Painting device for furniture

A furniture and machine body technology, applied in the direction of spraying devices, liquid spraying devices, machine tools suitable for grinding the edge of workpieces, etc., can solve problems that affect production quality, wooden board defects, and susceptibility to vibrations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

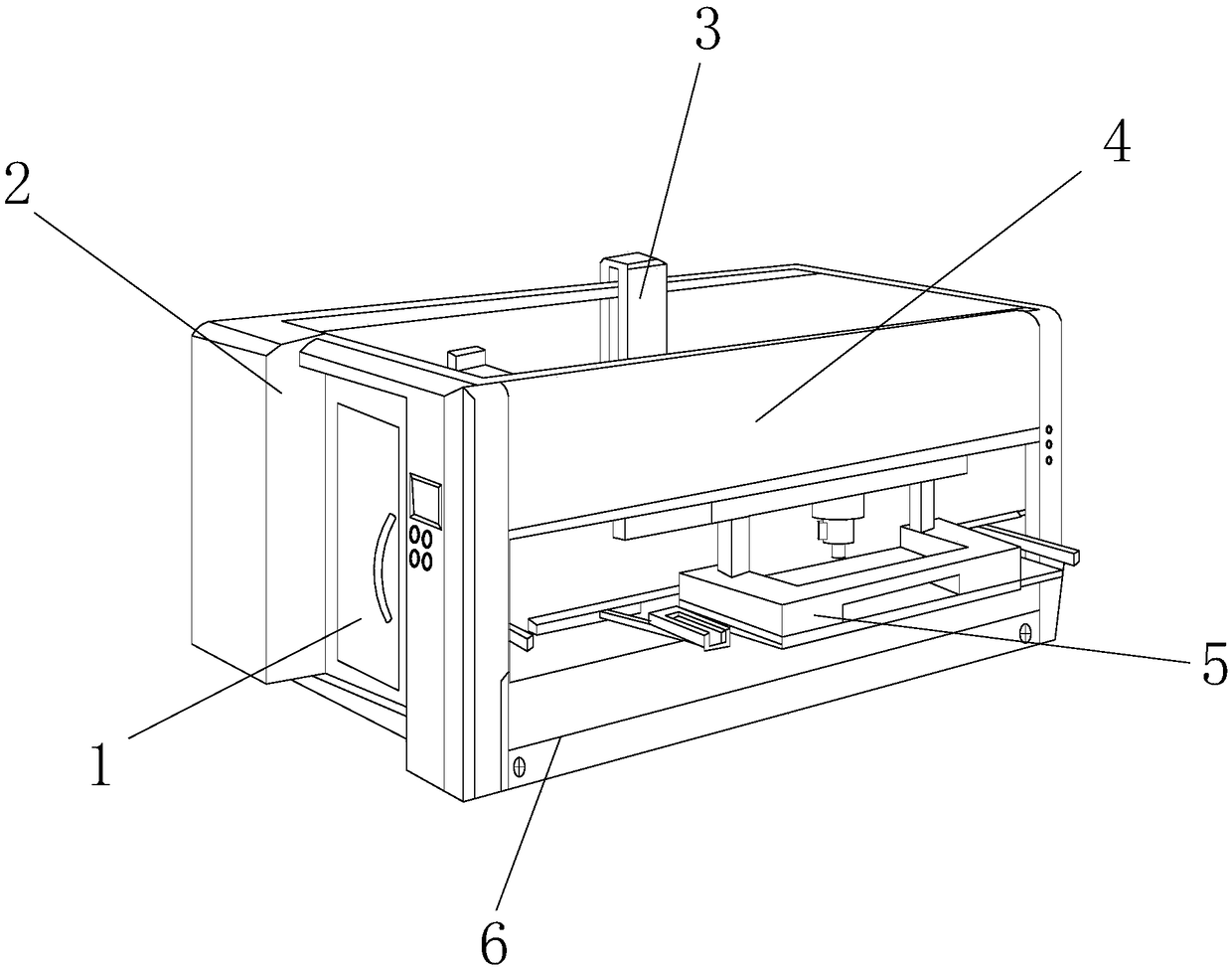

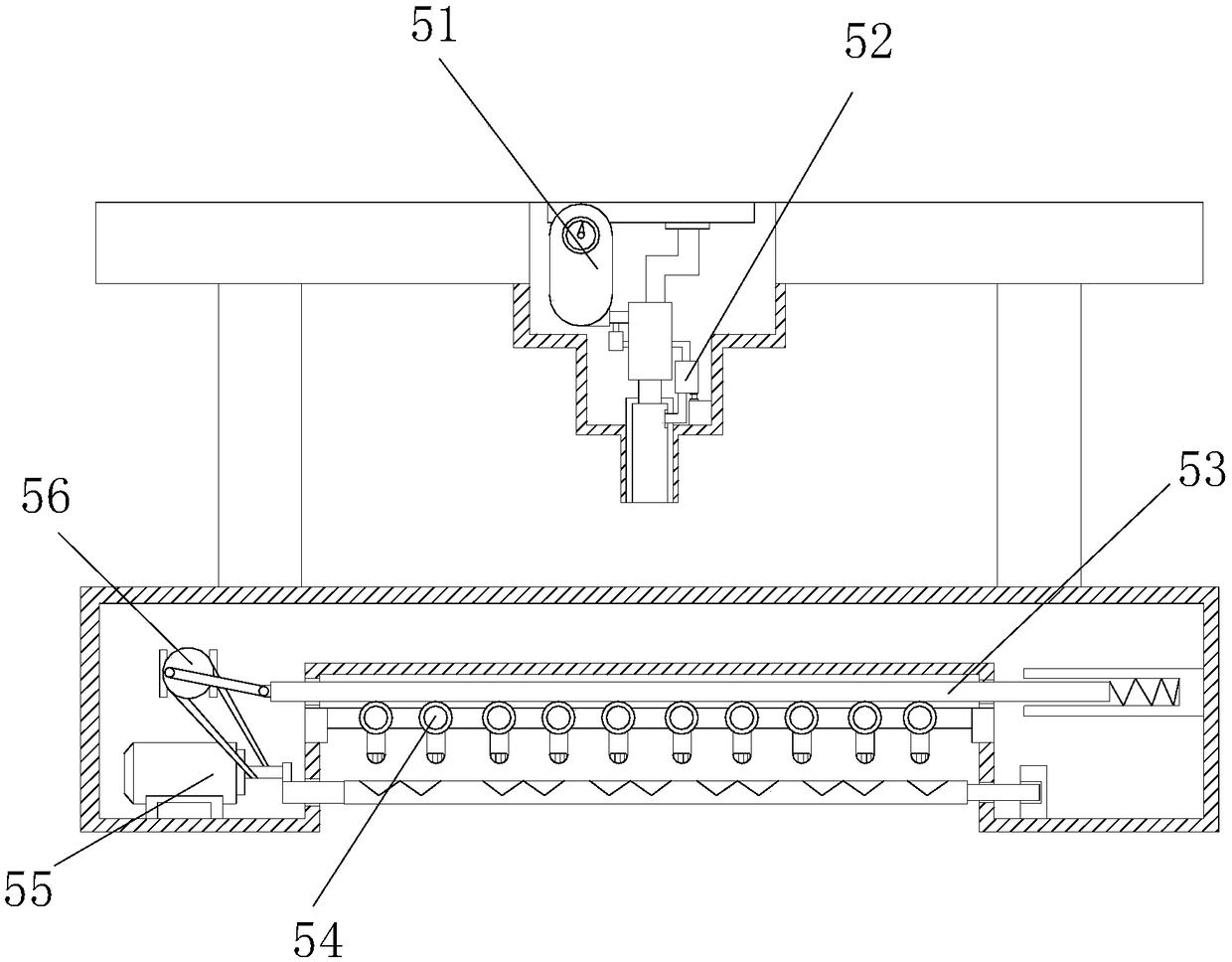

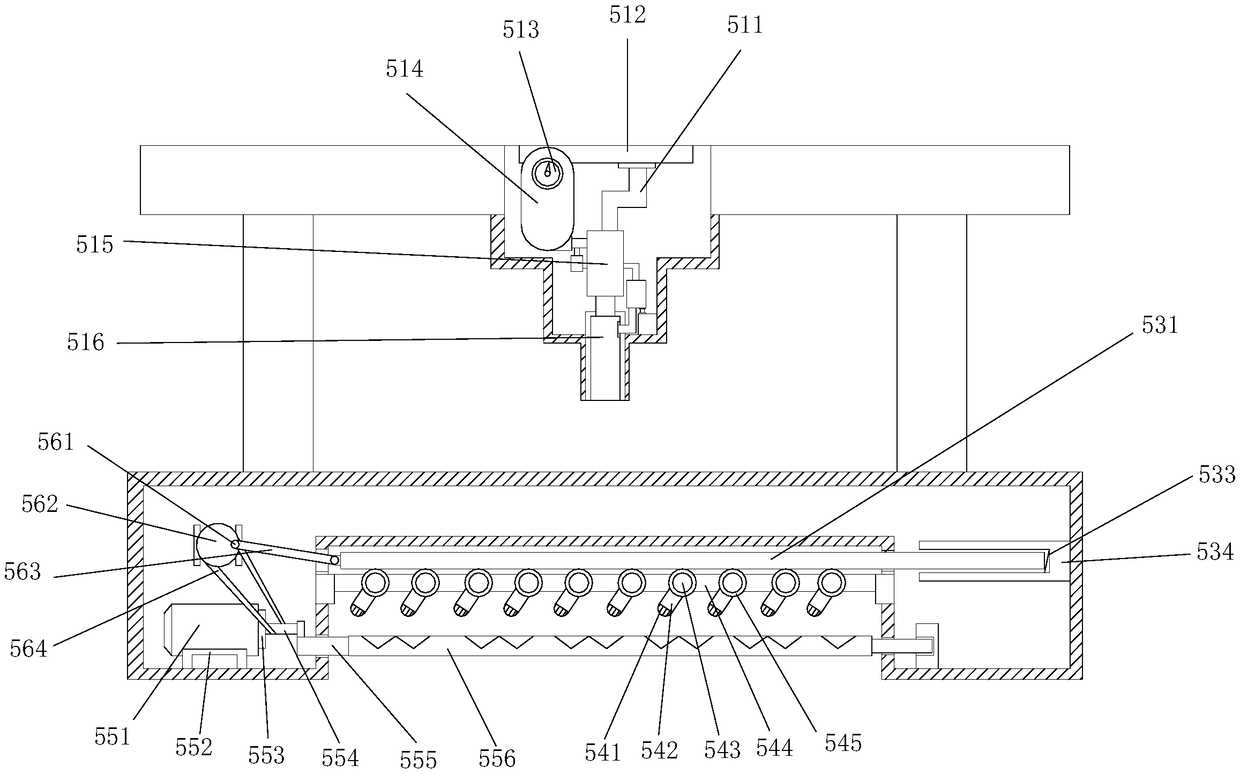

[0023] see Figure 1-Figure 5, the present invention provides a paint spraying device for furniture, its structure includes a side door 1, a body 2, a feeding tank 3, a baffle plate 4, a feeding paint spraying device 5, a base 6, the side door 1 is located on the left side of the body 2, and The two are hingedly connected, the rear end of the feeding tank 3 is welded to the body 2, the baffle plate 4 is arranged at the front end of the body 2, and the two are an integrated structure, and the feeding paint spraying device 5 is located on the baffle plate 4 directly below, the base 6 is set at the bottom of the body 2, and the two are an integrated structure, the feeding paint spraying device 5 includes a feeding drive assembly 51, a backflow compensation mechanism 52, a reciprocating push mechanism 53, a deburring mechanism 54. Conveying drive mechanism 55, reciprocating drive mechanism 56, the feeding drive assembly 51 is arranged on the top of the backflow compensation mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com