/cutting auxillary devicesHydraulic cylinderStructural engineering

The invention relates to the technical field of vehicle machining and production, in particular to a vehicle exhaust pipe hot end welding fixture tool. The vehicle exhaust pipe hot end welding fixturetool comprises a base, an exhaust pipe is arranged at the upper end of the base, a clamping block is arranged on the rear side of the upper end of the base in a sliding mode, side plates are vertically welded to the front end and the rear end of the left side of the upper end surface of the base, a hydraulic cylinder and a fixing clamp are correspondingly arranged on the inner sides of the pair of side plates in sagittal symmetry, and the end part of a telescopic rod of the hydraulic cylinder is fixedly arranged on the rear side of the clamping block. The vehicle exhaust pipe hot end weldingfixture tool has the beneficial effects that the clamping block pushed by the hydraulic cylinder is arranged, so that an exhaust pipe is fixedly clamped, meanwhile, an inserting rotating rod with a limiting clamping groove is utilized, so that the clamping force is limited, and through cooperation of the rotating rod capable of rotating, the inclination angle of the exhaust pipe device is adjusted; and through cooperation of a rotating groove and a rotating arc plate, autorotation adjustment of the exhaust pipe after being clamped and fixed is realized, so that circumferential rotating weldingis realized in the welding process, manual rotation is avoided, and therefore the welding and fixing precision is greatly improved.

Owner:江门市瑞跃实业有限公司

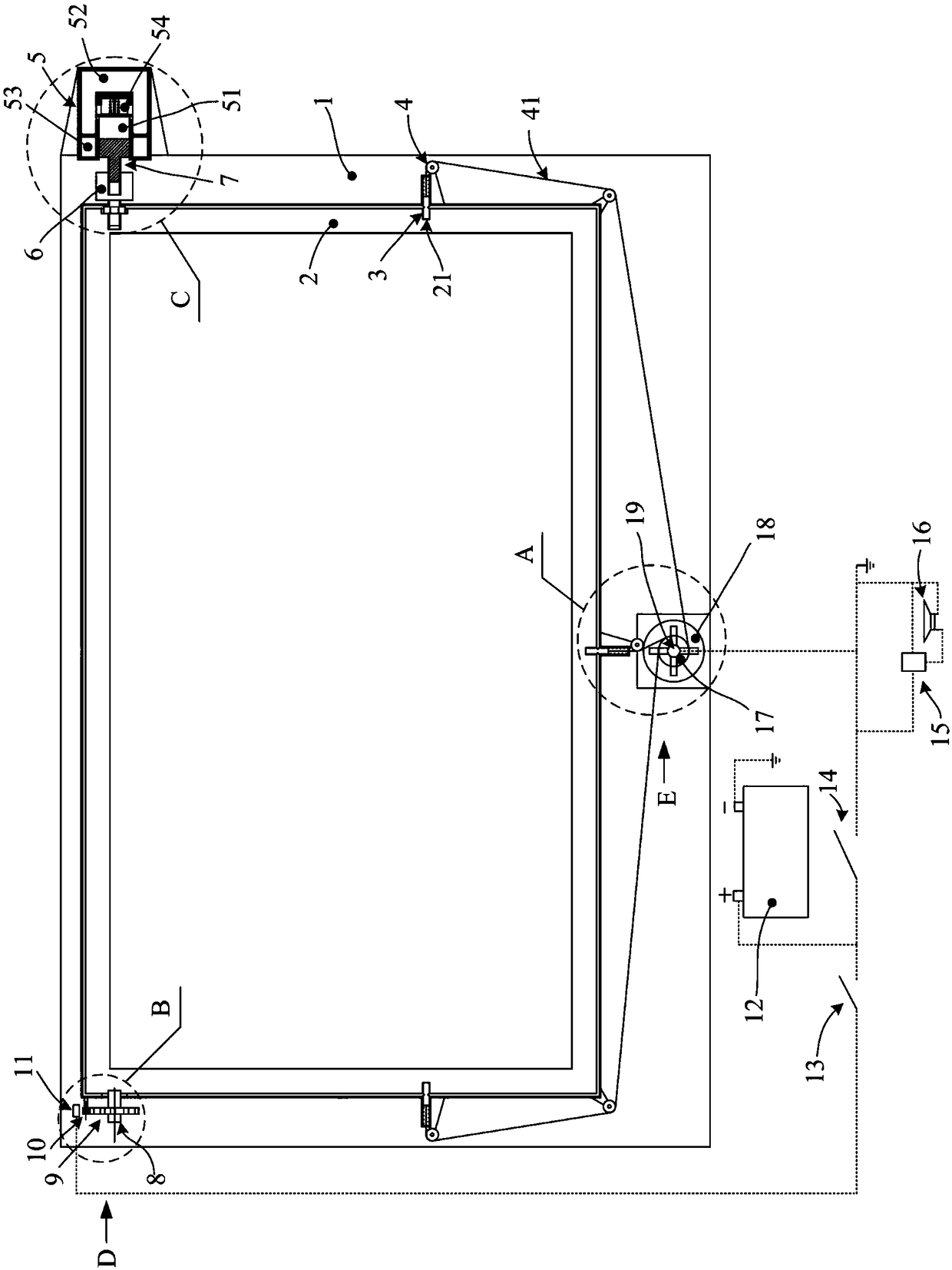

Emergency vehicle window of passenger car

The invention discloses an emergency vehicle window of a passenger car, which comprises a side window, wherein the top of the side window is pivotally connected with a vehicle body, the edges of the left side, the right side and the lower side of the side window are respectively provided with lock pin jacks capable of being inserted with lock pins, the side edges of the side window in the vehiclebody are provided with lock pins capable of telescopically extend out and the lock pins are inserted into the lock pin jacks. The device also comprises a window opening motor, wherein the output end of the window opening motor is connected with the center of a driving pulley, a plurality of steel wire ropes are wound on the peripheral surface of the driving pulley, the steel wire ropes are respectively connected with the end part of the lock pin after passing through a transition wheel, and the window opening motor is electrically connected with a window opening switch and a storage battery inturn through leads. Compared with the prior art, the technical scheme of the emergency vehicle window of the passenger car has the advantages of safety, convenience, reliability and the like, and caneffectively improve the convenience and the survival rate of the escape of the side window of the public transportation tool.

Owner:GUANGDONG MECHANICAL & ELECTRICAL COLLEGE

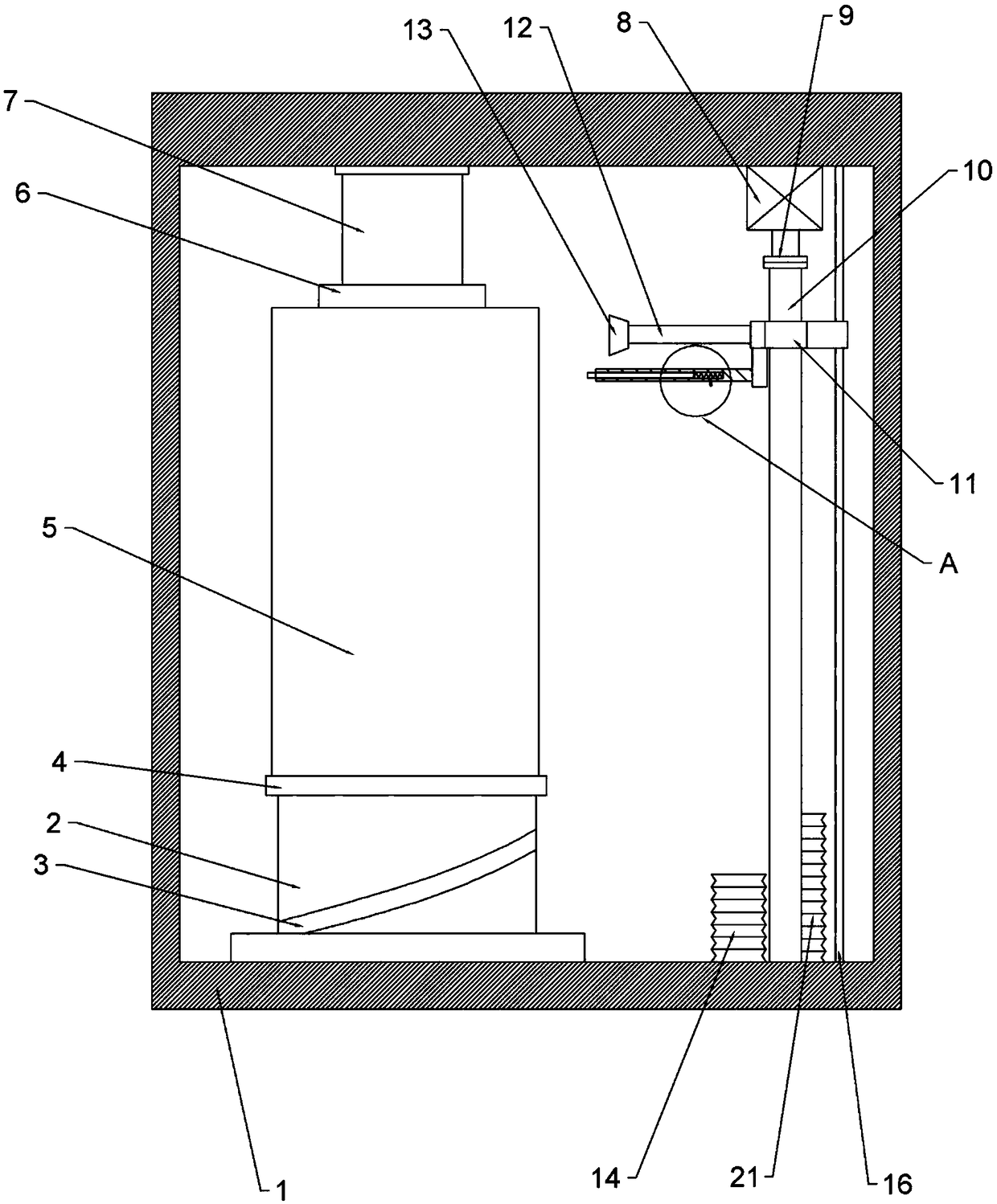

Wind power generation power distribution cabinet surface paint spraying device

ActiveCN109351517AAvoid affecting the painting effectUniform paint effectSpraying apparatusSprayerEngineering

The invention belongs to the field of paint spraying devices, and particularly discloses a wind power generation power distribution cabinet surface paint spraying device. The wind power generation power distribution cabinet surface paint spraying device comprises a shell, a rotation barrel, a one-way bearing and a rotation disc. The lower end of the rotation barrel is rotationally connected with the bottom of the shell, and the upper end of the rotation barrel is connected with the rotation disc through the one-way bearing. The shell is internally provided with a paint spraying structure and amoving structure. The paint spraying structure comprises a paint storage bin, a communication pipe and a sprayer, and the two ends of the communication pipe are connected with the paint storage bin and the sprayer correspondingly. The moving structure comprises a power source, a screw and a threaded piece, wherein the power source is fixedly connected with the shell, the screw is vertically arranged, an output shaft of the power source is connected with one end of the screw, the other end of the screw is rotationally connected with the shell, the threaded piece and the screw are in threaded fit, a guide rod parallel to the screw is arranged in the shell, and the guide rod is in sliding fit with the threaded piece. The sprayer is fixedly connected with the threaded piece. The 1 / 4 circumference face of the rotation barrel is provided with a chute, and the threaded piece is provided with a lifting lever capable of being inserted in the chute. The device can achieve automatic power distribution cabinet paint spraying, and paint spraying is uniform.

Owner:CHONGQING WANGBIAN ELECTRIC GRP CORP

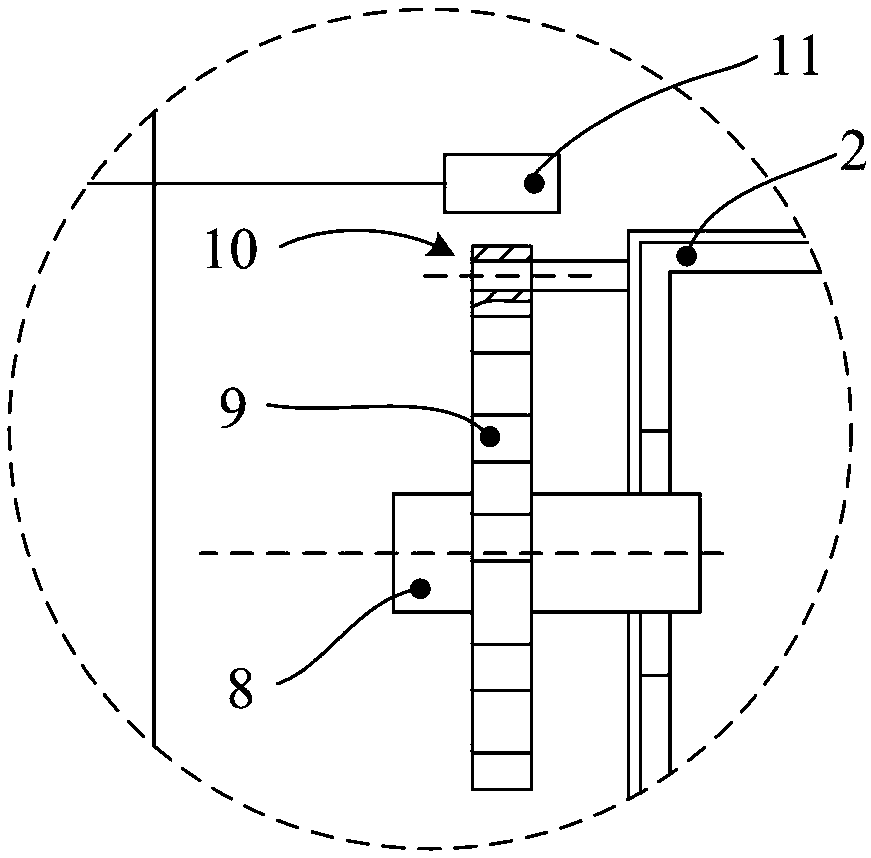

Automatic overturning system for building pipe pile mold clamping bolt

The invention relates to an automatic overturning system for a building pipe pile mold clamping bolt. The automatic overturning system is innovatively characterized by comprising a supporting base, guide mold plates, an installation bracket, nylon brushes and an adjusting mechanism; the automatic overturning system for the building pipe pile mold clamping bolt is installed on the two side edges of a pipe pile mold track; the nylon brush on the lower portion of the overturning system is obliquely located under the mold clamping bolt in a vertical state and closely attached to the mold clamping bolt; and when the mold clamping process is conducted after a pipe pile mold is filled with concrete, a driving motor drives the nylon brushes to rotate, the mold clamping bolt is rotated around a pipe pile lower mold body through the nylon brush on the lower portion and then rises and makes contact with the nylon brush on the upper portion of the overturning system, thus, the nylon brush on the upper portion drives the mold clamping bolt to continuously rotate, 180-degree rotation is achieved, and a worker can conveniently tighten the mold clamping bolt.

