Patents

Literature

50results about How to "Avoid affecting the painting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

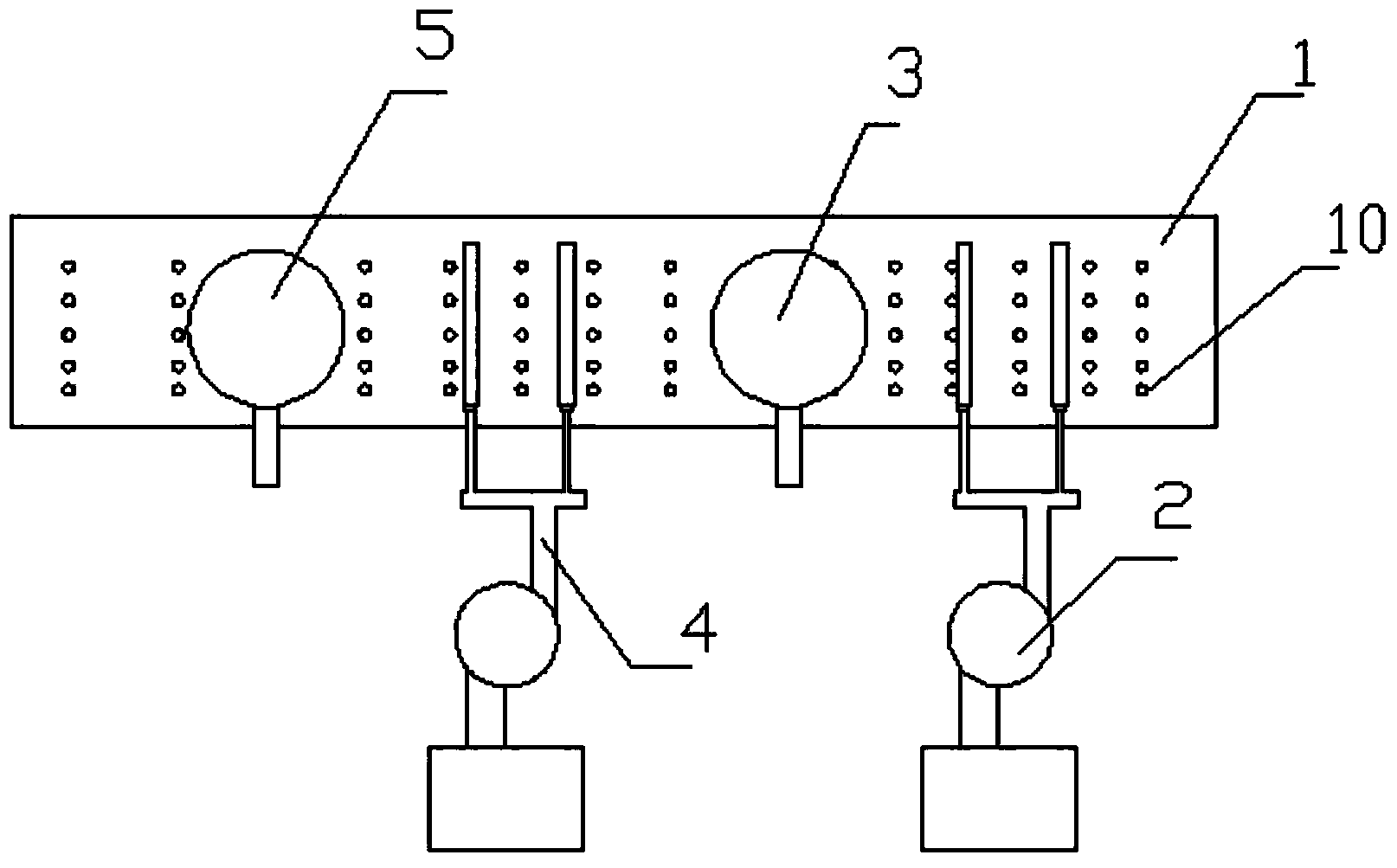

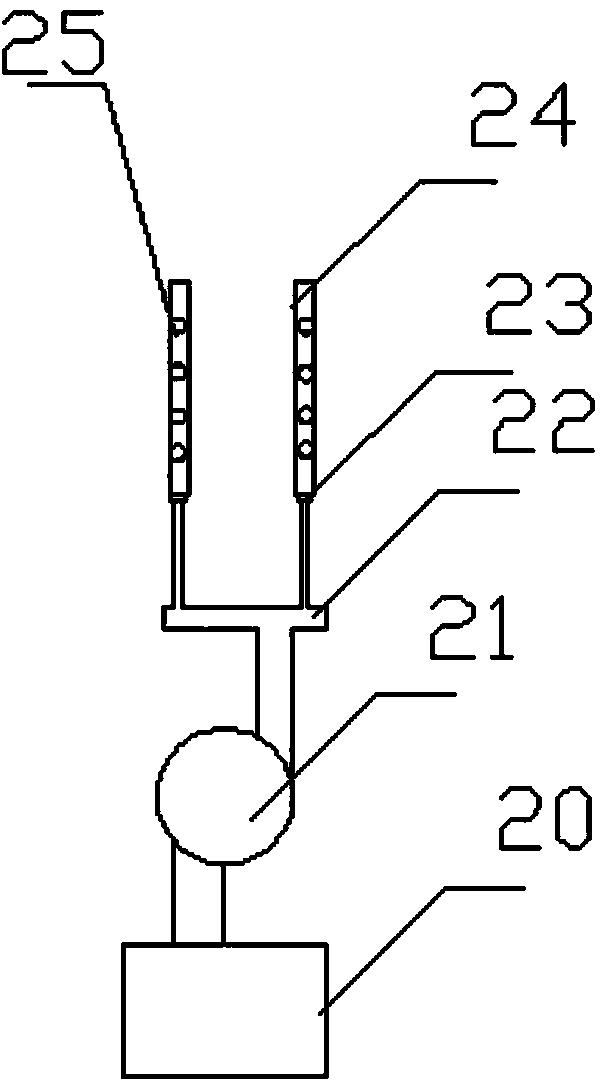

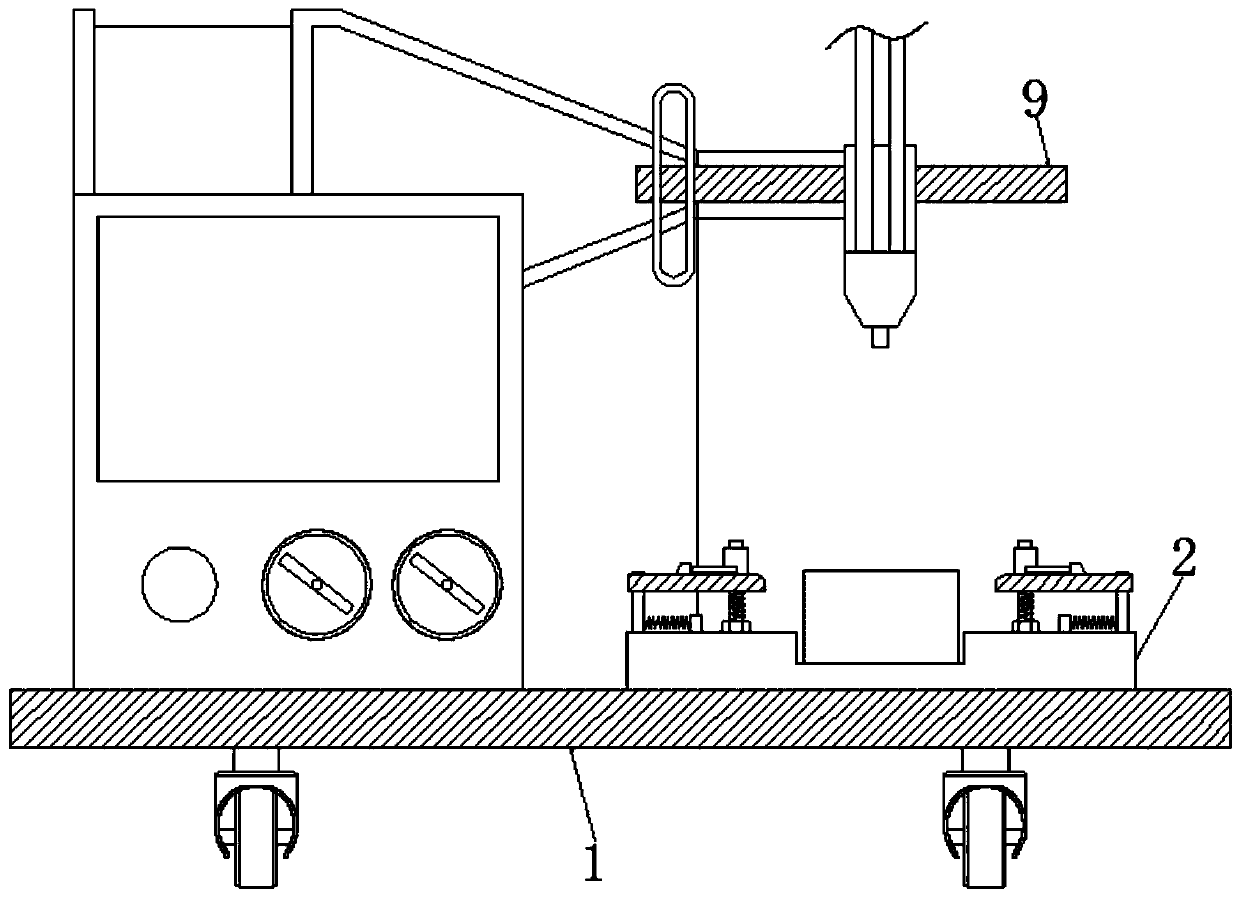

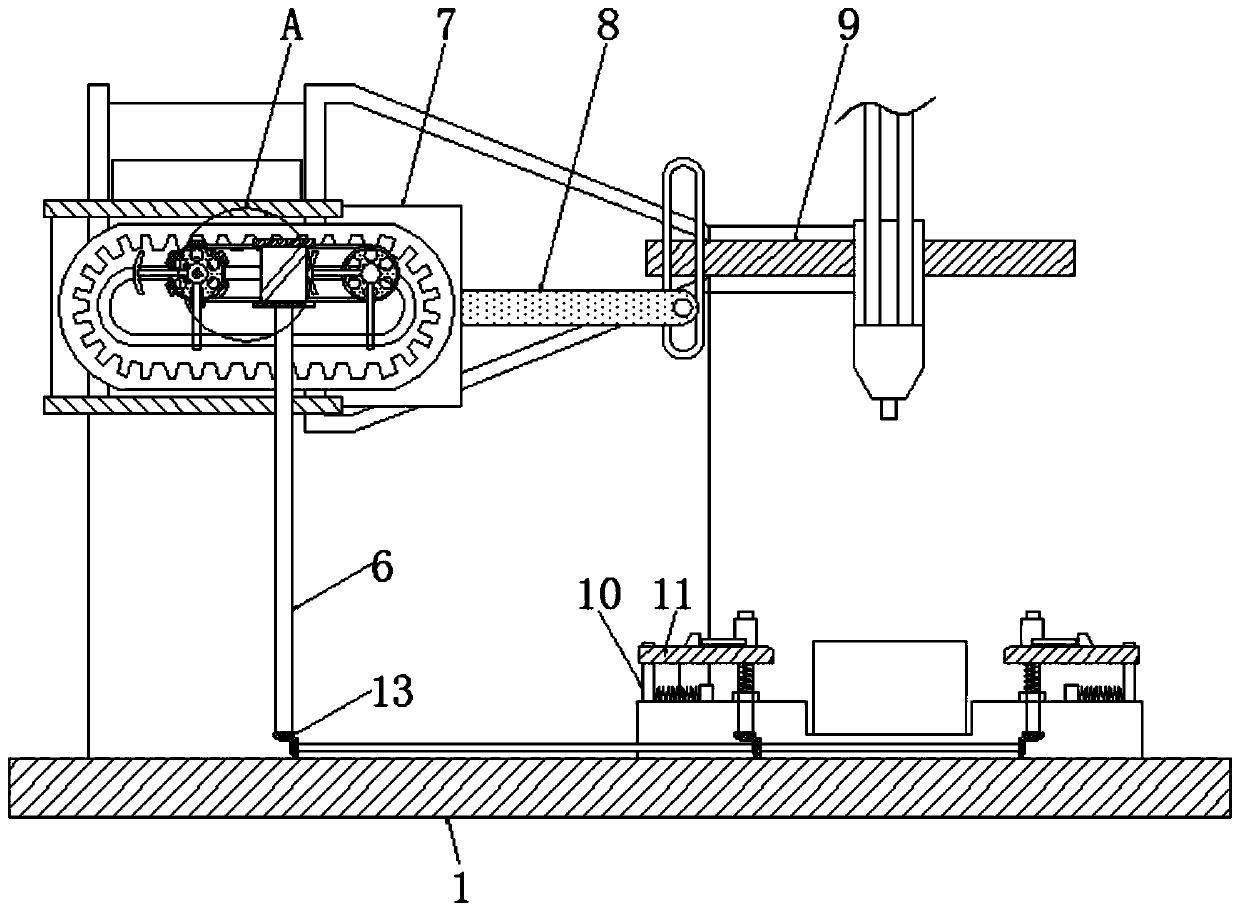

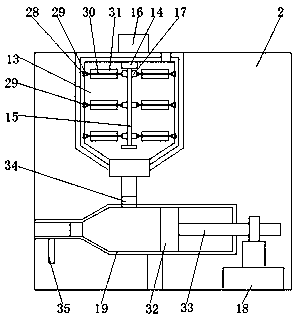

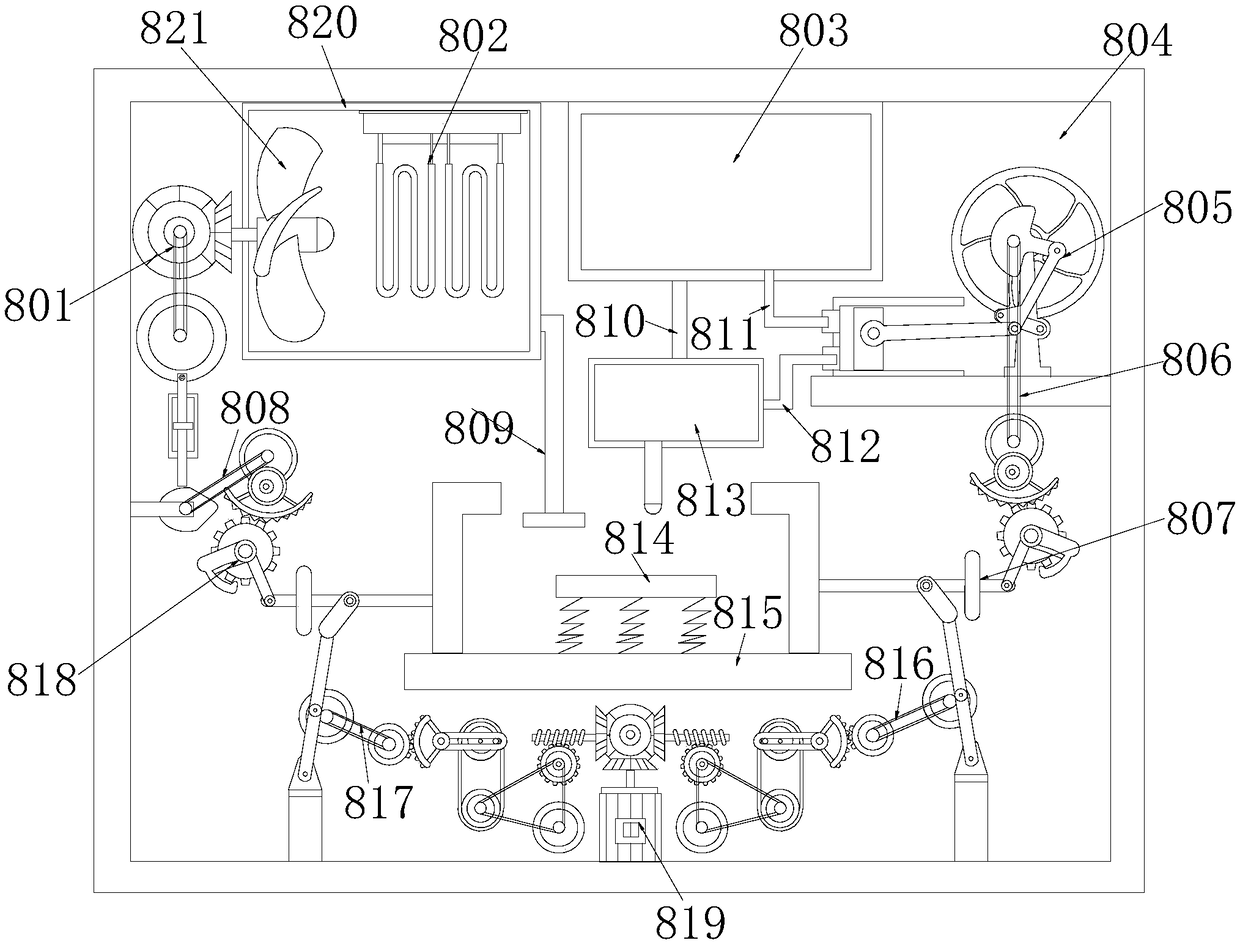

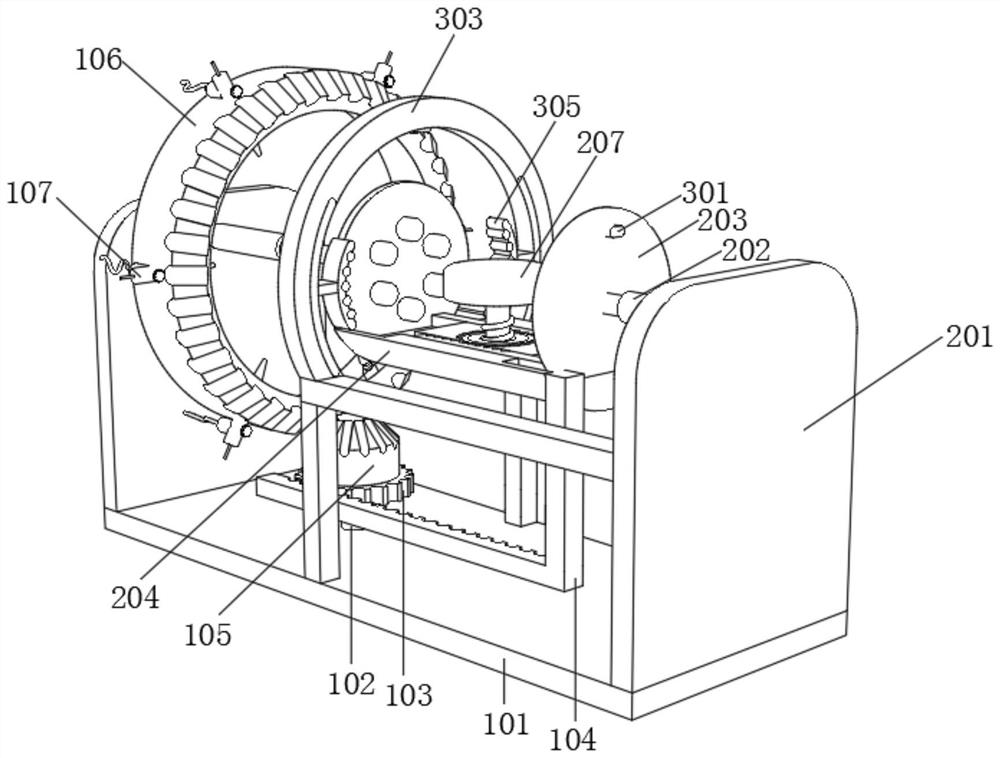

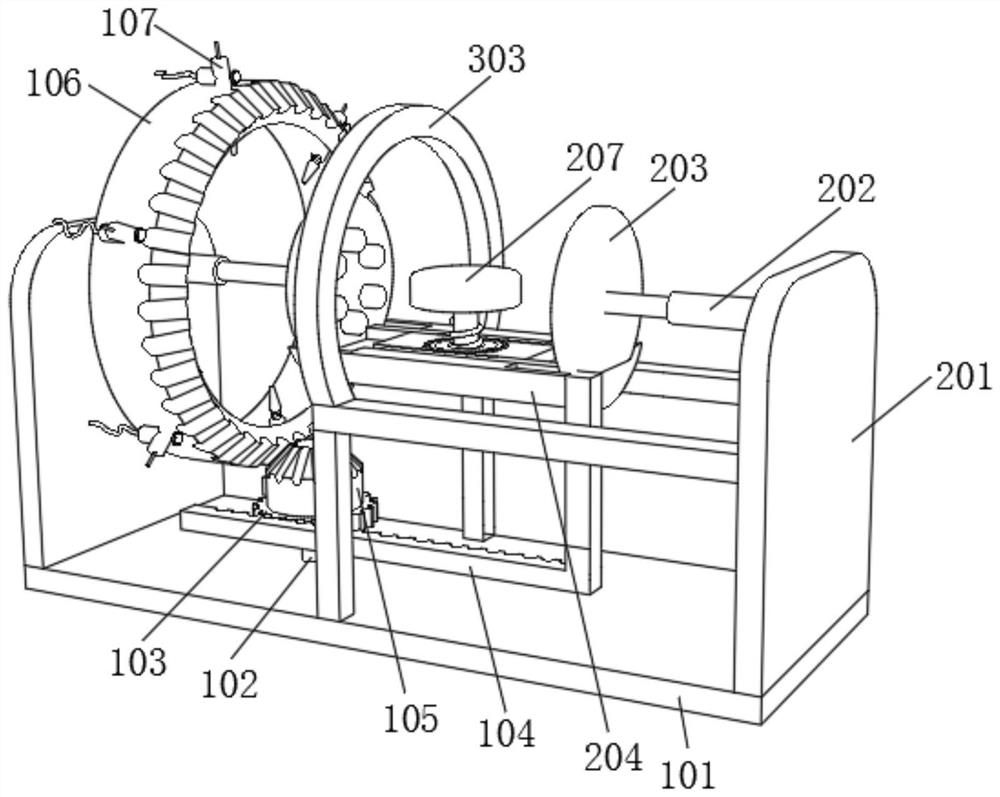

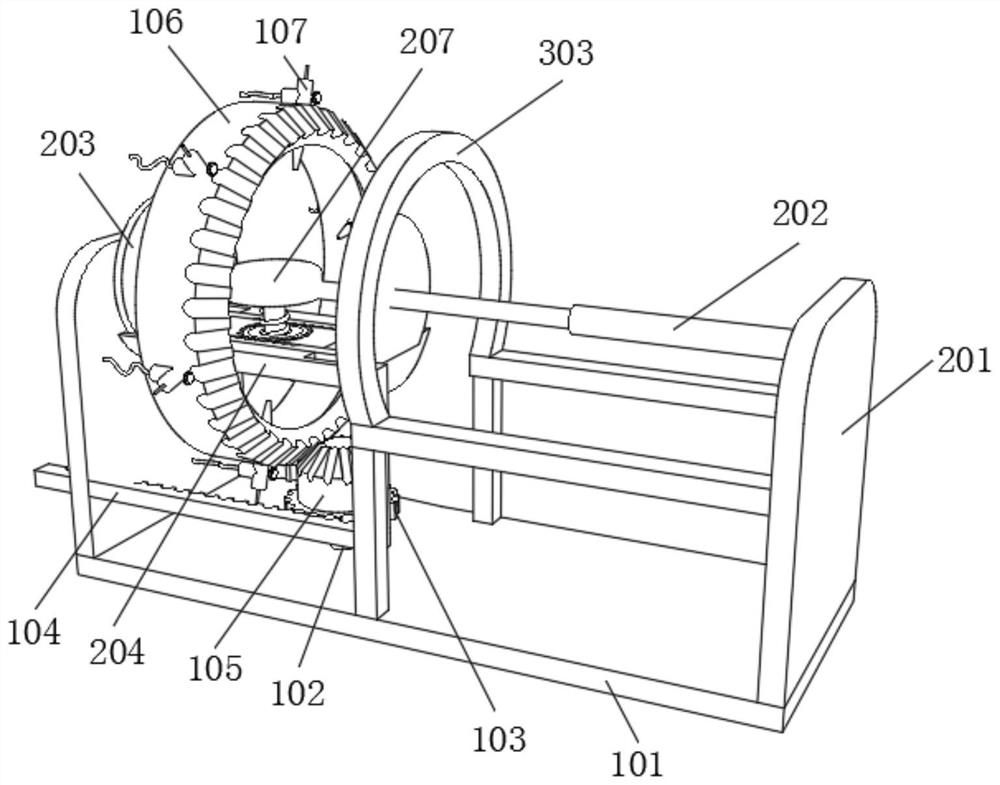

Automatic spraying system for fire extinguisher bottle

ActiveCN110841849AGuaranteed production efficiencyRealize automatic feeding processSpray boothsEngineeringFire extinguisher

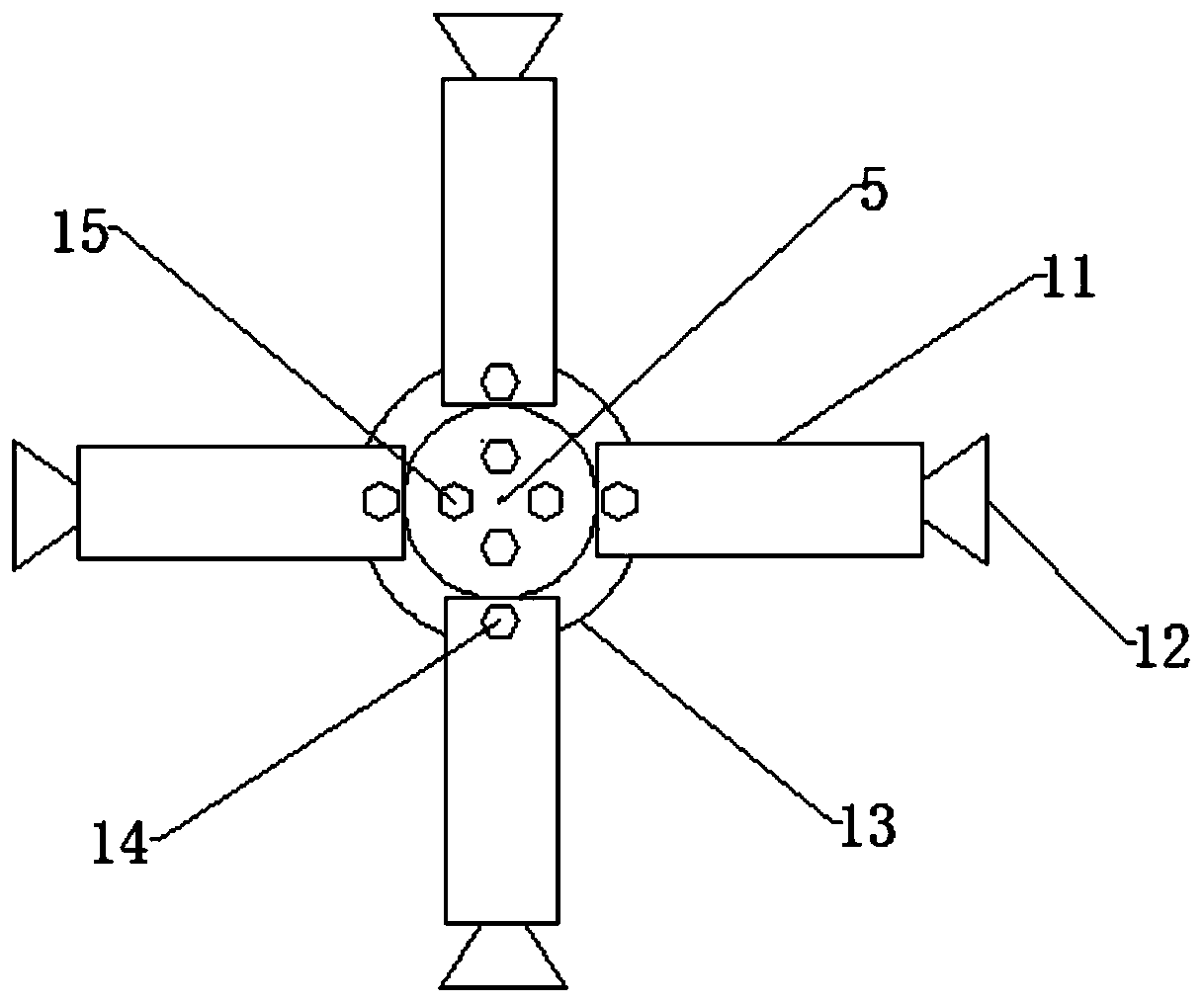

The invention relates to an automatic spraying system for a fire extinguisher bottle. The automatic spraying system comprises a bottle grabbing device for grabbing the fire extinguisher bottle and ischaracterized by comprising a spraying box, a lower conveying component, an upper conveying component, a plurality of hanging racks and a guide rail component, wherein the spraying box is arranged ina spraying chamber, the lower conveying component is used for receiving the fire extinguisher bottle from the bottle grabbing device, the upper conveying component is arranged above the lower conveying component and used for conveying the fire extinguisher bottle to pass through the spraying chamber, the hanging racks are arranged on the upper conveying component and used for hanging the fire extinguisher bottle, and the guide rail component is arranged between the upper conveying component and the lower conveying component and used for driving the hanging racks to incline; each hanging rack comprises a rod and a supporting module, the supporting module is arranged on the rod, is expandable and is used for bearing the weight of the fire extinguisher bottle, and with the rods as benchmarks,when the supporting modules bear axially upward force, the supporting modules contract and can penetrate into a fire extinguisher bottle opening. The automatic spraying system for the fire extinguisher bottle has the advantages of being convenient to use and high in automation degree.

