Automatic spraying system for fire extinguisher bottle

An automatic spraying and fire extinguisher technology, which is applied in the direction of spraying booths and spraying devices, can solve problems such as inconvenient use, affecting the area of spraying paint, and affecting the production of fire extinguisher bottles, so as to ensure production efficiency, improve automation, and realize automatic feeding and The effect of automatic unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

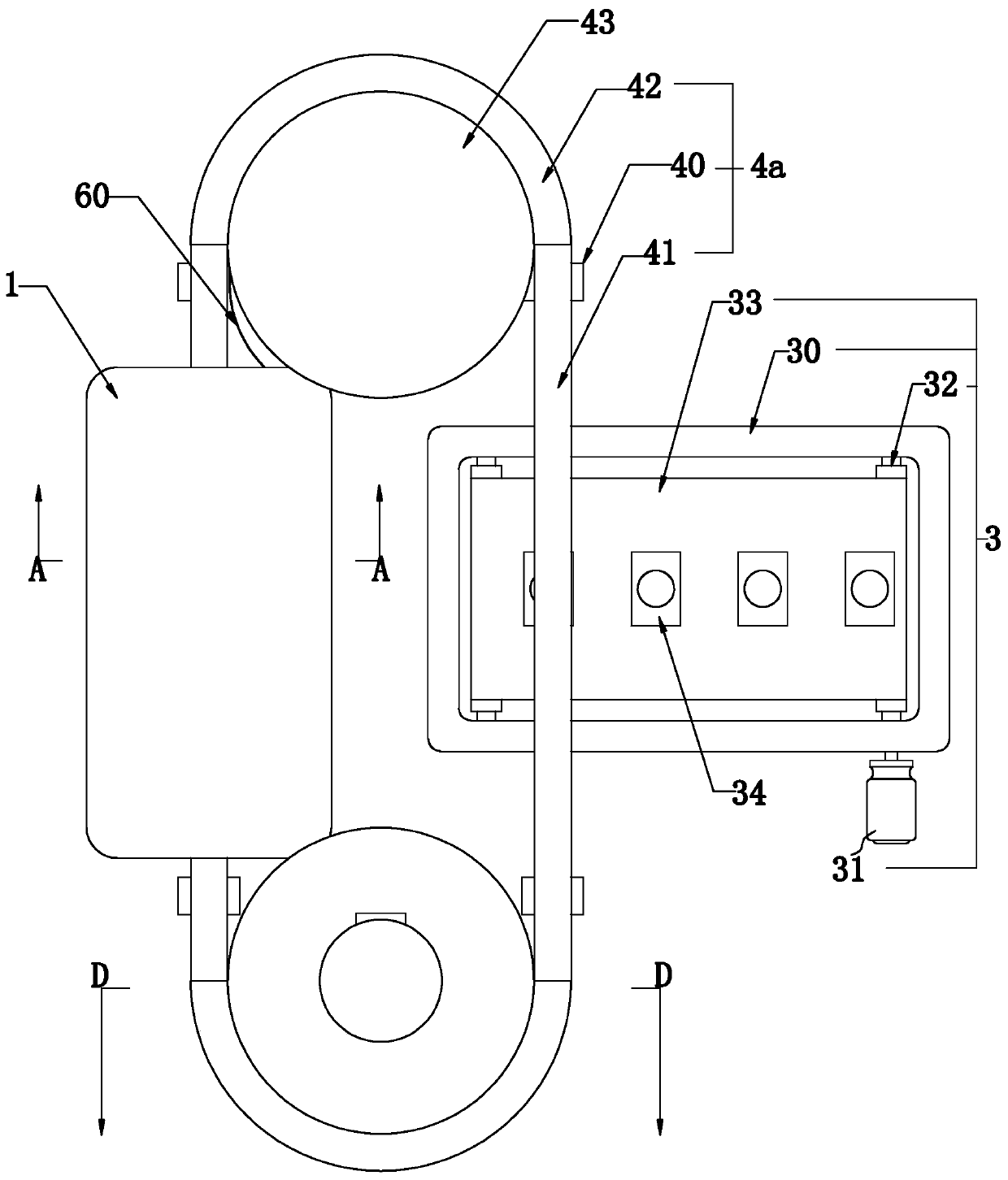

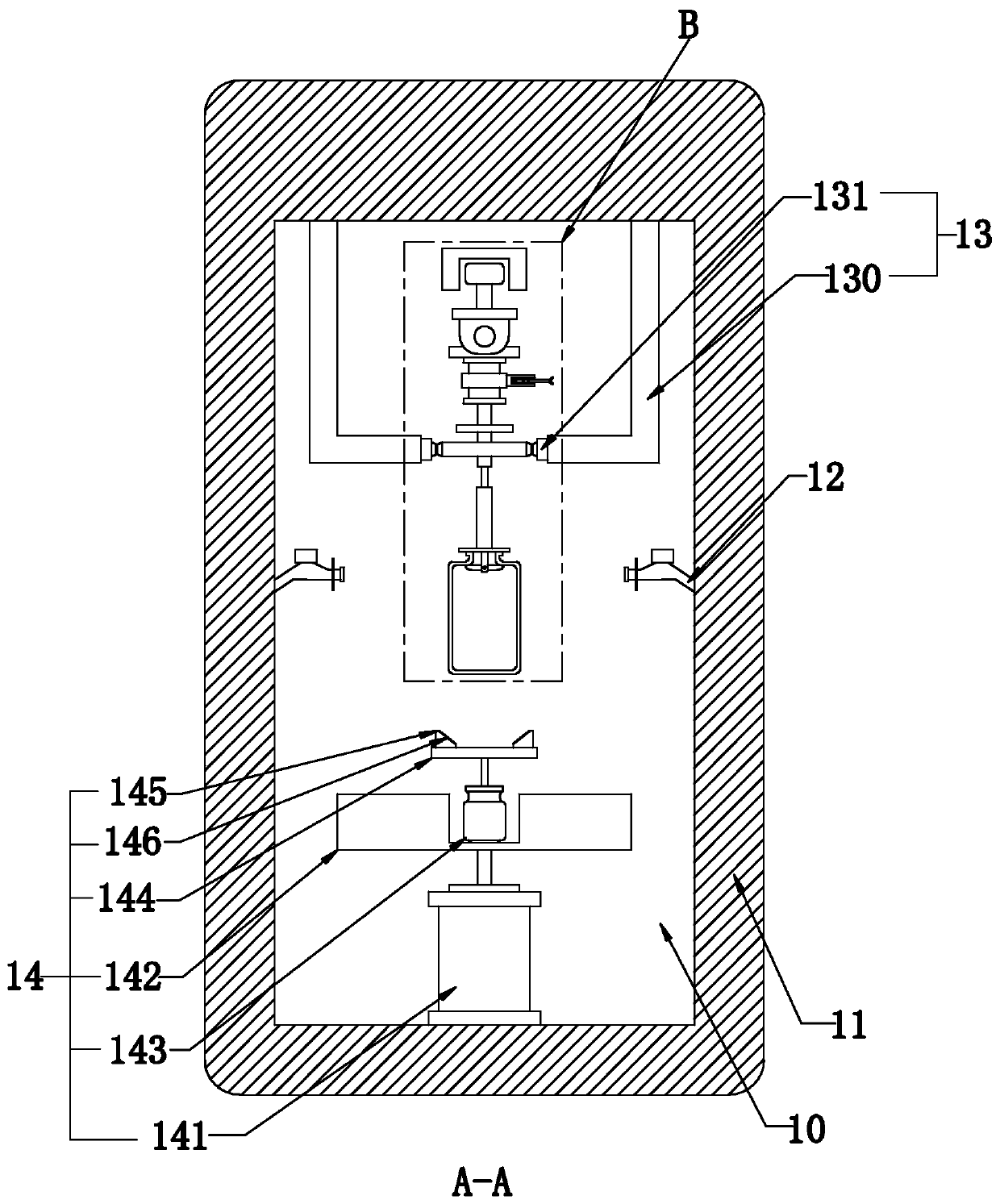

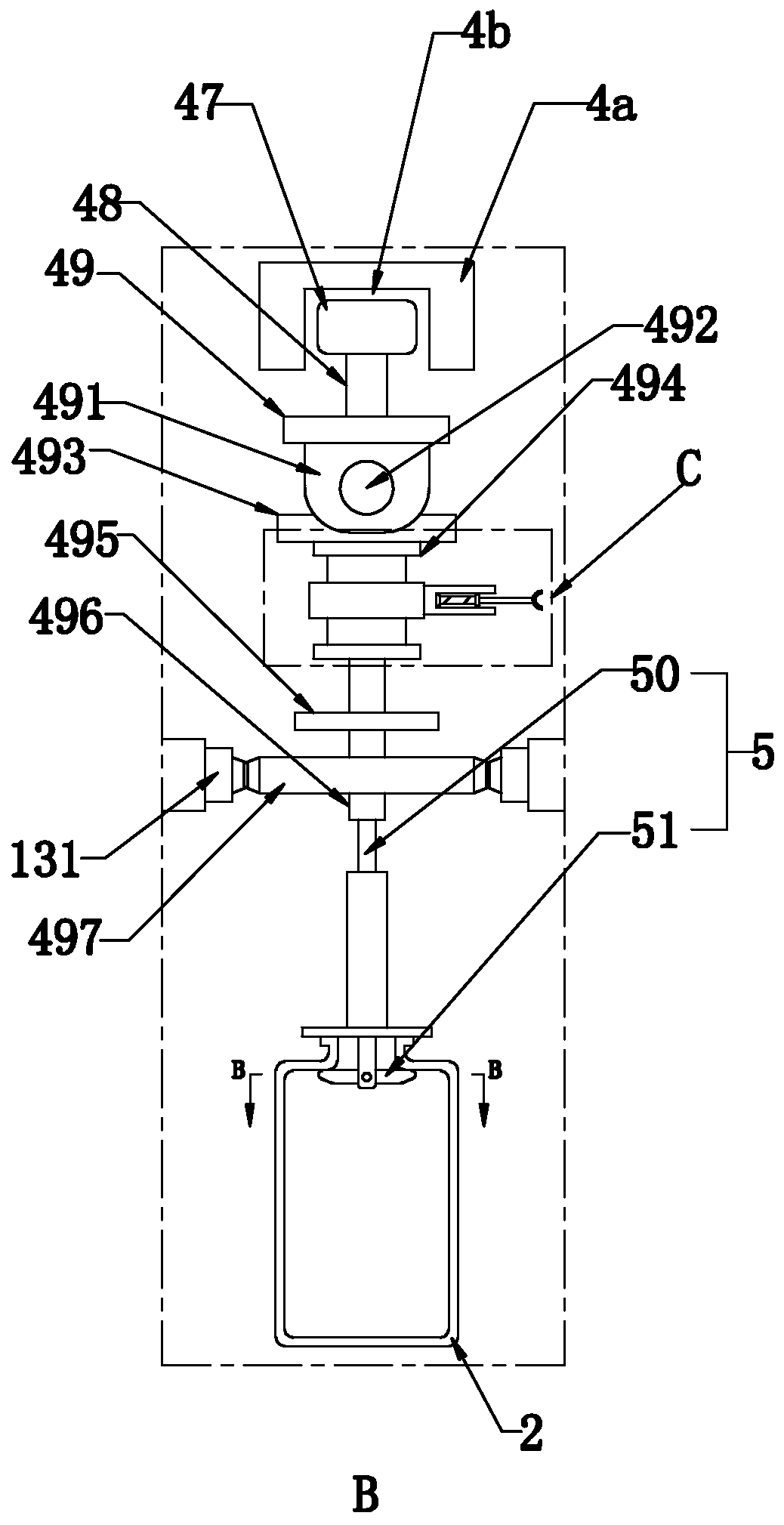

[0036] Such as Figure 1 to Figure 11 As shown, the present invention discloses a fire extinguisher bottle automatic spraying system, including a bottle grasping device for grabbing a fire extinguisher bottle, in a specific embodiment of the present invention, including a spray box 1 with a spray chamber 10, The lower conveying assembly 3 that receives the fire extinguisher bottle body 2 from the bottle grasping device, the upper conveying assembly 4 that is arranged above the lower conveying assembly 3 and is used to convey the fire extinguisher bottle body 2 through the spraying chamber 