Wall surface whitewashing equipment

A kind of equipment and painting technology, which is applied in the direction of construction and building construction, can solve the problems of water loss, dripping of the surface of the painting roller, and pollution of equipment, and achieve the effect of avoiding paint dripping, good uniformity, and ensuring timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

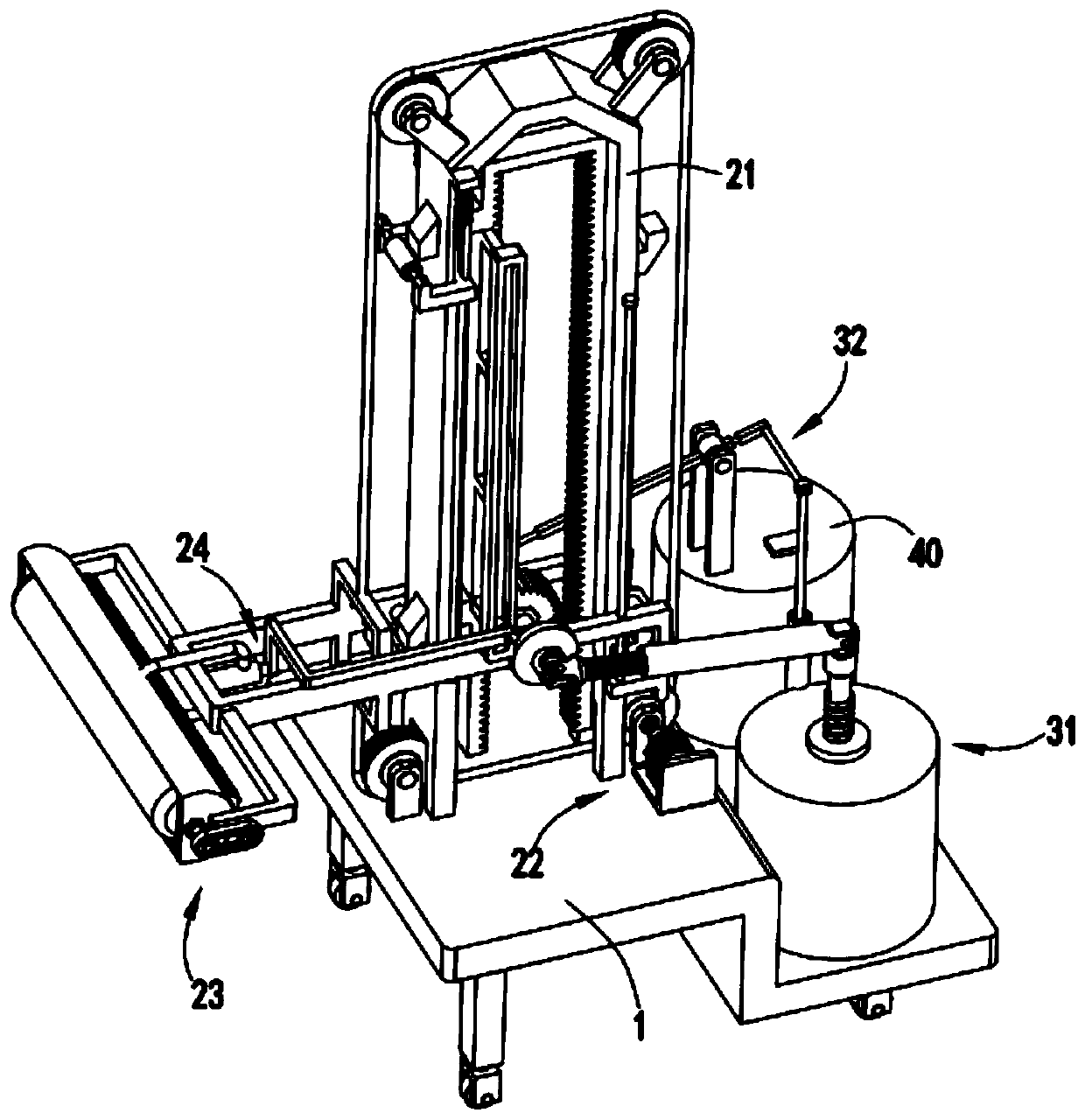

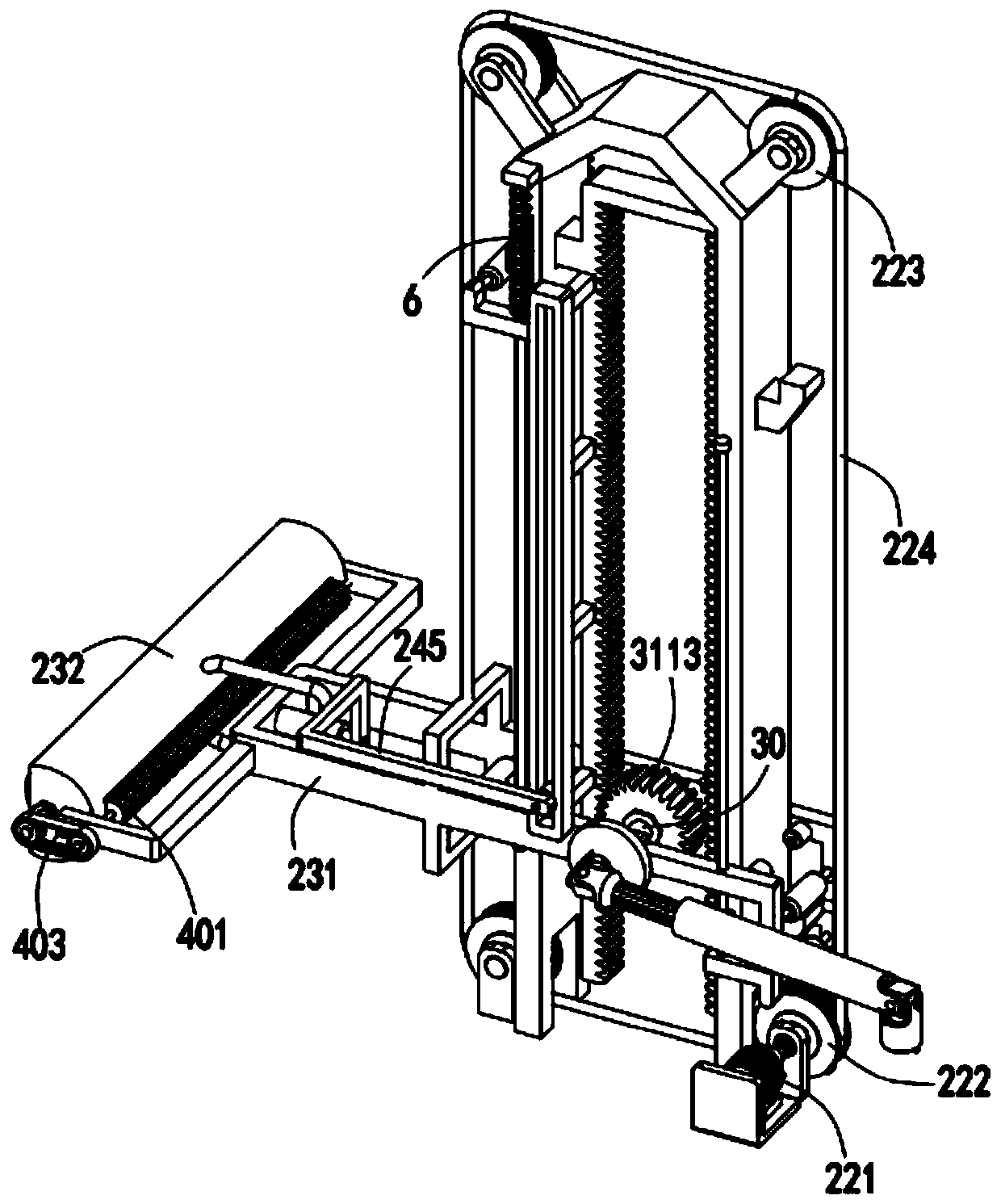

[0046] Such as Figure 1 to Figure 10 Shown, a kind of wall painting equipment comprises mobile frame 1, and described mobile frame 1 is provided with painting device 2 and feeding device 3, and described painting device 2 comprises support frame 21 that is arranged