Owner:潍坊华宝消防器材有限公司

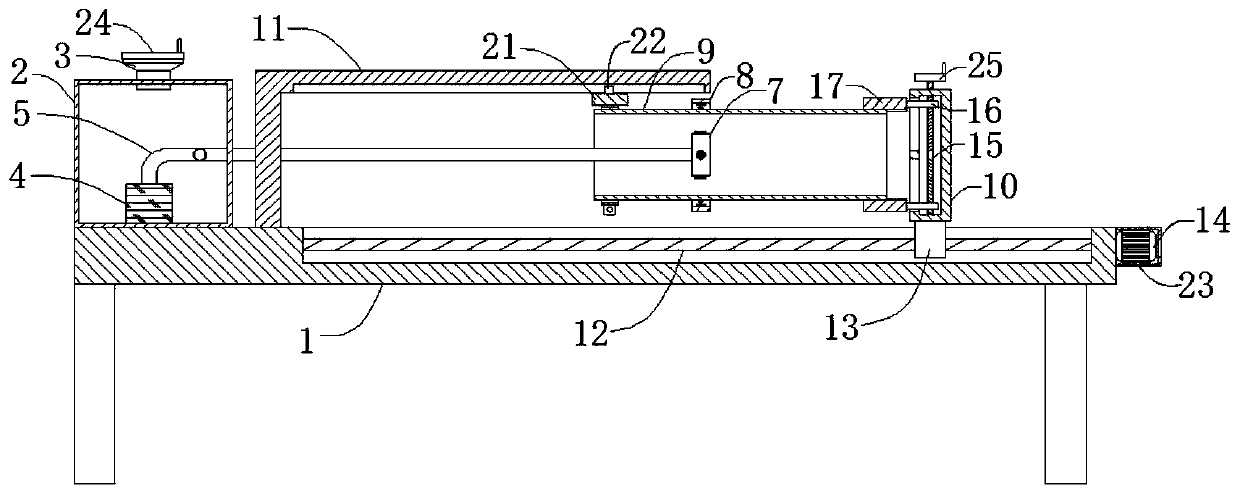

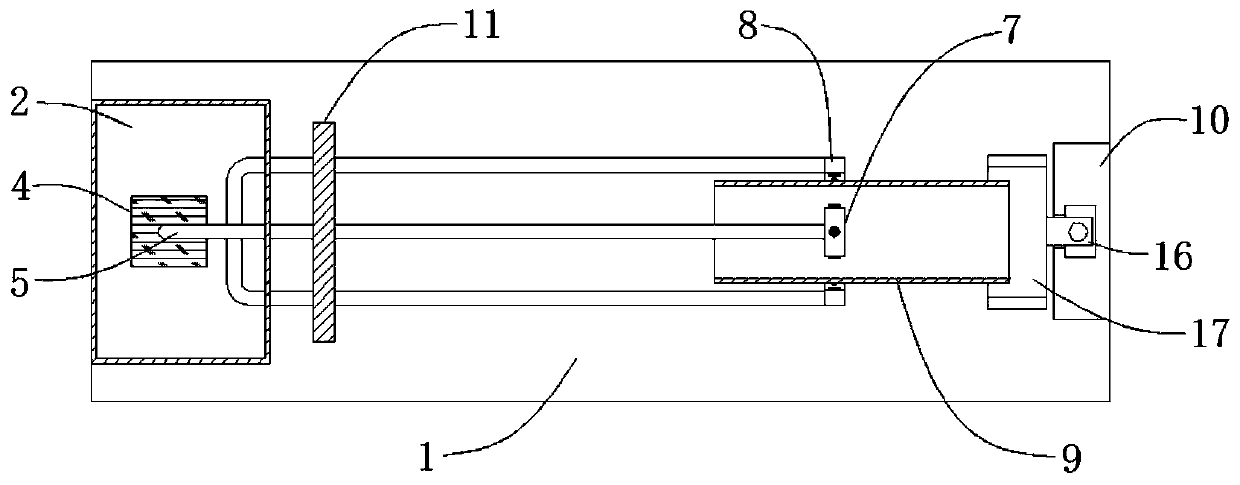

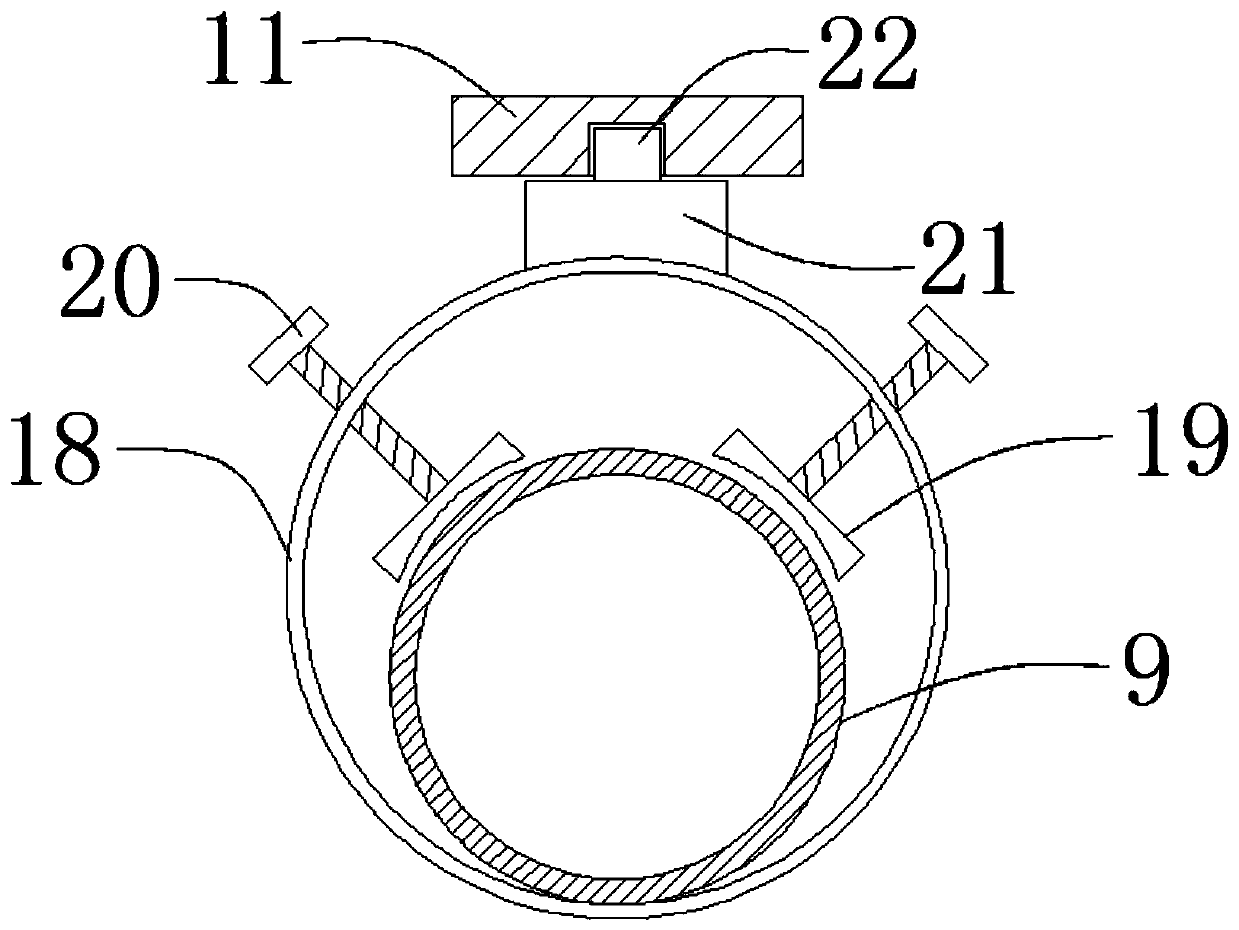

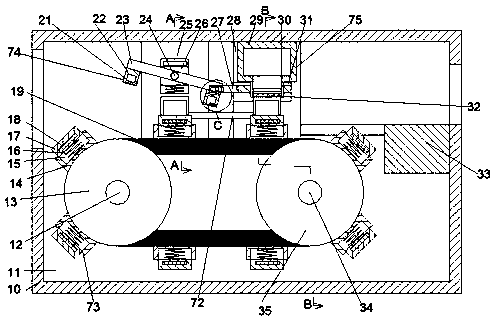

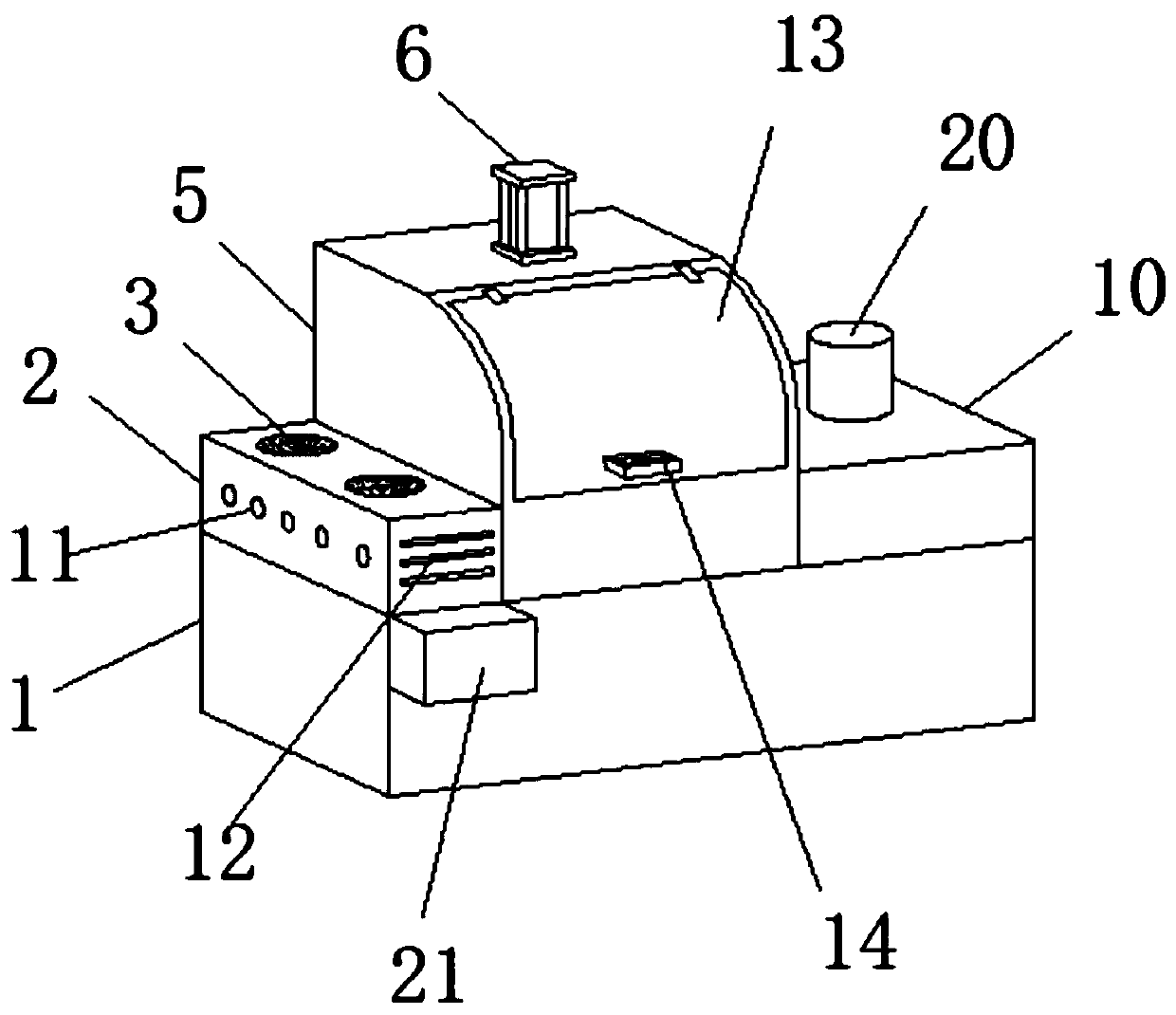

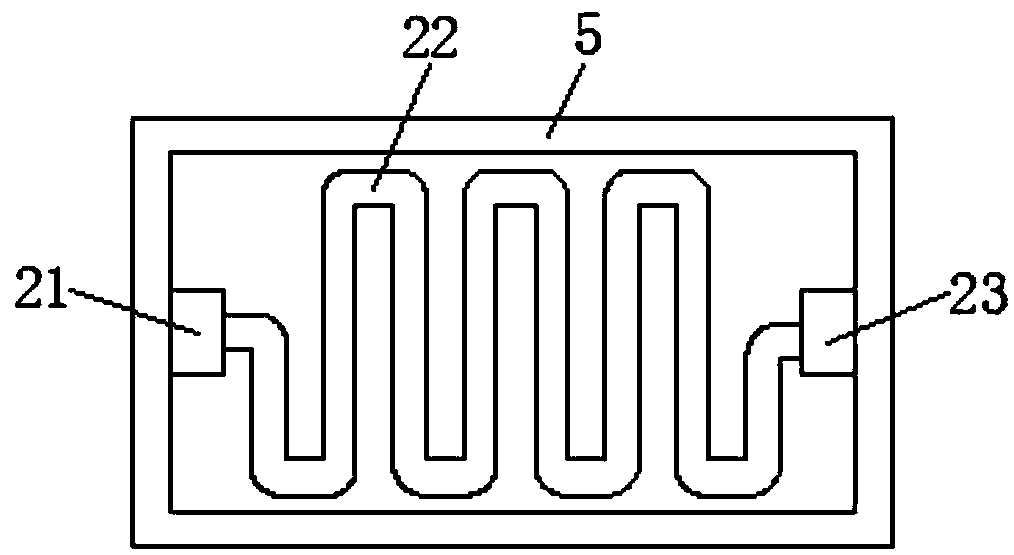

Inner and outer side wall continuous spraying equipment for epoxy ceramic pipe production

PendingCN110639721AUniform coatingEasy to useLiquid spraying apparatusMaterials scienceSpray painting

The invention relates to the technical field of pipeline spraying equipment and discloses inner and outer side wall continuous spraying equipment for epoxy ceramic pipe production. The equipment comprises a paint spraying table. The left side of the upper end of the paint spraying table is fixedly connected to a paint storage box, the upper end of the paint storage box is fixedly connected to a feeding hopper, the lower inner side wall of the paint storage box is fixedly connected to a paint spraying pump, the output end of the paint spraying pump is fixedly connected to a first conveying pipe, the end, far away from the paint spraying pump, of the first conveying pipe penetrates the right side wall of the paint storage box and stretches outside, the front and back sides of the end, located in the paint storage box, of a pipe wall of a horizontal part of the first conveying pipe are fixedly connected to a second conveying pipe, and an inner round spray head and an outer annular spray head are arranged above the paint spraying table. The equipment can spray paint to the inner and outer side walls of the epoxy ceramic pipe simultaneously, and can prevent the epoxy ceramic pipe from inclining and swinging in the paint spraying process to affect the paint spraying effect, so that the equipment is used conveniently.

Owner:荆门正源光华管业有限公司

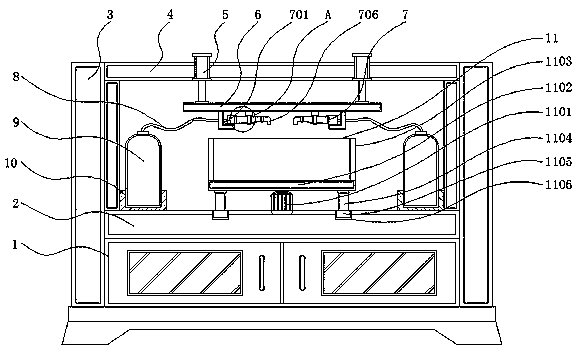

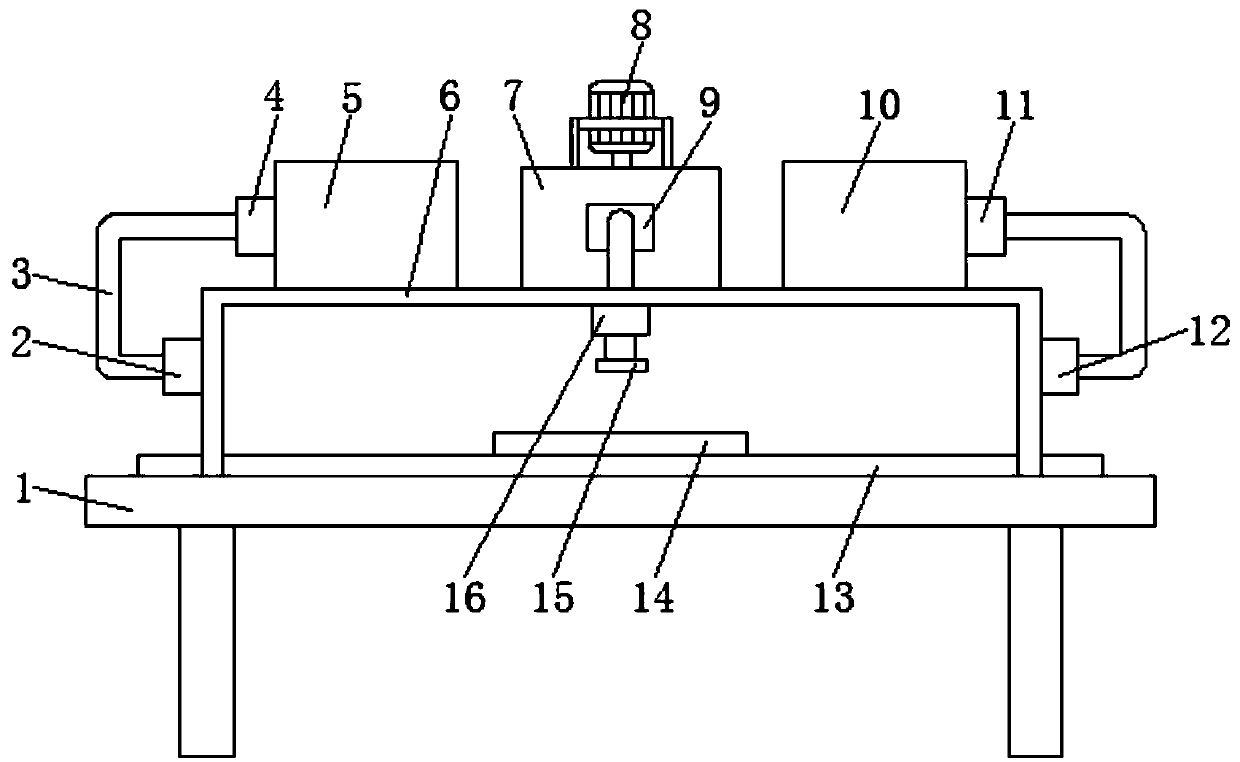

Paint spraying apparatus for boards used for furniture

ActiveCN104107787AQuickly solidifies and dries upAvoid affecting the painting effectLiquid surface applicatorsCoatingsLacquerEngineering

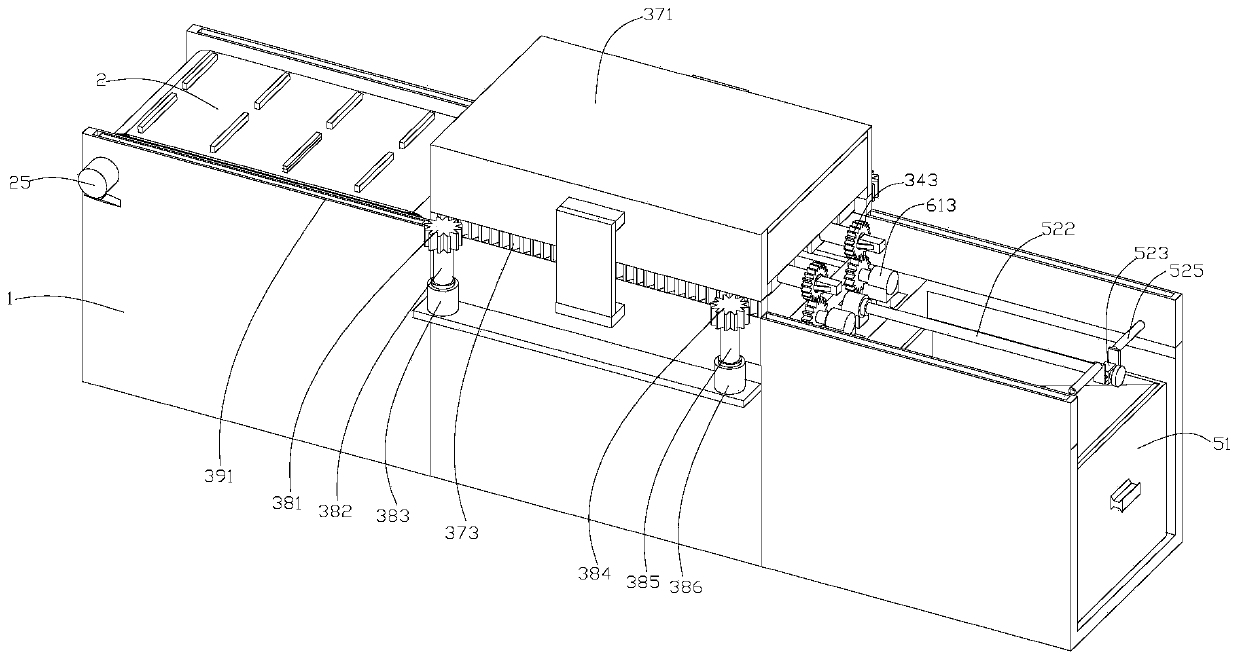

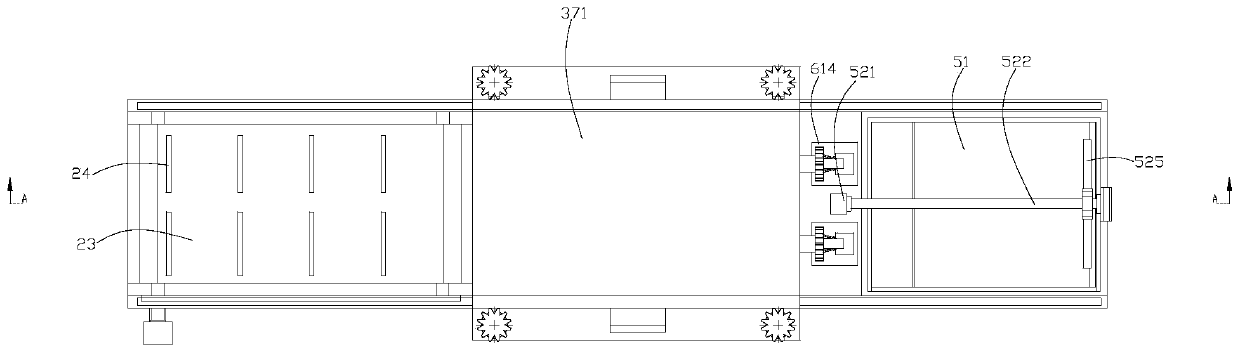

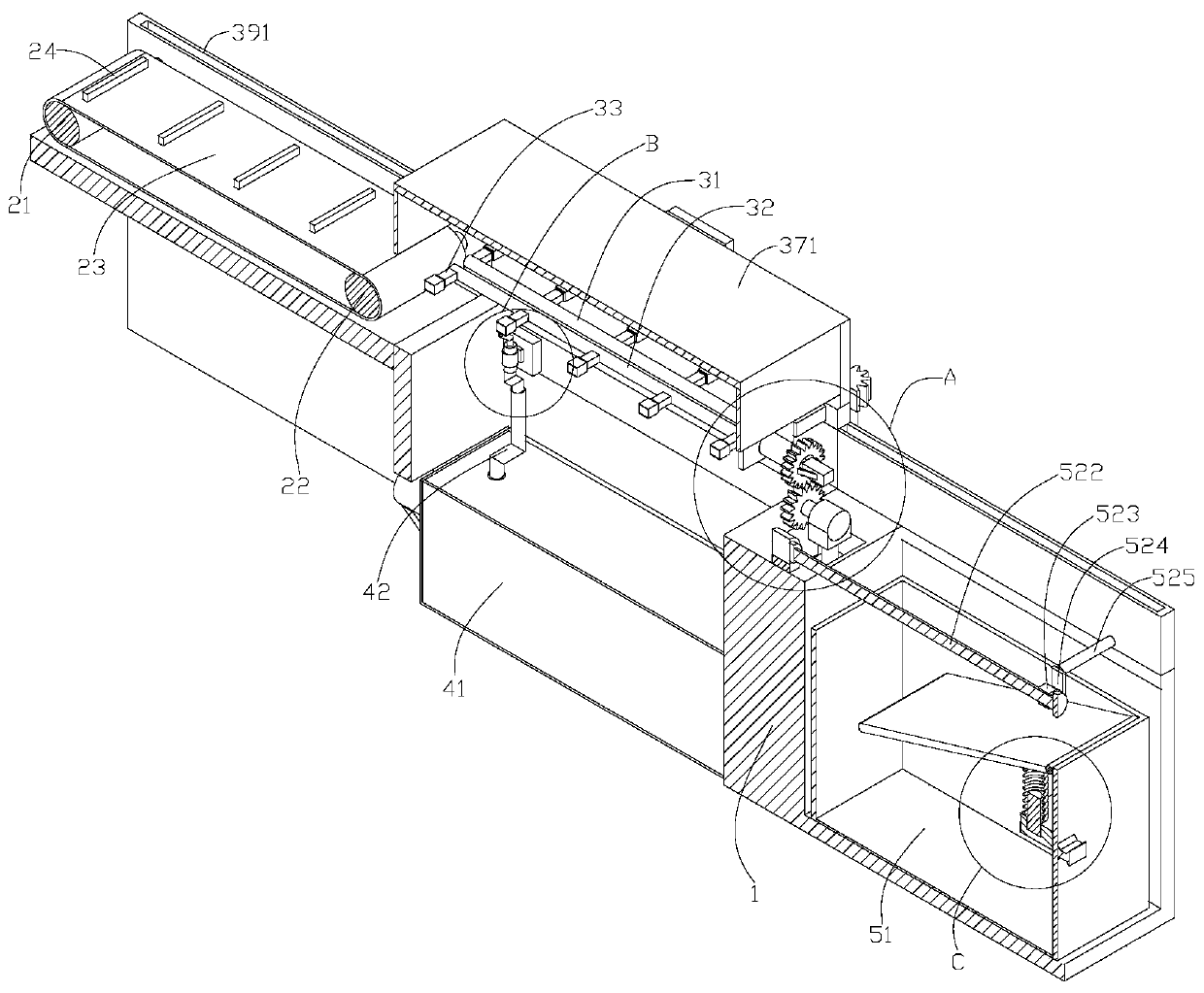

The invention relates to a paint spraying apparatus for boards used for furniture. The paint spraying apparatus comprises a conveyer belt, a washing mechanism, a first drying mechanism, a paint spraying mechanism and a second drying mechanism, wherein the washing mechanism, the first drying mechanism, the paint spraying mechanism and the second drying mechanism are arranged at one side of the conveyer belt. In terms of the moving direction of the conveyer belt, the washing mechanism is located before the first drying mechanism, the paint spraying mechanism is located behind the first drying mechanism, and the second drying mechanism is located behind the paint spraying mechanism. The paint spraying apparatus can totally replace people in paint spraying, enables sprayed paint to be uniformly adhered on the boards of furniture and has high paint spraying quality.

