Vertical paint spraying device

A vertical, spray gun technology, applied to the surface coating liquid device, coating, etc., can solve the problems of long time-consuming painting operation, easy to produce defective products, etc., and achieve the effect of uniform painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

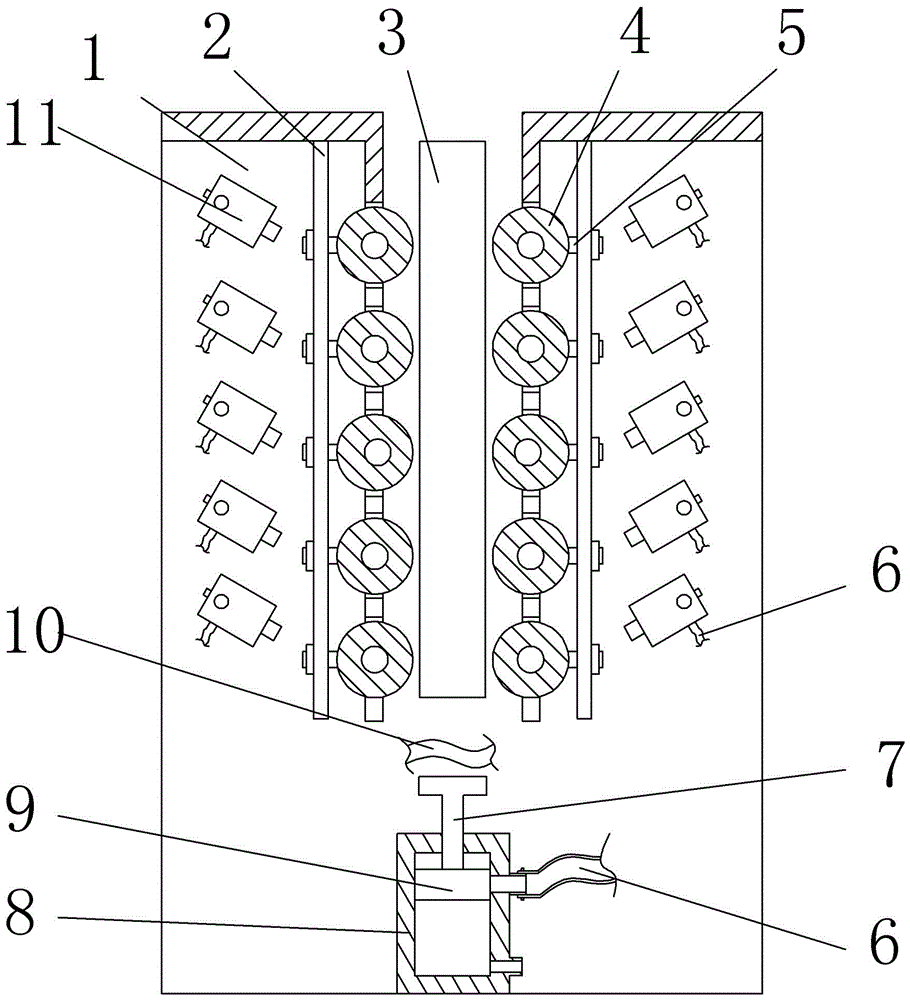

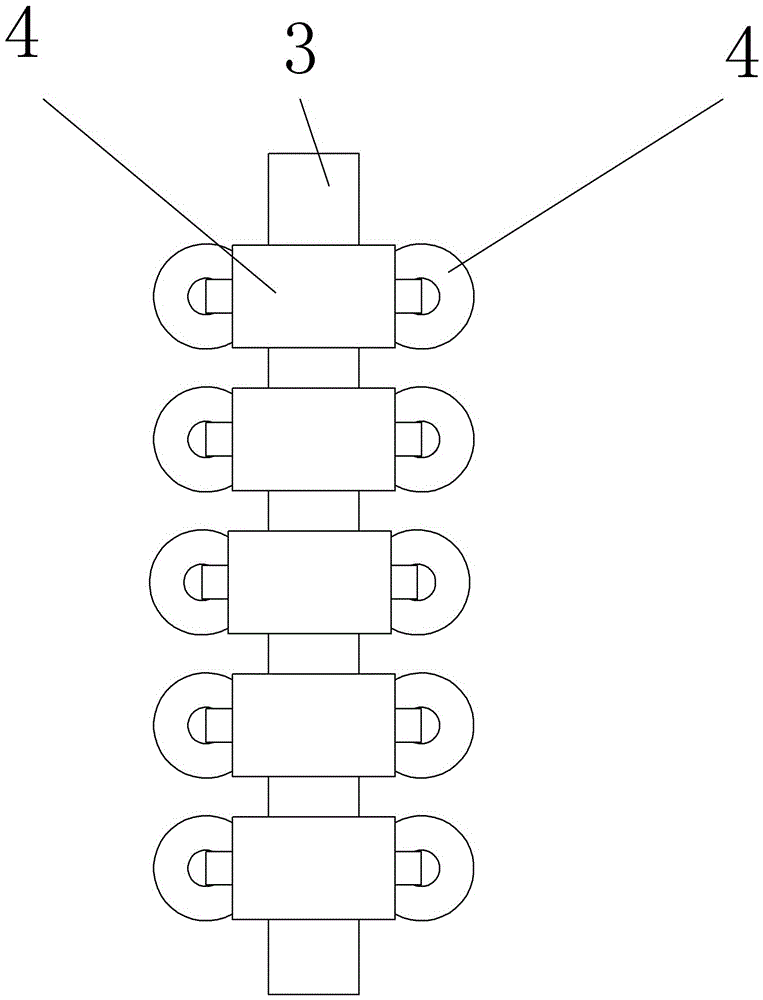

[0017] Embodiment: a kind of vertical paint spraying device in this scheme, is used for the spray paint of composite door leaf 3, as shown in Figure 1, comprises frame 1, several rollers 4, several spray guns 11 corresponding to the positions of rollers 4, Paint supply unit, recovery tank and baffle 2. As shown in Figure 2, the rollers are vertically and evenly distributed on the 3 peripheral surfaces of the door leaf. The baffle plate 2 is integrally formed with a through hole, the roller 4 is located in the through hole, the central axis of the roller 4 is welded with a connecting rod, the connecting rod is threaded with the frame 1, the spray gun 11 is connected to the frame 1 in rotation, and the spray gun 11 is processed with a bolt structure for fixing the spray gun 11, and the spray gun 11 is connected with the paint supply device. The paint supply hose 10 for controlling the paint supply device is placed on the movement track of the door leaf 3, and the recovery cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com