Water-milled rice noodle processing system and process method

A processing system and rice flour technology, applied in grain processing, etc., can solve the problems of poor automation, labor and material resources consumption, slow cooling speed, etc., and achieve the effects of fast cooling speed, fast drainage speed and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solution of the present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but not limited thereto.

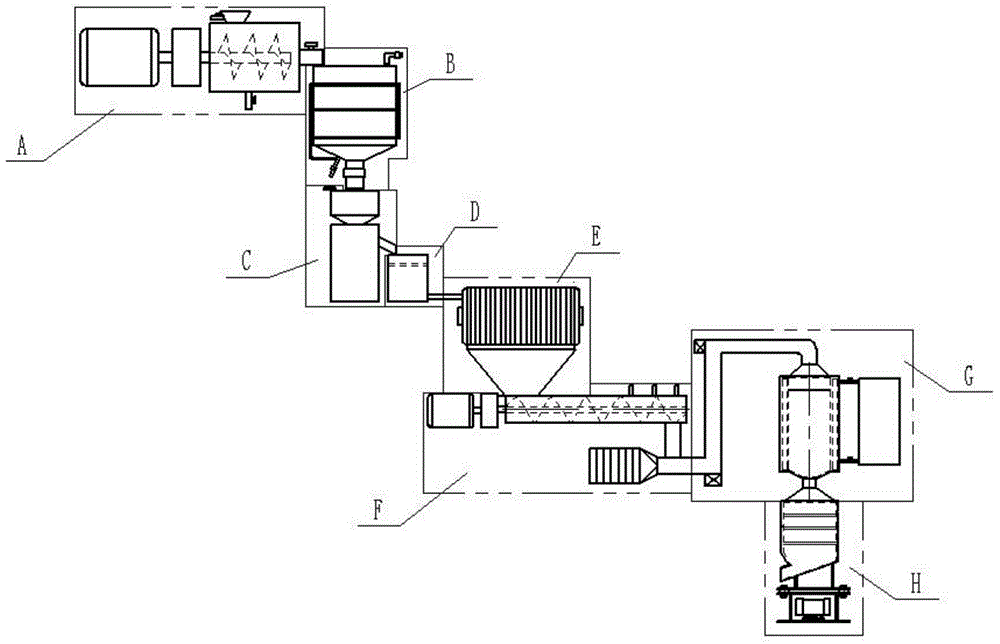

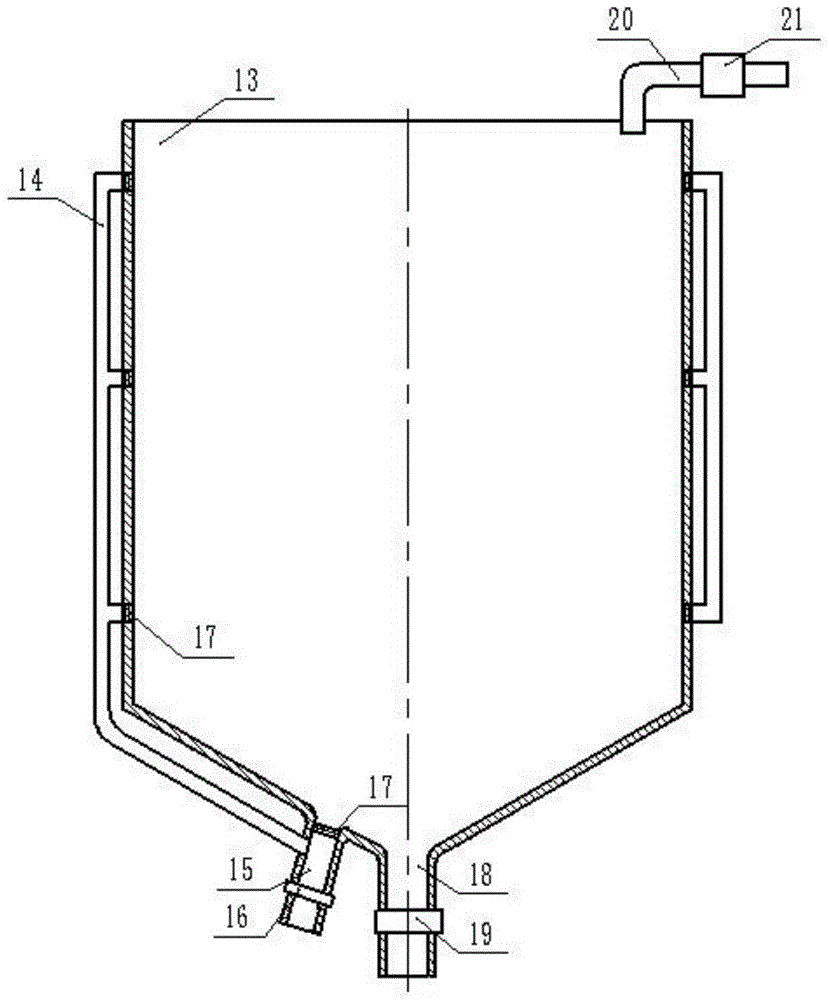

[0048] Such as Figure 1-10 As shown, a kind of water grinding rice flour processing system provided by the present invention comprises cleaning device A, soaking device B, refiner C, filtering device D, dehydration device E, drying device F, cooling device G, screening device H,

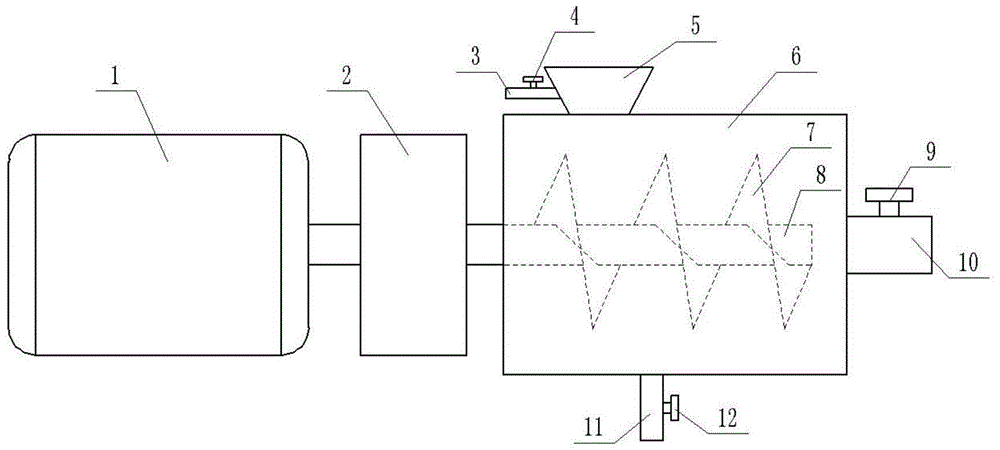

[0049] The cleaning device A includes a tank body 6, the upper end of the tank body 6 is provided with a funnel-shaped feed inlet 5, the left side of the feed inlet 5 is provided with a water inlet 3, and the water inlet 3 is provided with an inlet Water valve 4, a rotating shaft 8 is provided in the middle of the tank body 6, a spiral blade 7 is arranged on the rotating shaft 8, a brush is installed on the spiral blade 7, and the left end of the rotating shaft 8 is connected to the reducer in sequence 2 and the motor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com