Owner:GUANGDONG KNOYA HOME FURNISHING CO LTD

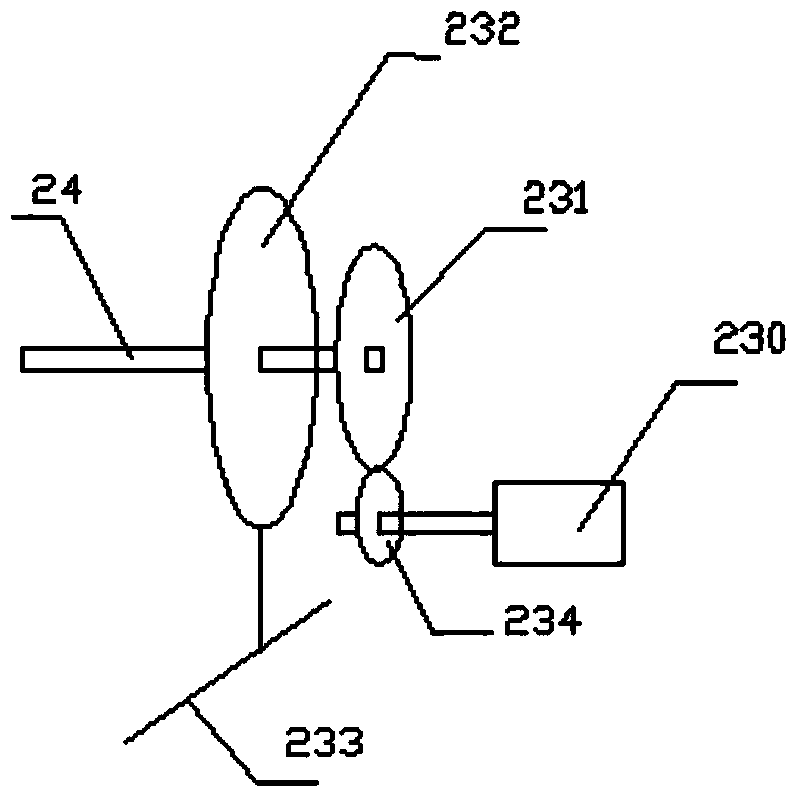

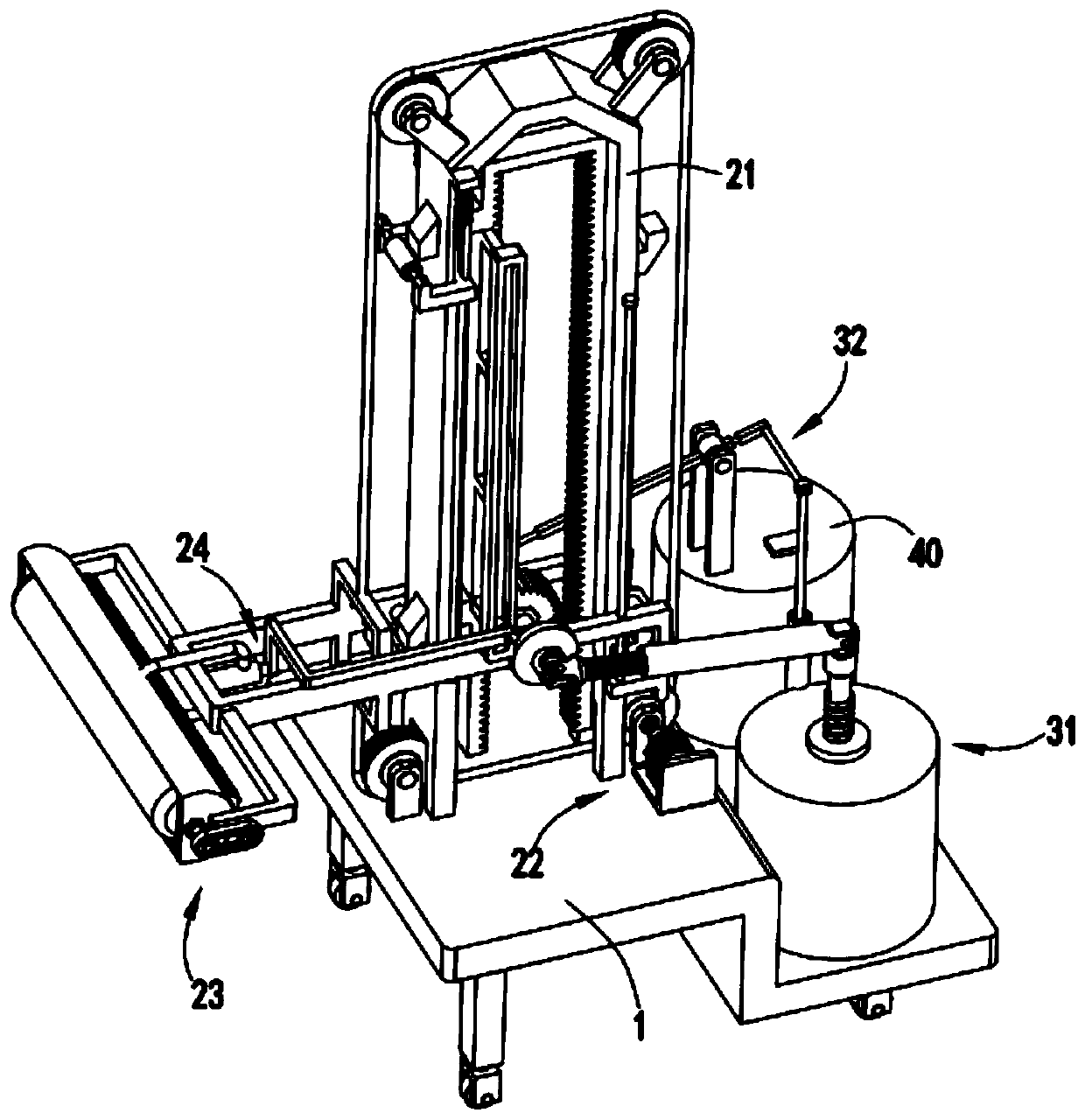

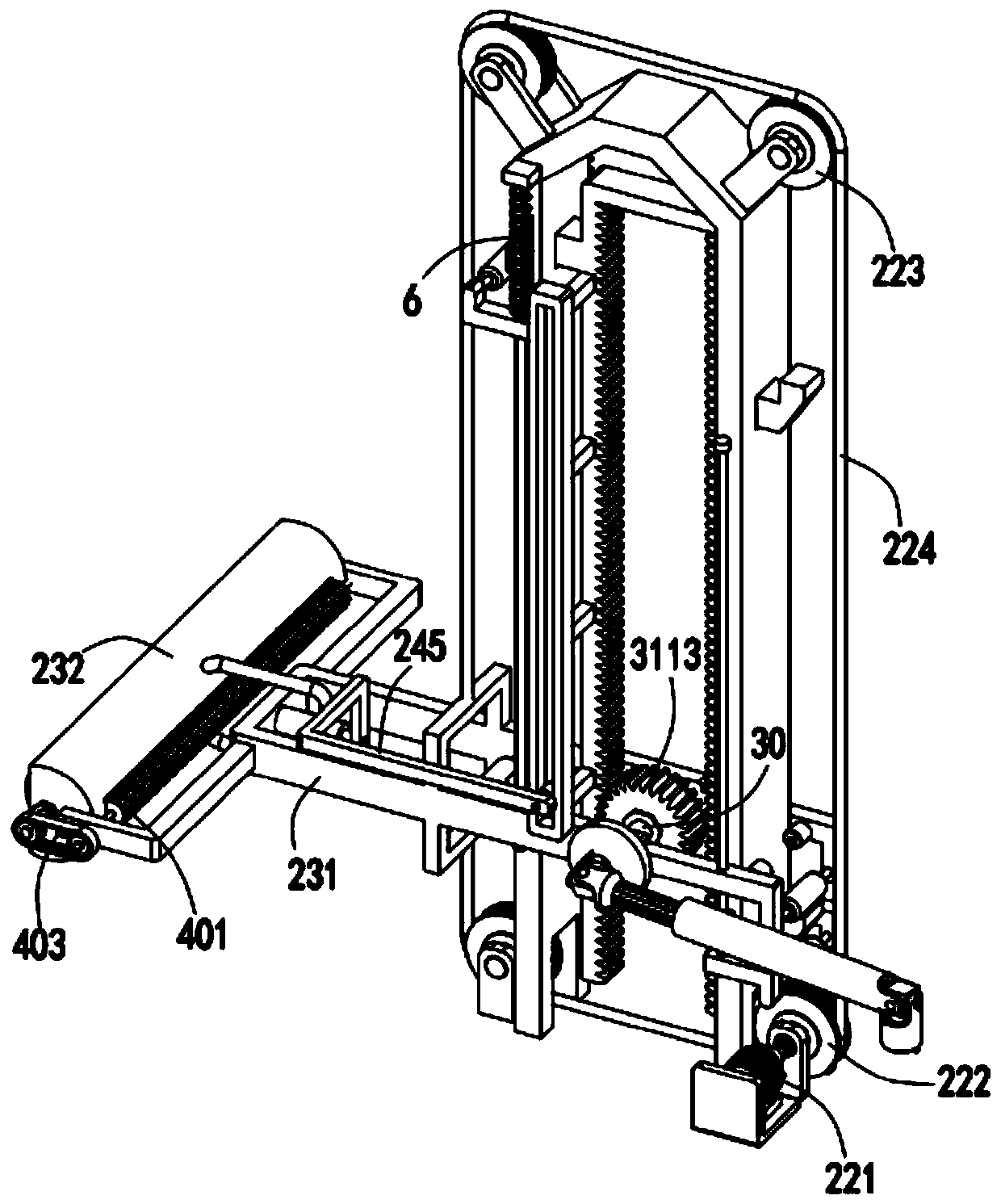

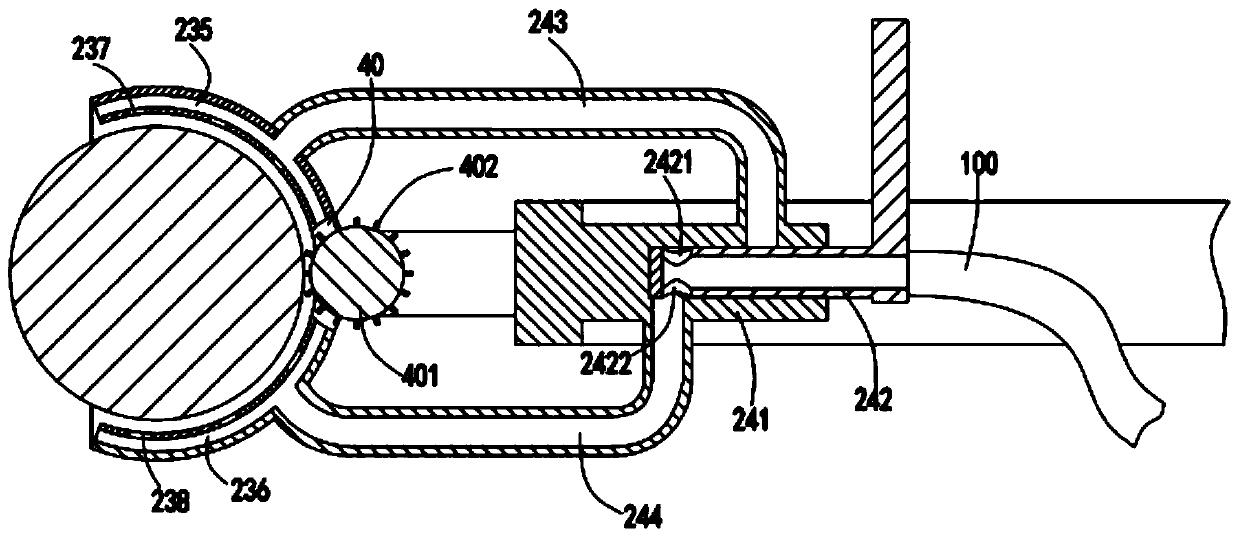

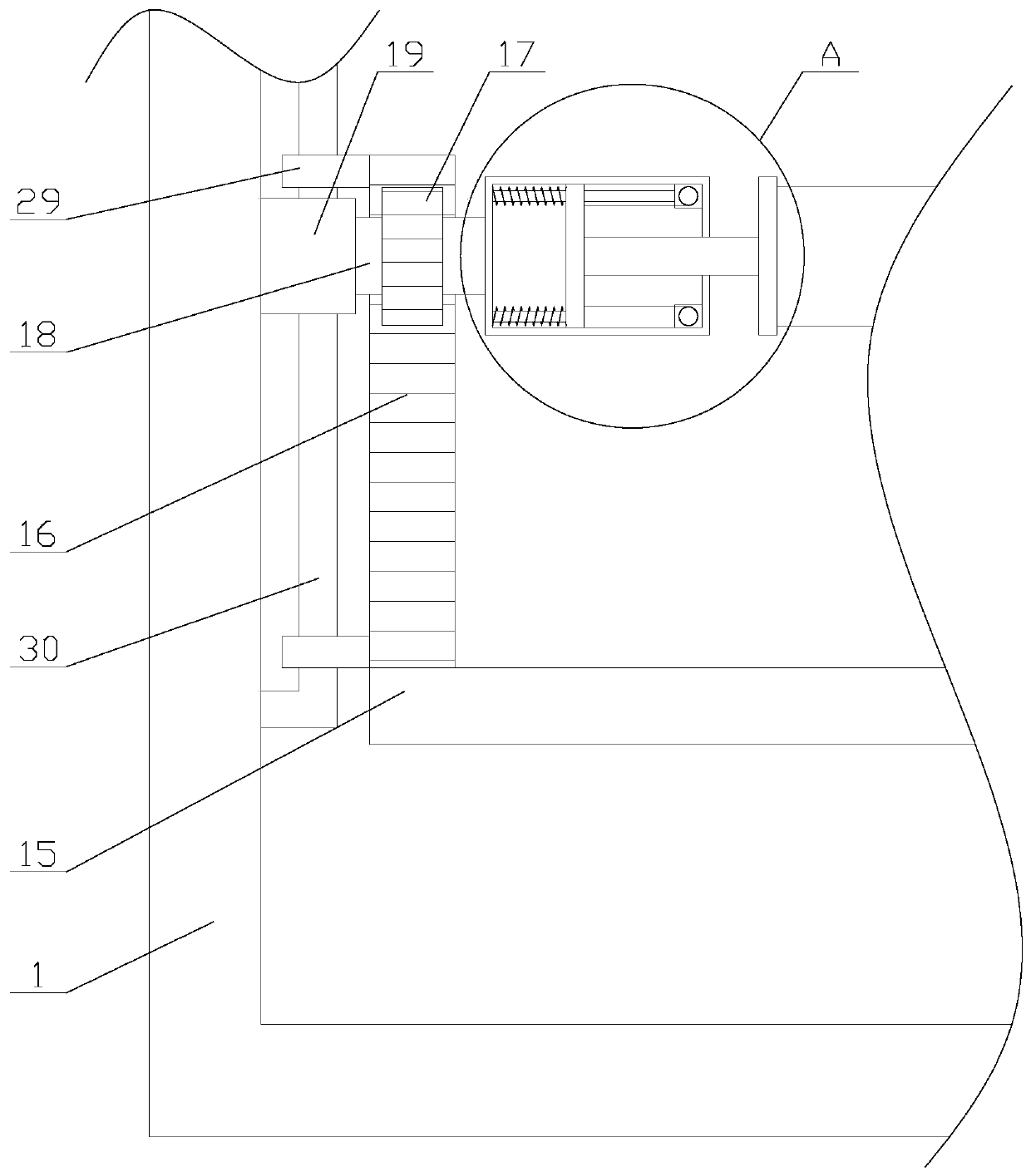

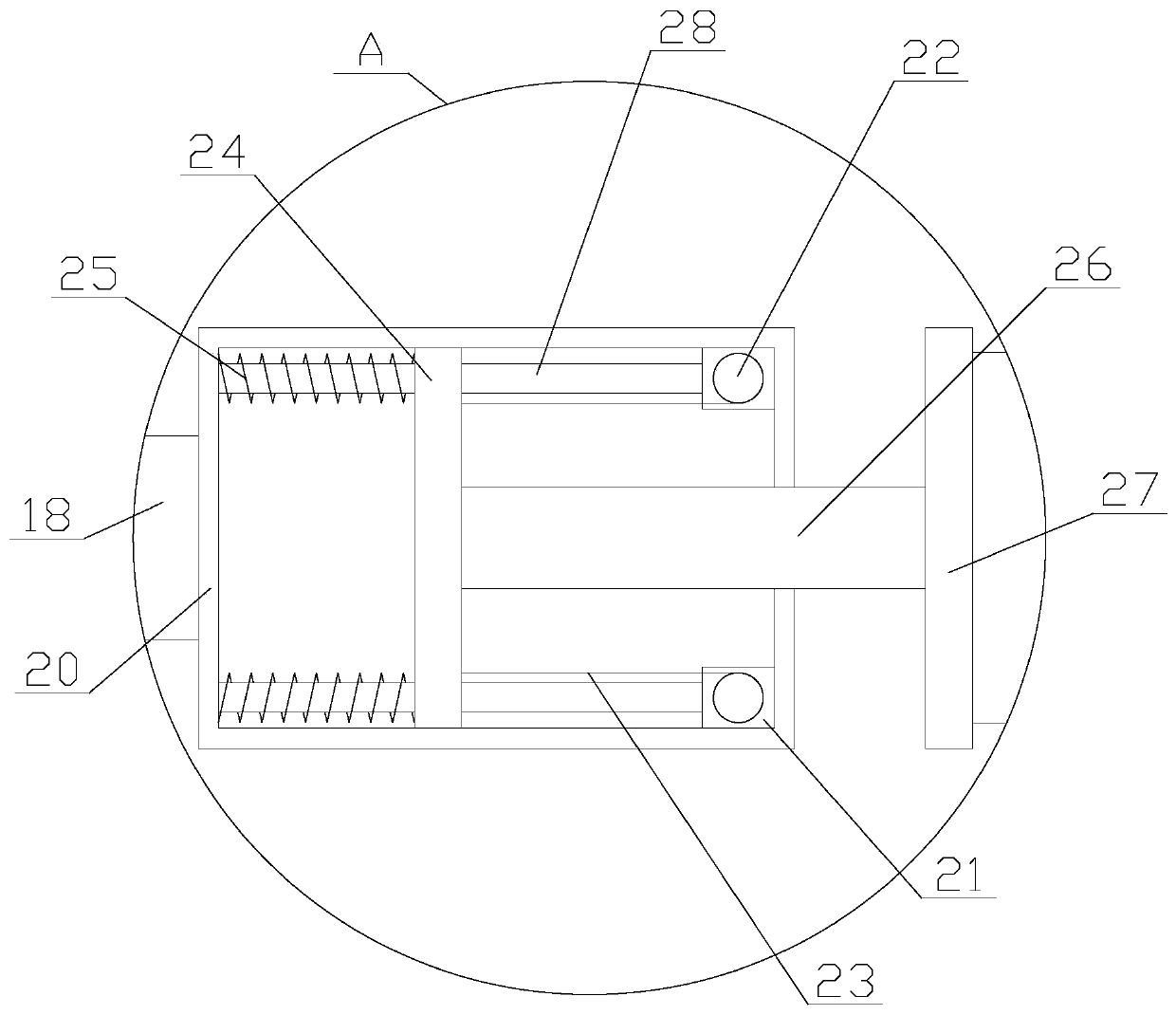

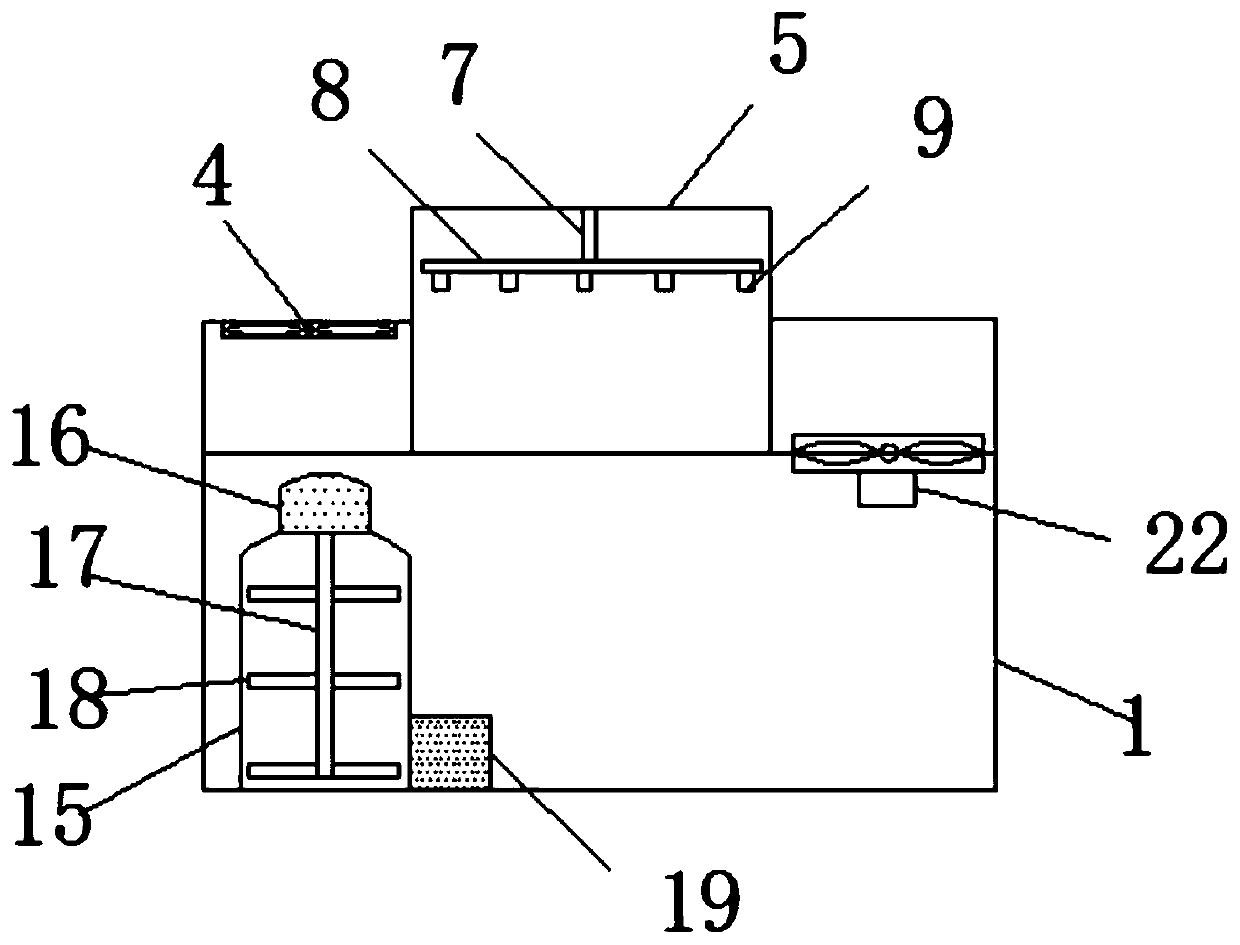

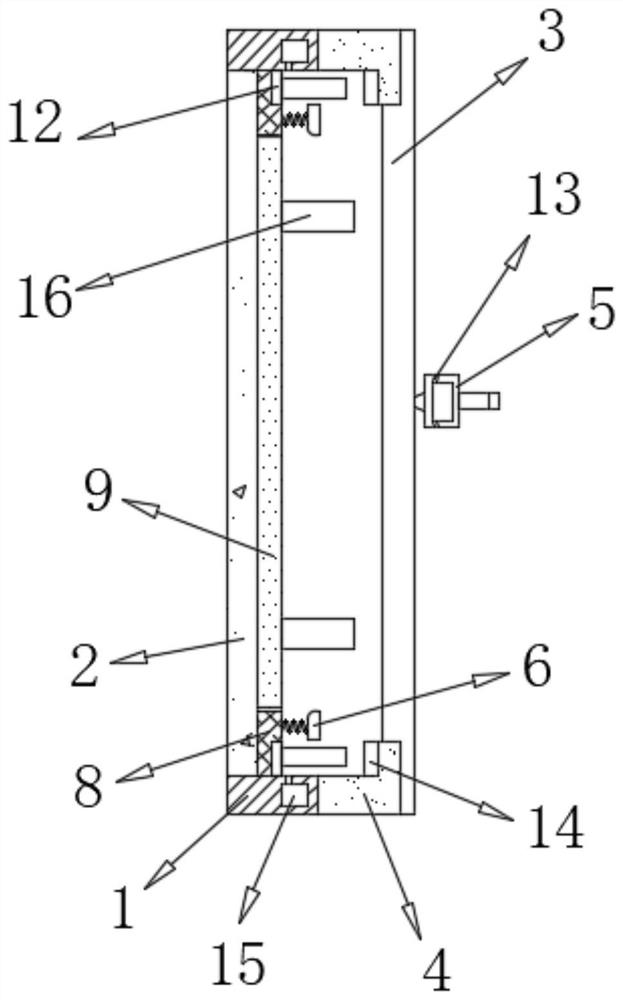

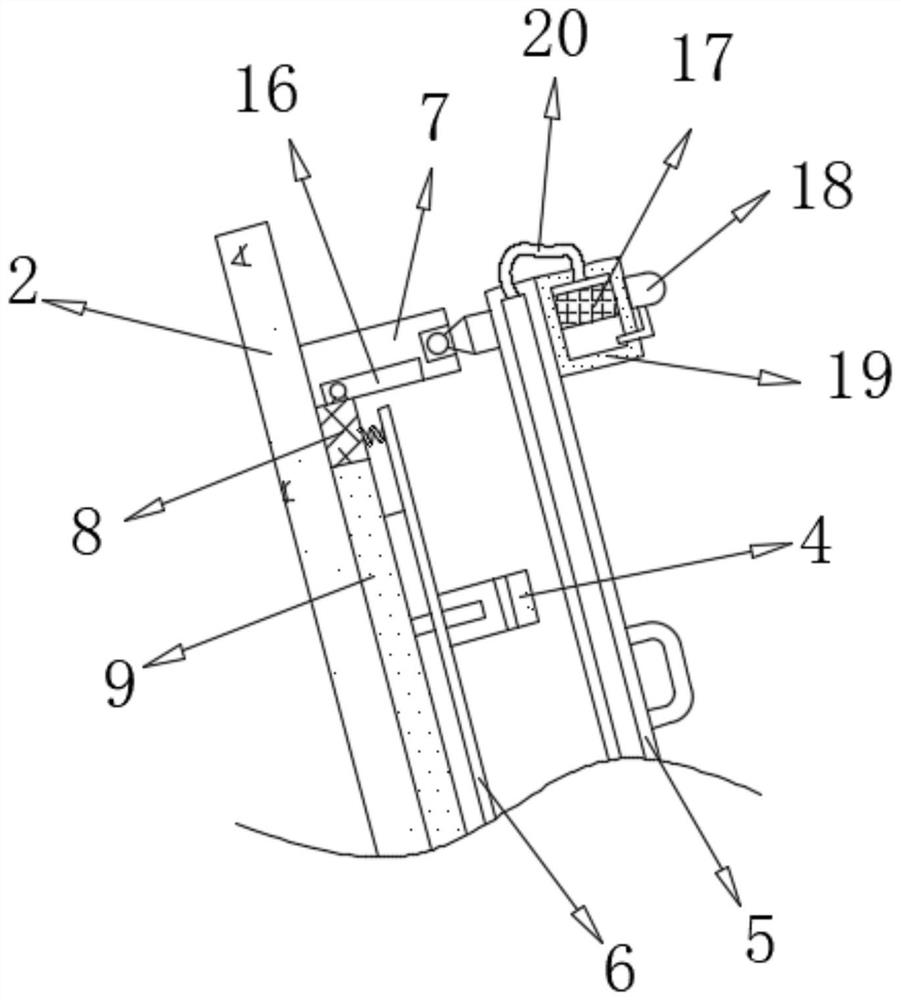

Wall surface whitewashing equipment

ActiveCN109898809AQuality assuranceGuaranteed timelinessBuilding constructionsEvaporationMoving frame

The invention relates to wall surface whitewashing equipment. The wall surface whitewashing equipment comprises a moving frame, and a whitewashing device and a feeding device are arranged on the moving frame; the whitewashing device comprises a supporting frame on the moving frame, a traction mechanism on one side of the supporting frame and a whitewashing mechanism driven by the traction mechanism to move up and down along the supporting frame; the feeding device comprises a feeding mechanism for supplying coating for the whitewashing mechanism and an adjusting mechanism arranged on one sideof the feeding mechanism and used for adjusting the feeding pressure; and the whitewashing mechanism comprises a whitewashing roller, a switching mechanism is further arranged at the position of the whitewashing mechanism, when the whitewashing mechanism moves upwards, the switching mechanism controls the coating to be sprayed to the whitewashing roller from the upper right part, and when the whitewashing mechanism moves downwards, the coating is controlled to be sprayed to the whitewashing roller from the lower right part. According to the wall surface whitewashing equipment, the problems that the coating supplied onto the surface of the whitewashing roller is prone to drippage and causes waste and pollution on the equipment and the bottom face, the sprayed part coating cannot be whitewashed on the wall surface and water evaporation is prone to occurring to affect the performance, and the coating spraying amount affected by gravity is uneven when whitewashing is carried out at different height positions are solved.