Owner:如皋市磨头建设开发有限公司

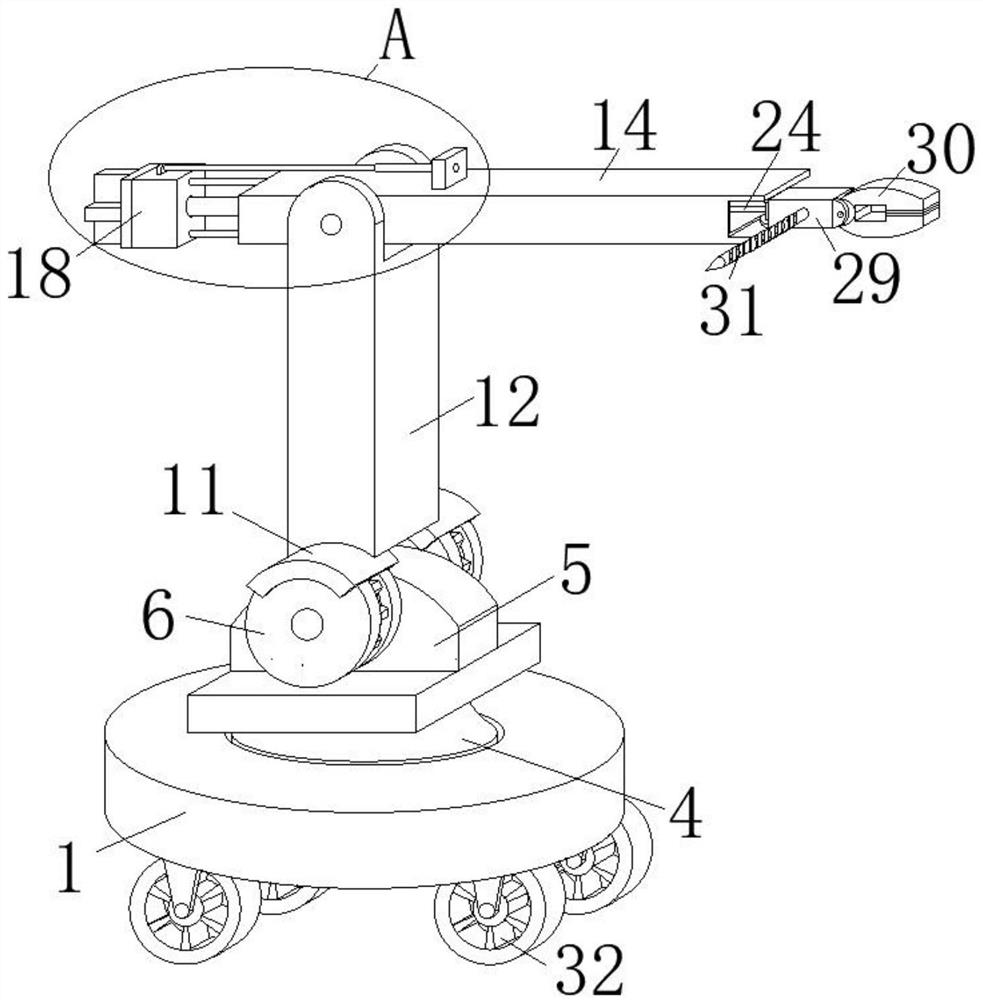

Multifunctional industrial mechanical arm and using method thereof

InactiveCN112372617AAvoid manual rotationExpand the scope of operationProgramme-controlled manipulatorRobotic armDrive shaft

The invention discloses a multifunctional industrial mechanical arm and a using method thereof. The multifunctional industrial mechanical arm comprises a base, a first groove and a first cavity are formed in the top face and the side wall of the base correspondingly, a motor is installed on the bottom face of the first cavity, a first transmission shaft is fixedly connected to the output end of the motor, the other end of the first transmission shaft extends into the first groove, a rotating disc is fixedly connected to the input end of the first transmission shaft, the rotating disc is rotatably connected with the first groove in a sleeving mode, a connecting block is fixedly connected to the top surface of the rotating disc, a second cavity is formed in the side wall of the connecting block, and a shell is fixedly connected to the side wall of the connecting block. The operation range of the industrial mechanical arm can be enlarged, meanwhile, any point in a three-dimensional spacecan be accurately machined, the working efficiency is improved, production adjustment is facilitated, the use function of the mechanical arm can be replaced, the mechanical arm is diversified in function, the multi-aspect requirements of modern industrial production can be met conveniently, and the production efficiency is improved.