on mobile frame 1, The traction mechanism 22 arranged on one side of the support frame 21 and the painting mechanism 23 that moves up and down along the support frame 21 to paint the front side under the drive of the traction mechanism 22;

[0047] The feeding device 3 includes a feeding mechanism 31 for supplying paint to the painting mechanism 23 and an adjusting mechanism 32 arranged on one side of the feeding mechanism 31 for adjusting the feeding pressure of the feeding mechanism 31;

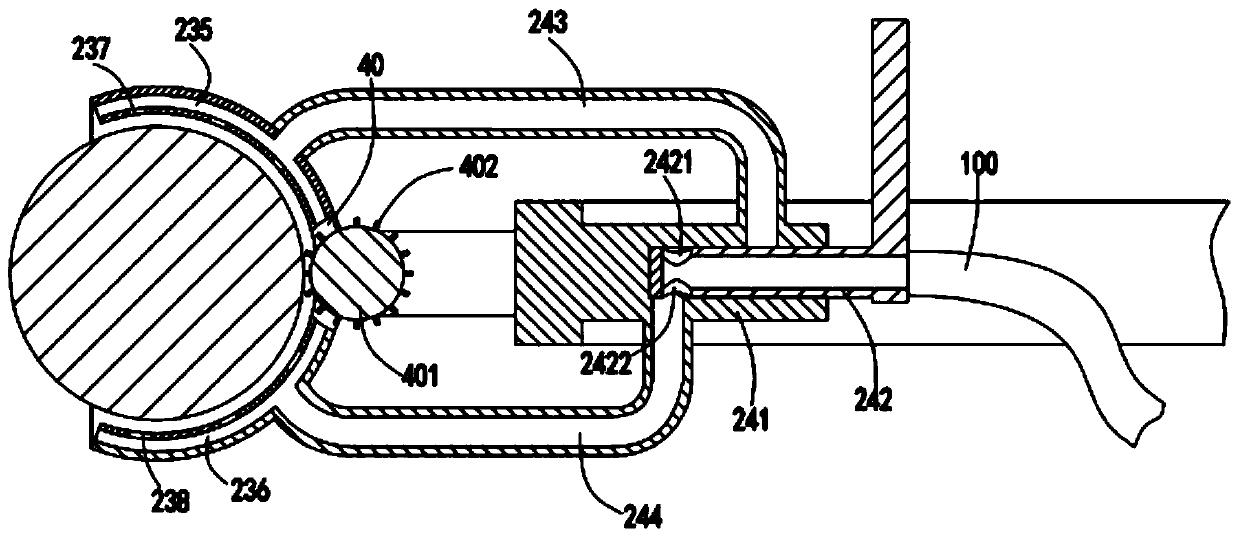

[0048] The painting mechanism 23 includes a painting roller 239, and the painting mechanism 23 is also provided with a switching mechanism 24. When the painting mechanism 23 moves upwards, the switching mechanism 24 controls the...

Embodiment 2

[0070] Such as Figure 7 and Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: the right support column 213 of the support frame 21 is provided with a sliding frame b5, and the sliding frame b5 slides up and down along the chute b2131 provided on the right support column 213, The sliding frame b5 is provided with an auxiliary dial b51, and the lower end of the sliding frame b5 is also fixedly connected with a sliding bar b52, and the sliding bar b52 is slidably matched with the guide hole b20 provided on the bracket 231, and its lower end is provided with a limited Position block b53, when the second dial 3119 is close to the right inclined block a3116 when the bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com