Owner:东营硕明信息技术有限公司

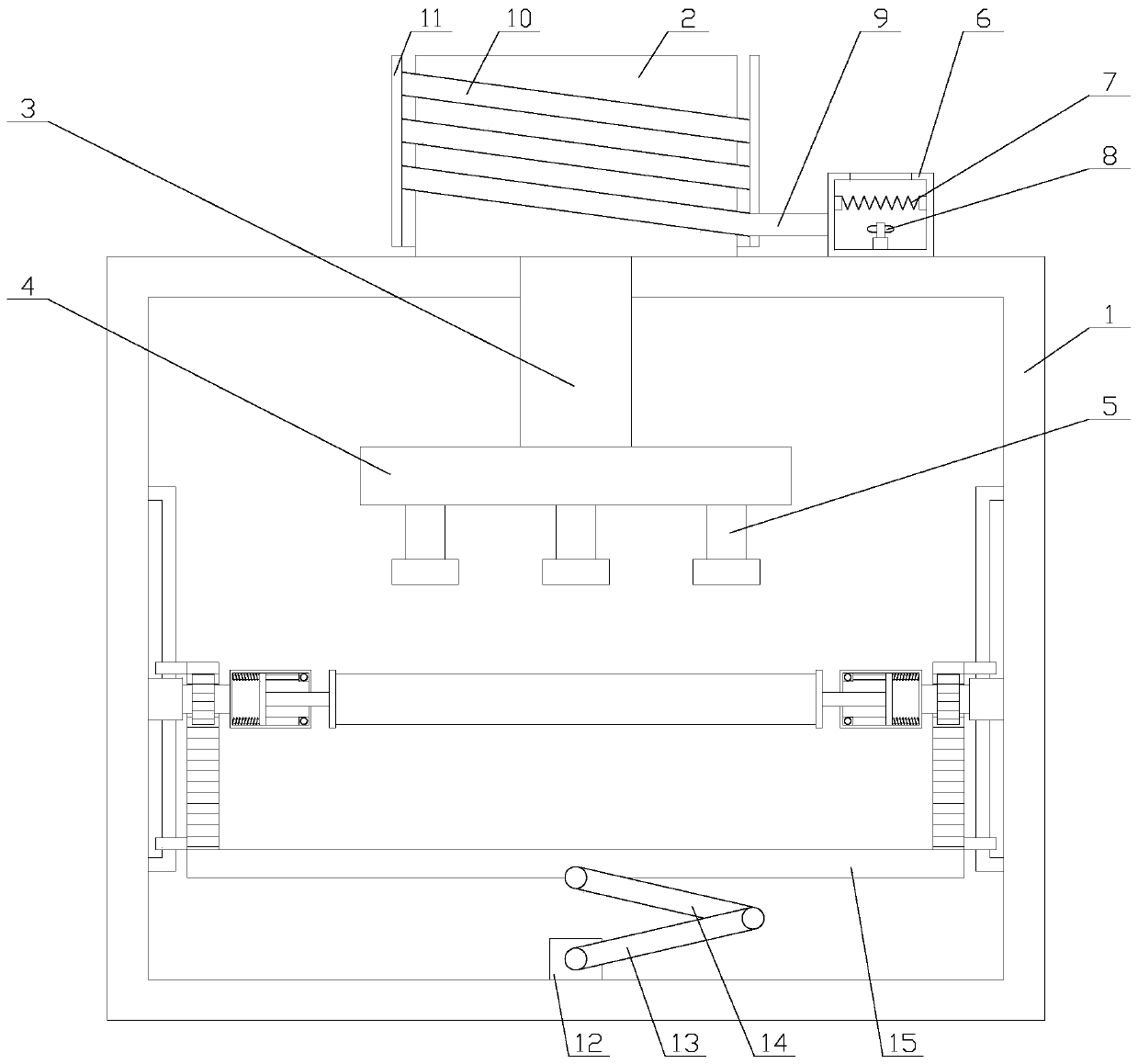

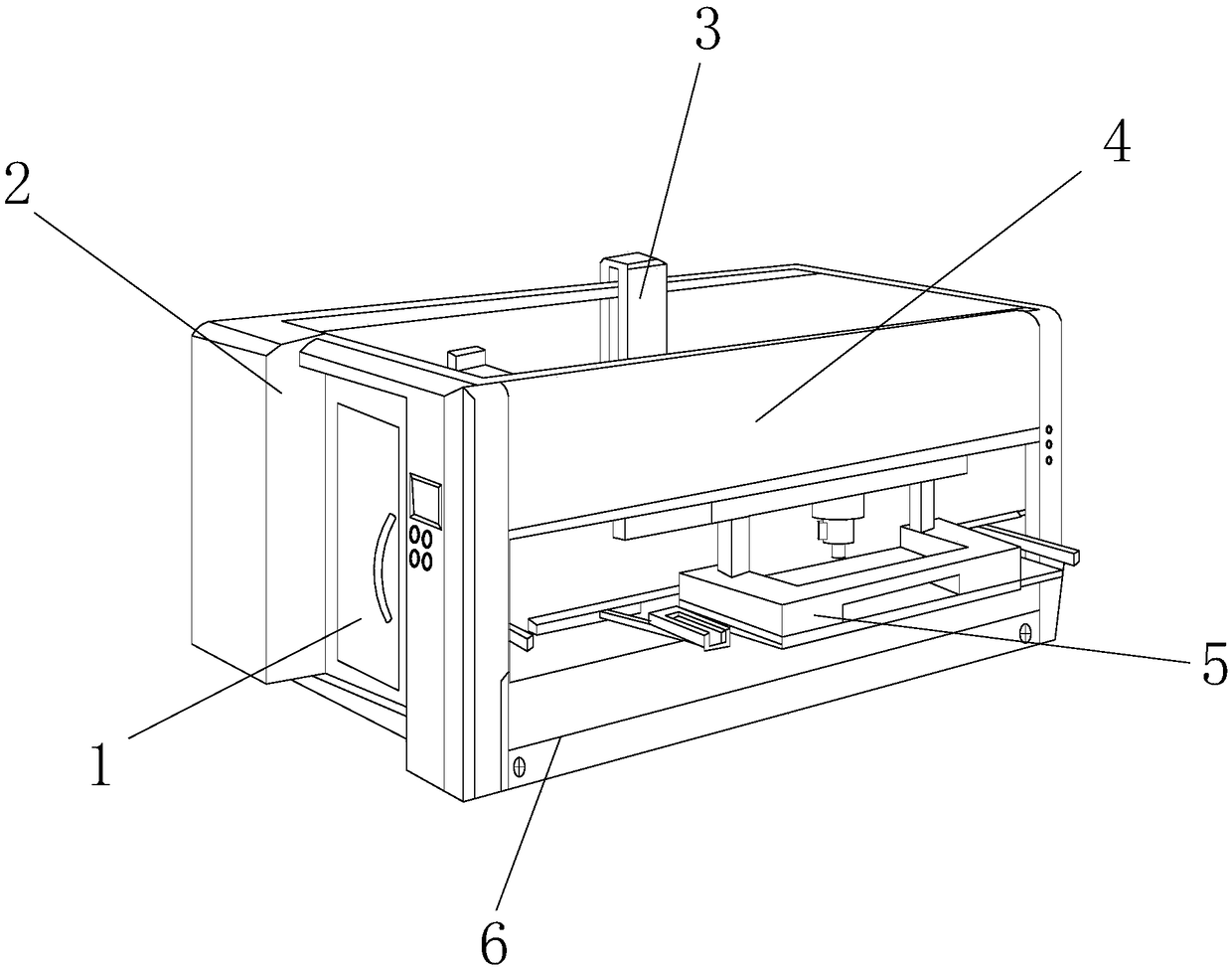

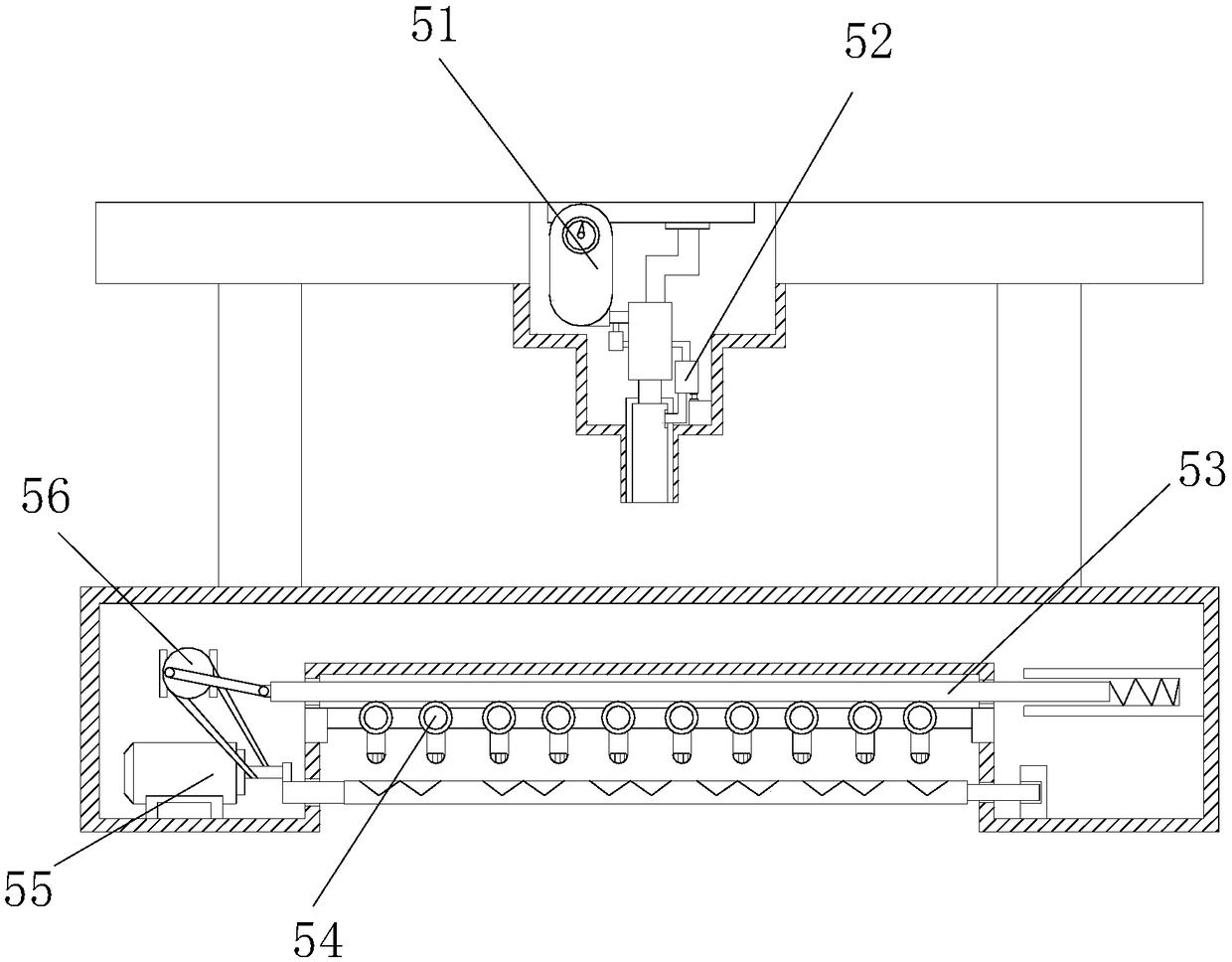

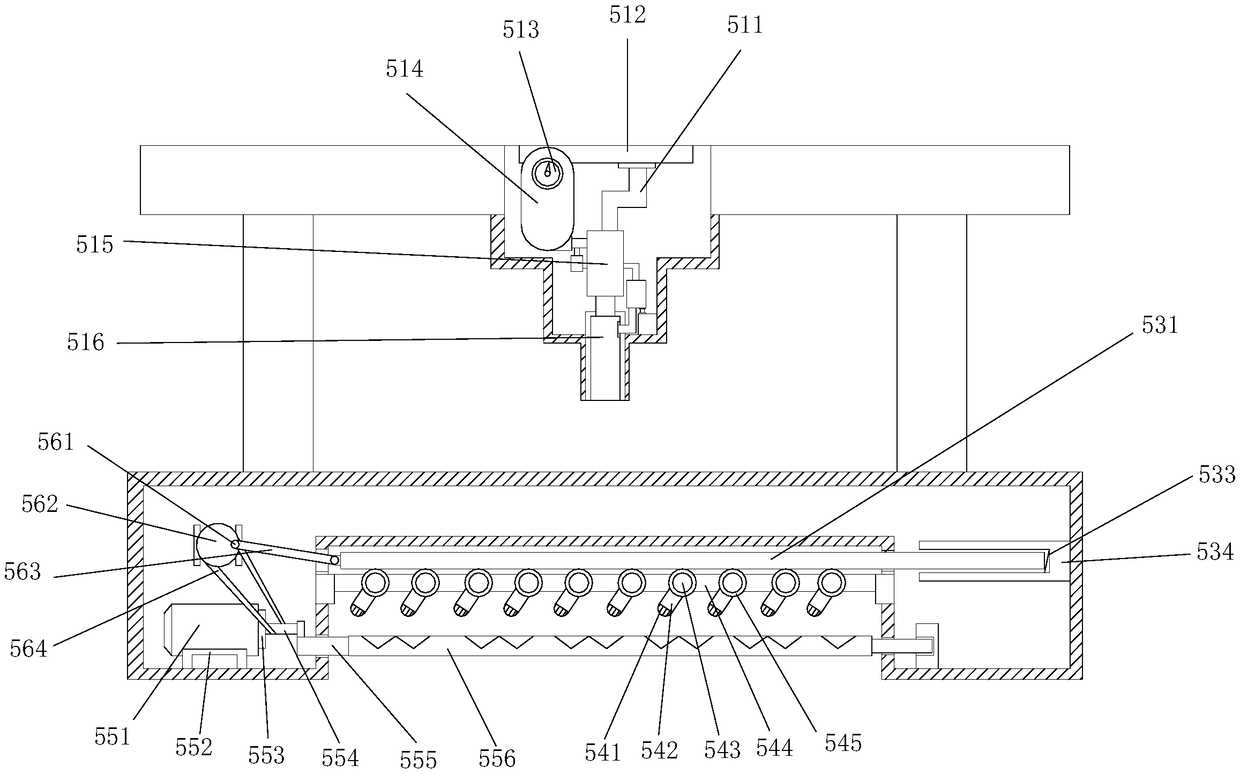

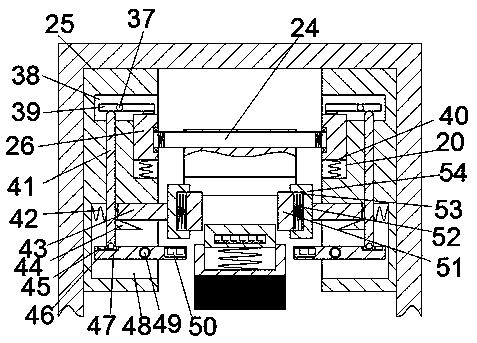

Efficient floor machining paint spraying device with anti-caking function

InactiveCN110013933AImprove efficiencyImprove practicalitySpraying apparatusSpray nozzleElectric heating

The invention relates to an efficient floor machining paint spraying device with an anti-caking function. The efficient floor machining paint spraying device with the anti-caking function comprises abody, a paint box, a flow distributing box, a communicating pipe and a plurality of spray nozzles. The efficient floor machining paint spraying device with the anti-caking function further comprises an overturning mechanism and a heating mechanism. The overturning mechanism comprises a drive assembly, two overturning assemblies and two fixing boxes. Each overturning assembly comprises a rotating shaft, a gear, a rack and a bearing. A moving plate, a moving rod, a fixed plate and two fixing assemblies are arranged in each fixing box. The heating mechanism comprises a heating box, a connection pipe and a heating pipe. A ventilation device and an electric heating wire are arranged in the heating box. By the adoption of the efficient floor machining paint spraying device with the anti-caking function, by means of an overturning mechanism, a wooden board to be sprayed with paint can be overturned so that the other face can undergo paint spraying, and therefore the paint spraying efficiencyis improved; by means of the heating mechanism, paint in the paint spraying box can be heated, and therefore it is avoided that the paint cakes and influences the paint spraying effect.

Owner:GUANGZHOU OUSHU ENVIRONMENTAL PROTECTION TECH CO LTD

Anti-rusting paint spraying device used for wrench processing and provided with multiple clamping mechanisms

InactiveCN110743733AImprove painting efficiencyAvoid tilting the swivel seatSpray nozzlesPhysicsElectric machinery

The invention discloses an anti-rusting paint spraying device used for wrench processing and provided with multiple clamping mechanisms, and relates to the technical field of wrench processing. The anti-rusting paint spraying device comprises a device body, a paint spraying mechanism and the clamping mechanisms, wherein a working table is mounted above the device body, side plates are fixed on thetwo sides of the working table, a top plate is fixed above the side plates, the top plate is in riveted joint with the side plates, an air cylinder is mounted below the top plate, a lifting plate isfixed below the air cylinder, the paint spraying mechanism is mounted below the lifting plate, paint guiding pipes are connected with the two sides of the paint spraying mechanism, a storage tank is fixed below the paint guiding pipes, and a limiting seat is arranged on the outer side of the bottom of the storage tank. The anti-rusting paint spraying device has beneficial effects as follows: a rotating mechanism is arranged to conveniently drive a wrench to rotate for spraying paint, and a motor conveniently drives a rotating seat to rotate, so that the wrench clamped on the upper side of therotating seat is driven to rotate, uniform and comprehensive paint spraying on the outer side of the wrench can be realized, and the paint spraying efficiency is improved accordingly.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

Floor paint spraying device capable of ensuring quantification and uniform paint spraying based on intermittent motion

The invention relates to the technical field of floors, and discloses a floor paint spraying device capable of ensuring quantification and uniform paint spraying based on intermittent motion. The floor paint spraying device comprises a base, wherein a fixed plate is fixedly connected to the upper portion of the base to support a floor. According to the device, through cooperative use of a moving plate, a connecting rod, a push rod and a pinion, a spray head is driven to move left and right for automatic paint spraying, paint spraying is more uniform, the paint spraying quality is improved, paint is prevented from being accumulated at same position of the floor, through cooperative use of a vertical rod, a brake block and a second rotating shaft, intermittent braking is conducted on the floor, the floor is enabled to be in a static state in the paint spraying process, the paint spraying effect is prevented from being affected, the staying time of the floor is kept consistent, it is guaranteed that quantitative paint spraying is conducted on the floor, waste of the paint is avoided, through cooperative use of a rotary disc, a first rotary shaft, a rotary rod and a bevel gear, the linkage step is conducted, the linkage performance of the whole device is improved, and operation is easier.

Owner:合肥哈罗沃信息科技有限责任公司

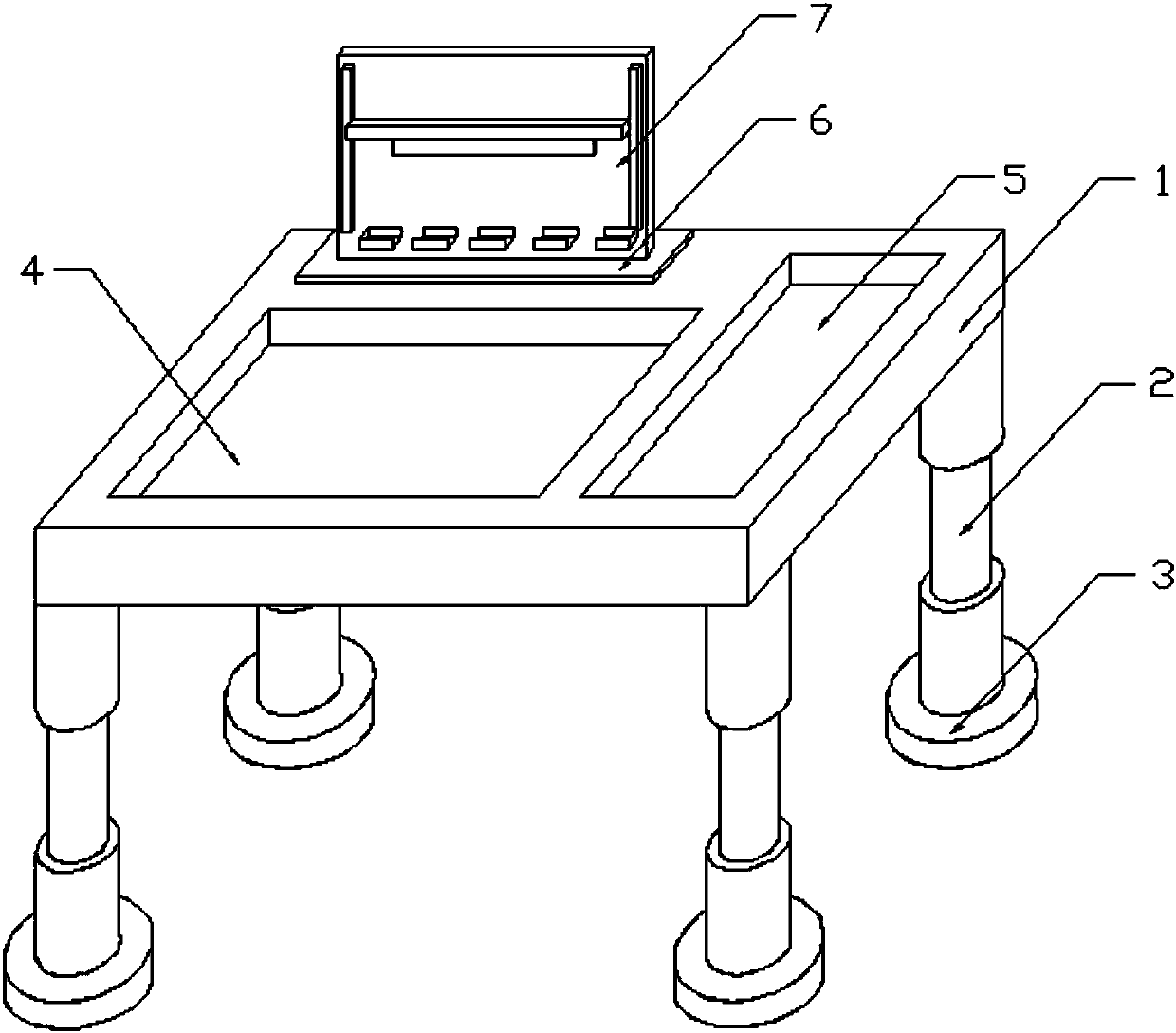

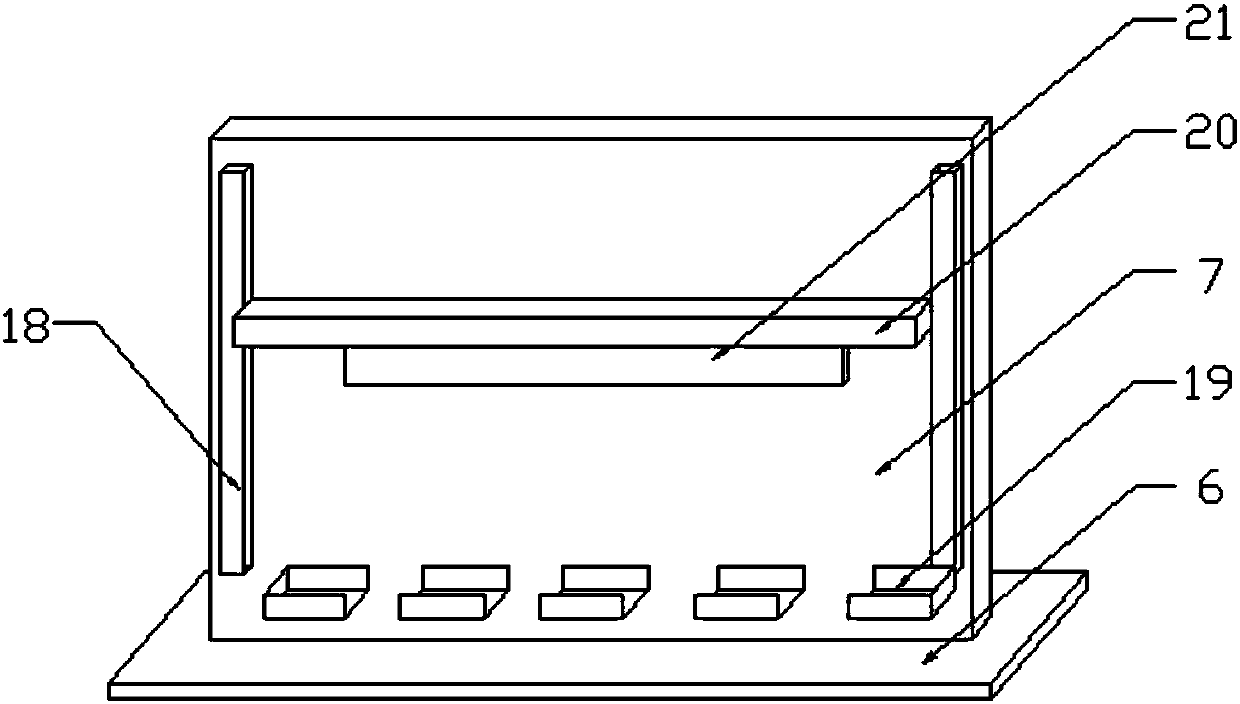

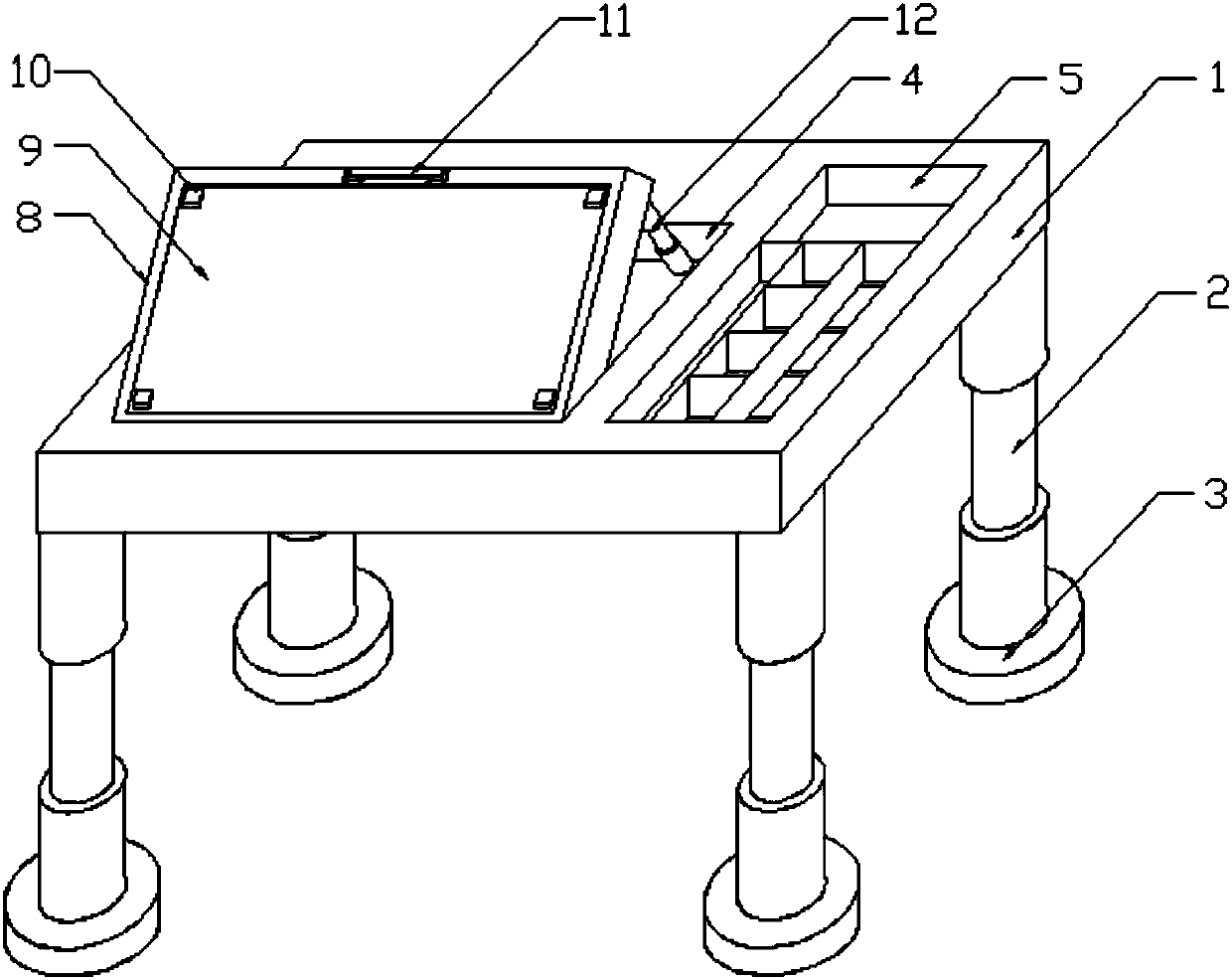

Multifunctional fine art drawing displaying integrated table

InactiveCN108041823AComplete and compact structural designRealize lifting functionDrawing desksOther artistic work equipmentsTablet computerPersonal computer

The invention discloses a multifunctional fine art drawing displaying integrated table. Through first electric expansion rods, the lifting function of the table body is achieved, and then according tothe drawing or displaying needs of a drawer, the specific height of the table body is adjusted; through a drawing plate, the drawing function of the drawer is achieved; through color modulation checks, the color modulation effect of drawing pigment is achieved; through a heating plate, the inside of a color modulation tank is heated, and it is avoided that the solid-liquid state of the pigment isinfluenced and then the drawing effect is influenced when the temperature is too low; through a support plate, the supporting effect of a mobile phone or a tablet personal computer is achieved, according to the height of the mobile phone or the tablet personal computer, an intelligent controller is utilized to adjust the position of an electric slide block on electric slide rails, and the heightof a first mobile plate is adjusted; through a table lamp, the light supplement effect during drawing is achieved, then it is avoided that the drawing effect is influenced due to dim light, and the drawing table achieves the integrated functions of drawing and displaying.

Owner:HEFEI UNIV

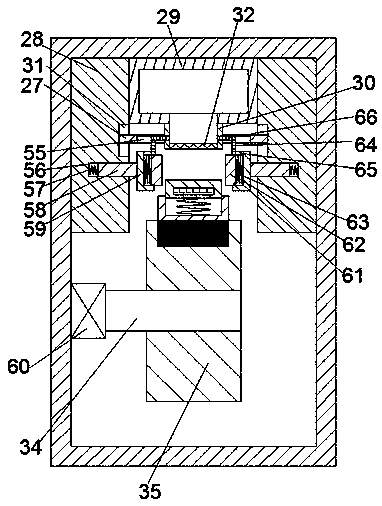

Painting device for furniture

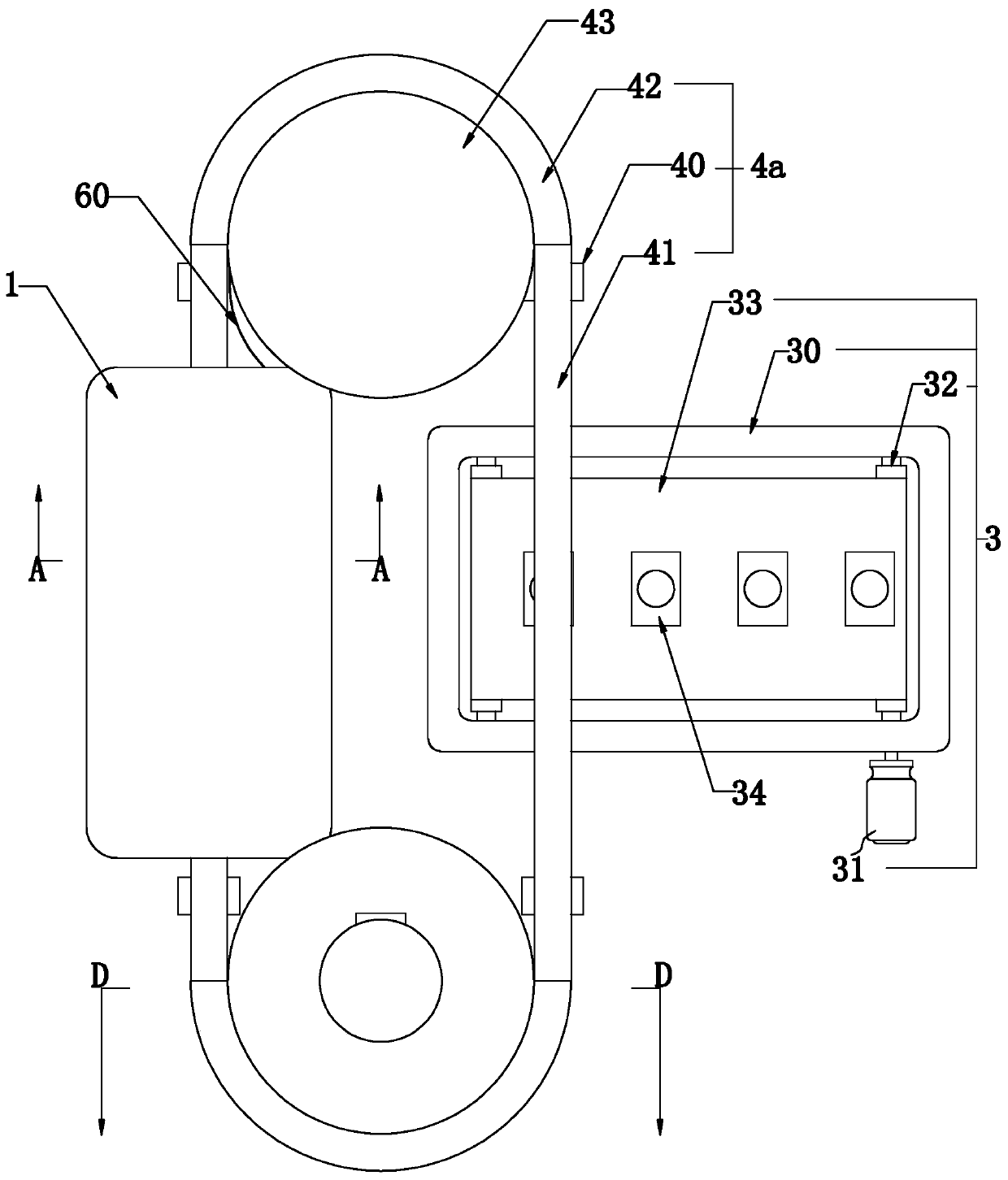

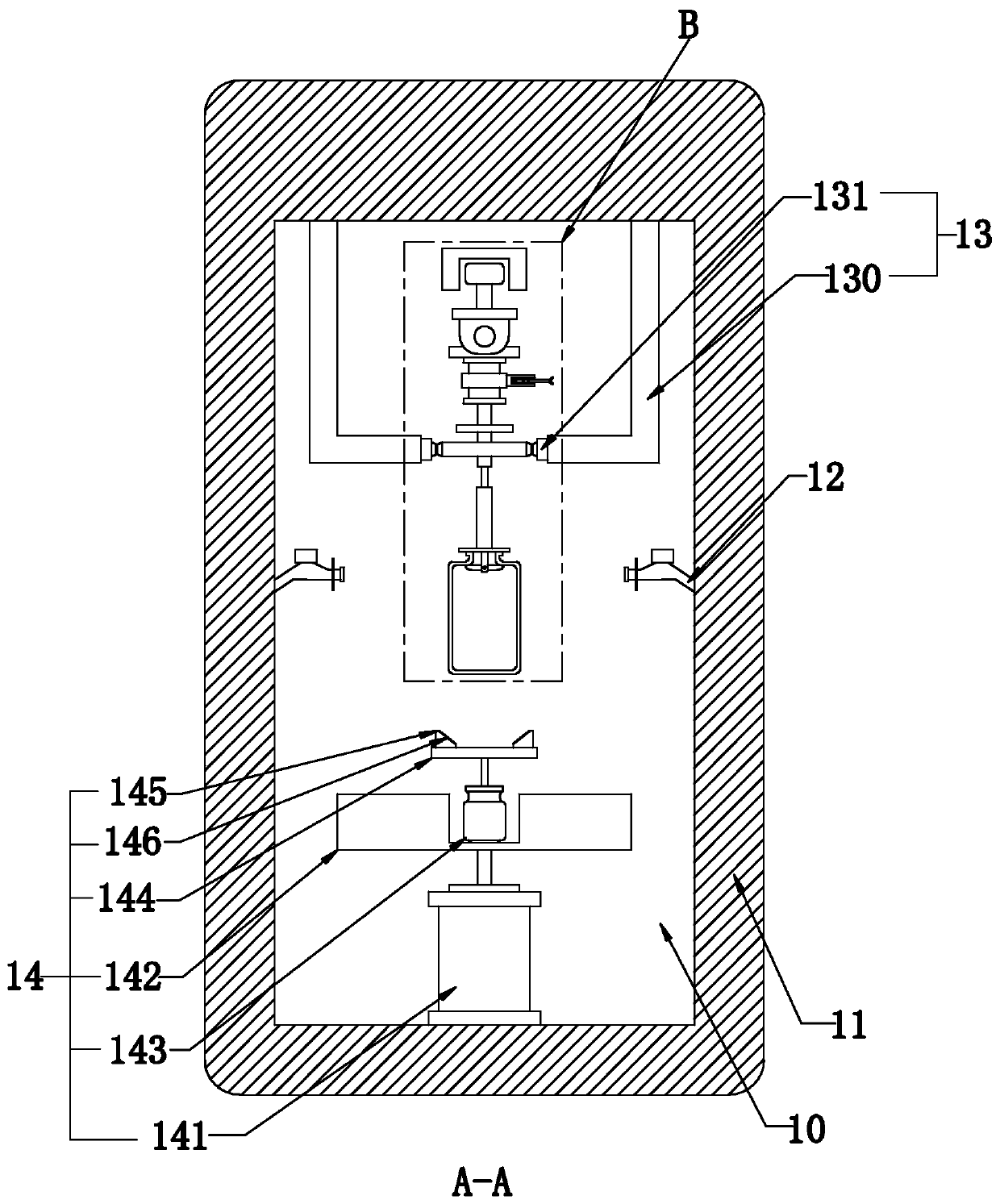

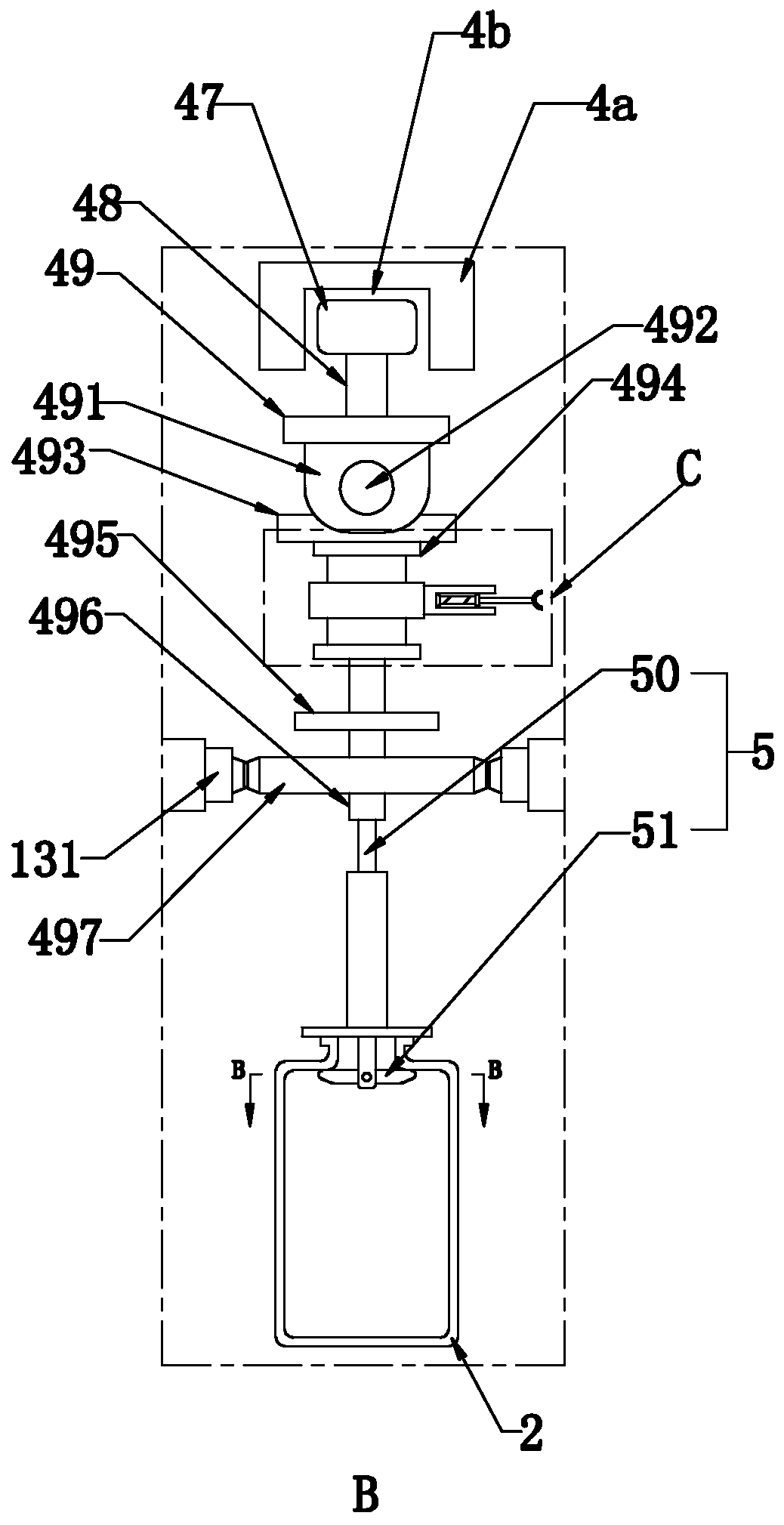

ActiveCN109261393AAvoid affecting the painting effectEdge grinding machinesLiquid spraying apparatusFeed driveNozzle

The invention discloses a painting device for furniture. The painting device structurally comprises a side door, a body, a feeding tank, a baffle, a feeding painting device and a base. The side door is arranged on the left side of the body and hinged to the body. The rear end of the feeding tank is welded to the body, the baffle is arranged at the front end of the body and integrated with the body, the feeding painting device is located under the baffle, and the base is arranged at the bottom end of the body. The partial structure of the device is improved, so that a feeding driving assembly is matched with a backflow compensation mechanism, after the device stops, the backflow compensation mechanism adsorbs residual liquid on a nozzle to prevent the residual liquid from condensing on thenozzle, dripping on a processed wood board and causing defects needing regrinding by workers. At the same time, burrs on the wood can be rubbed and cleaned when the wood is conveyed by matching of a reciprocating pushing mechanism and a deburring mechanism, and the fact that the painting effect is affected by the burrs on the wood is avoided.