Owner:合肥酷显智能科技有限公司

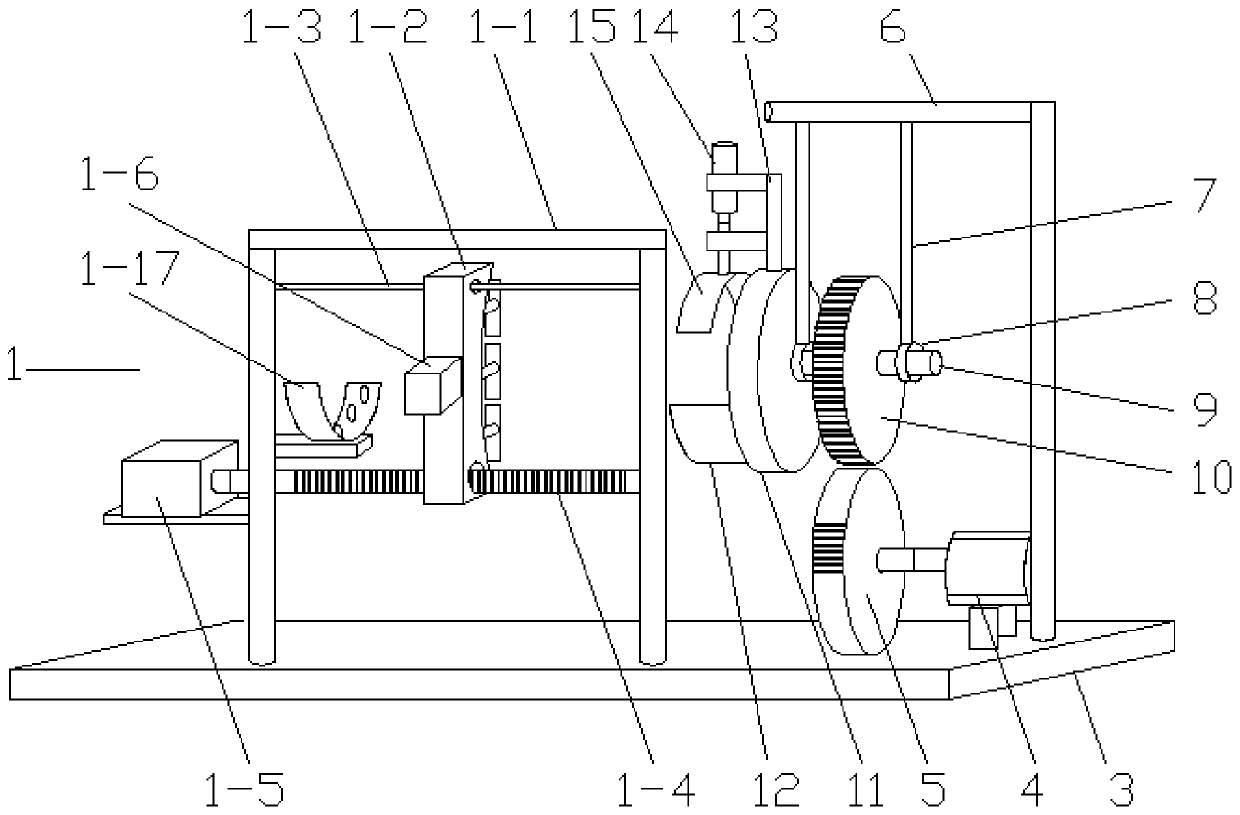

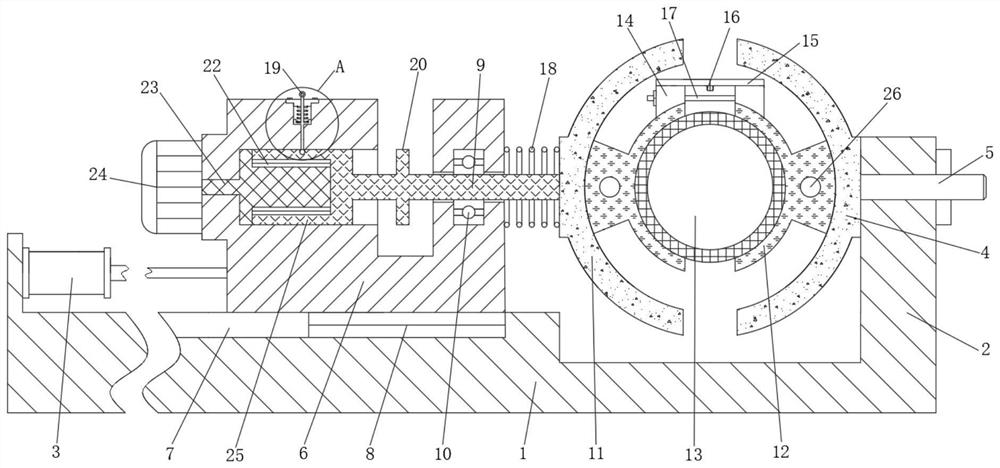

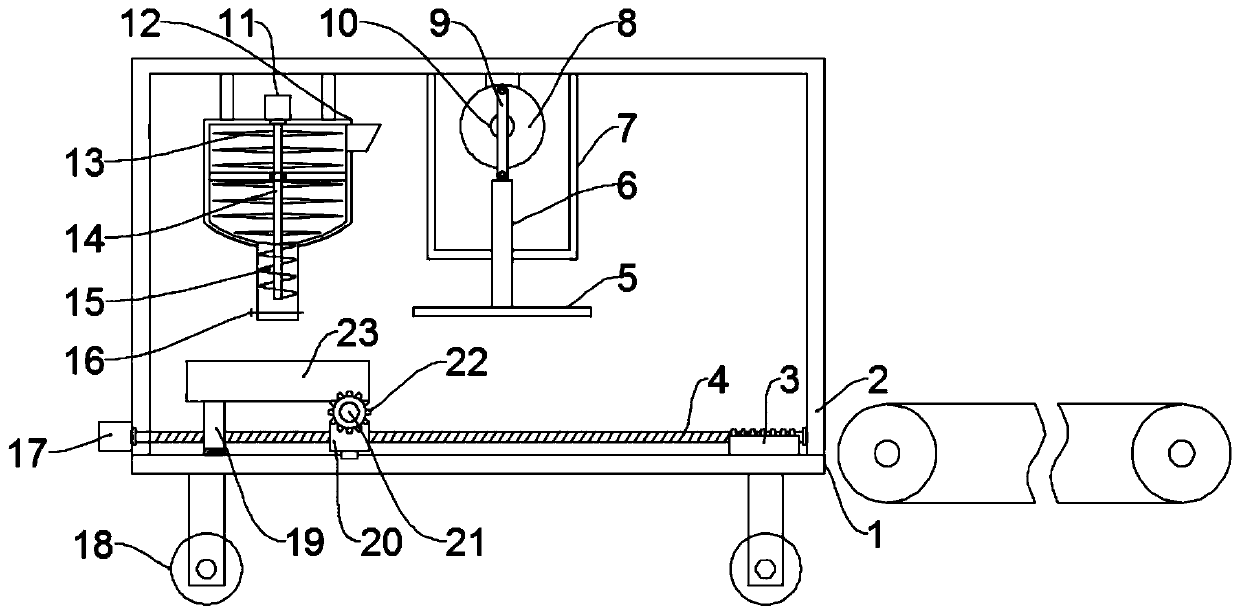

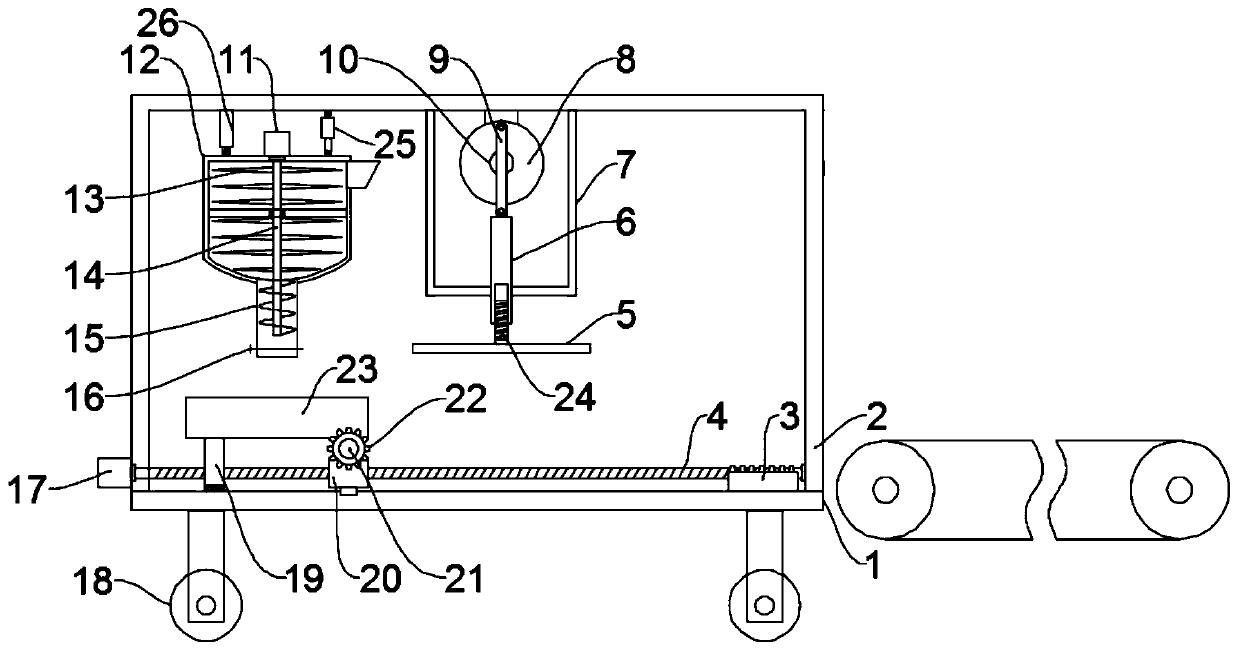

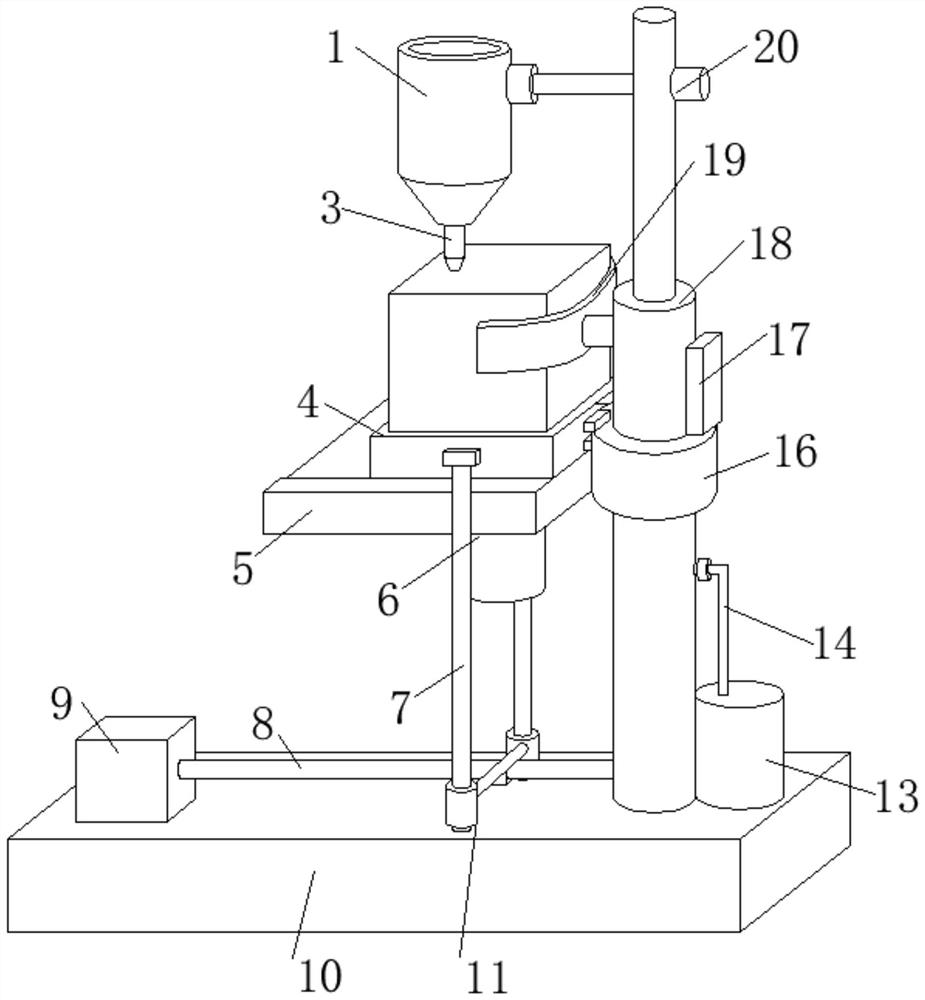

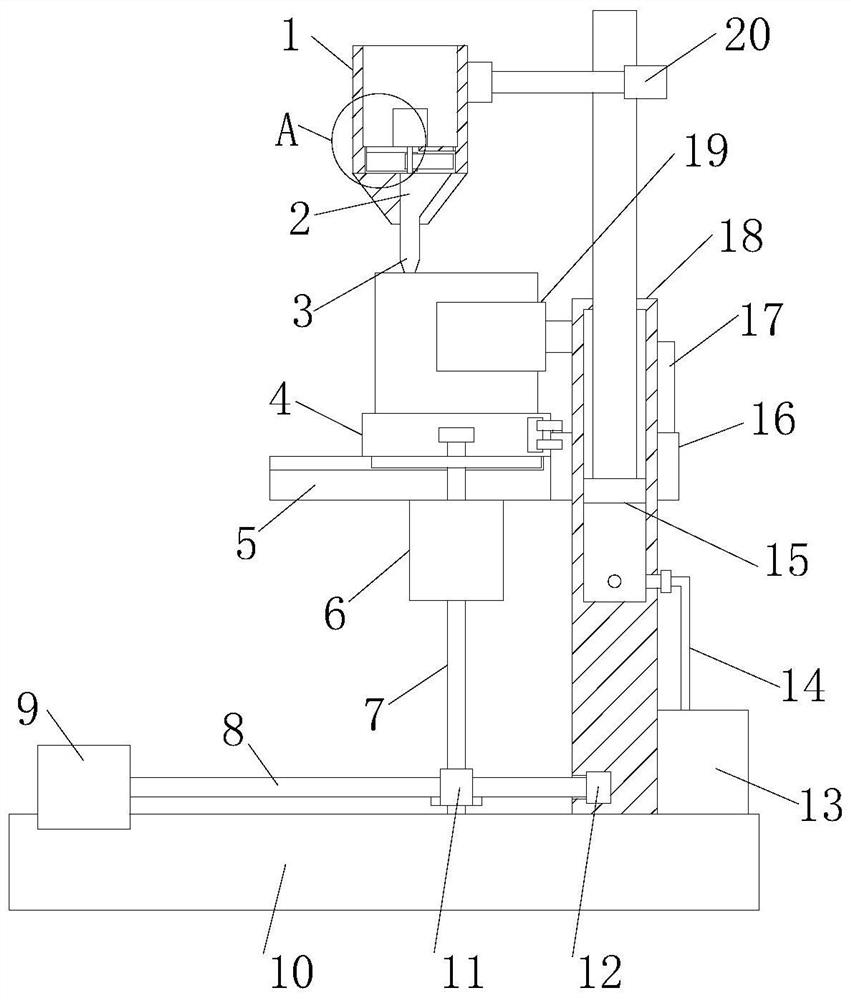

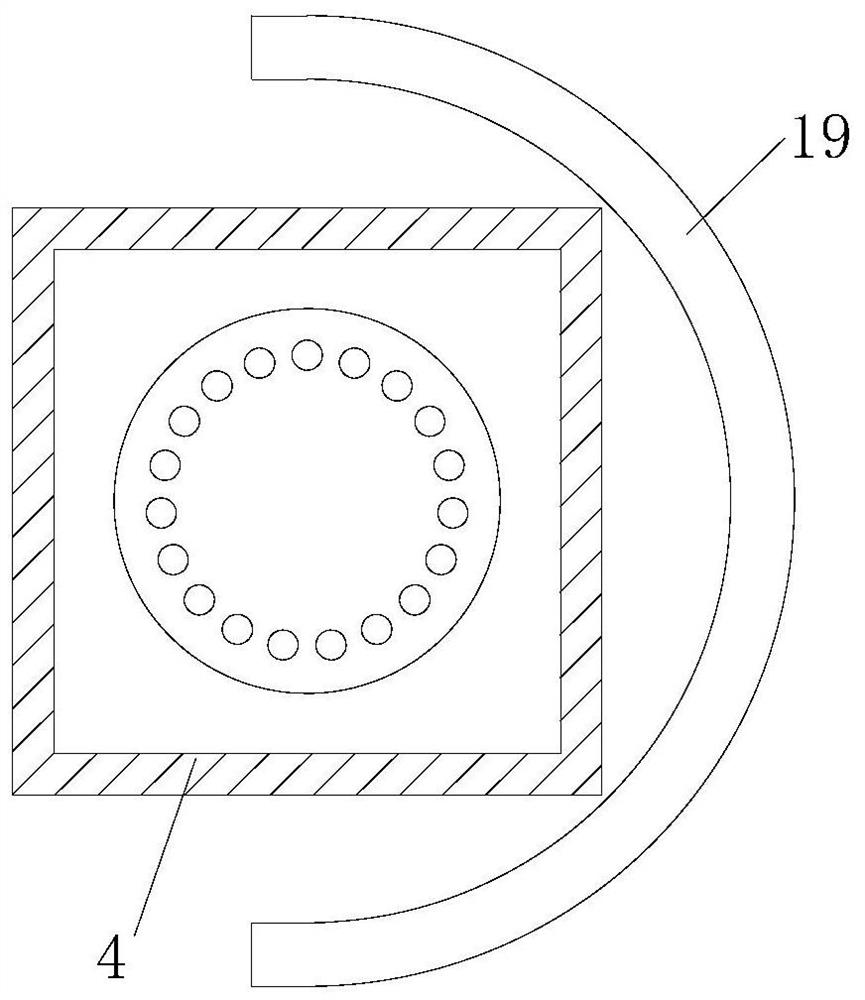

Farming and stockbreeding waste fuel forming machine

ActiveCN109747208AAvoid manual rotationReduce labor intensityGrain treatmentsShaping pressProduction lineCompression device

The invention discloses a farming and stockbreeding waste fuel forming machine, and relates to the technical field of farming and stockbreeding waste utilization. The problem that existing farming andstockbreeding waste fuel production equipment is simplex in function and requires manual material transfer is mainly solved. The forming machine comprises a substrate and a crushing device and a compression device; a door-type frame is fixed to the upper surface of the substrate; the crushing device is mounted on the door-type frame; the compression device is mounted on one side of the crushing device; a conveying device is arranged at the position, below the crushing device and the compression device, of the upper surface of the substrate; and the conveying device comprises a third motor, afirst threaded rod, a movable block, a collecting frame, a mounting shaft, a gear and a rack. The crushing device, the compression device and the conveying device are arranged, waste can be sequentially conveyed to the position below the crushing device and the compression device through the conveying device, then fed into a conveyor belt to be fed to the next process, production line processing and integrated arranging are achieved, the automation degree is high, the work efficiency is improved, waste manual rotation is avoided, and the labor intensity of staff is relieved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Special efficient cutter sharpening device for saw blade

InactiveCN108515232AEasy chip removalPrecise chip removalSawing tools dressing arrangementsOther manufacturing equipments/toolsEngineeringSharpening

The invention discloses a special efficient cutter sharpening device for a saw blade. The special efficient cutter sharpening device for the saw blade is simple and reasonable in structure, low in production cost, convenient to mount and complete in function, the saw blade can be rotated during cutter sharpening, and the problems of inefficiency and labor waste in manual rotation are avoided. Thedistance between the saw blade and a cutter sharpening grinding wheel can be precisely regulated by lead screws, the saw blade is pressed by rotating a handle, and the position of the saw blade can befine adjusted left and right by pushing a sliding seat through a pressure bar. A rotation shaft can rotate through a bearing in a rotating seat to adjust the angle of the saw blade. A first hand wheel is shaken, so that a slide bar moves on the first lead screw to achieve left and right moving of the cutter sharpening grinding wheel. A second hand wheel is shaken, so that a motor mounting bar moves on the second lead screw to achieve up and down moving of the cutter sharpening grinding wheel n. The cooling fluid is extracted by a water pump to cool the saw blade during cutter sharpening.

Owner:王春姿

Rotating platform for abdominal cushion machine

PendingCN109693926AIncrease productivityImprove rotation efficiencyConveyor partsPulp and paper industryConveyor belt

The invention relates to a rotating platform for an abdominal cushion machine. The rotating platform for the abdominal cushion machine comprises a supporting frame, wherein a plurality of parallelly distributed third conveyor belts are arranged on the supporting frame; a pressing frame is arranged above the third conveyor belts, a rotating plate is connected to the two ends of the top of the pressing frame through adjusting assemblies, and a rotating air cylinder is arranged at the top of the rotating plate; a pressing plate is arranged at the upper end of the rotating air cylinder, a pressingair cylinder is arranged on the pressing plate, and the pressing air cylinder is arranged at the top of the supporting frame; auxiliary compaction mechanisms symmetrically arranged are further arranged in the pressing frame, and the auxiliary compaction mechanisms are used for assisting to tightly press fabric. According to the rotating platform for the abdominal cushion machine, the operation isconvenient and fast and effective, the 90-degree rotation of the fabric can be completed automatically, the whole process is automatically completed, the rotation efficiency and the accuracy of the fabric are high, manual rotation is avoided, the following production efficiency of abdominal cushions is improved, and the rotating platform for the abdominal cushion machine better meets the production and machining requirements.