10, and several upper conveying assemblies 4 and is used to hang the hanger 5 of the fire extinguisher bottle body 2 and the guide rail assembly 6 arranged between the upper conveying assembly 4 and the lower conveying assembly 3 and used to drive the hanger 5 to tilt; wherein, the hanger 5 includes a rod body 50. A support module 51 provided on the rod body 50 that can shrink and bear the we...

Embodiment 2

[0057] Embodiment 2, the difference with embodiment 1 is that

[0058] Such as Figure 12 ~ Figure 13 As shown, in a specific embodiment of the present invention, the support module 51 includes two grooves 51a arranged on the outer wall of the rod body 50 and distributed at equal intervals in the circumferential direction, and two grooves 51a are connected to each groove 51a through the rotating shaft 51b respectively. The support piece 51c that the side groove wall is rotatably connected; wherein, when each support piece 51c is in contact with the notch bottom of the groove 51a, the distance L2 between the free ends of the two support pieces 51c is greater than the diameter of the bottle mouth of the fire extinguisher.

[0059] By adopting the above-mentioned technical scheme: setting each support piece in different grooves can reduce the pressure on the same rotating shaft (that is: the cylindrical pin in Embodiment 1), that is, the pressure of the fire extinguisher bottle t...

Embodiment 3

[0060] Embodiment 3, the difference with embodiment 1 is that

[0061] Such as Figure 14 ~ Figure 15 As shown, in a specific embodiment of the present invention, the support module 51 includes two first telescopic slots 51d arranged on the outer wall of the rod body 50 and distributed at equal intervals in the circumferential direction, and connected with each of the first compression springs 51e The groove bottom of the first telescopic groove 51d is fixedly connected and partly exposes the first telescopic groove 51d and is used to support the support block 51f of the fire extinguisher bottle body 2; wherein, each support block 51f is away from the side end surface of the first compression spring 51e and the bottom end surface thereof The junction is set as an arc surface 51h.

[0062] By adopting the above technical scheme: when the rod body is inserted into the fire extinguisher from the bottle mouth of the fire extinguisher, the support blocks will provide the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com