Owner:清远市劳卡家具有限公司

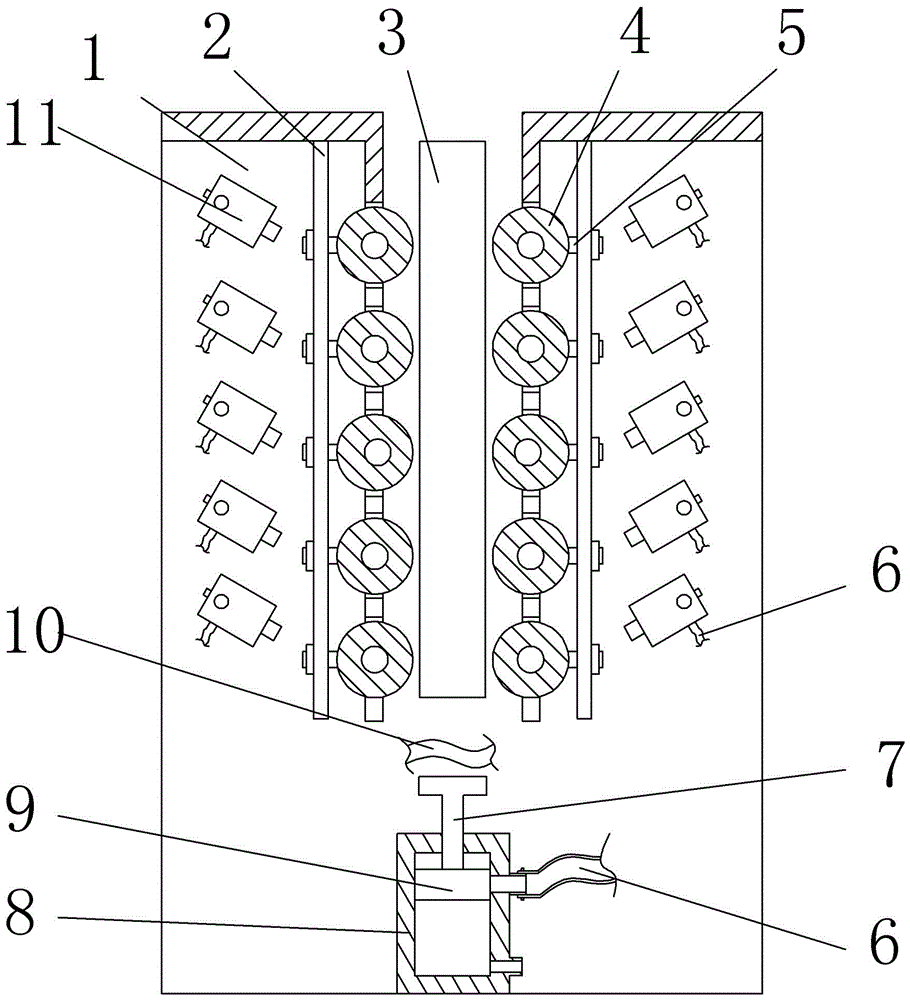

Vertical paint spraying device

ActiveCN106622844AEvenly paintedSolve the problem that the painting operation takes a long time and is prone to defective productsLiquid surface applicatorsCoatingsLacquerViscosity

The invention belongs to the field of configuration or mounting of spray heads, and discloses a vertical paint spraying device, which is used for spraying paint onto a door leaf of a composite door. The vertical paint spraying device comprises a frame, a plurality of rollers, a plurality of spraying guns and a paint supply device, wherein the rollers are uniformly distributed vertically on the circumferential surface of a door leaf; the positions of the spraying guns correspond to the positions of the rollers; the spraying guns incline downwards towards the side of the door leaf; the rollers and the spraying guns are fixed to the frame; the spraying guns are connected with the paint supply device. The door leaf falls slowly by means of the rotation of the rollers and the viscosity of the paint, so that the surface of the door leaf is painted uniformly. The rollers are uniformly distributed vertically on the circumferential surface of the door leaf, meanwhile the four circumferential sides of the door leaf are painted without secondary spraying, so that the problems of long painting operation time and tendency to production of defective products in a paint spraying device in the prior art are solved.

Owner:徐州市旺缘家具有限公司

Whitewashing device for decorating wall surfaces at stairs of building

ActiveCN111472522AAdjustable distanceEase of workRotary stirring mixersTransportation and packagingMechanical engineeringSteel rope

The invention discloses a whitewashing device for decorating wall surfaces at stairs of a building. The whitewashing device comprises a main device body, a second reel and a first limiting block, wherein a movable rod is connected to the upper position of the right side of the main device body, a first slide groove is formed in a guide block, a first telescopic rod is arranged at the inner side ofthe movable rod, a second telescopic rod is arranged at the inner side of the first telescopic rod, the second reel is arranged at the upper end of a stirring rod, and a steel rope is connected between the second reel and a first reel. The whitewashing device for decorating the wall surfaces at the stairs of the building can be conveniently installed at the outer side of a stair railing of a passageway, convenience is brought for the device to move in the passageway and conduct automatic whitewashing on the wall surfaces at different heights, the automation degree of the device is improved, and operation is facilitated; and meanwhile, in the whitewashing process, coating in a coating bucket can be automatically stirred in real time, and the situation that the whitewashing effect of the device is influenced when the coating sinks to the bottom is avoided.

Owner:新疆及地建设工程有限公司

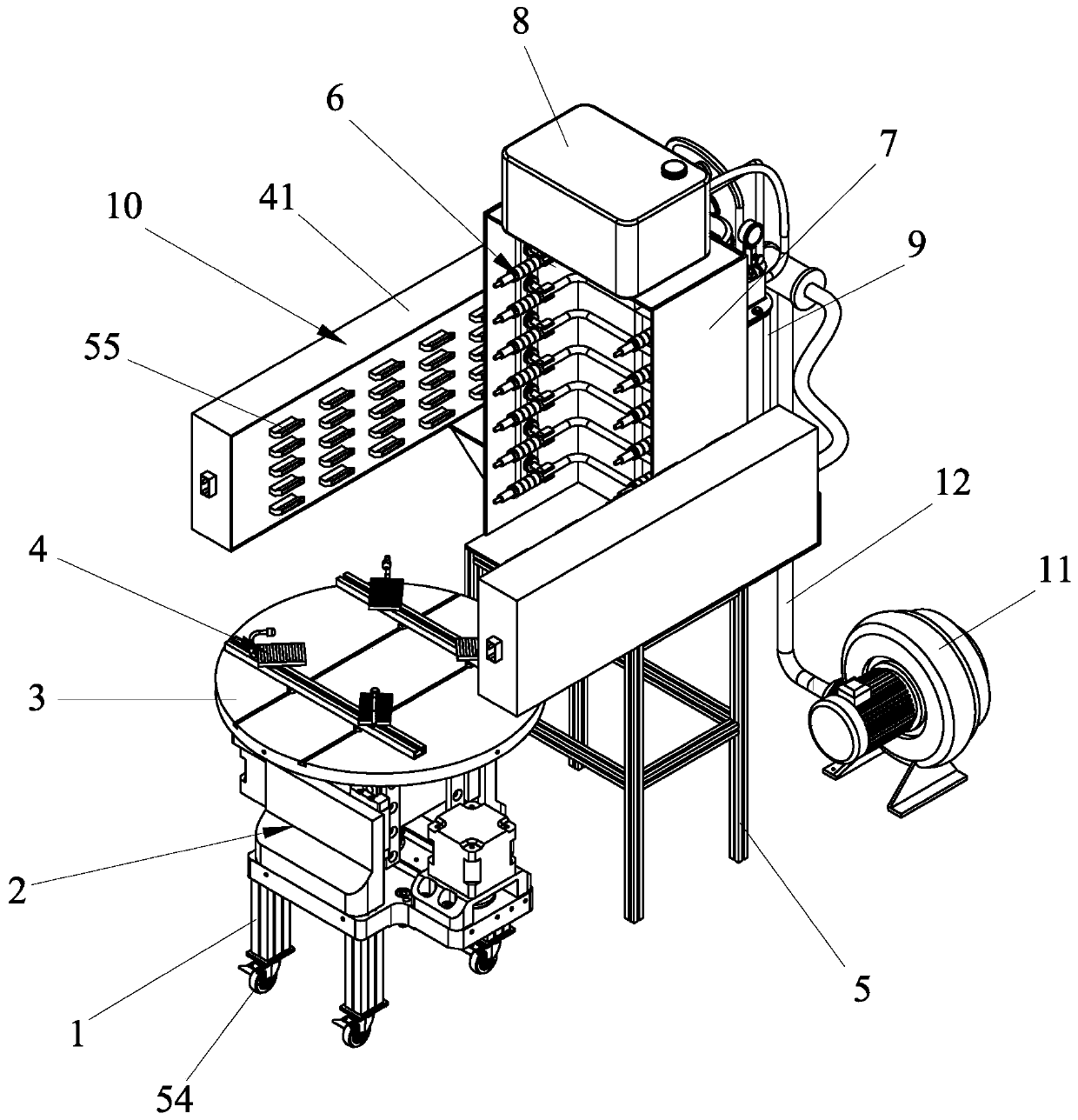

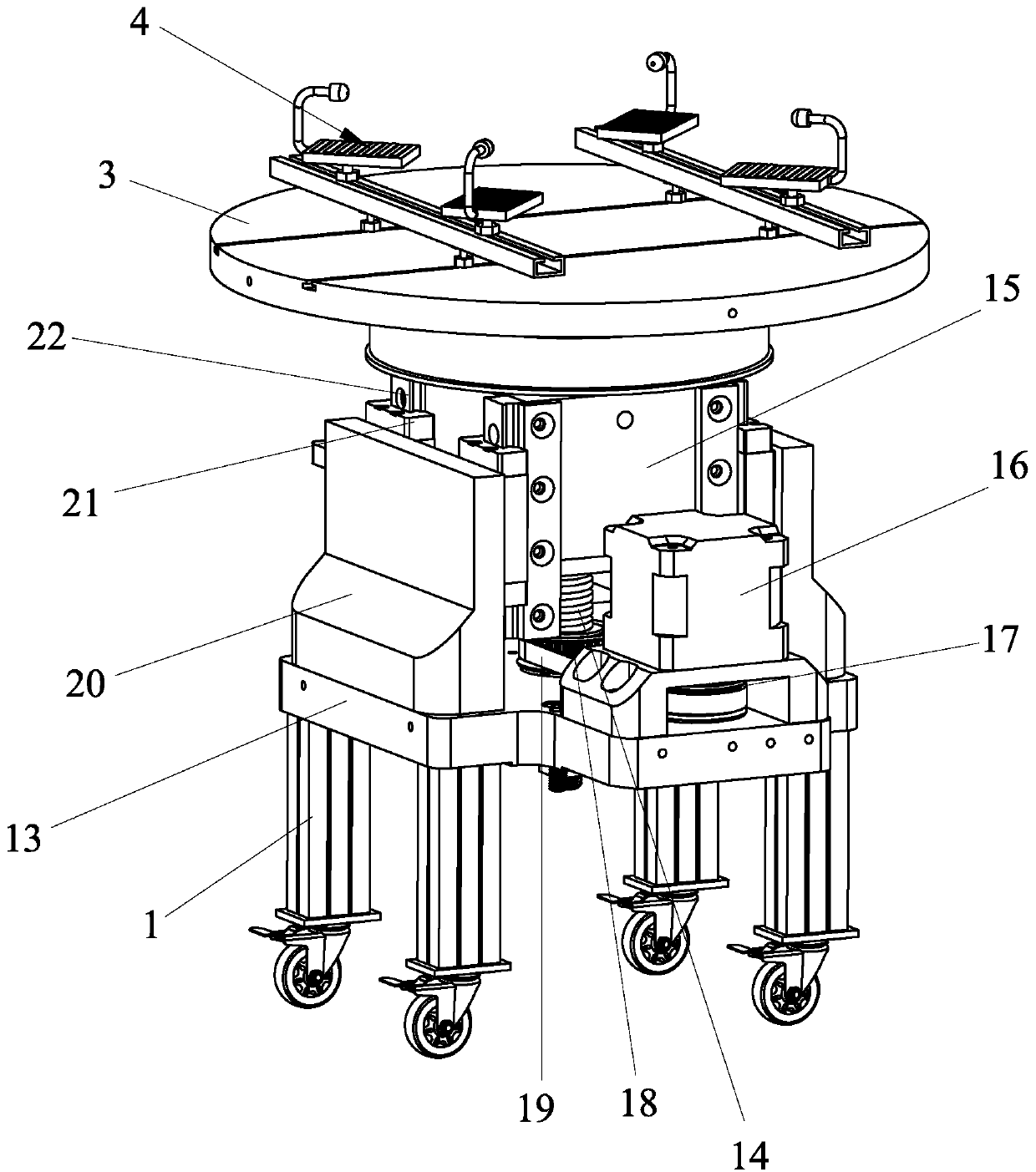

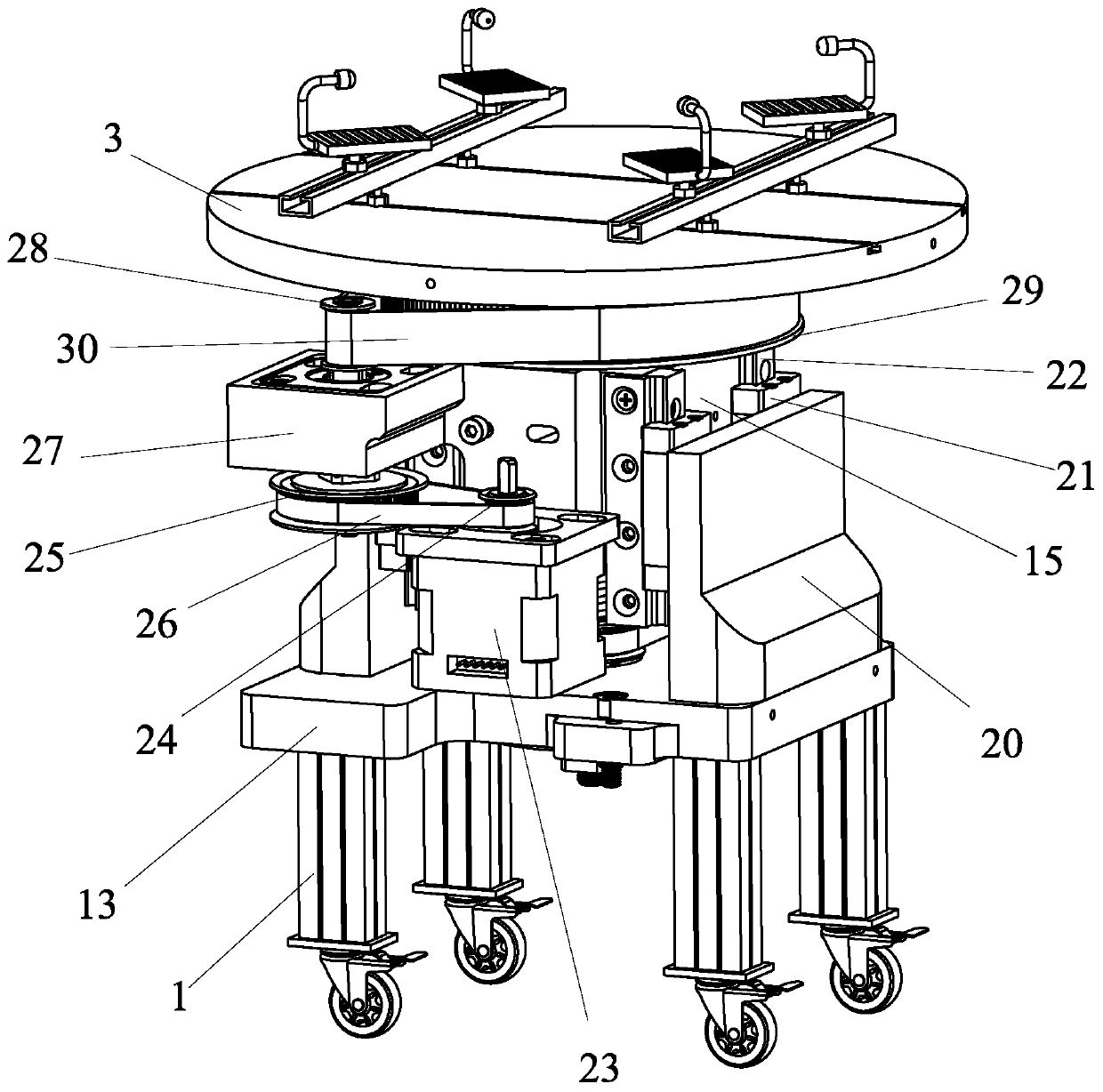

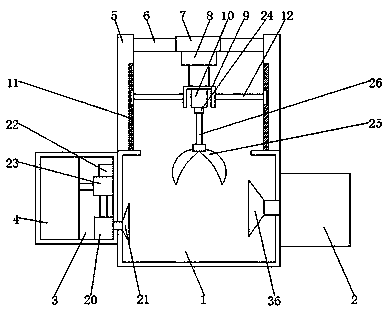

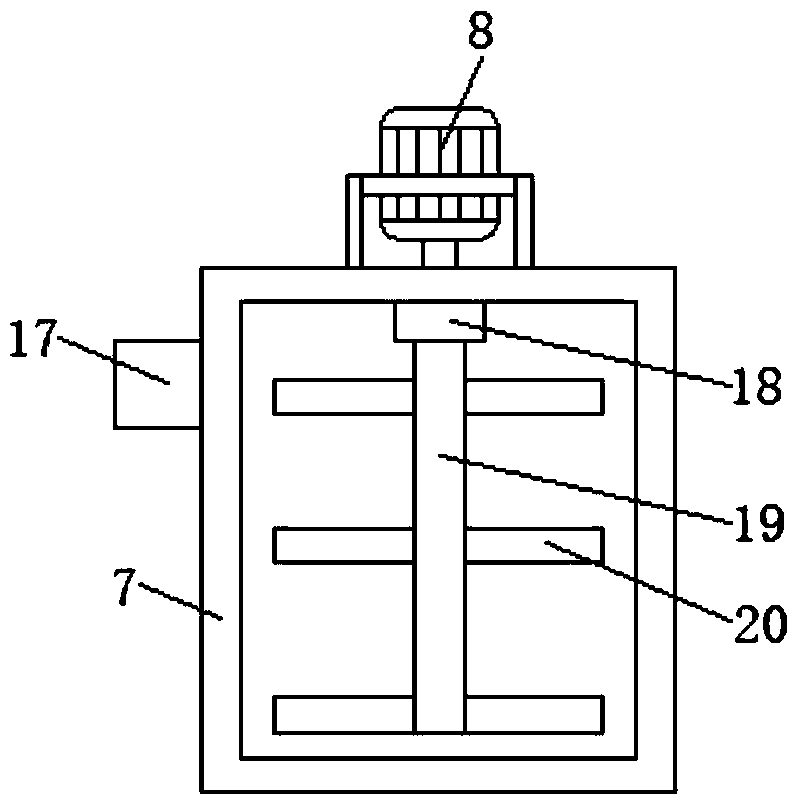

Transformer shell paint spraying device

InactiveCN110369191AImprove painting efficiencyImprove work efficiencySpray boothsFixed frameEngineering

The invention discloses a transformer shell paint spraying device which comprises a rack, a lifting rotary mechanism on the rack, a working table on the lifting rotary mechanism, a clamping mechanismon the working table, a fixed frame on one side of the rack, and a paint spraying mechanism on the fixed frame, wherein the lifting rotary mechanism drives the working table to lift and rotate; the clamping mechanism is used for fixing a transformer shell; the paint spraying mechanism is used for spraying paint on the transformer shell and comprises a mounting cabinet arranged on the fixed frame;a paint box is arranged above the mounting cabinet; a paint pump connected with the paint box is arranged on the rear side of the mounting cabinet; a plurality of spray guns are arranged on the innerside of the mounting cabinet; one end of each of the spray guns is connected with the paint pump via a hose; an atomizer is arranged at the other end of the spray gun; and the atomizer aligns with thetransformer shell on the working table. The transformer shell paint spraying device can greatly lower the labor cost, improves the working efficiency, and can also protect the life safety of a technician during the working process.

Owner:ZHEJIANG POWER TRANSFORMER

Hardware part paint spraying device

The invention provides a hardware part paint spraying device. The device comprises a paint spraying box, the right side of the paint spraying box is fixedly provided with a coating box, the left sideof the paint spraying box is fixedly provided with a refrigeration box, a nitrogen box is fixedly arranged on the left side of an inner cavity of the refrigeration box, two supporting columns are fixedly arranged on the top of the paint spraying box, a supporting plate is fixedly mounted on the tops of the two supporting columns, an air cylinder is fixedly arranged on the bottom of the supportingplate, an air rod is fixedly arranged on the bottom of the air cylinder, the bottom of the air rod is fixedly provided with a motor box, and a first motor is fixedly arranged in the motor box. According to the hardware part paint spraying device, through a closed type coating box, impurities are prevented from falling in a material chamber, coating is in the micro-motion state, discharging is convenient, blockage is avoided, a second transmission rod drives a sliding block to slide on a guide rail, a third motor drives a screw rod to rotate, coating is rapidly stirred, bubbles are prevented, and paint spraying effect is prevented from being affected.

Owner:JIANGYIN CHANGJING CAR & SHIP ACCESSORY

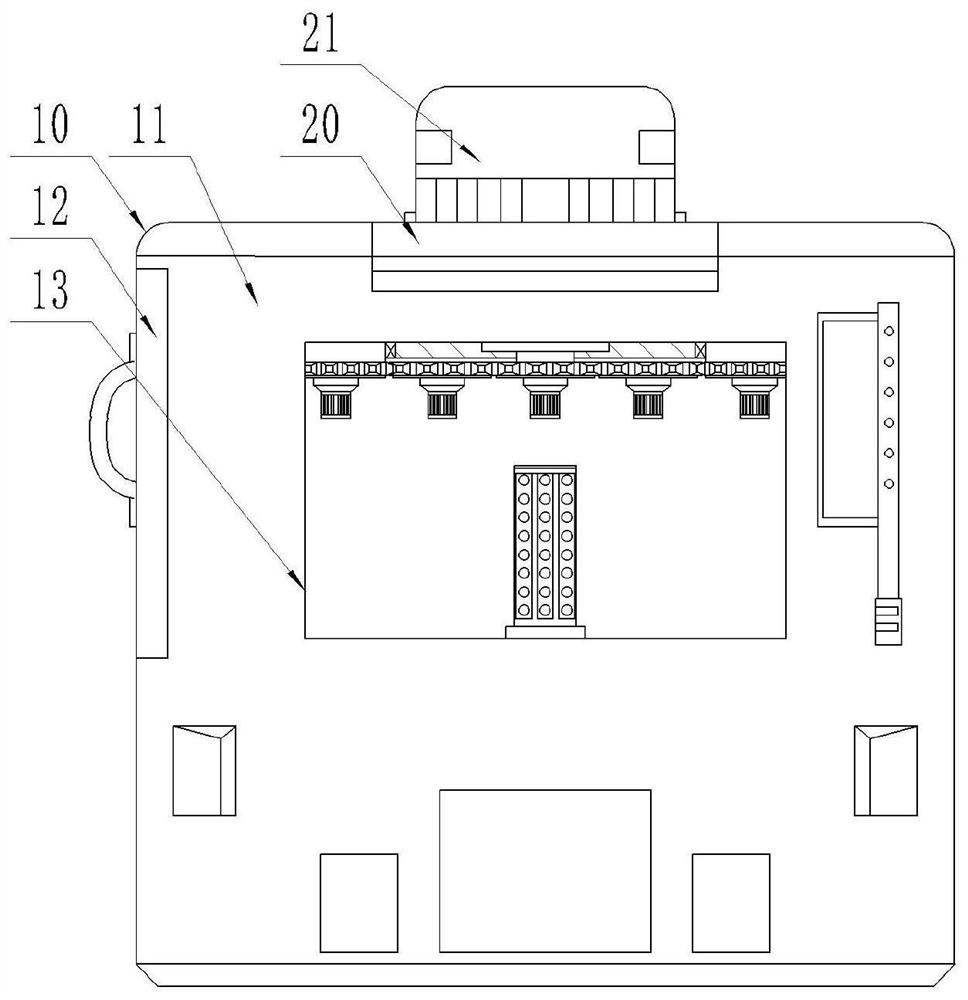

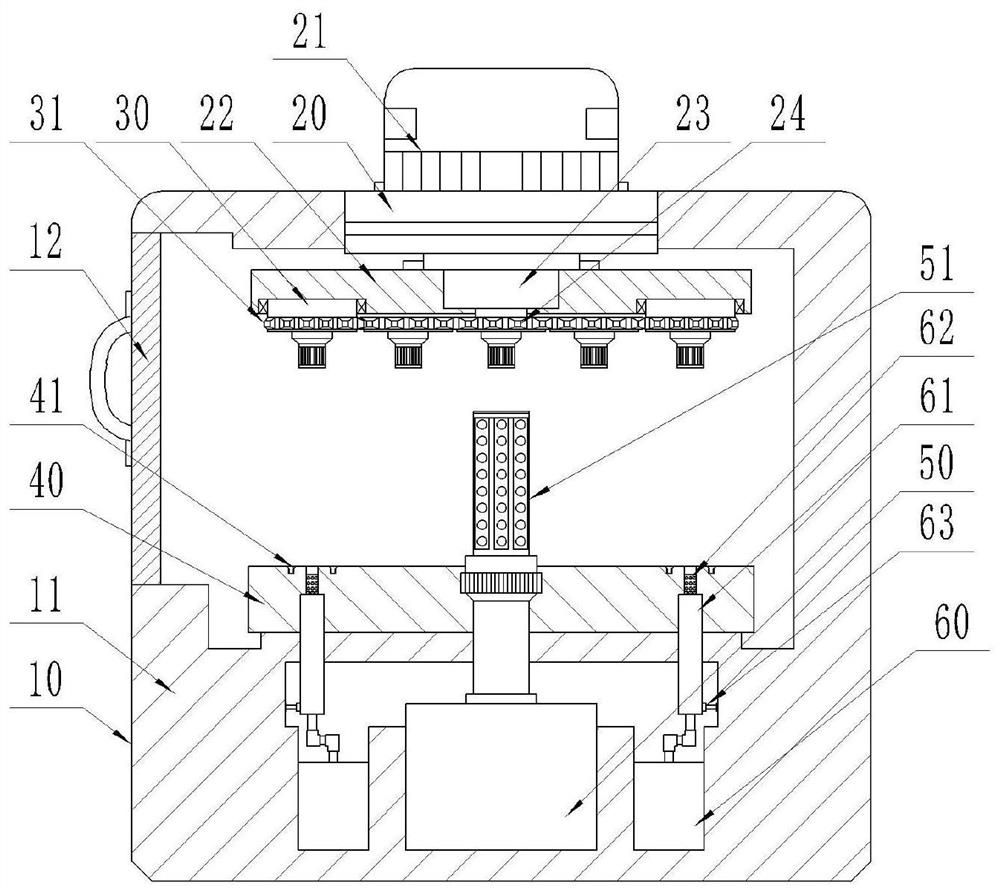

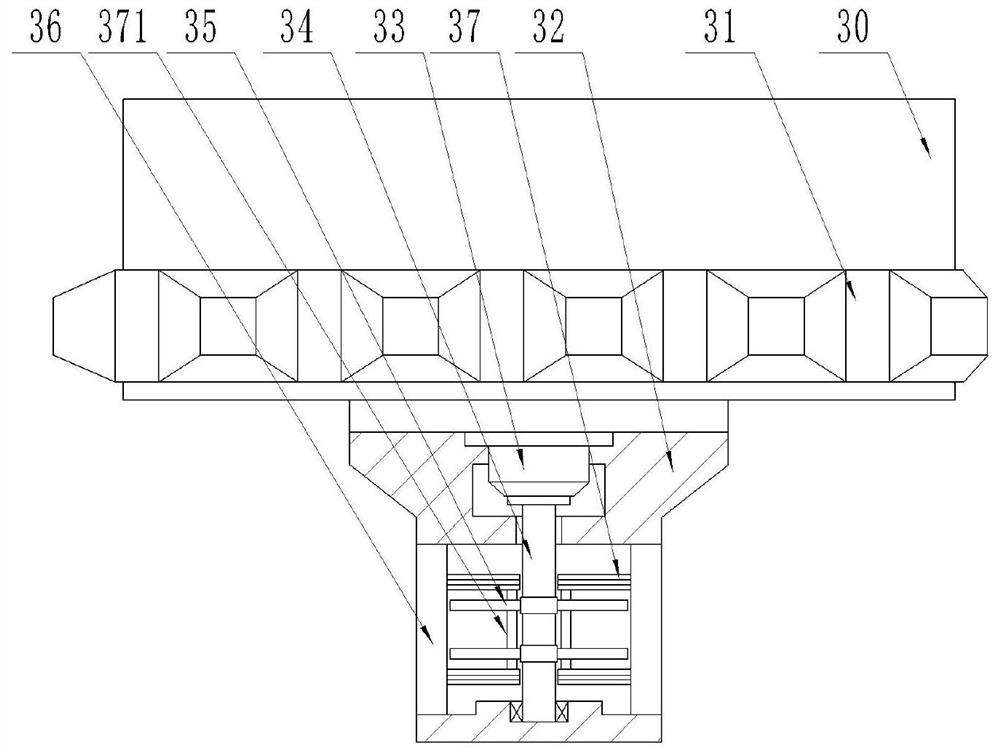

Surface spraying device for building steel material

ActiveCN111570145AAvoid wastingAvoid affecting the painting effectSpraying apparatusCleaning using toolsStructural engineeringSpray painting

The invention discloses a surface spraying device for a building steel material. The surface spraying device comprises an installation box; an installation cavity is arranged in the installation box;a clamping mechanism is arranged in the installation cavity; the clamping mechanism comprises fixed blocks I which are symmetrically fixedly installed at the outer end wall of the installation cavityin the front-rear direction; each fixed block I is internally provided with a drive chamber; a drive shaft equipped with a torsional spring is rotationally installed inside the left end wall of the drive chamber; and a drive rod is fixedly installed on the drive shaft. According to the surface spraying device disclosed by the invention, the steel material is clamped and cannot fall off in a spraying process so that the paint spraying effect is not affected; during paint spraying, the steel material is moved to realize surface paint spraying; and moreover, during paint spraying, the surface width of the corresponding steel material is adjusted for paint spraying.