Owner:SUZHOU TRANSPARENT TECH CO LTD

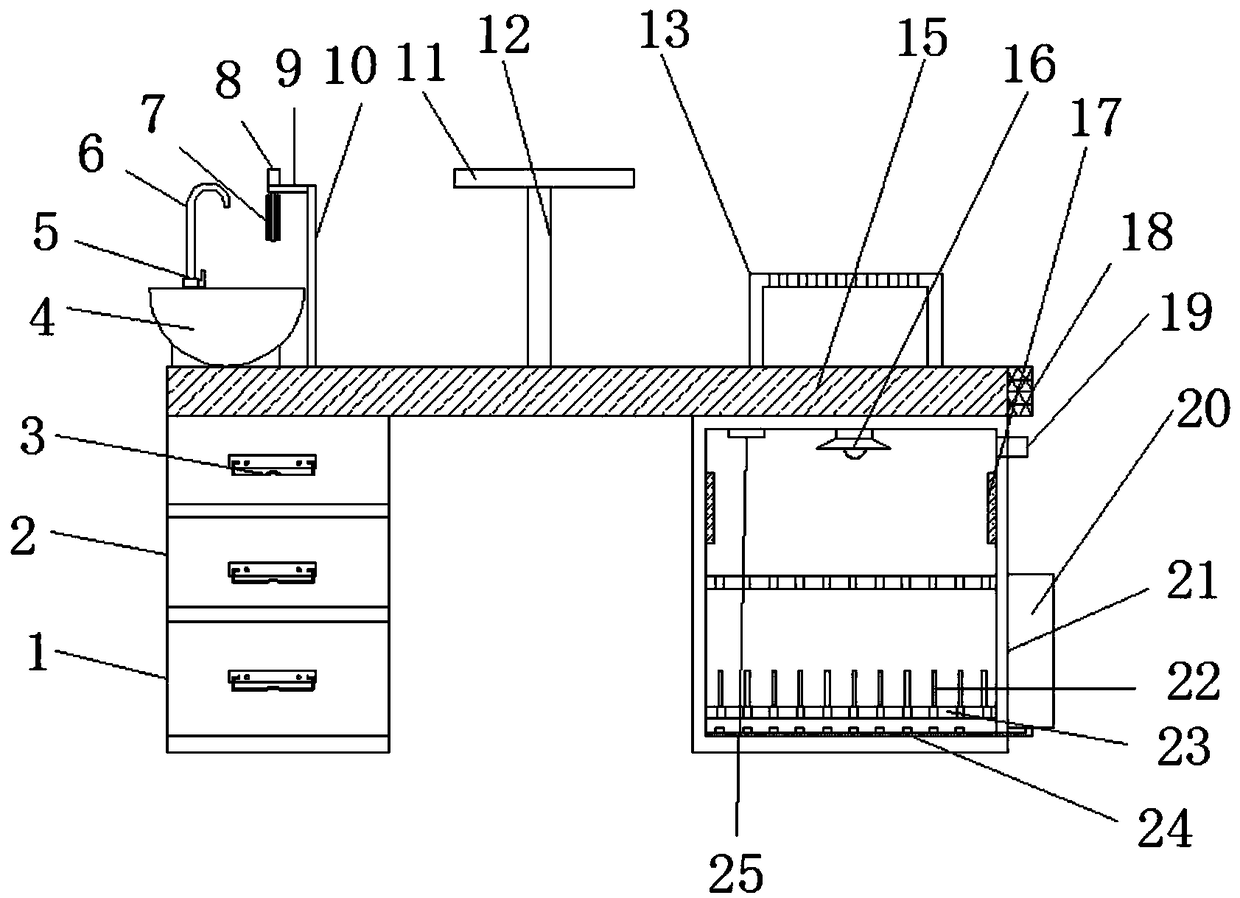

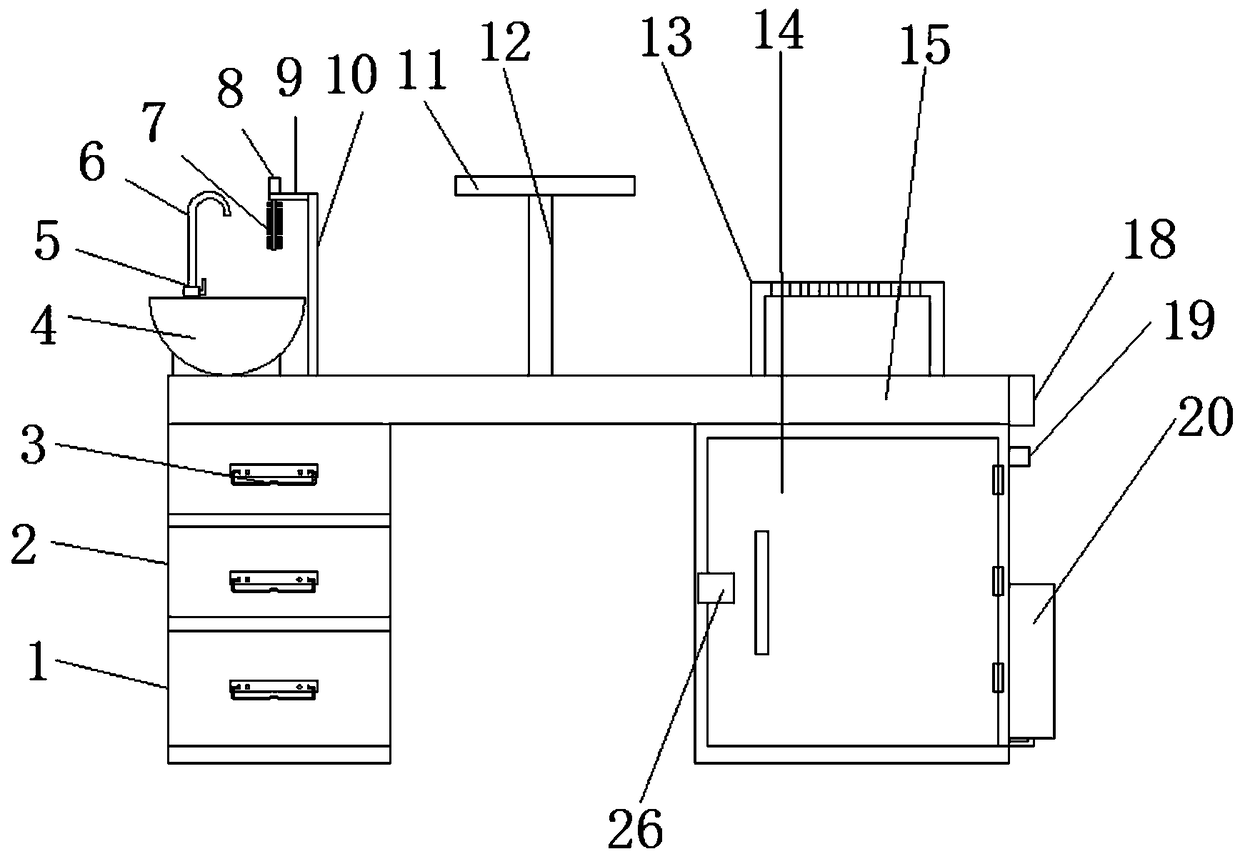

Conveniently cleaned and dried test bench used for chemical product technology research and development

InactiveCN109248724AQuick washAvoid manual rotationLaboratory benches/tablesTechnology researchChemical products

The invention discloses a conveniently cleaned and dried test bench used for chemical product technology research and development. The test bench comprises a bench body. The bottom side of the bench body is connected with a locker by bolts, the top side of the bench body is connected with a cleaning tank by the bolts, the top of one side of the cleaning tank is connected with a limited flow valveby the bolts, and the top of the limited flow valve is connected with an outlet pipe through a ferrule. The test bench is provided with the cleaning tank, an electric motor, a cleaning brush and the outlet pipe, when the vessels after the chemical experiment are cleaned, a controller controls the electric motor to drive the cleaning brush to rotate, manual rotation can be avoided, manpower is saved, the outer wall of the vessel is cleaned in the cleaning tank, the inner wall is cleaned by the cleaning brush, the vessel can be quickly cleaned, the time is saved, the test tubes can be placed ina test tube placement rack, the test tubes are placed upside down outside a support column while drying, and an ultraviolet germicidal lamp can sterilize the vessel.

Owner:ZHENGZHOU ZHENGXIAN PHARMA CO LTD

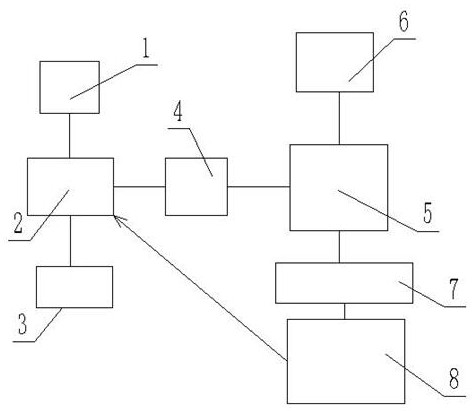

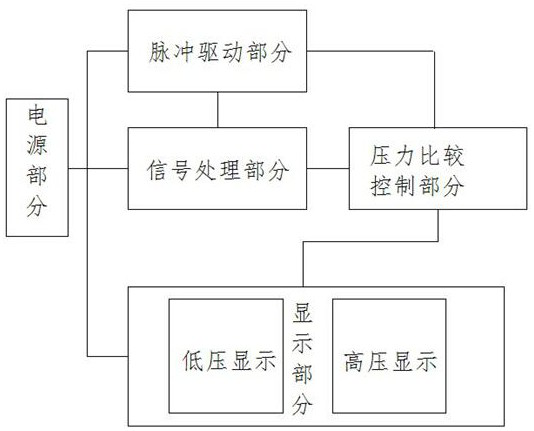

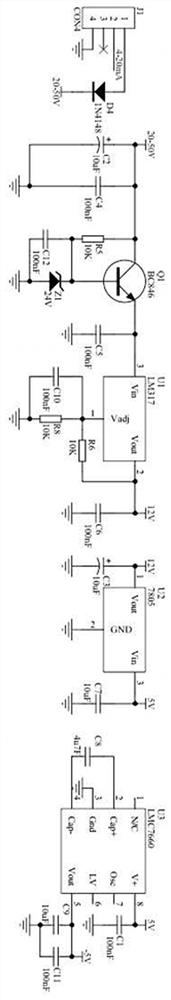

Ventricular drainage-pressure control system

InactiveCN112316285AAvoid manual rotationReduce workloadTransistorPulse generation by bipolar transistorsIntracranial infectionElectrocardiographic monitor

The invention discloses a ventricular drainage-pressure control system. The ventricular drainage-pressure control system comprises a pressure sensor and a ventricular drainage tube, wherein the pressure sensor and the ventricular drainage tube are connected with the same electromagnetic three-way valve, a deconcentrator is connected to the pressure sensor, the deconcentrator has a one-to-two interface, and an electrocardiogram monitor and a pressure data branch line are respectively connected to the deconcentrator; and a pressure measuring and adjusting module is connected to the front end ofthe pressure data branch line, and is also directly connected with the electromagnetic three-way valve. The system has the advantages that the operation is automatic, manual rotation of the three-wayvalve is avoided, the intracranial infection is reduced, the workload of medical personnel is reduced, the intermittent drainage is realized, and the risk caused by the continuous drainage at presentis avoided.

Owner:张军

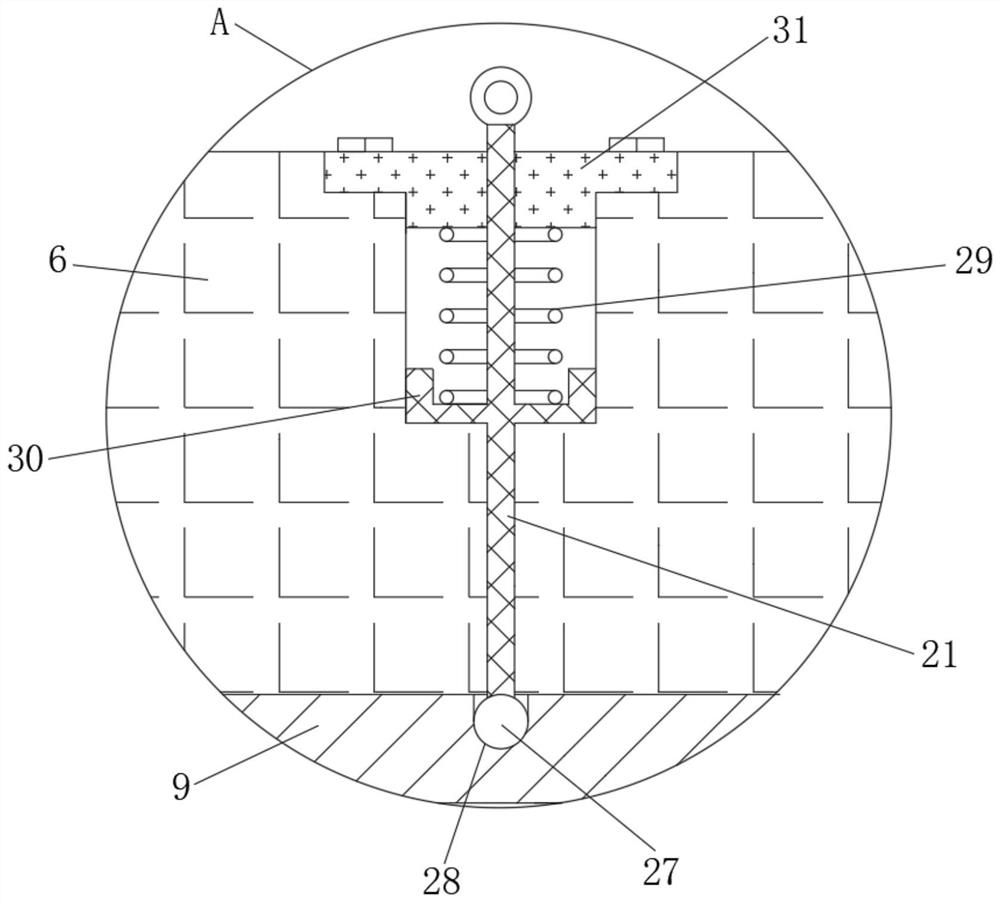

Tubular pile mold bolt turnover device

The invention discloses a tubular pile mold bolt turnover device, and relates to the field of tubular pile molds. According to the device, a rotary disc is arranged on the upper surface of a supporting frame, a rotary shaft is arranged on the bottom face of the rotary disc, a main shaft is arranged on a mounting frame, one end of the main shaft is connected with a driving device, the other end ofthe main shaft is connected with a cam lifting mechanism, the middle of the main shaft is in transmission connection with the rotary shaft through a transmission gear set, a first sliding plate is arranged on the upper surface of the supporting frame in a sliding mode, a transmission sliding groove is formed in the first sliding plate, an eccentric rod eccentrically connected with the rotary discis arranged in the transmission sliding groove in a sliding mode, the first sliding plate is fixedly connected with a plurality of second sliding rods, the tail end of each second sliding rod is provided with a corresponding overturning wheel used for driving mold closing bolts to overturn, and power elements in transmission connection with the overturning wheels are arranged on the first slidingplate. According to the device, the overturning wheels drive the mold closing bolts to rotate, the overturning wheels are driven to do arc motion to overturn the tubular pile mold closing bolts to anupper mold from a lower mold of a tubular pile, manual one-by-one overturning is avoided, and the labor intensity of workers is relieved.

