Paint spraying device and method applied to hardware workpiece

A kind of hardware and hardware technology, applied in the field of hardware processing equipment, can solve problems such as affecting the overall effect of painting and inability to paint hardware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

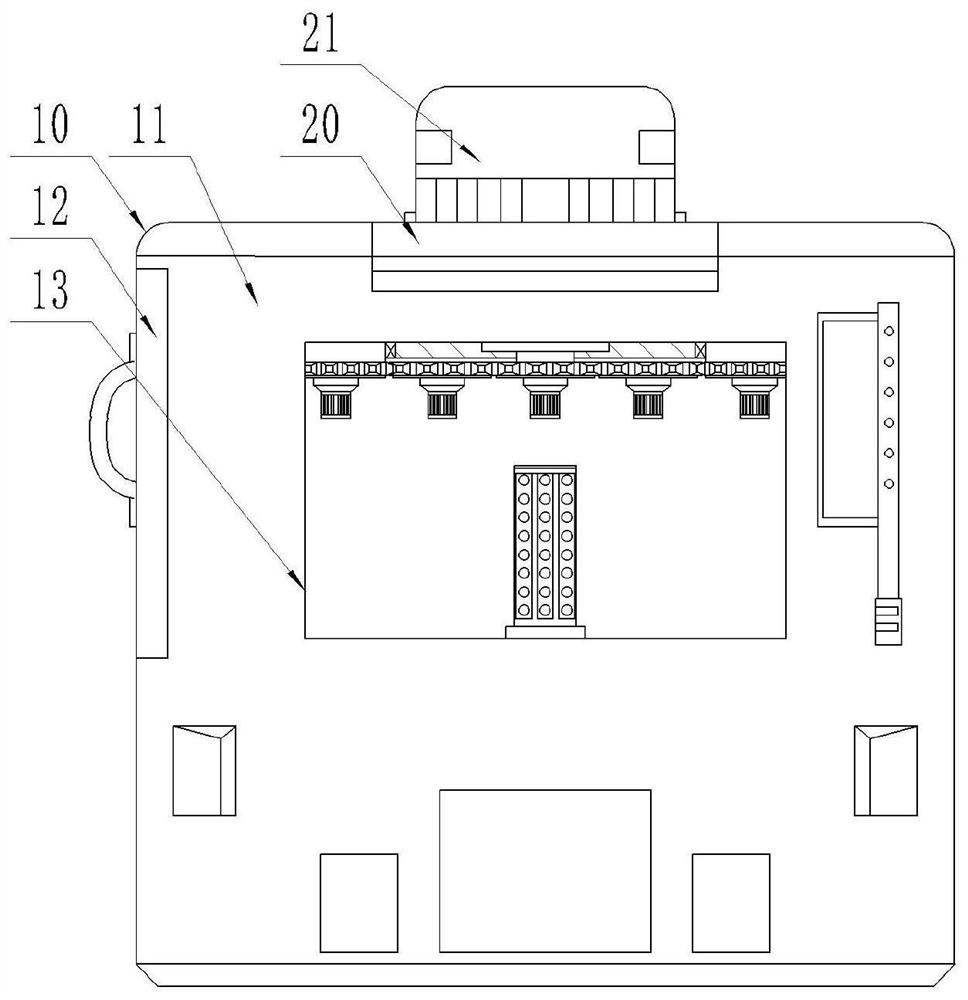

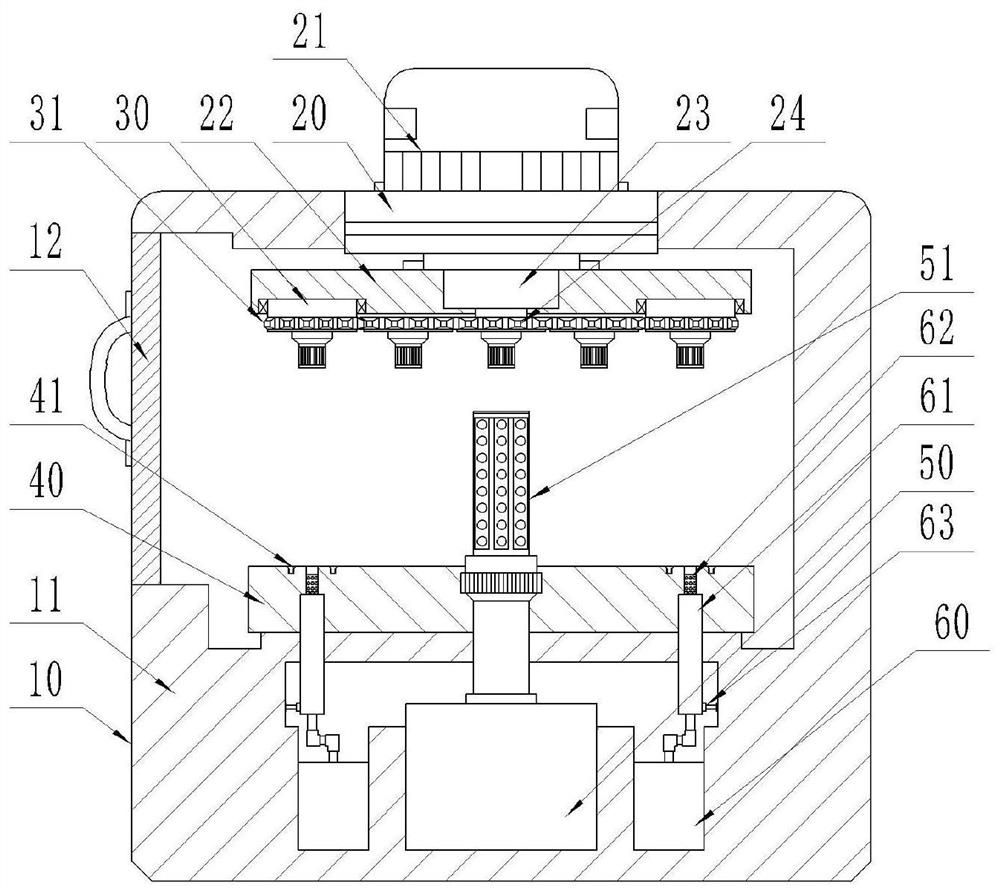

[0064] A paint spraying device applied to hardware workpieces, wherein, such as figure 1 , 2 As shown, it includes: a mounting mechanism 10, a displacement mechanism 20, a clamping mechanism 30, a placement table 40, and a feeding mechanism 50.