Owner:江阴市澄祥鑫建设有限公司

Special automatic paint spraying device for electrical machines

InactiveCN110624745ATo achieve the effect of dust removal and static electricityAvoid dustCleaning using gasesSpray boothsEngineeringPneumatic cylinder

The invention discloses a special automatic paint spraying device for electrical machines. The device comprises a case, wherein a dust removing chamber is fixedly connected with the top end of the case, a dust removing screen is fixedly connected with the top of the dust removing chamber, an ion fan is in inlaid connection with the top end in the dust removing chamber, a paint spraying chamber isfixedly connected with one side of the dust removing chamber, an electronic control pneumatic cylinder is fixedly connected with the top end of the paint spraying chamber, a telescopic rod is movablyconnected with the top end in the paint spraying chamber, a communicating guide pipe is fixedly connected with the bottom end of the telescopic rod, an atomizing nozzle is fixedly connected with the bottom end of the communicating guide pipe, a drying chamber is fixedly connected with the other side of the paint spraying chamber, and a hot air fan is in inlaid connection with the bottom end in thedrying chamber. The device is novel in design and simple in structure, has a good paint spraying effect, can prevent resources from being wasted and can rapidly dry painted cables, so that the processing of the next process of the cables is facilitated, and the working efficiency of workers can be increased.

Owner:泰州市荣诚纸制品有限公司

Cylinder warning paint spraying device

ActiveCN112090644AEasy to operateHigh precisionLiquid spraying apparatusStructural engineeringSpray painting

The invention relates to paint spraying equipment, in particular to cylinder warning paint spraying equipment. The cylinder warning paint spraying equipment can achieve accurate paint spraying and iseasy to operate. The cylinder warning paint spraying equipment comprises an arc-shaped base, a hinge plate, a moving mechanism, a fixing mechanism and a spraying mechanism, wherein the hinge plate isrotationally connected to the arc-shaped base; the moving mechanism is connected between the arc-shaped base and the bottom of the hinge plate; the fixing mechanism is connected between the arc-shapedbase and the hinge plate; and the moving mechanism is connected with the spraying mechanism. Through the cooperation of the fixing mechanism, the moving mechanism and the spraying mechanism, the device can be fixed to a warning pile, the paint spraying effect is achieved by rotating the spraying mechanism, and the operation is easy, the precision is high; and through the cooperation of a pressingmechanism, it can be effectively avoided that the arc-shaped base and the hinge plate fall down as soon as the warning pile is loosened, the paint spraying effect is influenced, and a protective cover can effectively block splashed paint.

Owner:NANJING LINGQUE INTELLIGENT MFG CO LTD

Paint spraying device for hub of new energy automobile

ActiveCN112221777AAvoid affecting the painting effectRealize fixed-point quantitative sprayingSpraying apparatusNew energyEngineering

The invention relates to the technical field of automobile paint spraying, and discloses a paint spraying device for a hub of a new energy automobile. The paint spraying device comprises a movable piece, wherein a lever is movably connected to the upper portion of the movable piece, a sliding block is movably connected to the lower end of the lever, a pulling rod is fixedly connected to the left side of the sliding block, a rotating plate is movably connected to the left end of the pulling rod, a limiting column is arranged on the lower portion of the rotating plate, a second spring is arranged outside the limiting column, a baffle is arranged at the left side of the limiting column, a rotating disc is rotationally connected to the rear face of a second fixing shaft, and the hub is fixedlyinstalled in front of the rotating disc. According to the paint spraying device, the movable piece moves upwards to enable the right portion of the lever to rotate, the sliding block moves leftwardsto drive the rotating plate to rotate, the limiting column rotates clockwise and drives the to-be-machined hub on the rotating disc to rotate by a certain distance, the second spring is extruded whenthe limiting column rotates anticlockwise, finally the limiting column stays on the baffle without driving the to-be-machined hub on the rotating disc to rotate, and it is guaranteed that all parts ofthe hub are painted through rotation of the hub.

Owner:聊城市飓风工业设计有限公司

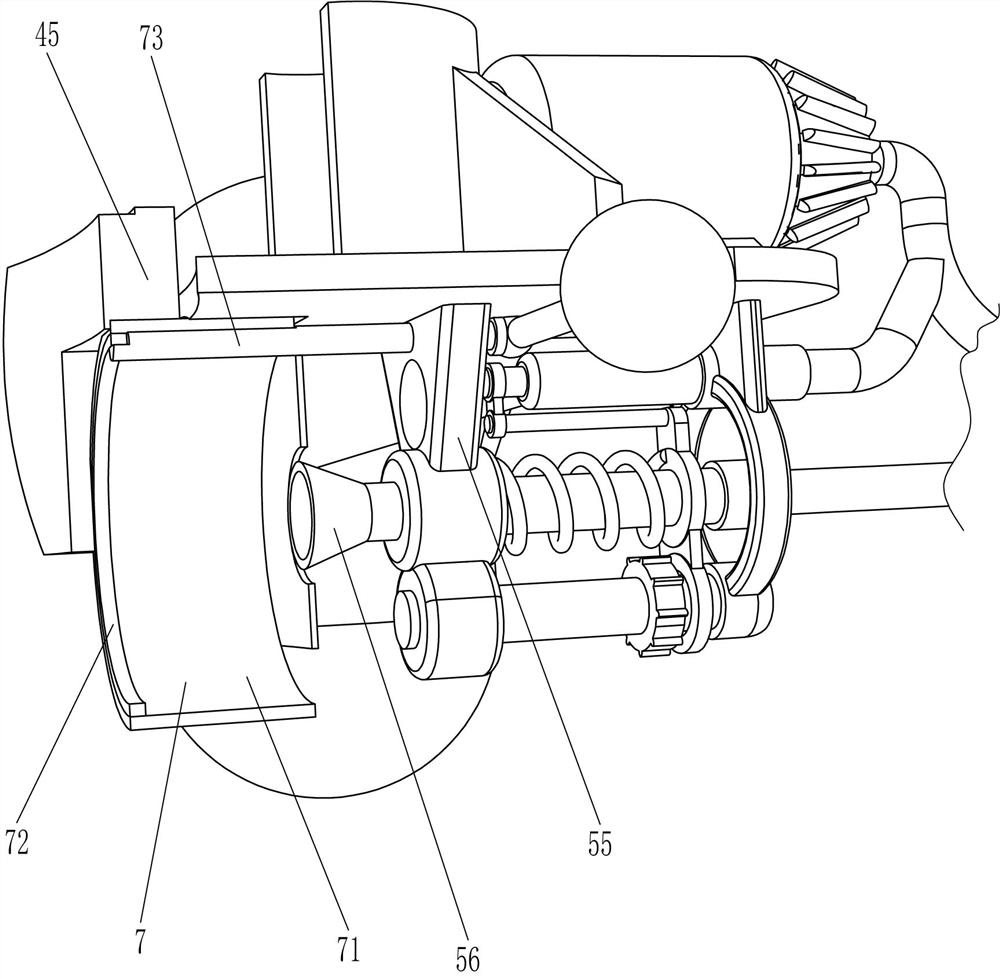

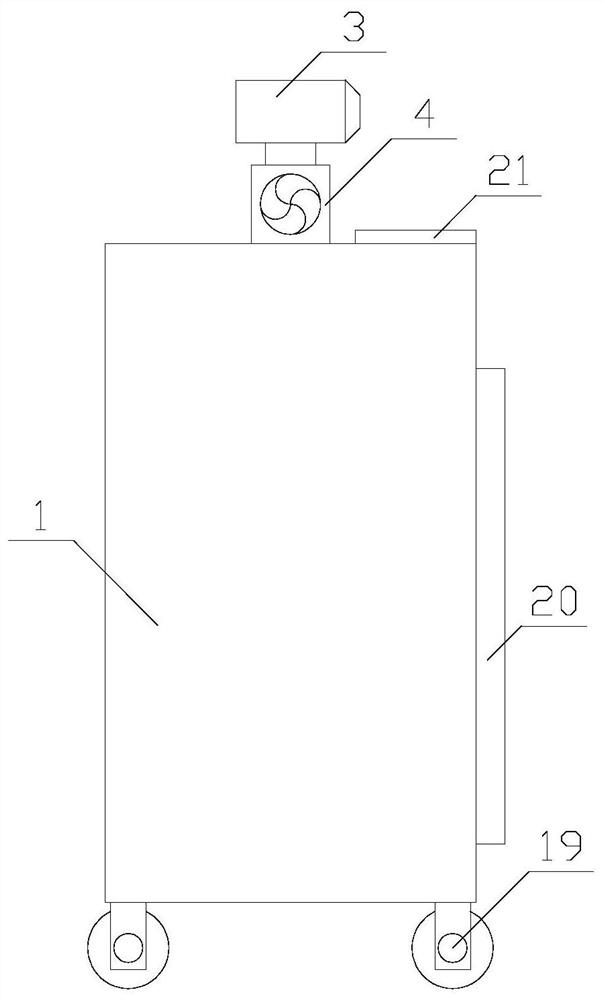

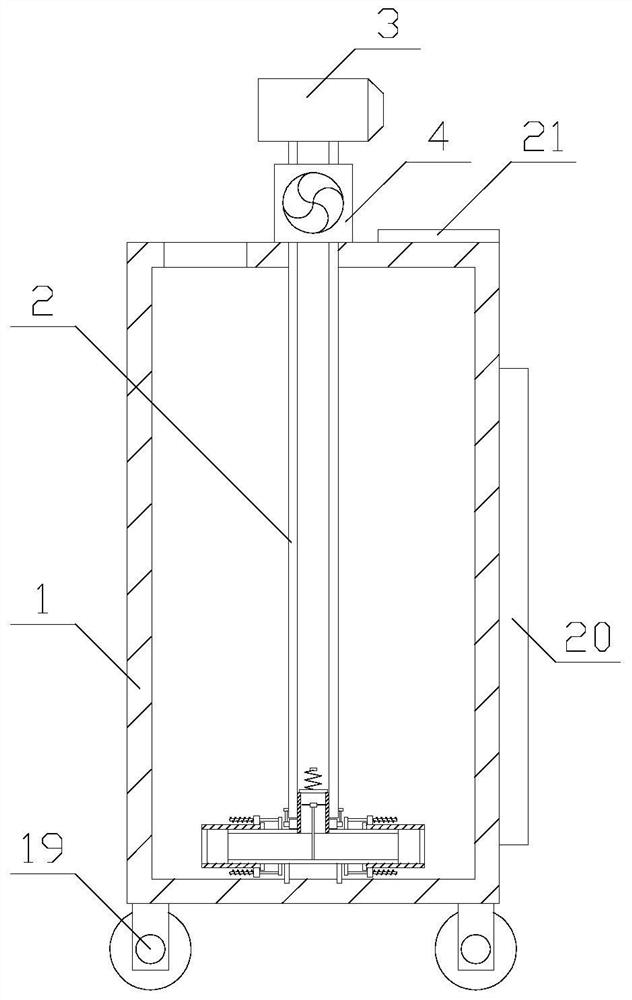

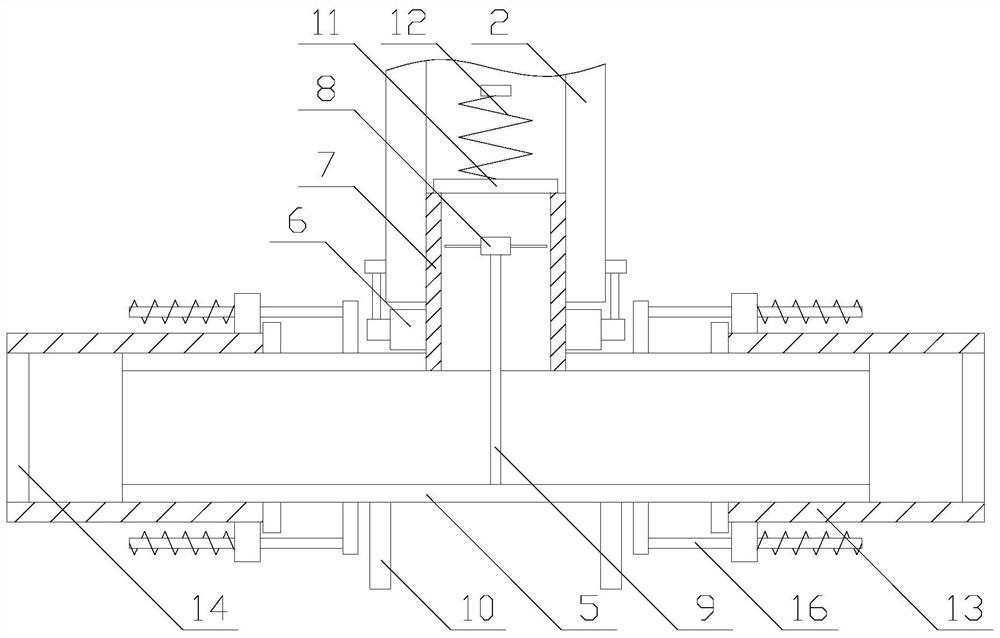

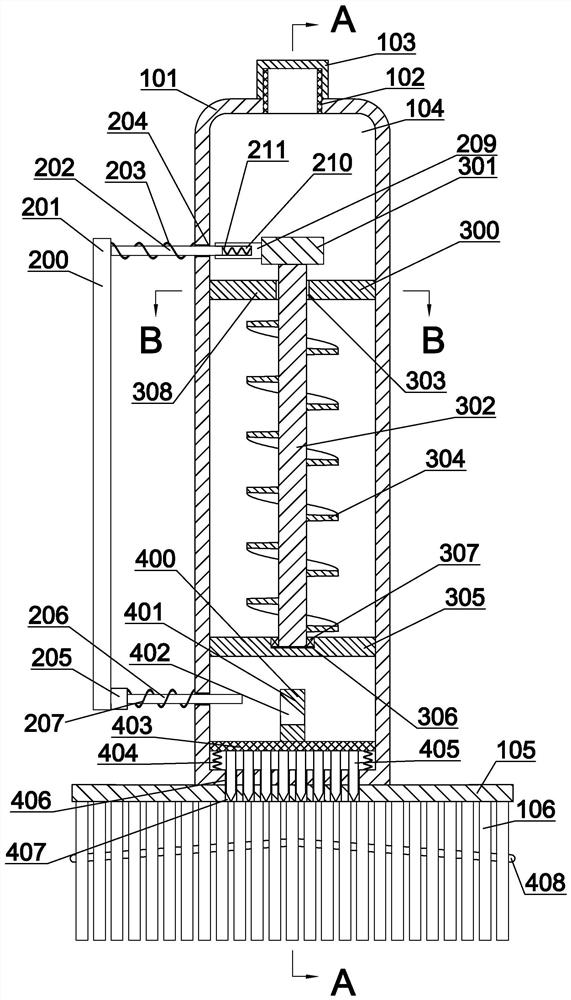

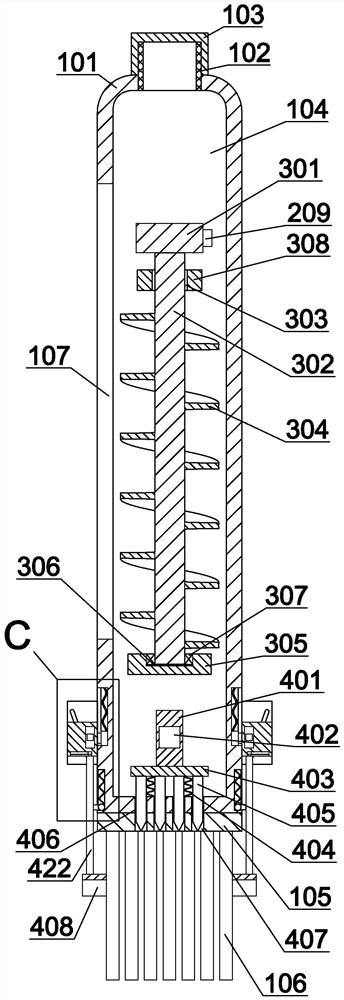

Anti-blocking type paint spraying equipment for automobile production

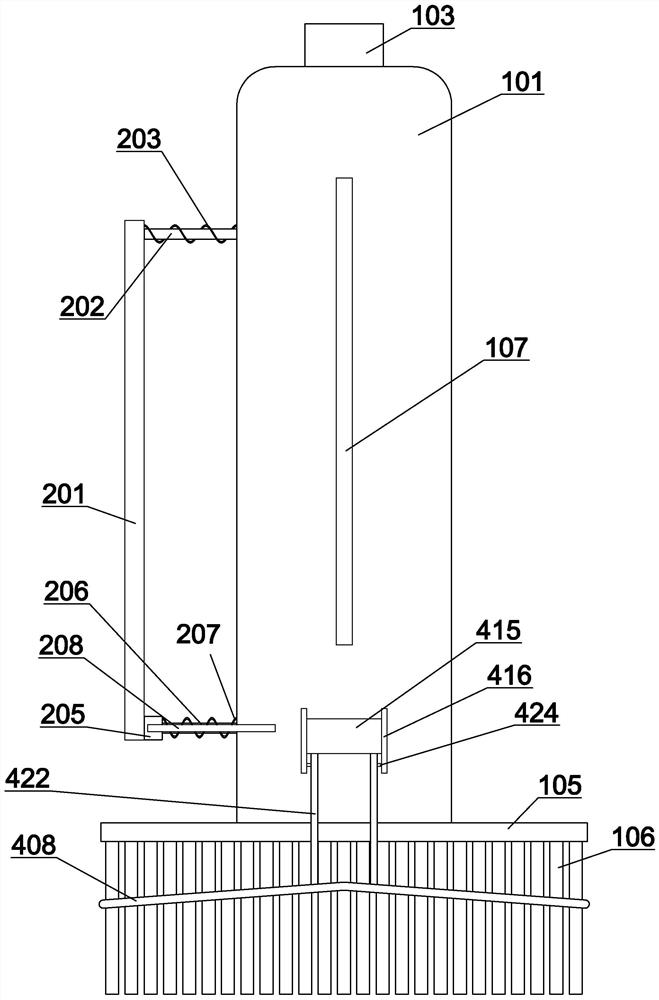

InactiveCN112517289AEasy to removeAvoid affecting the painting effectSpraying apparatusDrive shaftEngineering

The invention relates to anti-blocking type paint spraying equipment for automobile production. The equipment comprises a box body, a connecting pipe, a nozzle and a power pump; the box body is cylindrical and is vertically arranged; a mounting hole and a feeding hole are formed in the top of the box body; the connecting pipe and the box body are coaxially arranged and penetrate through the mounting hole; the connecting pipe is in sliding and sealed connection with the inner wall of the mounting hole; a gap is formed between the bottom end of the connecting pipe and the bottom in the box body;the power pump is fixed to the top of the box body; the connecting pipe is mounted on the power pump; the nozzle is mounted at the top end of the connecting pipe; a stirring mechanism and an auxiliary mechanism are arranged in the box body; and the stirring mechanism comprises a rotating pipe, a bearing, a supporting pipe, a paddle, a transmission shaft and two elastic rods. According to the anti-blocking type paint spraying equipment for automobile production, the function of paint stirring is achieved through the stirring mechanism, the situation that the paint spraying effect is affected due to precipitation of the paint is prevented, and in addition, the function of blocking prevention is achieved through the auxiliary mechanism.

Owner:南京智云会想信息科技有限公司

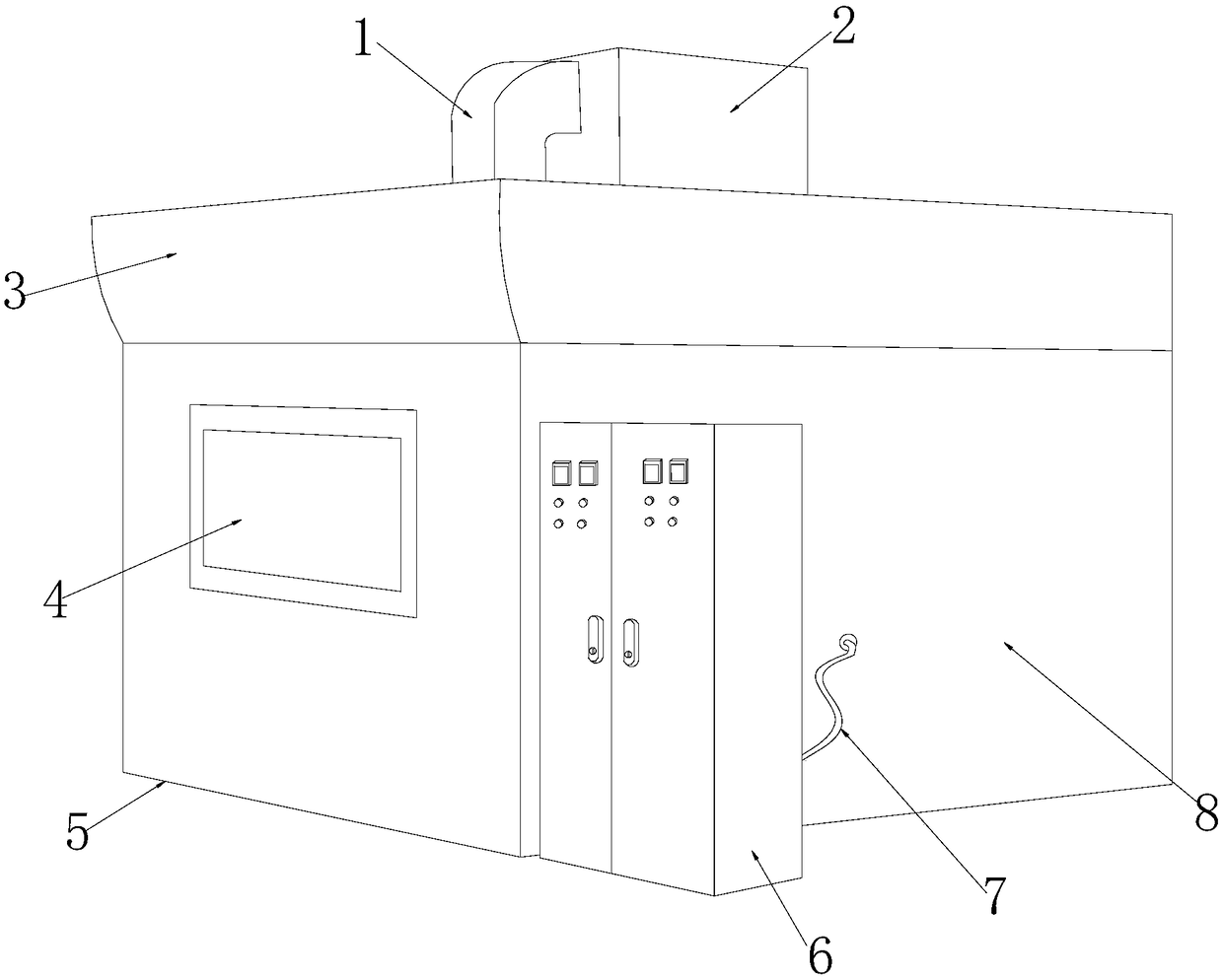

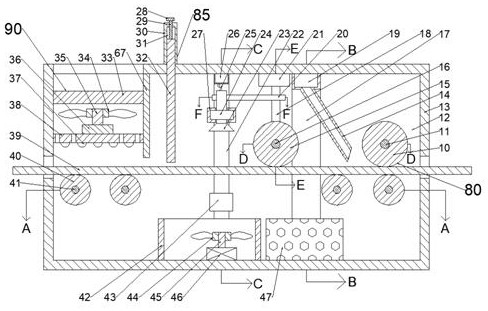

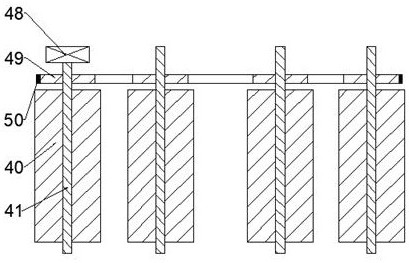

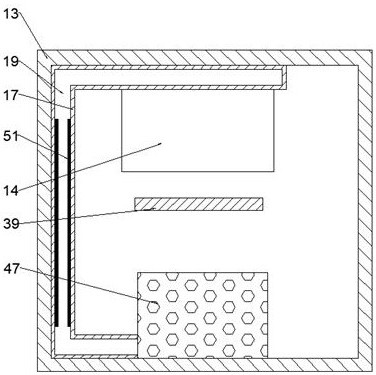

Fast surface treatment equipment for manufacturing springs

InactiveCN108452968AAvoid affecting the painting effectImprove work efficiencyPretreated surfacesLiquid spraying apparatusEngineeringDust collector

The invention discloses fast surface treatment equipment for manufacturing springs. The equipment structurally comprises a dust collecting conveying pipe, a dust collector, an upper portion connectingbase, an observation window, a spring treatment chamber, an electronic control cabinet, a power source connecting line and a spring treatment device. The dust collector is connected to the upper endsurface of the upper portion connecting base through the dust collecting conveying pipe. The lower end surface of the upper portion connecting base is attached to the upper end surface of the spring treatment chamber. An observation window is embedded in the front end surface of the spring treatment chamber. The spring treatment device is arranged on the inner surface of the spring treatment chamber. The electronic control cabinet is connected with spring treatment device through the power connecting line. According to the equipment, by means of mutual combination of the parts, the equipment can clamp the springs automatically in the working process, the situation that in the paint spraying process of the equipment, the springs roll, and the paint spraying effect is influenced is prevented, meanwhile, the painted springs can be dried, the working efficiency of the equipment is improved, and practicality is high.