Owner:惠州市海恒建材机械有限公司

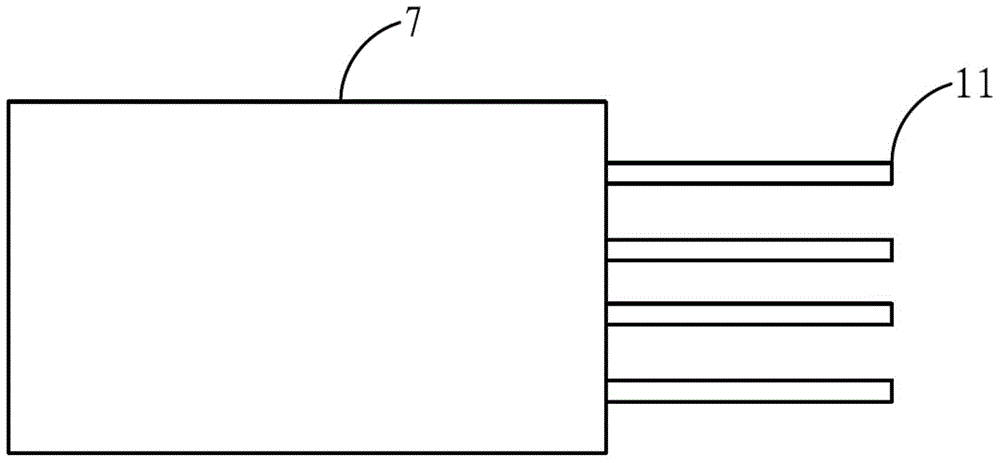

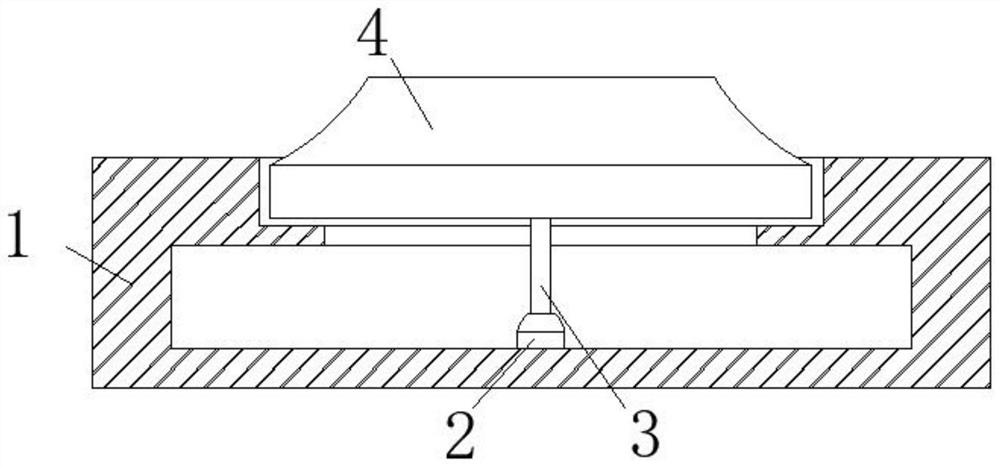

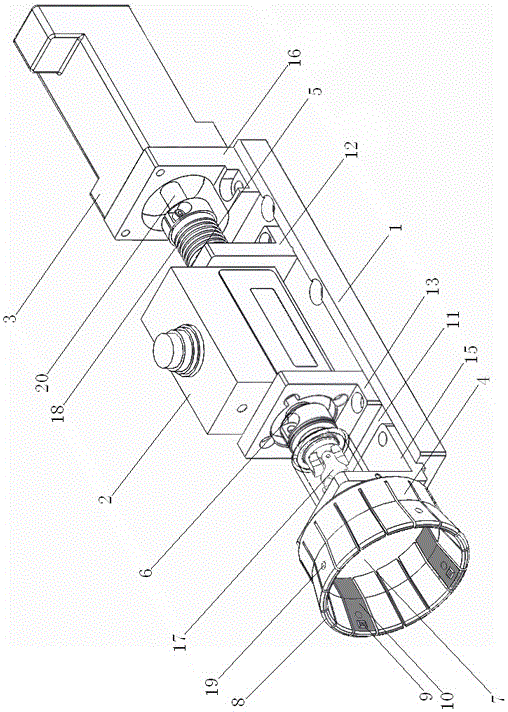

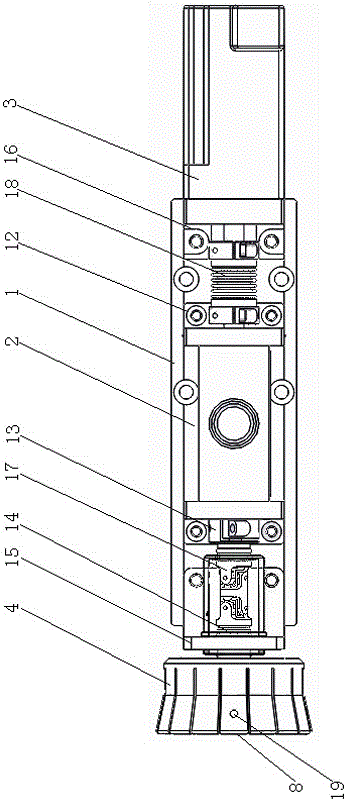

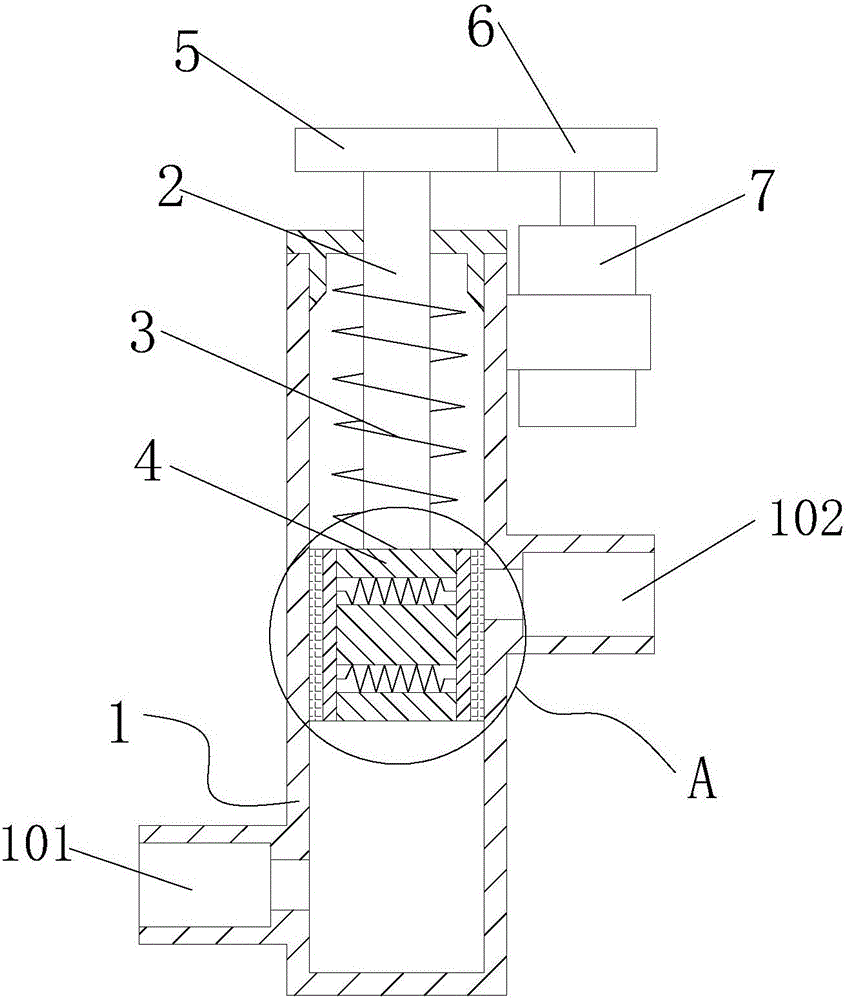

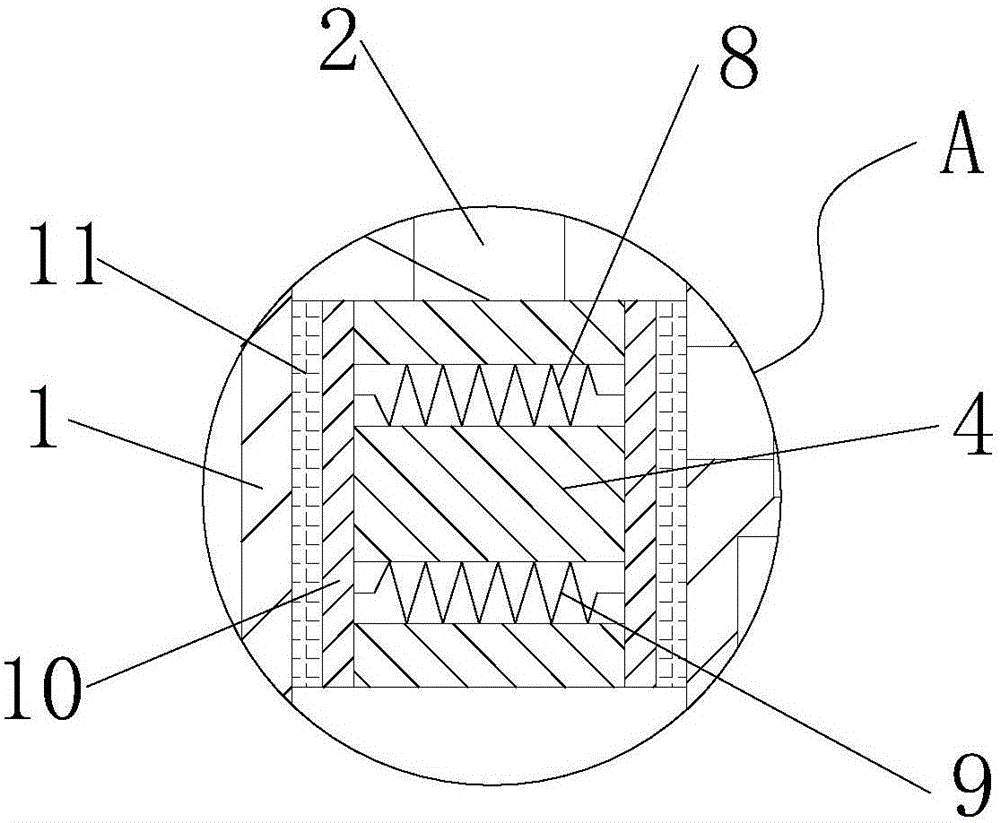

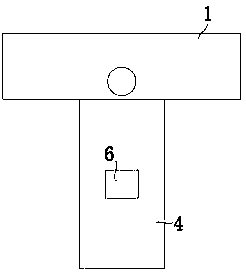

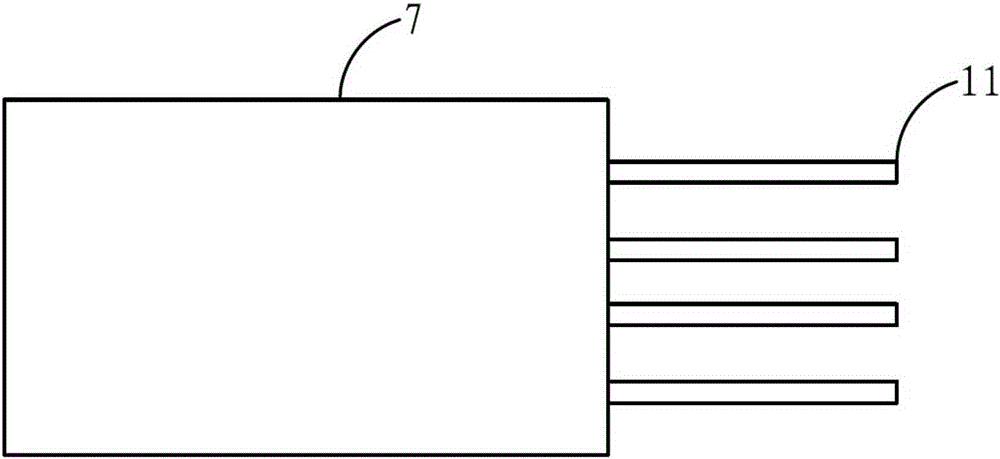

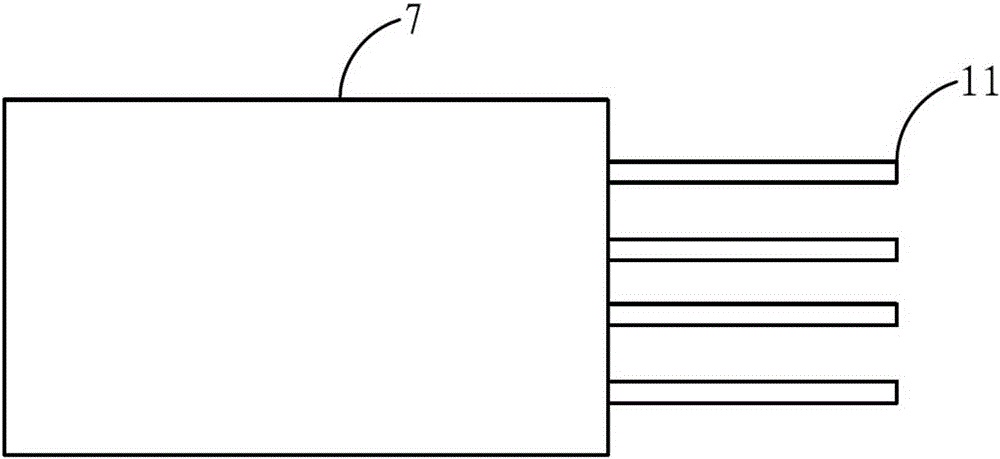

Rotating handle test probe

ActiveCN106482887AHigh Acquisition AccuracyAvoid manual rotationMeasurement of force applied to control membersSoft layerData acquisition

The invention discloses a rotating handle test probe which possesses advantages that the structure is simple, operation is convenient and data acquisition precision can be effectively increased. The probe comprises a seat board (1), a torsion sensor (2), a motor (3) and a sleeve (4). The torsion sensor (2) comprises an input shaft (5) and an output shaft (6). The sleeve (4) comprises a circular base plate (7) and several side plates (8) arranged on a periphery of the circular base plate (7) in a surrounding mode. Each side plate (8) is an elastic plate. A gap is arranged between the two adjacent side plates (8). An inner side of the side plates (8) is provided with a flexible contact point (9). And the inner side of the side plates (8) is also provided with a soft layer (10). The soft layer (10) covers the flexible contact point (9). The probe is applied in the rotating handle test probe technology field.