[0065] The installation mechanism 10 has a housing 11 , and a painting space is arranged inside the housing 11 . The installation mechanism 10 also has an installation door 12 and a window 13 . One end of the installation door 12 is movably connected with the opening side of the housing 11 . A window 13 is embedded in the housing 11 for viewing the work in the painting space.

[0066] Such as figure 2 As shown, the displacement mechanism 20 is mounted on the painting space of the housing 11 . The displacement mechanism 20 has: a lifting motor 21 , a connecting plate 22 , a rotating motor 23 , and a driving gear 24 .

[0067] The lifting motor 21 links to each other with the housing 11, the connecting disc 22 links to each other ...

Embodiment 2

[0079] A paint spraying device applied to hardware workpieces has the same characteristic structure as that of Embodiment 1, wherein, as Figure 11 As shown, the paint spraying head 51 includes an outer shell 52 and an inner shell 53, the inner shell 53 is arranged in the outer shell 52, an airflow gap 521 for air circulation is formed between the inner shell 53 and the outer shell 52, and a stepped spray paint is provided in the inner shell 53. The mouth 531 and the airflow gap 521 are distributed at the outlet of the paint spraying mouth 531 .

[0080] The inner casing 53 is provided with a shroud 54 made of soft material, which is distributed on the side of the paint spray port 531 , and an air compressor 55 for compressing air is arranged outside the shroud 54 , and the air supply compressor is located in the airflow gap 521 .

[0081] Utilize the lateral stress produced by the paint flowing in the stepped paint spraying port 531 in the inner shell 53 to extrude the shroud...

Embodiment 3

[0083] A method for spraying paint applied to hardware workpieces, comprising the following steps:

[0084] Place the metal pipe fittings on the placement platform 40 so that the nozzle of the hardware pipe fittings corresponds to the base body 32 of the clamping mechanism 30, and then start the lifting motor 21 of the displacement mechanism 20 to drive the connection plate 22 down, so that the connection plate 22 under the connection plate 22 and the clamping The mechanism 30 is close to the hardware pipe, so that the base 32 of the clamping mechanism 30 extends into the nozzle of the hardware pipe.

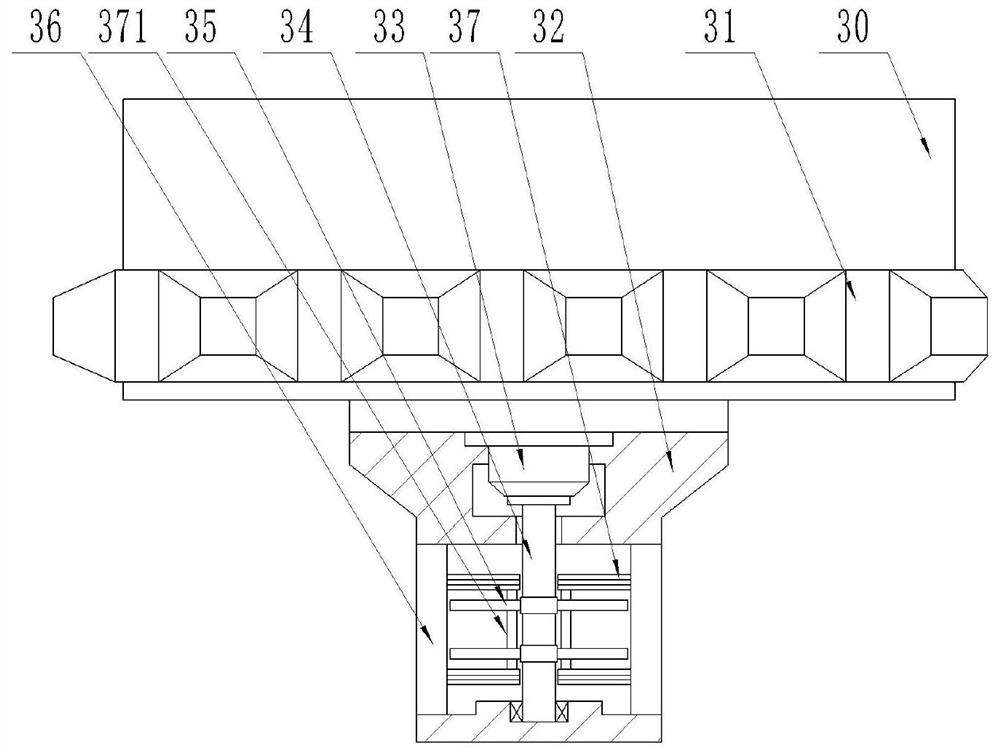

[0085] At this moment, start the rotating motor 23 in the base body 32 to drive the rotating shaft 34 and the vortex ring 35 on the rotating shaft 34 to rotate, and push the matching piece 371 connected with the sliding connection to move through the vortex-shaped slideway gradually extending outward in the vortex ring 35, Then the sliding part 37 slidably connected with the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com