Owner:张鲤双

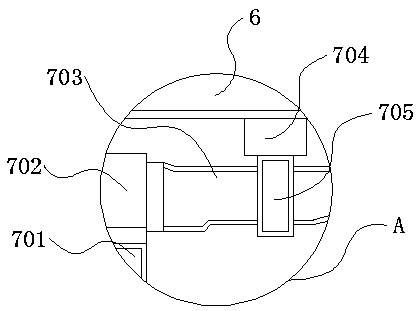

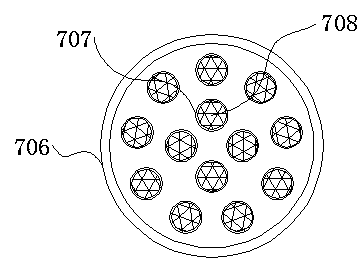

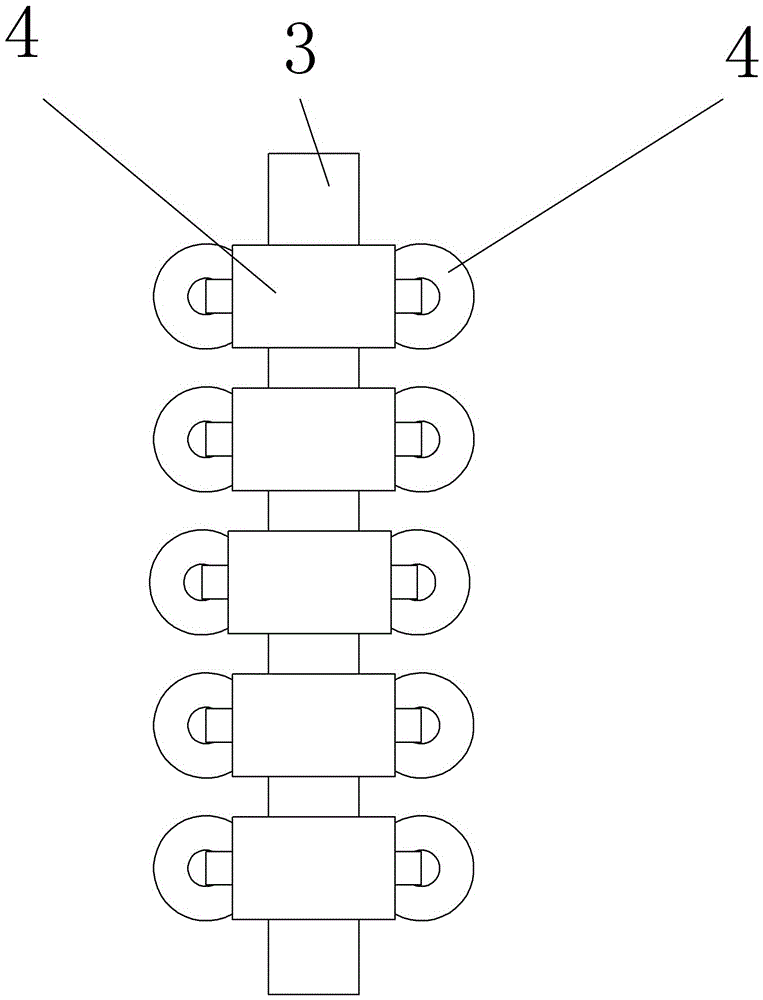

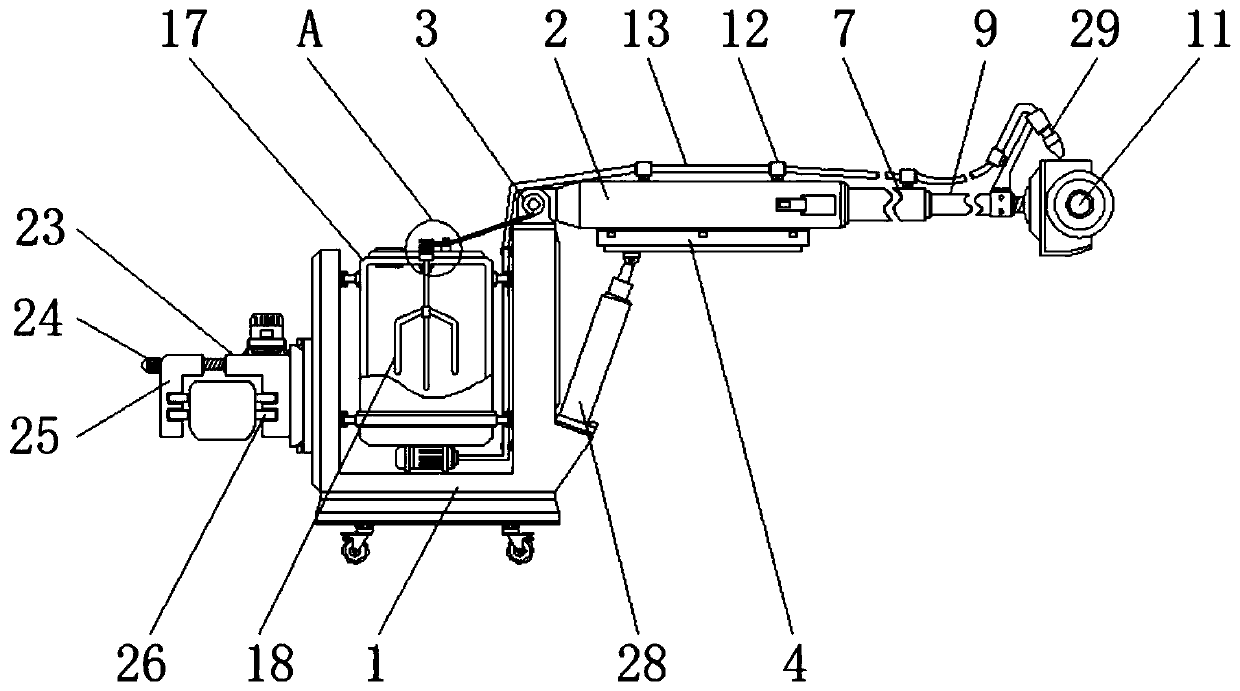

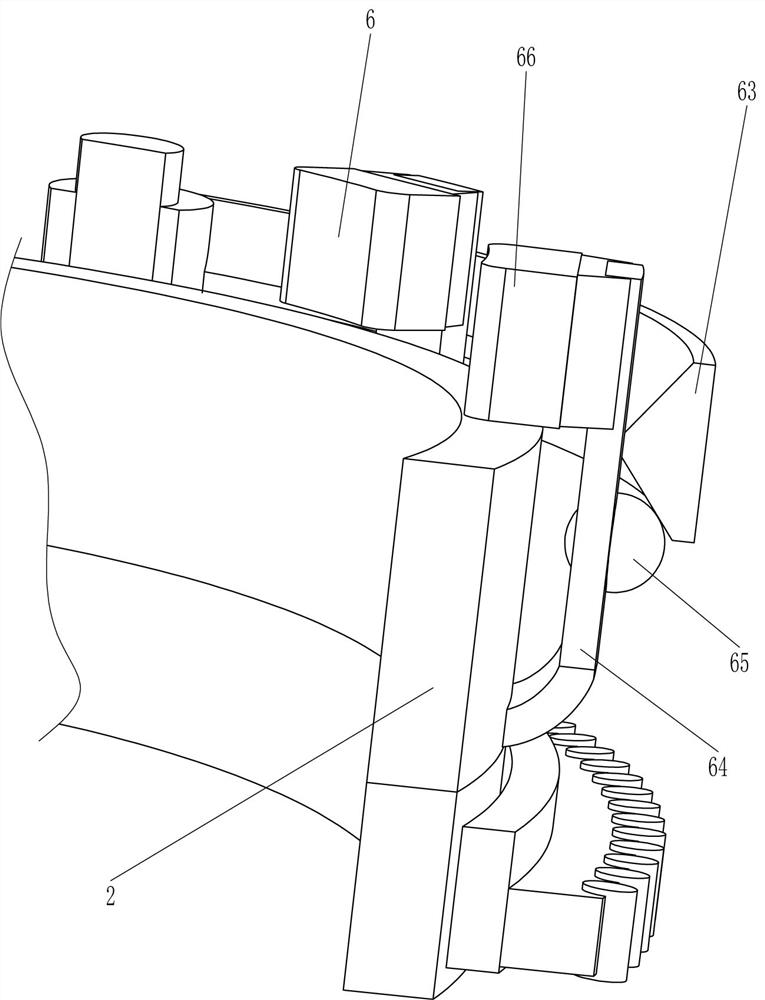

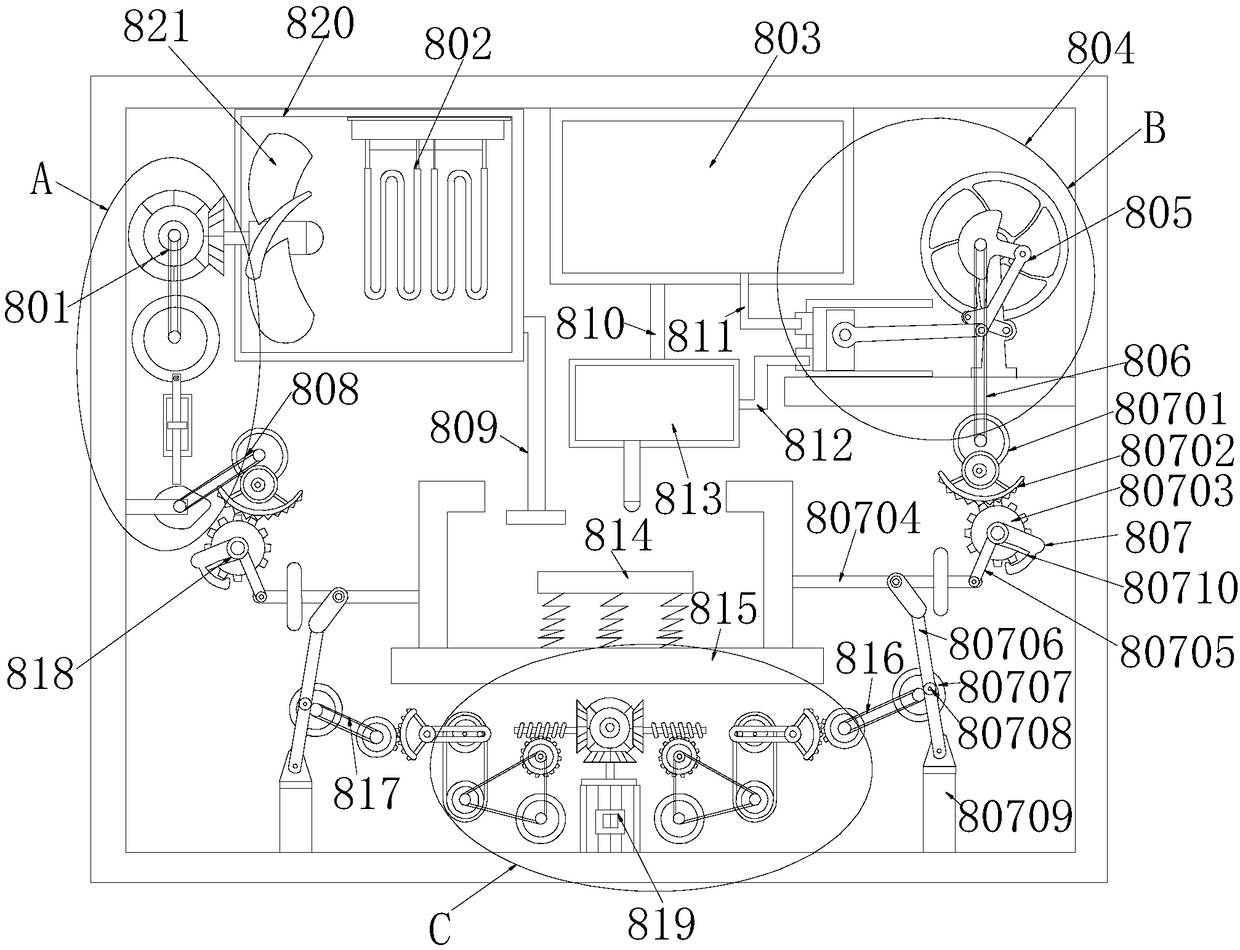

A painting manipulator used in the production of auto parts

The invention discloses a paint spraying mechanical arm used for production of automobile parts. The paint spraying mechanical arm comprises a base, a mechanical arm body, a pipe bundling device and a paint spraying device. The mechanical arm body is fixedly arranged on the upper portion of the base, a protrusion is circumferentially arranged on a fourth shaft of the mechanical arm, and the pipe bundling device is connected with the protrusion in a sliding mode. The pipe bundling device comprises an upper semi-ring, a lower semi-ring and a T-shaped slider, the paint spraying device is installed on a sixth shaft of the mechanical arm body, the paint spraying device comprises sprayers, nozzles, a flange plate and paint pipelines. In the paint spraying mechanical arm, the pipe bundling device is arranged so that line pipes on the mechanical arm can be bundled, and the situation that the line pipes are scattered and accordingly the mechanical arm is jammed or the line pipes fall off is avoided; the paint spraying device is arranged and comprises the sprayers, the nozzles, the flange plate and the paint pipelines, so that various different paint is sprayed out through different paint pipelines and different nozzles, the situation that different paint is mutually mixed so that the paint spraying effect is affected is avoided, the structure is simple, and the paint spraying mechanical arm is convenient to use and practical.

Owner:明光市龙腾科技工贸有限公司

Full-frame type glass rack automatic spraying device

The invention discloses a full-frame type glass rack automatic spraying device. The full frame type glass rack automatic spraying device comprises a rack, a conveying device, a supporting device, a discharging device and a paint spraying device, wherein the conveying device is arranged at the left end part of the rack, the supporting device is used for placing a glass rack, and the discharging device and the paint spraying device are arranged at the right end part of the rack; the discharging device comprises a collecting box, a scraping used for conveying the painted glass rack into the collecting box and a guiding assembly in the collecting box. According to the full-frame type glass rack automatic spraying device, automatic paint spraying operation to the glass rack can be realized, manpower and material resources are saved, and the processing efficiency is further greatly improved; the painted glass rack can be quickly collected, damage on the glass rack can be effectively avoidedin the collecting process, and thus the passing rate of the glass rack processing can be increased.

Owner:温州立尚眼镜制造有限公司

Environment-friendly paint spraying dryer

InactiveCN111992401AGuaranteed flatnessControl thicknessSpray boothsHazardous substanceElectric machinery

The invention discloses an environment-friendly paint spraying dryer. The environment-friendly paint spraying dryer comprises a machine body, wherein a placement space is formed in the machine body; agrinding and cleaning mechanism is arranged in the placement space; the grinding and cleaning mechanism comprises a first motor fixed on the inner wall of the upper side of the placement space; the lower end surface of the first motor is rotationally connected with a first driving shaft; the lower end of the first driving shaft is fixedly connected with a first bevel gear; the first bevel gear ismeshed with a second bevel gear; and the second bevel gear is fixedly connected to a cleaning shaft. According to the environment-friendly paint spraying dryer, the grinding and cleaning mechanism isarranged to grind and clean the surface of a wood board; a height-adjustable scraper plate is designed in a spraying mechanism, so that the spraying thickness of paint can be controlled, and redundant paint can be reused; and a drying mechanism is arranged at the rear end, so that solidification of the paint can be accelerated, release of harmful substances of the paint can be accelerated, the harmful substances can be collected and treated, and harm to people can be prevented.

Owner:台州池泽科技有限公司

A paint spraying device for wheel hub processing

The invention discloses a paint spraying device for hub machining. The paint spraying device comprises a support frame, a shell is fixedly installed on the top of the support frame, a sliding rail is arranged in the shell, the two ends of the sliding rail both extend to the outer side of the shell, and a containing plate is fixedly installed on the top of the sliding rail; a storing box is fixedly installed on the top of the shell, a feeding pipe is fixedly installed on a left side plate of the storing box, a motor is fixedly installed on the top of the storing box, a rotation shaft of the motor penetrates through a top plate of the storing box and extends into the storing box, and a stirring shaft is connected to the end, located in the storing box, of the rotation shaft of the motor in a transmission mode through a coupler. According to the paint spraying device for hub machining, by arranging a cooling box on the top of the shell, cooling air can be generated in the working process, a hub obtained after paint spraying is cooled, therefore, paint spraying molding can be sped up, the natural cooling time can be shortened, and the working efficiency can be improved.

Owner:沙迪克南通机电科技有限公司

Pressing type paint brush capable of automatically adding paint and using method thereof

InactiveCN112545151AAvoid affecting the painting effectAvoid blockingBrushesEngineeringScrub brushes

The invention discloses a pressing type paint brush capable of automatically adding paint. The paint brush comprises a machine body, a liquid storage cavity is formed in the machine body, a liquid injection pipe is arranged on the upper side wall of the liquid storage cavity in a communicating mode, the liquid injection pipe penetrates through the upper side wall of the liquid storage cavity and enters an external space, and the upper end of the liquid injection pipe is in threaded connection with a sealing cover; a first mounting plate is fixedly connected to the lower side face of the machine body, a plurality of brushes are fixedly connected to the lower side face of the first mounting plate, and a rectangular groove is formed in the front side wall of the liquid storage cavity. The paint brush can store paint and the paint can be flowed onto the brush by pressing during use, and the conditions that paint dipping is carried out in a paint bucket during paint brushing, the operationis tedious, paint can drop in the moving process of the brush, the paint waste is caused, and pollution to a non-operation face can be reduced.

Owner:薛舜

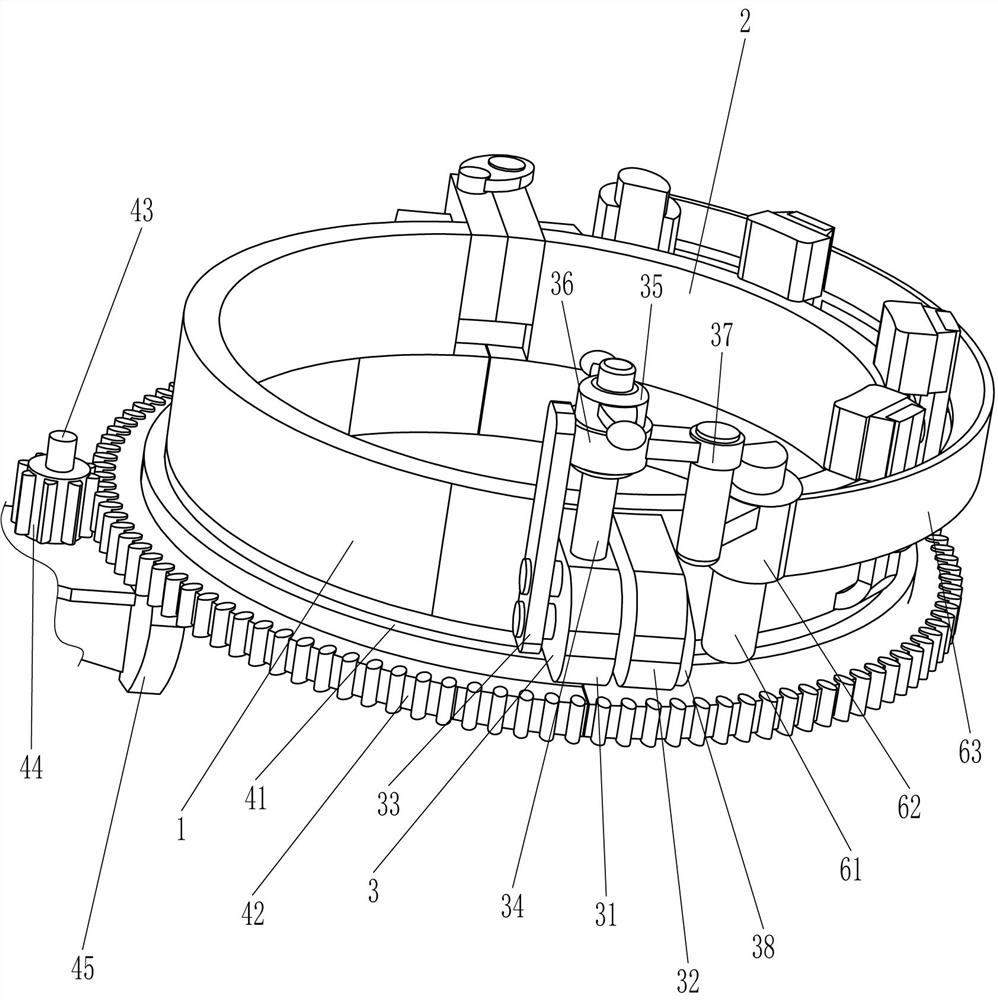

Paint spraying device and method applied to hardware workpiece

PendingCN113426609ANot easy to changeAvoid affecting the painting effectSpraying apparatusComputer hardwarePipe fitting

The invention discloses a paint spraying device applied to a hardware workpiece, and relates to the technical field of hardware processing equipment, and the paint spraying device comprises a displacement mechanism and a clamping mechanism. The clamping mechanism is controlled by the displacement mechanism to extend into the hardware pipe fitting for clamping, so that the hardware pipe fitting can be suspended during ascending, and the situation that paint flows along the hardware pipe fitting during paint spraying and converges at the lower end of the hardware pipe fitting to affect the overall paint spraying effect is avoided. The clamping mechanism adopts a rotating motor to drive a vortex ring to rotate so as to drive a matching piece to move along a vortex-shaped sliding way extending outwards in the vortex ring, and under the limitation of a sliding piece connected with a base body in a sliding mode, a clamping piece is finally made to stably move outwards in a linear path to clamp the inner wall of the hardware pipe fitting, at the moment, the clamping piece makes contact with the inner wall of the hardware pipe fitting in a face-to-face contact mode, the situation that the hardware pipe fitting is not prone to displacement when rotated and painted is avoided, when the clamping piece clamps the inner wall of the hardware pipe fitting, the paint spraying process is not affected by the clamping piece, paint can be comprehensively sprayed to the outer surface of the hardware pipe fitting, and the overall paint spraying effect is improved.

Owner:JIANGSU HONGBAO HARDWARE

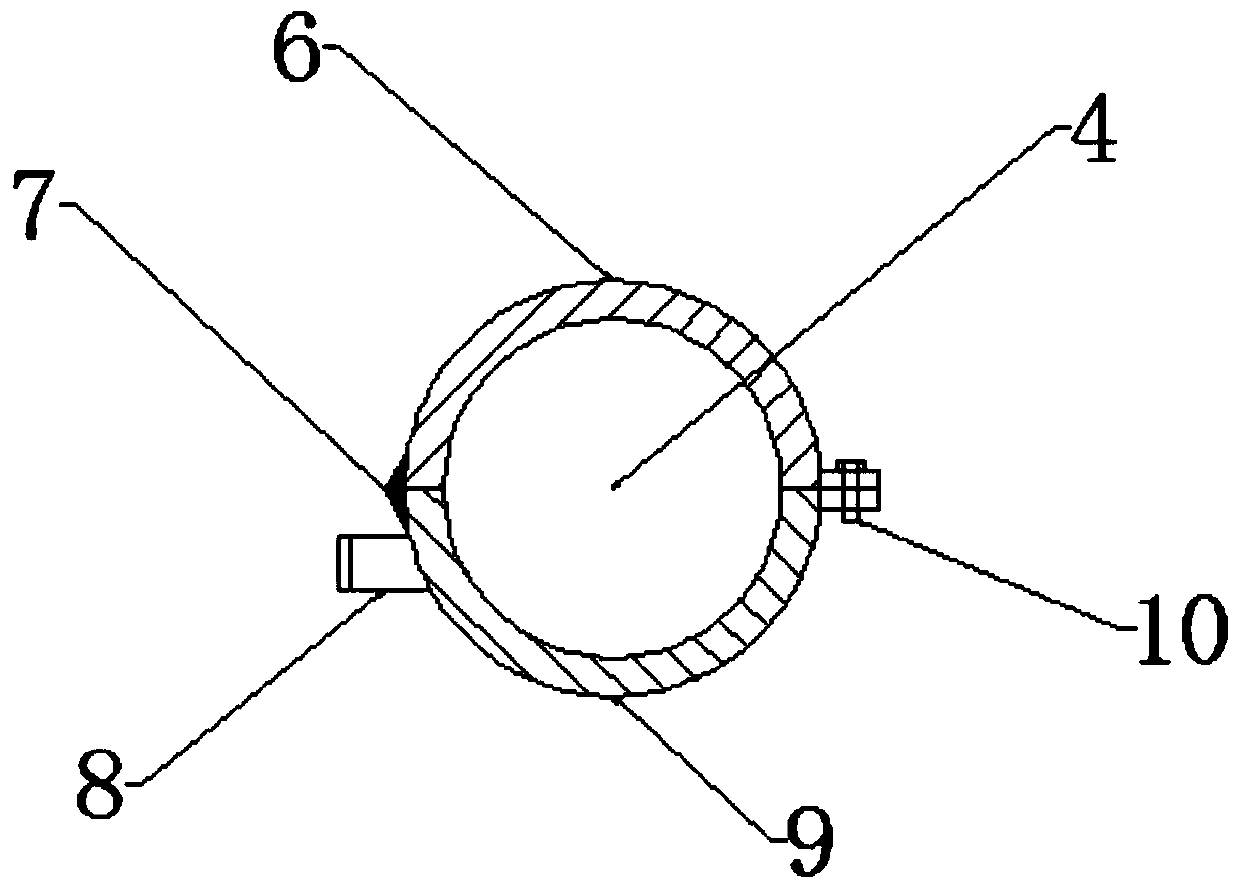

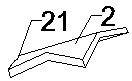

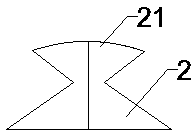

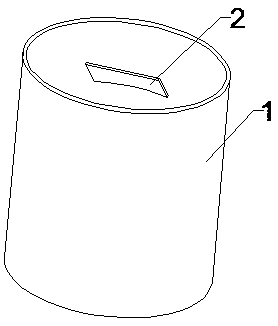

Paint bucket capable of preventing paint from dripping

The invention discloses a paint bucket capable of preventing paint from dripping. The paint bucket comprises a barrel body (1) and a material blocking plate (2), wherein the material blocking plate (2) is of a dovetail-shaped structure and can be obliquely fixed at the upper part of the inner wall of the barrel body (1), the connecting end surface of the material blocking plate (2) and the inner wall of the barrel body (1) is of a cambered structure and is matched with the shape of the inner wall of the barrel body (1), and the cross section of the material blocking plate (2) is an inverted V-shaped structure. According to the paint bucket, through the material blocking plate (2), during actual use, a brush can make direct contact with the end surface of the material blocking plate (2) toscrape off excess paint after the brush extends into the barrel body (1) and dips in the paint, so that the paint brushing effect is prevented from being influenced by too much paint on the brush; meanwhile, the material blocking plate (2) is obliquely arranged and has section of an inverted V-shaped structure, so that the paint can be prevented from being accumulated on the upper end surface of the material blocking plate (2); and meanwhile, the material blocking plate is of a dovetail-shaped structure, so that the contact area of the paint and the material blocking plate (2) can be reduced,so that the paint can be effectively prevented from being accumulated at the upper end of the material blocking plate (2).

Owner:徐涓惠

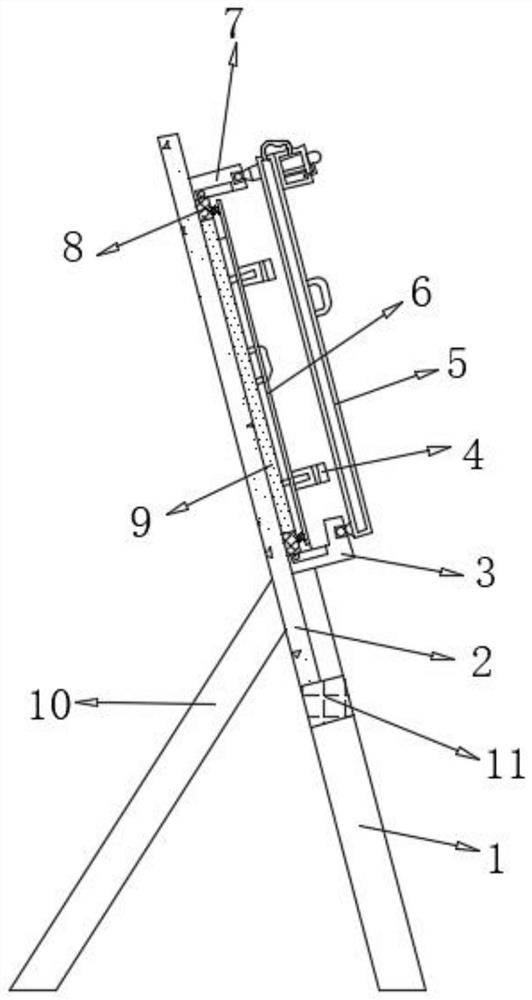

An art painting stand for students

ActiveCN111634151BImprove drying efficiencyEasy to moveOther artistic work equipmentsStructural engineeringMechanical engineering

The invention discloses an art painting stand for students, which comprises two side plates, the bottoms of the opposite sides of the two side plates are provided with the same cross brace, and the tops of the two side plates are provided with the same cross brace. The backboard, the bottom of one side of the backboard is provided with two supporting legs, the middle position of one side of the backboard is provided with a fixed drawing board, and the top of one side of the backboard is provided with a top plate, and the bottom of one side of the backboard is provided with a There is a bottom bracket, two guide grooves are opened on the opposite side of the bottom bracket and the top plate, and the same movable frame is slidably connected inside the four guide grooves. In the present invention, the drawing paper is laid on the fixed drawing board, the fixing bar is moved upwards and the two sides of the drawing paper are respectively laid on the bottom of the two fixing bars, when the fixing bar is loosened, the spring pulls the fixing bar to reset and the drawing paper is pressed and fixed. After the painting is completed, the movable frame is pulled by the handle to separate the back of the drawing paper from the fixed drawing board, leaving a gap between the fixed drawing board and the back of the drawing paper, which improves the drying efficiency of the drawing paper.

Owner:潘熠龙

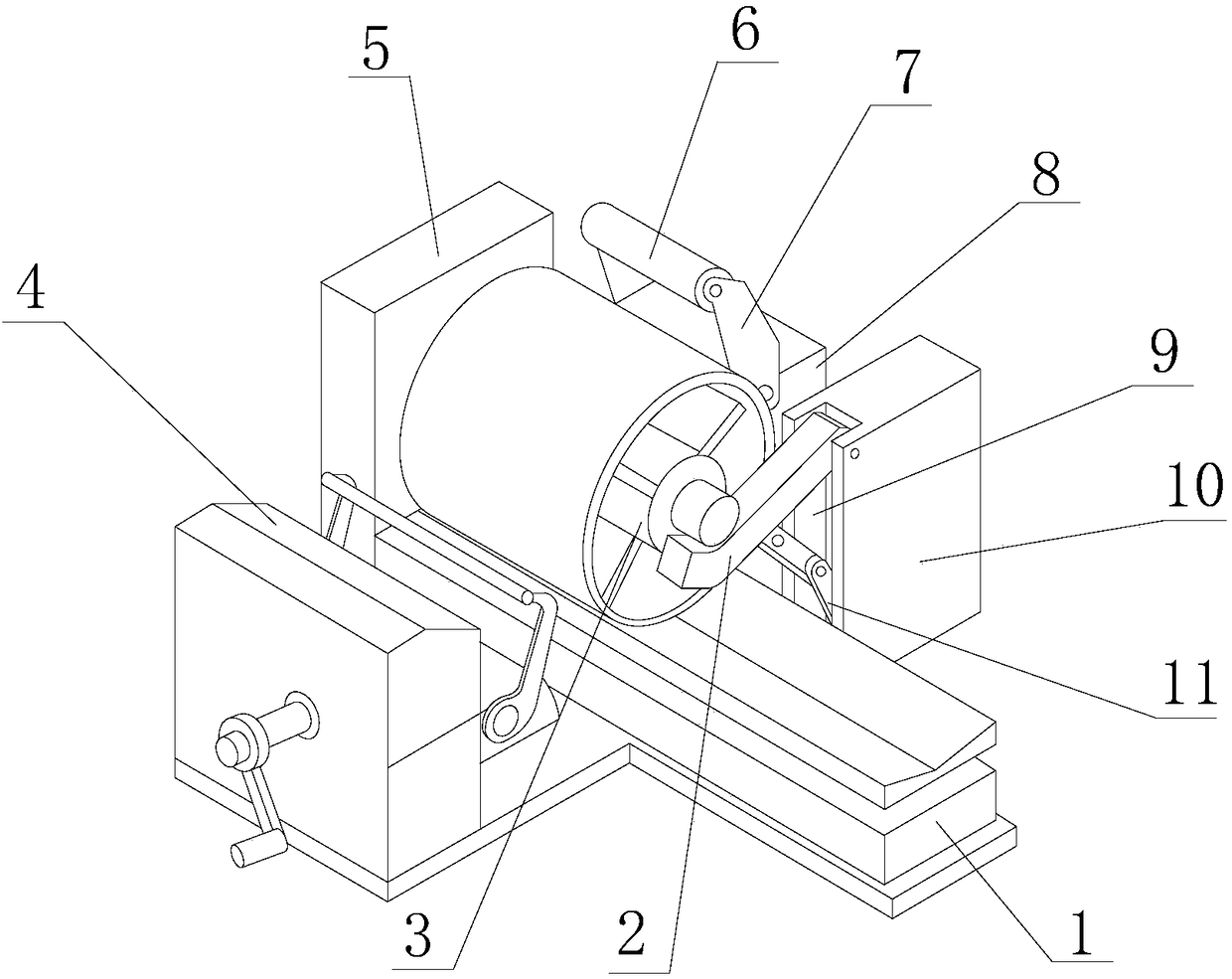

Paint spraying device used for valve machining and not prone to paint leakage

InactiveCN114632646ASecure AnywhereEnsure safetyEdge grinding machinesGrinding drivesGear driveGear wheel

The invention relates to the technical field of valve paint spraying, and discloses a paint spraying device for valve machining not prone to paint leakage. The paint spraying device comprises a bottom plate, a supporting column is fixedly connected to the top of the bottom plate, a transmission gear is fixedly connected to the top of the supporting column, and two transmission racks are arranged on the outer side of the transmission rack; the two transmission racks are meshed with a transmission gear, and the top of the transmission gear is fixedly connected with a conical wheel; according to the paint spraying device for valve machining and not prone to paint leakage, through downward pressing of an extrusion block, a pushing gear engaged with the extrusion block starts to rotate along a thread on the extrusion block, rotation of the pushing gear drives a driven strip to contract inwards, a clamping plate fixedly connected with the driven strip contracts inwards at the moment, and when the clamping plate contracts to a certain position, the clamping plate can rotate; the cylinders on the clamping plates can be clamped into the through holes in the left end and the right end of the valve, so that the valve is fixed, and the influence caused by infirm fixing of the valve in the spraying process is reduced.