Owner:P&R MEASUREMENT INC

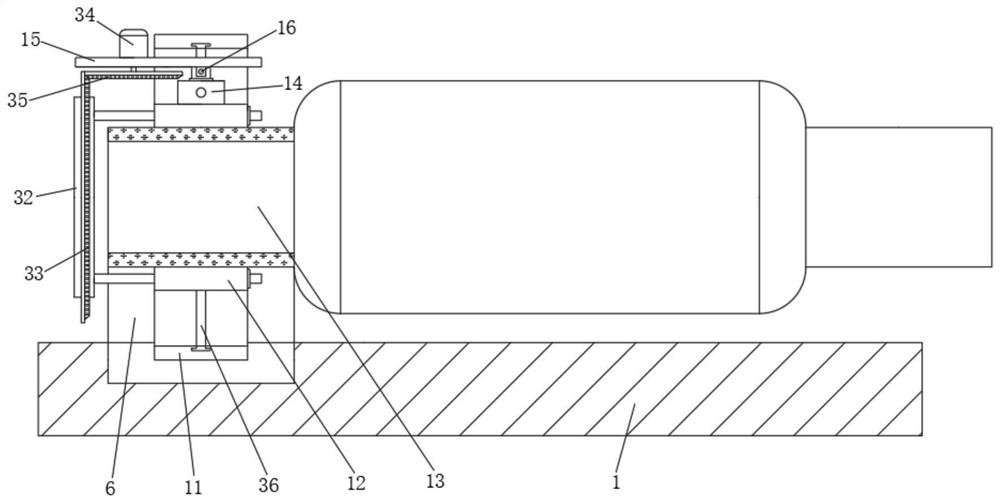

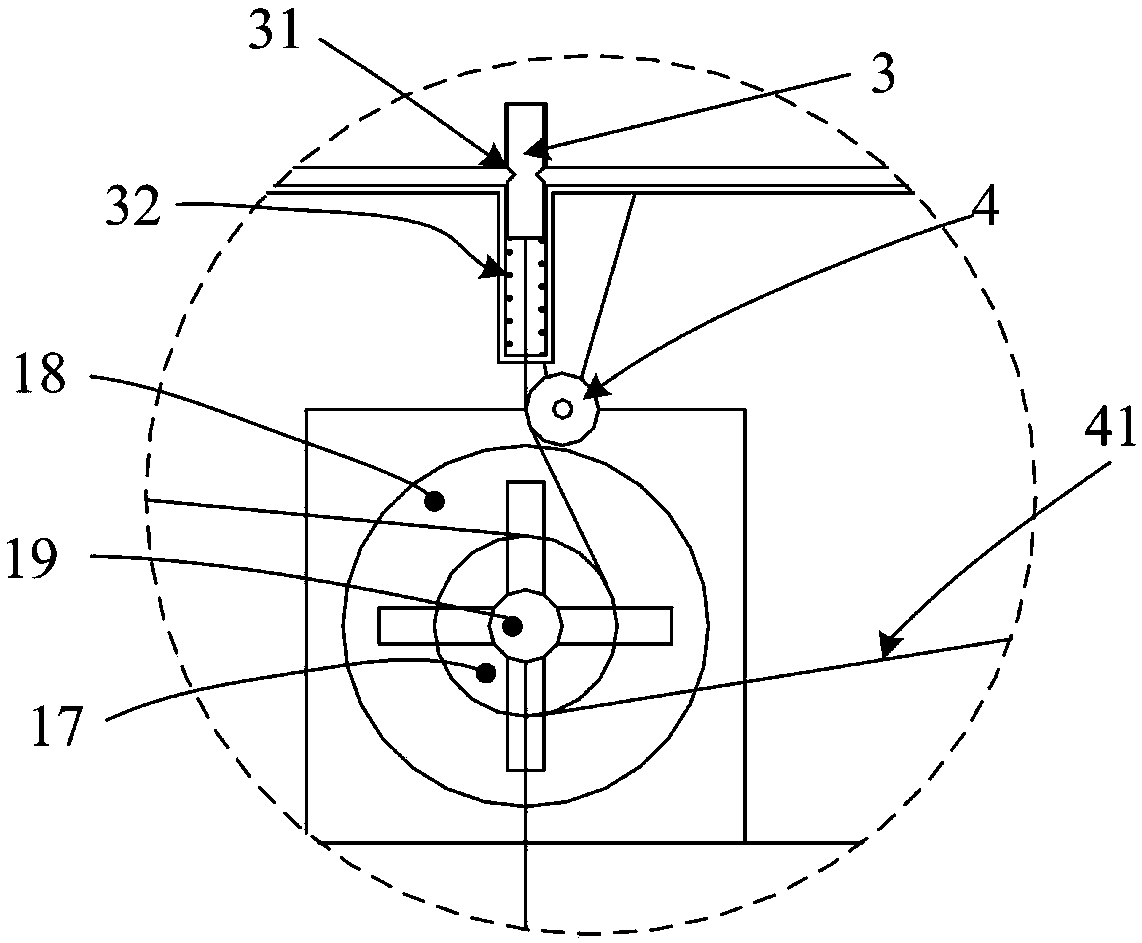

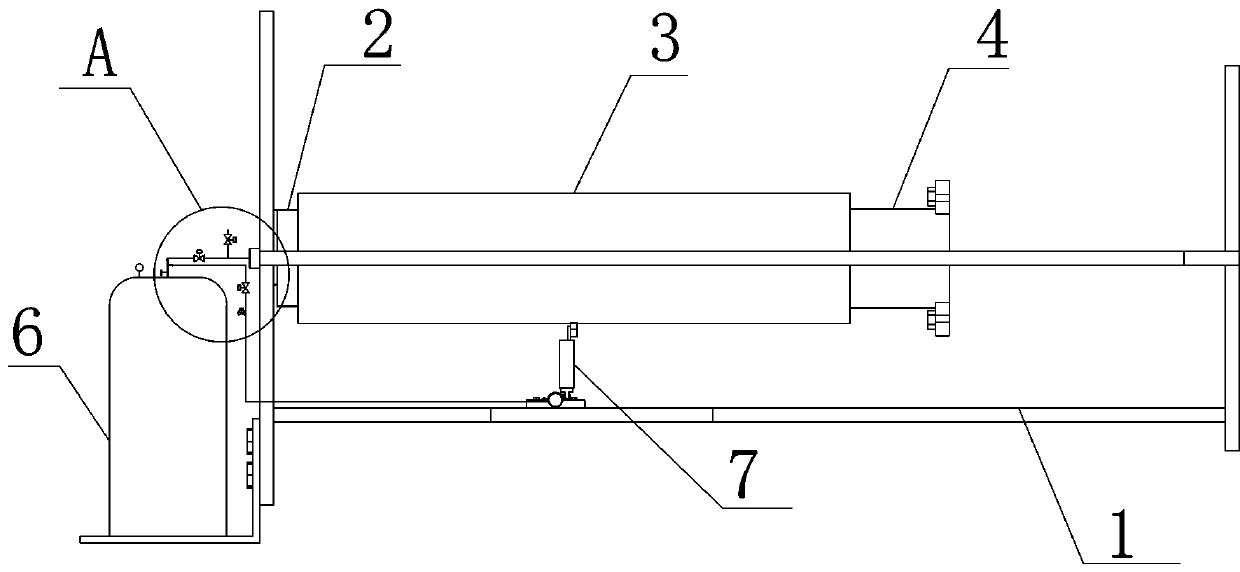

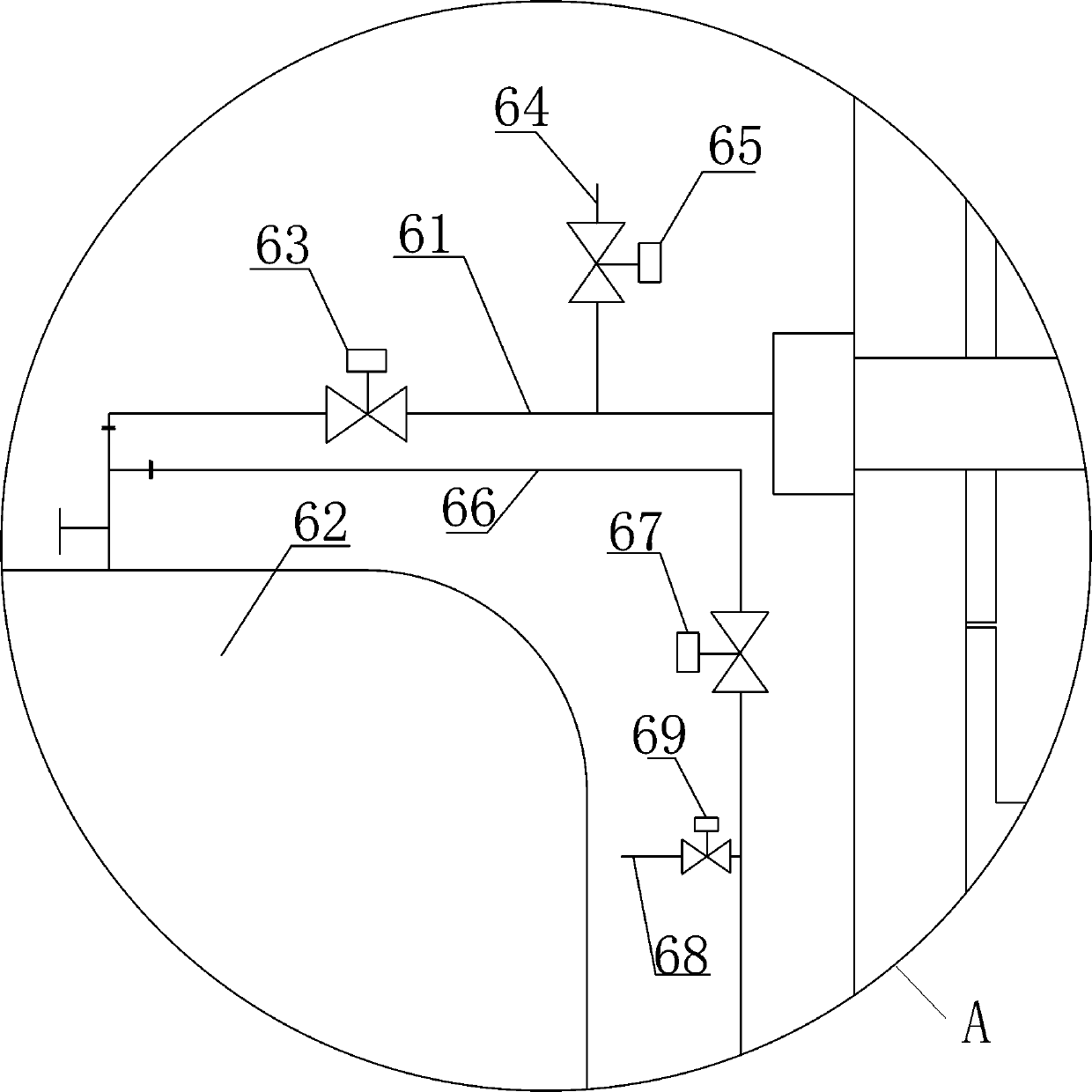

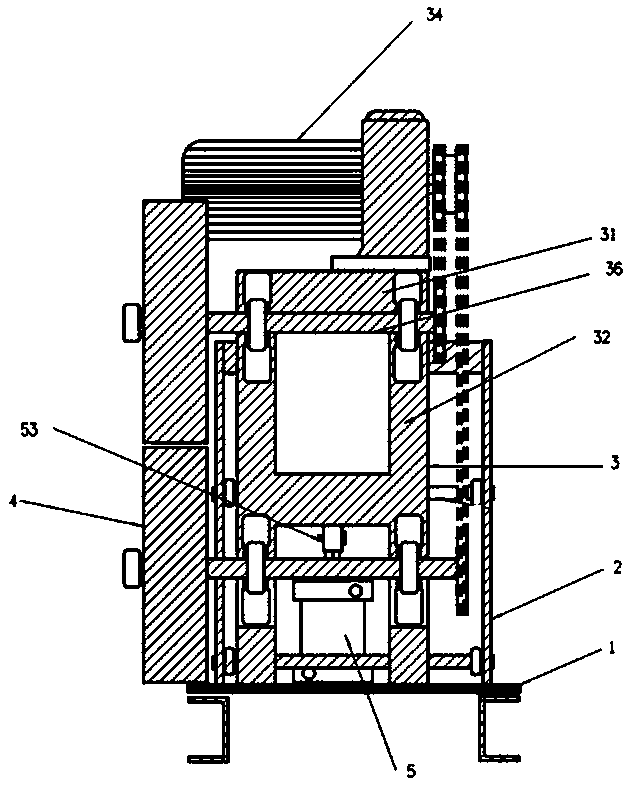

Endoscope execution mechanism used in float glass molten tin bath and adjusting method of endoscope execution mechanism

PendingCN110790488AAchieve translationExpand the scope of surveillanceTelescopesEngineeringMechanical engineering

The invention discloses an endoscope execution mechanism used in a float glass molten tin bath and an adjusting method of the endoscope execution mechanism. The endoscope execution mechanism comprisesa support frame, wherein the support frame is connected with a fixing cylinder; the fixing cylinder is rotationally connected with a rotational outer cylinder; a moveable inner column is sleeved by the rotational outer cylinder; an annular tooth groove is formed in the inner wall of the rotational outer cylinder; annular convex teeth are arranged on the outer wall of the moveable inner column; the annular convex teeth are matched with the annular tooth groove; the moveable inner column is inserted into the rotational outer cylinder to form a gas chamber in the rotational outer cylinder; an elastic mechanism is arranged inside the gas chamber; the rotational outer cylinder and the moveable inner column are mutually connected through the elastic mechanism; the gas chamber communicates witha gas inlet device; the outer wall of the rotational outer cylinder is driven to rotate by an angle adjusting mechanism; the moveable inner column is detachably connected with an endoscope device. Byadopting the endoscope execution mechanism, translation of an endoscope in a horizontal direction can be achieved, meanwhile, rotational of endoscope angles can be achieved, and the monitoring range of the endoscope can be widened.

Owner:YICHANG CSG PHOTOELECTRIC GLASS +1

Novel steel drum welding seam flattening device

ActiveCN113601068APrecise positioningAvoid extrusion deformationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention relates to the technical field of steel drum manufacturing, and discloses a novel steel drum welding seam flattening device. The device comprises a flattening mechanism and a conveying mechanism arranged below the flattening mechanism, a seam searching mechanism is arranged on the conveying mechanism and comprises a seam searching frame, a rotating part, a lifting part and a seam searching part, and the rotating part, the lifting part and the seam searching part are arranged on the seam searching frame. The seam searching part is arranged on the flattening mechanism on the seam searching frame, a seam searching sensor is arranged on the seam searching part and electrically connected with the rotating part and the lifting part, the flattening mechanism comprises a rack and two gripper assemblies arranged above the rack, a synchronous part is connected between the two gripper assemblies, and the synchronous part controls two sets of grippers to move in the same direction. Positioning barrels are arranged at the position, located at the two sides of the conveying mechanism, of the rack, and a correcting mechanism is arranged below the two positioning barrels. The device has the following advantages and effects that the position of a welding seam can be accurately found and the welding seam can be flattened, and the technical effects of accurately positioning the welding seam and preventing extrusion deformation are achieved.

Owner:荆州市先隆包装制品有限公司

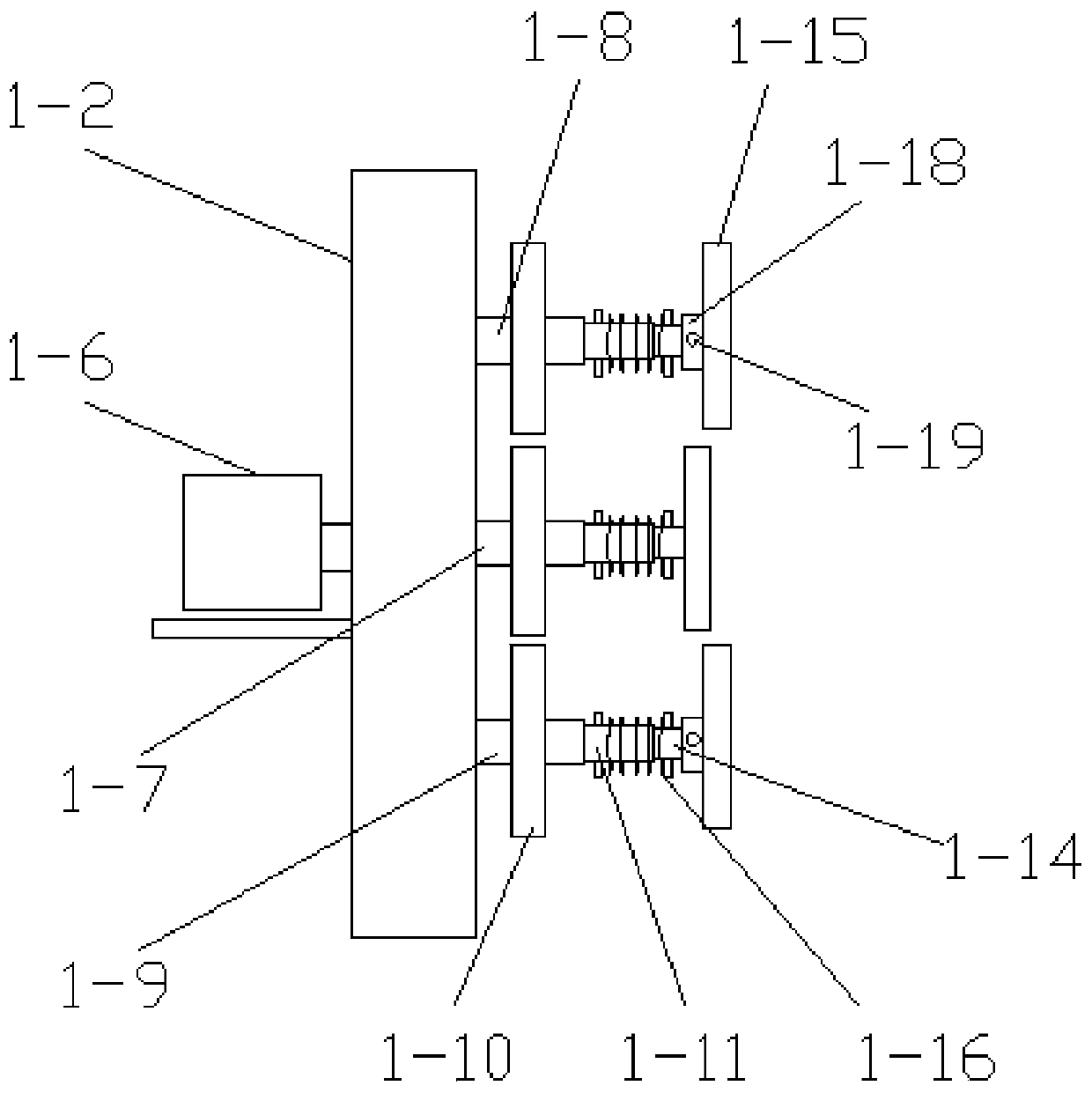

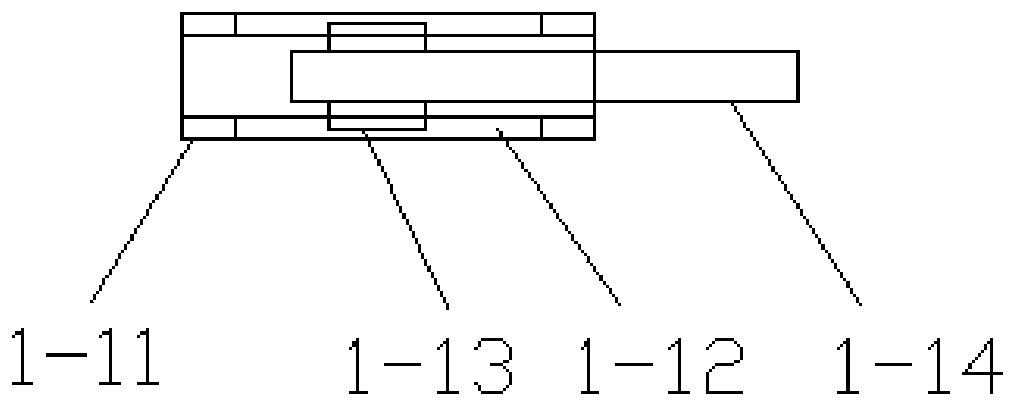

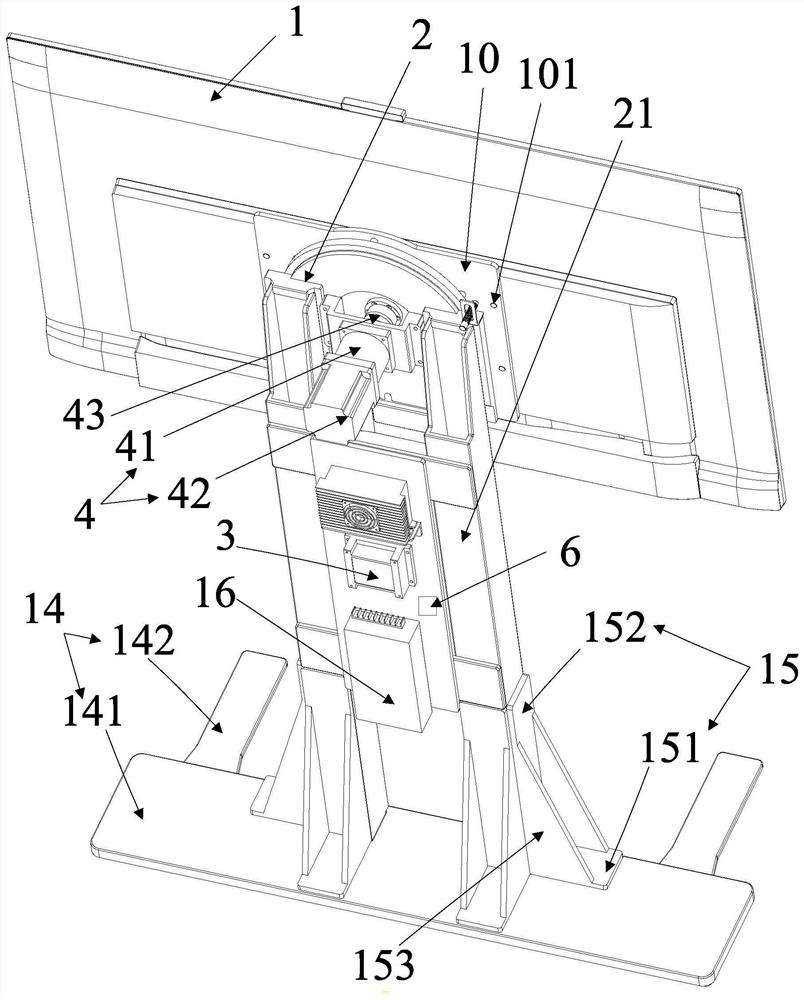

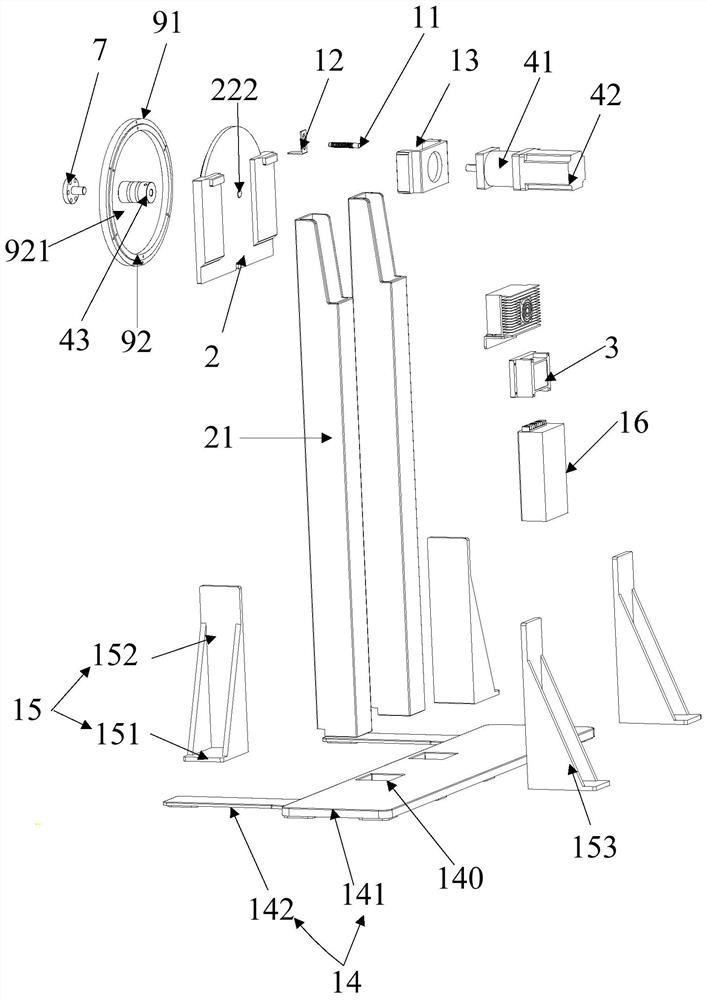

Rotating assembly and display device

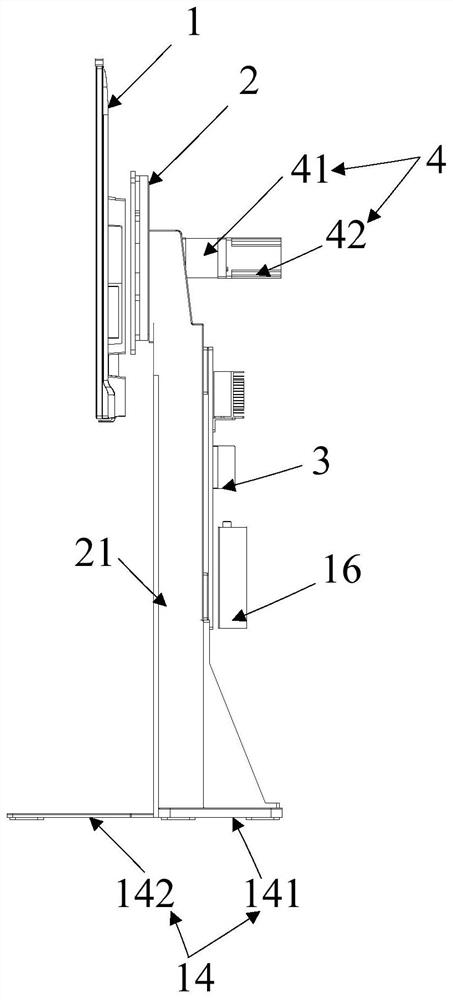

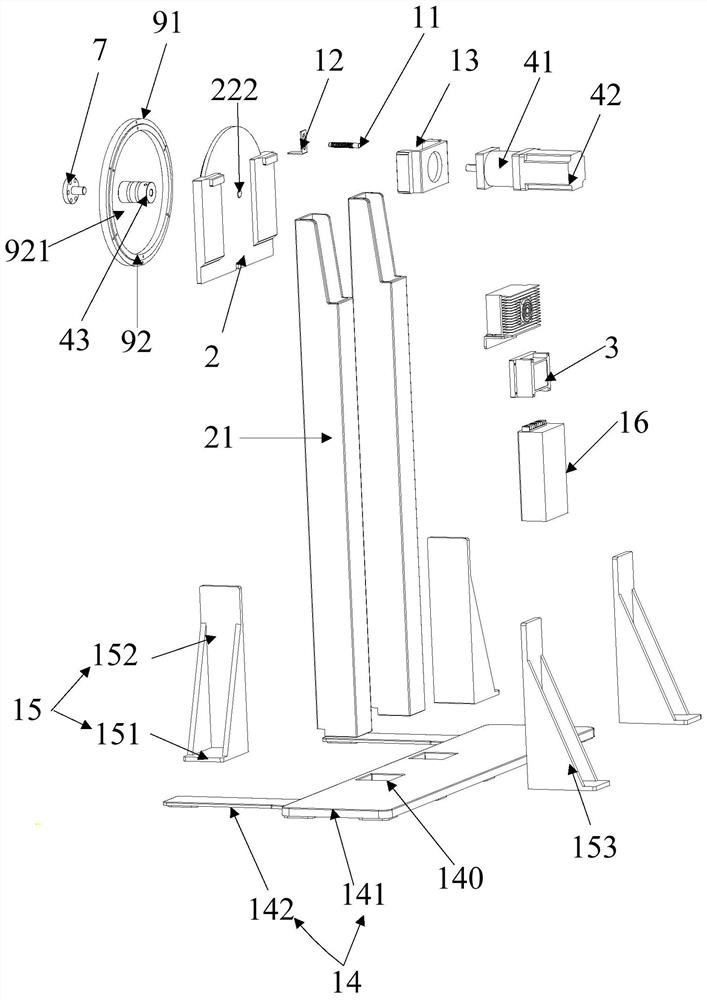

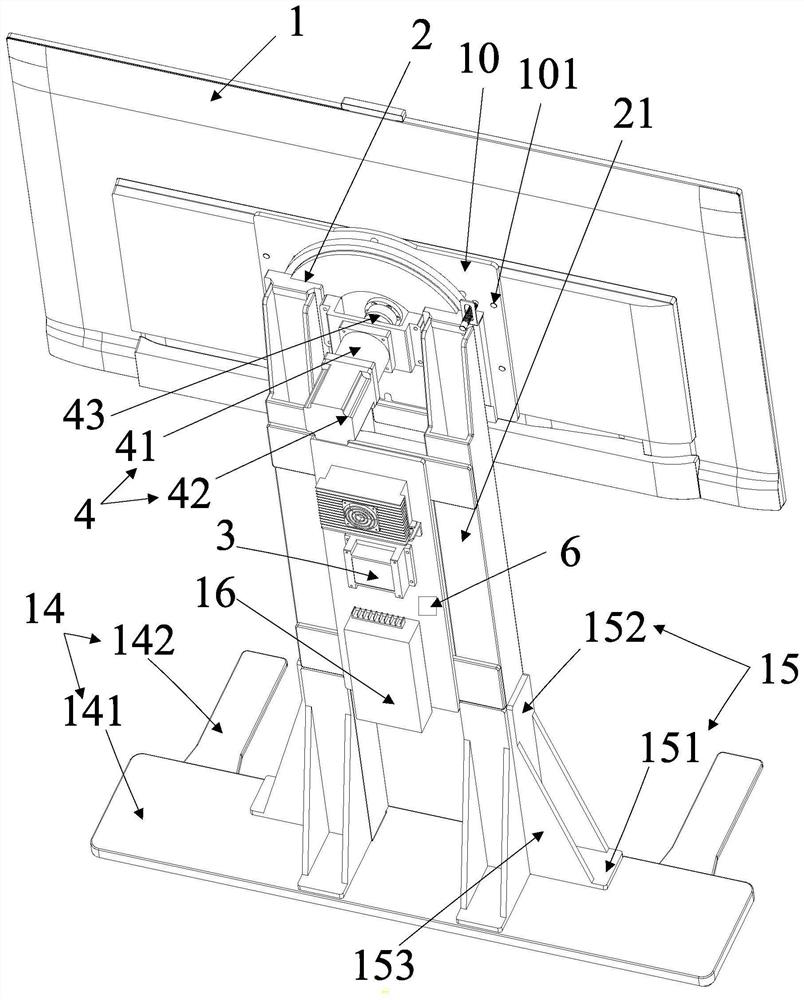

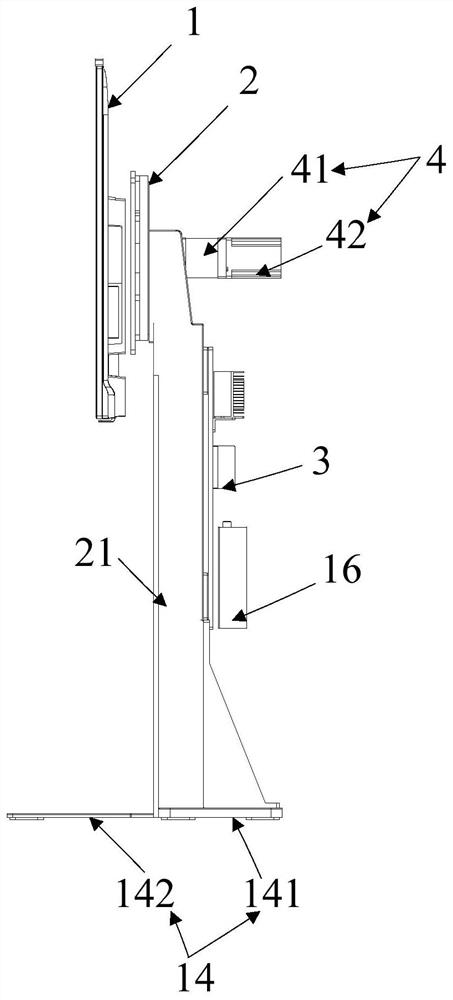

ActiveCN112344158ARealize autonomous rotationAvoid manual rotationStands/trestlesIdentification meansUser needsDisplay device

The invention discloses a rotating assembly and a display device. The rotating assembly comprises a support and a driving part, the support is used for supporting a to-be-driven component, and the driving part is used for being connected with the to-be-driven component and driving the to-be-driven component to rotate relative to the support. According to the invention, the to-be-driven component is connected with the driving part, and the to-be-driven component is driven by the driving part to rotate, so that the to-be-driven component can autonomously rotate according to user requirements.

Owner:TCL CORPORATION

Rotary component and display device

ActiveCN112344158BRealize autonomous rotationAvoid manual rotationStands/trestlesIdentification meansUser needsDisplay device

The invention discloses a rotating assembly and a display device, which include a bracket and a driving part, the bracket is used to support a part to be driven, and the driving part is used to connect the part to be driven and drive the part to be driven relative to The stand rotates. In the present invention, the part to be driven is connected to the driving part, and the part to be driven is driven to rotate through the driving part, so that the part to be driven can be rotated autonomously according to the user's demand.

Owner:TCL CORPORATION

Water-saving valve

InactiveCN106369204AFully contactedSimple structureOperating means/releasing devices for valvesLift valveWater savingDrive motor

Owner:周末

An automatic turning system of pipe pile clamping bolts

InactiveCN106003414BAchieve rotationImprove tightening efficiencyCeramic shaping apparatusElectric machineryDrive motor

The invention relates to an automatic turnover system of a die assembly bolt of a pipe pile. According to the innovation point, the turnover system comprises a supporting base, guide plates, a mounting rack, nylon brushes and an adjusting mechanism; the automatic turnover system of the die assembly bolt of the pipe pile is mounted on the two sides of a pipe pile die rail; the nylon brush on the lower portion of the turnover system is obliquely located below the die assembly bolt in a vertical state and is closely attached to the die assembly bolt; and when a die assembly procedure is carried out after pipe pile dies are filled with concrete, a drive motor drives the nylon brushes to rotate, the nylon brush on the lower portion enables the die assembly bolt to rotate around the lower pipe pile die and then ascend to be in contact with the nylon brush on the upper portion of the turnover system, and therefore the die assembly bolt is driven by the nylon brush on the upper portion to continue to rotate, 180-degree rotation is achieved, and the die assembly bolt can be screwed down by workers conveniently.

Owner:国鼎(南通)管桩有限公司

Punch press clamping device and using method thereof

InactiveCN108941350AReduce labor intensityAvoid manual rotationMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention discloses a punch press clamping device. The punch press clamping device comprises a mounting plate; sliding grooves are symmetrically formed in the left end and the right end of the bottom face of the mounting plate; sliding rods are slidably connected inside the sliding grooves; the sliding rods penetrate through the sliding grooves and extend out of the bottoms of the sliding grooves; and clamping blocks are arranged at the bottom ends of the sliding rods. A using method of the punch press clamping device specifically comprises the following steps that S1, the distance betweenthe clamping blocks is adjusted; S2, fine adjustment is carried out after products are well clamped; and S3, fixed rotation processing is carried out. Compared with the prior art, through arrangementof a screw rod, the sliding rods and the clamping blocks, the device can adapt to products of different sizes conveniently; by arranging drive motors, rotating blocks and tooth clamps on the clampingblocks, the products can be rotated under the action of the drive motors during clamping processing of the products, and artificial manual rotation is avoided, so that the working efficiency is improved, and the labor intensity of workers is relieved.

Owner:张维秀

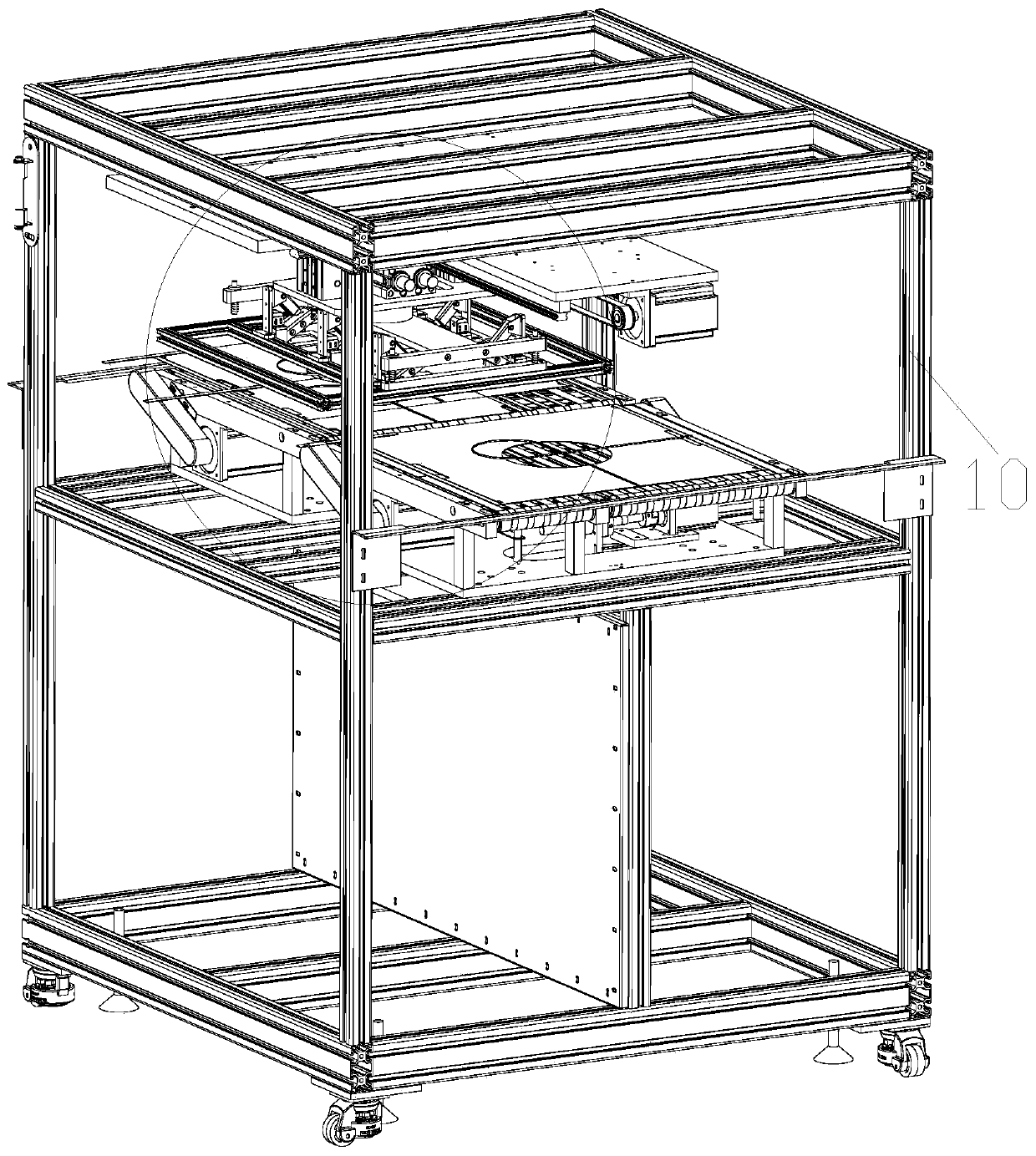

A bead filling device, a bead filling method, and a feeding mechanism and a moving mechanism for the bead filling device

ActiveCN111922662BAvoid manual rotationAvoid the trouble of unloadingMetal working apparatusCardboardAgricultural science