Owner:JIANGSU SHANGOU VALVE CO LTD

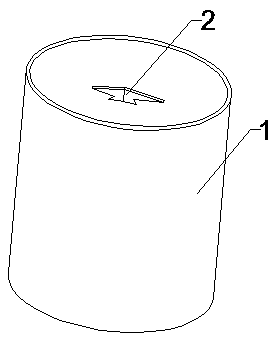

Paint bucket

InactiveCN109809007AAvoid affecting the painting effectSimple structureInternal fittingsEngineeringMechanical engineering

The invention discloses a paint bucket. The paint bucket comprises a bucket body (1) with the upper end capable of being sealed and further comprises a striker plate (2). The striker plate (2) can bedirectly fixed to the upper portion in the inner wall of the bucket body (1), the connecting end face (21) of the striker plate and the inner wall of the bucket body (1) is of a cambered surface structure, and the striker plate is matched with the inner wall of the bucket body (1) in shape. According to the device, as the striker plate (2) is arranged on the inner wall of the bucket body (1), during actual use, after a brush stretches into the bucket body (1) and is dipped in paint, the brush can directly make contact with the end face of the striker plate (2), redundant paint is scraped away,and the situation that the paint brushing effect is affected by excessive paint on the brush is avoided.

Owner:徐涓惠

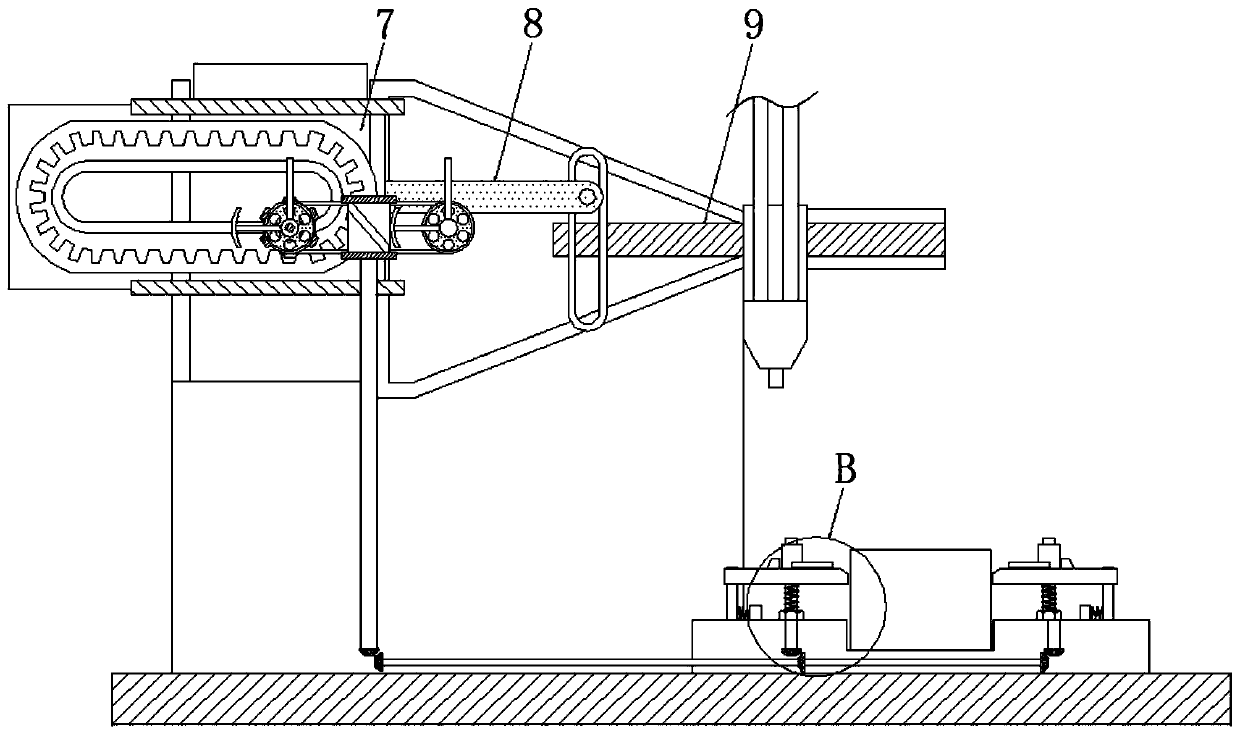

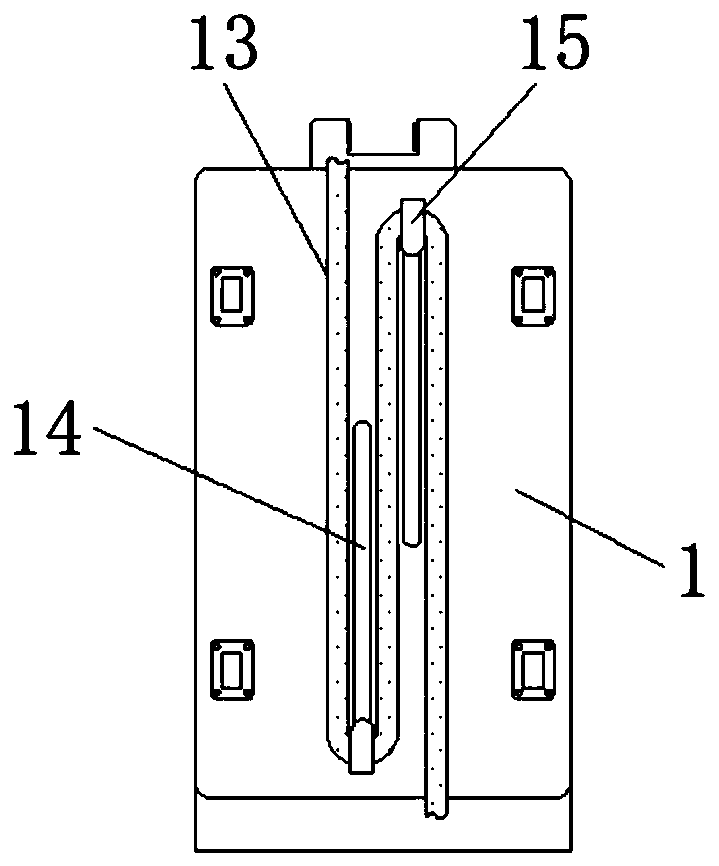

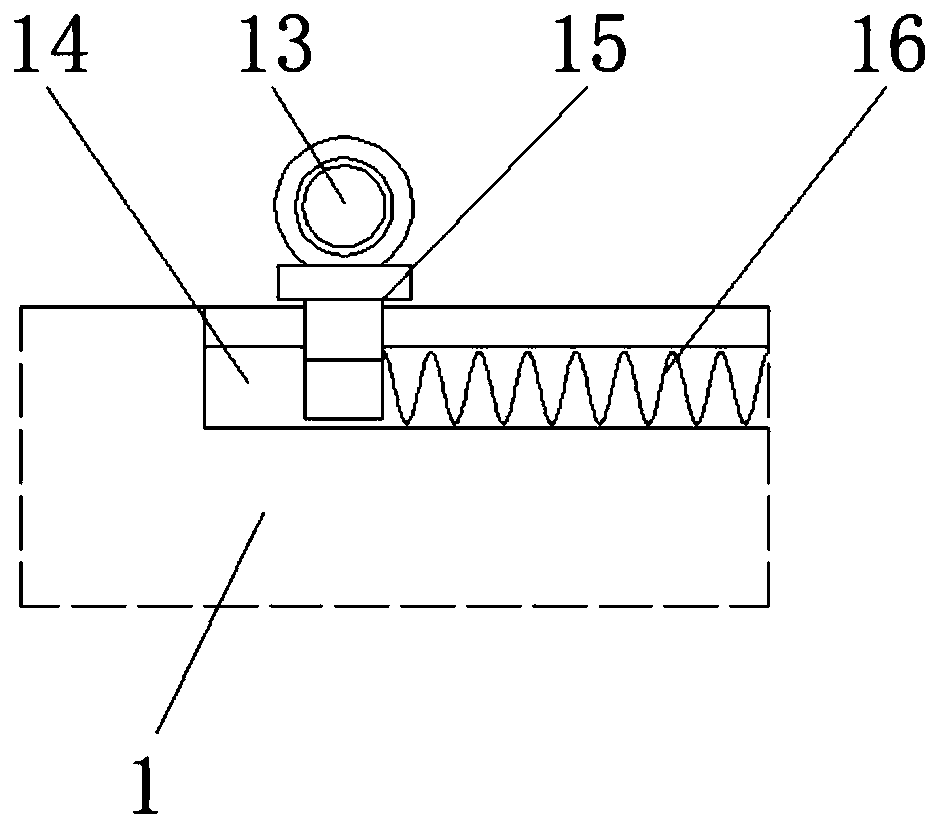

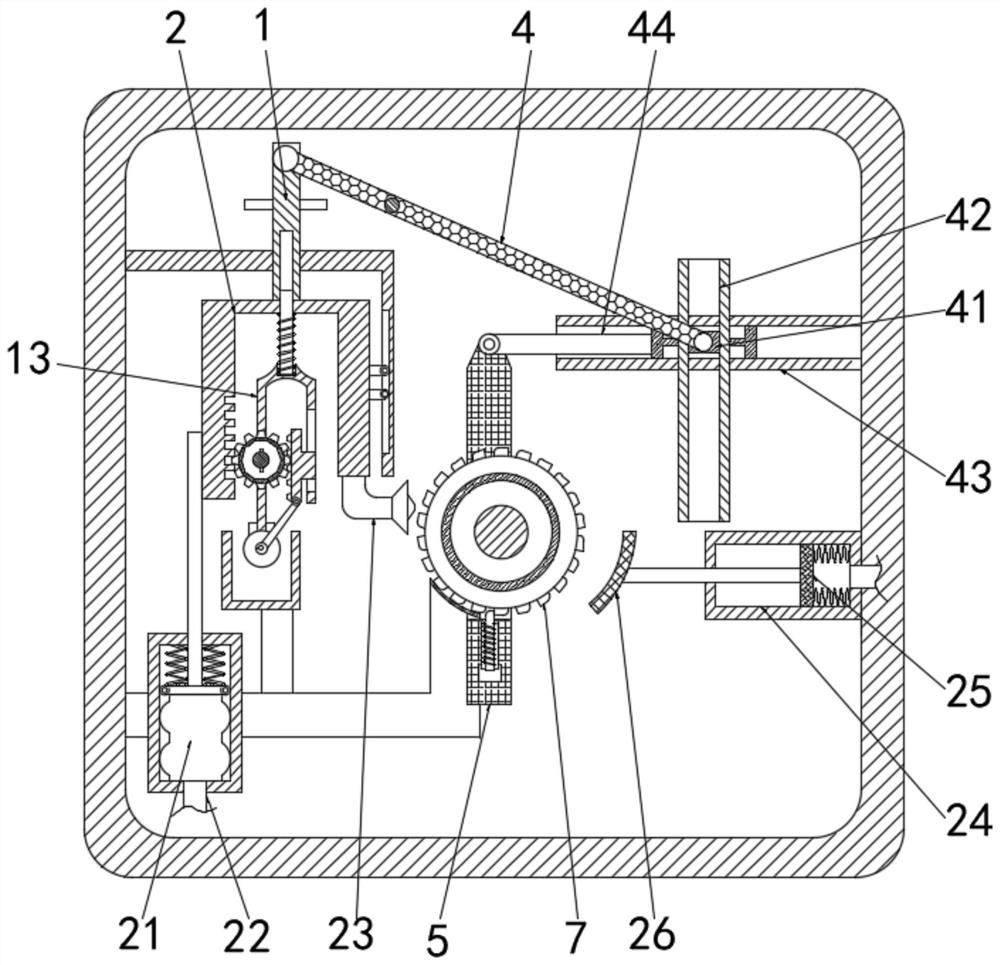

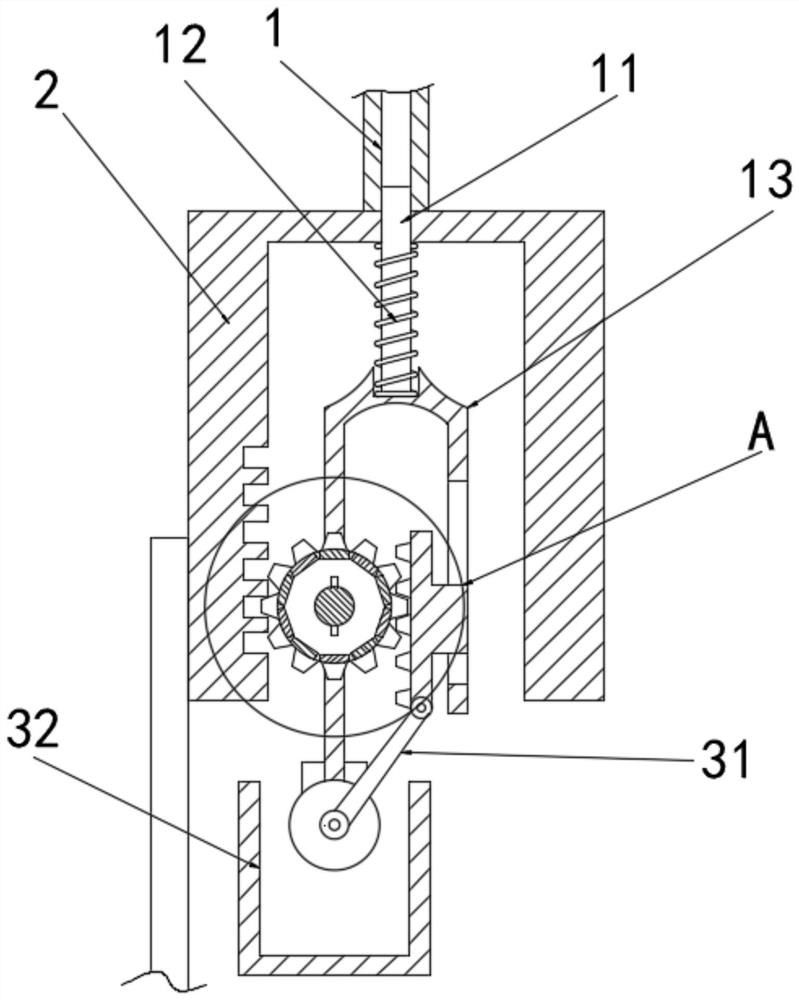

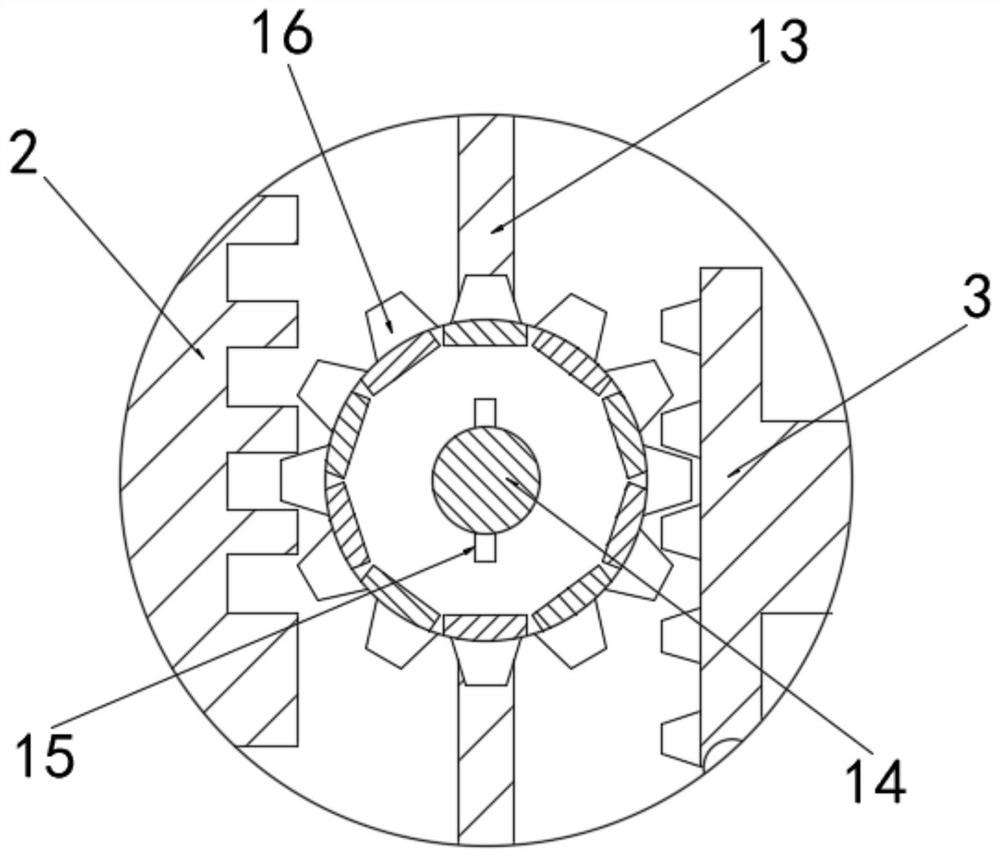

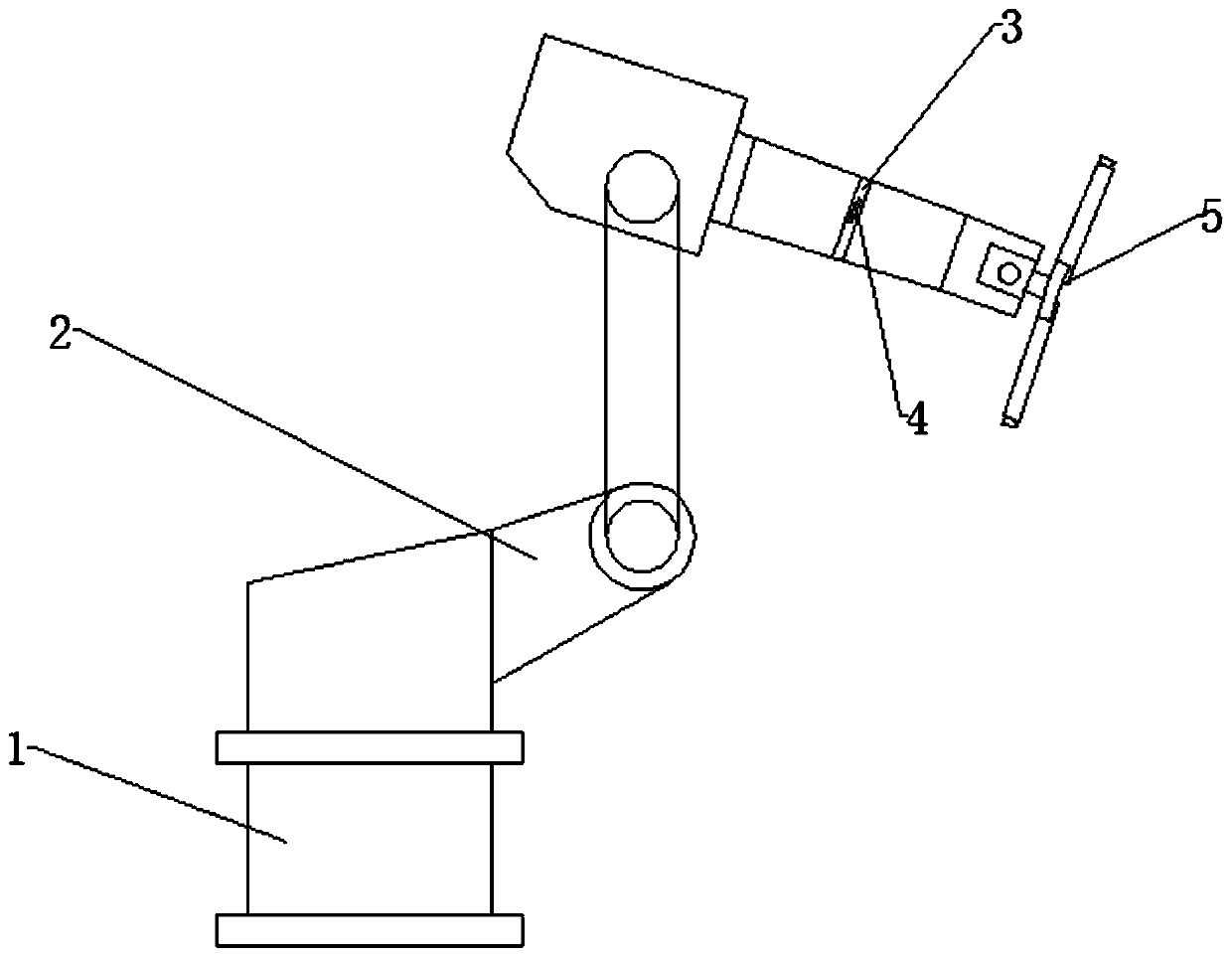

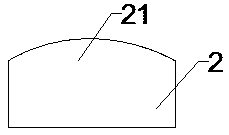

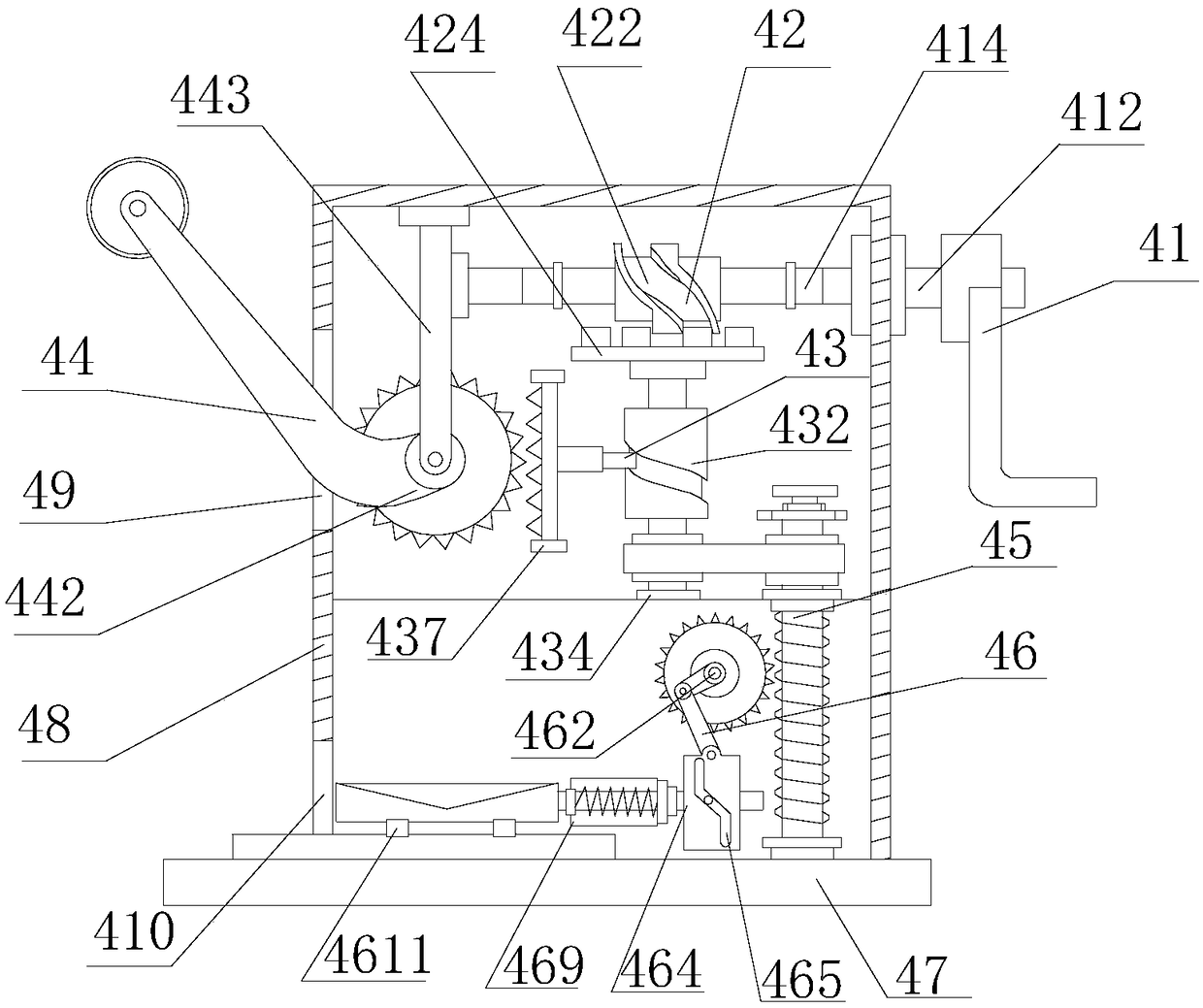

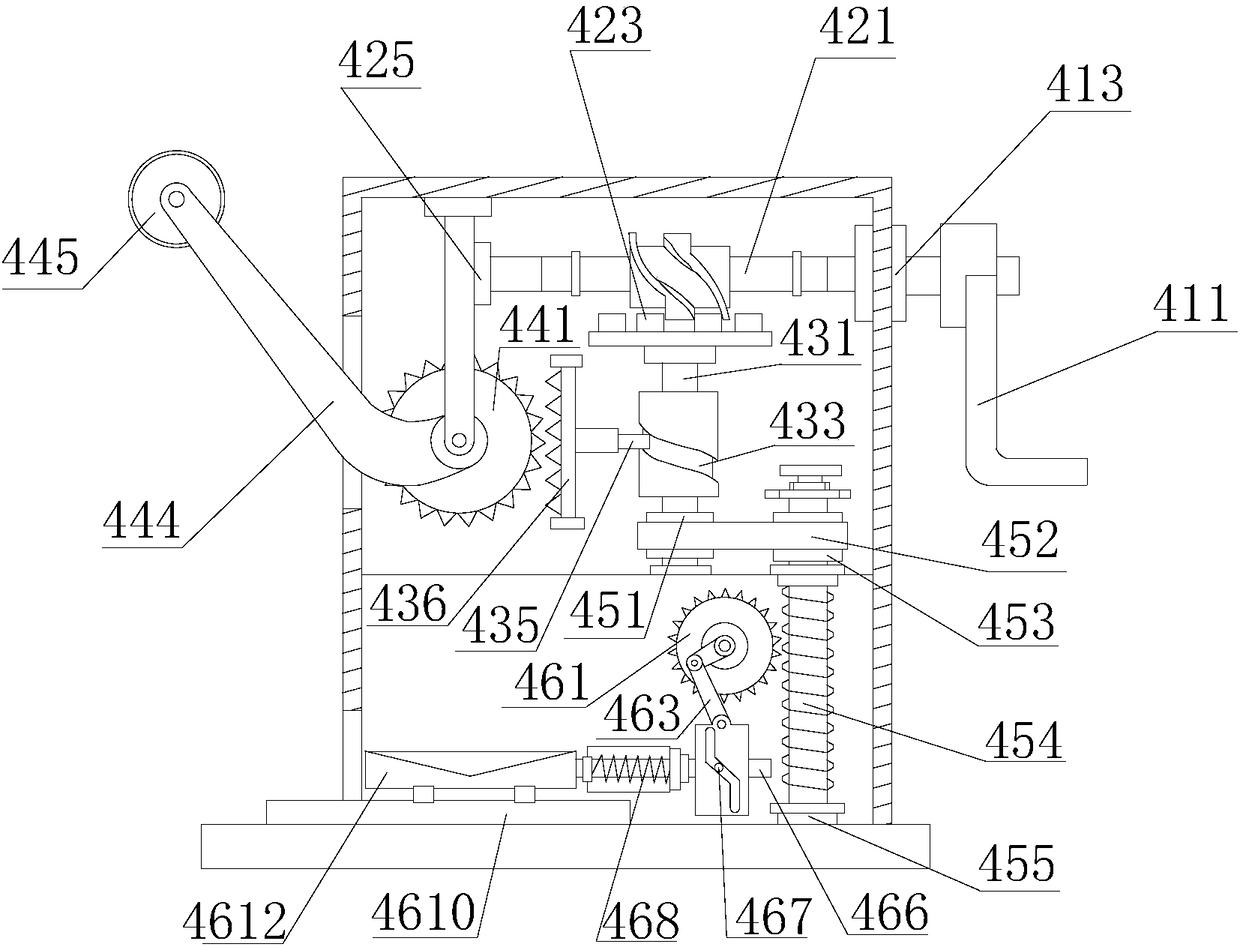

Inner supporting type paint device for outer wall of cylinder

InactiveCN108466153ARust removal achievedSolve the problem of easy falling offGrinding drivesGrinding machinesScrapSprocket

The invention discloses an inner supporting type paint device for an outer wall of a cylinder. The device structurally comprises a fixed base, a primary supporting arm, an inner supporting rotary shaft, a dedusting device, a limiting side plate, a paint brush, a paint brush supporting rod, a paint cabin, a movable groove, a supporting device and a secondary supporting arm, wherein the dedusting device comprises a manual adjusting structure, a cam transmission mechanism, a sheave transmission mechanism, a dedusting roller transmission mechanism, a chain wheel transmission mechanism, a scrap iron collecting mechanism, a device base, a device shell, an upper opening and a lower opening. The inner supporting type paint device for the outer wall of the cylinder solves the problem that the paintsurface, which is directly sprayed, of the outer wall of the cylinder is easy to fall as the surface of the outer wall of the cylinder cannot be dedusted before the conventional inner supporting typepaint device for the outer wall of the cylinder sprays paint to the cylinder, and can dedust the outer wall of the cylinder and collect scrap iron, so that the paint spraying quality is improved.

Owner:莆田市荔城区浩旺贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com