The application discloses a bead filling device, a bead filling method, a feeding mechanism and a moving mechanism for the bead filling device, and belongs to the technical field of ball workpiece processing. The bead filling device includes a funnel, a discharge port, a connecting pipe, a clamping plate, a bearing, Support plate, first motor, fixed rod, threaded rod, second motor, bottom plate, connection block, cross bar, sleeve block, air pump, air pipe, piston rod, collar, timing module, outer rod, limit sleeve, limit rod, a third motor, a fixed plate, a baffle plate, a fixed block, an arc hole and a limit block. The baffle plate and the fixed plate can control the drop of the beads, the connecting pipe can limit the drop range of the beads, the limit rod and the piston rod are conducive to the installation and height adjustment of the funnel, the support plate can support and protect the clamping plate; the fixed rod and the cross bar are conducive to clamping The plate moves smoothly, the first motor facilitates the rotation of the workpiece, the collar and the limit sleeve can limit the position of the clamping plate, avoiding the trouble of manually rotating the workpiece, and improving work efficiency.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

Abalone separator

InactiveCN105325532AAvoid manual rotationReduce processing stepsShellfish processingBristleLong axis

Owner:江苏徐耐新材料科技股份有限公司

Lamp post base welding tool

PendingCN113634966AEasy to operateAvoid manual rotationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a lamp pole base welding tool and relates to the technical field of welding tools. The lamp pole base welding tool comprises a foundation base and a sliding block, a second sliding groove is formed in the foundation base, a second sliding block is movably installed in the second sliding groove, a clamping table is movably installed in the second sliding block, and driving teeth are movably installed on the back of the clamping table; and a first spring is fixedly installed on one side of the clamping table, a clamping block is fixedly installed at the end of the first spring, a second connecting block is fixedly installed on one side of the sliding block, and a buckling block is fixedly installed outside the second connecting block. According to the lamp pole base welding tool, by means of the driving teeth, driven teeth, a rotating handle and other assemblies, the base can be rotated while being clamped, the problem that manual rotation is needed during welding is avoided, the problem that a constructor needs to move the position during welding is avoided, and for the welding work of one circle of the base, the welding work can be carried out by rotating the rotating handle.

Owner:JIANGSU JINGCHENGYUAN ELECTRIC GRP CO LTD

An efficient automatic processing equipment for abalone

InactiveCN104920577BAvoid manual rotationReduce processing stepsShellfish processingTransmission beltElectric machine

The invention provides efficient fully-automatic abalone processing equipment. The efficient fully-automatic abalone processing equipment comprises a conveyor belt, wherein oval holes are formed in the conveyor belt, and the direction of long axes of the oval holes is consonant with the movement direction of a transmission belt; a blocking limited block is arranged above the transmission belt, a rotating wheel is arranged on the left side of the limited block, a cylindrical rotary brush is arranged on the left side of the rotating wheel, and brush finish is arranged on the side surface of the circumference of the rotary brush; a platform is arranged in the transmission belt, a collecting hopper is arranged under the transmission belt, and a feed hopper is arranged on the upper left side of the transmission belt; the transmission belt and the rotary brush are driven by a motor, and the conveyor belt and the rotary brush rotate in a clockwise direction. According to the efficient fully-automatic abalone processing equipment disclosed by the invention, abalones can automatically rotate to positions where abalone meat faces upwards, the abalones can be automatically processed, the problem of manually rotating and processing the abalones is solved, the working efficiency is improved, and the labor cost is reduced.

Owner:JIANGHUA YAO AUTONOMOUS COUNTY JINNIU DEV & CONSTR CO LTD

Water-milled rice noodle processing system and process method

The invention discloses a water-milled rice noodle processing system, which includes a cleaning device, a soaking device, a refiner, a filtering device, a dehydrating device, a drying device, a cooling device, and a screening device. Below the feed port, the refiner is arranged below the discharge port of the soaking device, the filter device is arranged below the pulp outlet of the refiner, and the dehydrator is arranged at the filter device On the right side, the slurry outlet of the filter device is connected to the inlet of the plate and frame filter press of the dehydration device, the drying device is arranged below the dehydration device, and the outlet of the dehydration device collecting hopper is connected to the inlet of the dehydration device. The feed port of the drying device is connected, the cooling device is arranged on the right side of the drying device, the feed port of the cooling device is connected with the hot air pipe of the drying device, and the sieve The sub-device is arranged directly below the outlet of the horn of the cooling device. The present invention integrates the design of each device to provide an automatic production and processing line for rice noodles, which has a high degree of automation, high production efficiency, labor saving, and reliable production quality.

Owner:CHANGSHA XUEHUANG GRAIN & OIL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com